Filtering material for removing iron and manganese

A technology for filtering materials and removing water, which is applied in the fields of filtration and separation, other chemical processes, chemical instruments and methods, etc. It can solve the problems of high specificity, difficulty in backwashing, low mechanical strength of filter materials, and limited filtering effect, etc., and achieves excellent results, The effect of high mechanical strength and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

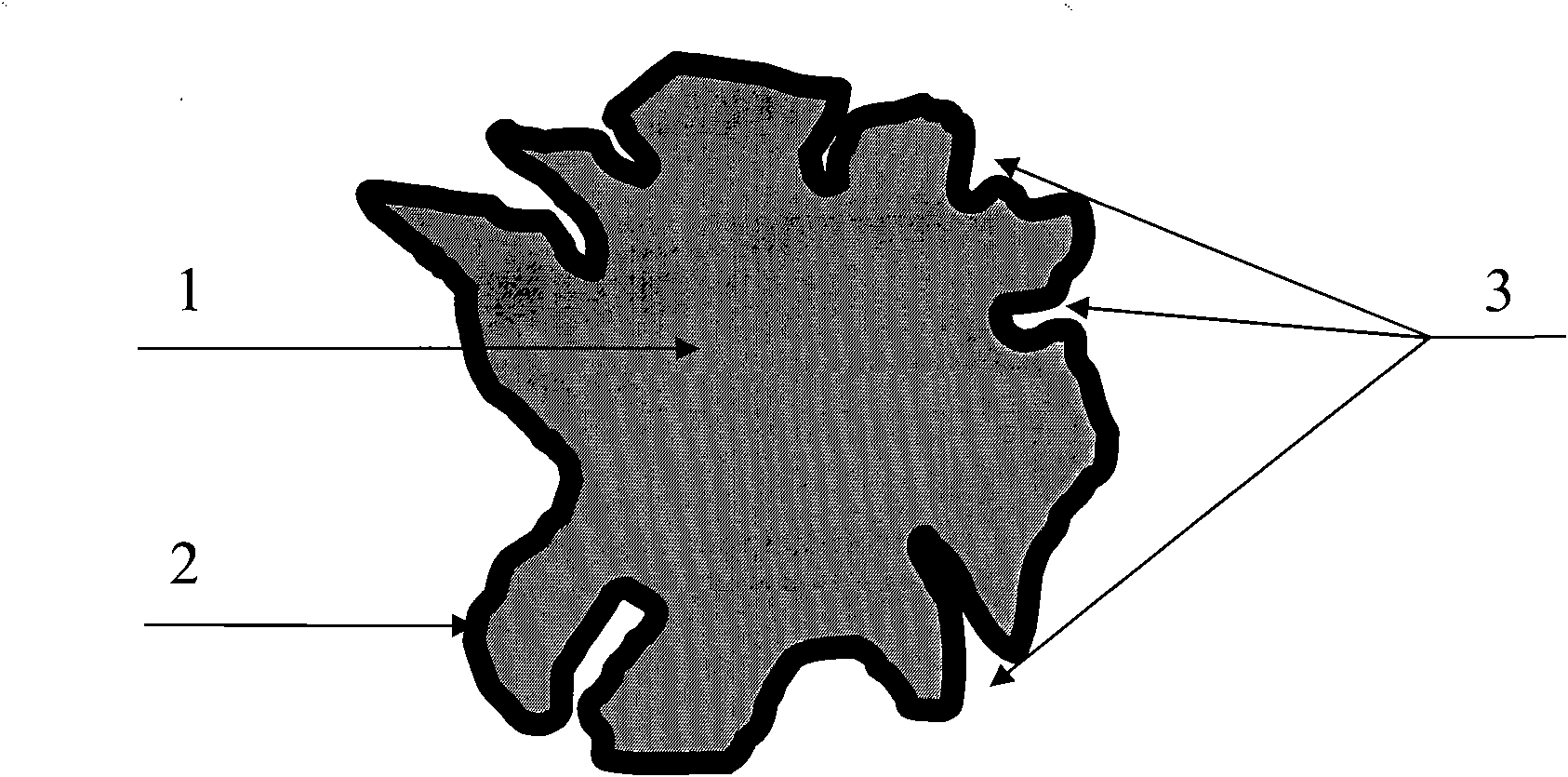

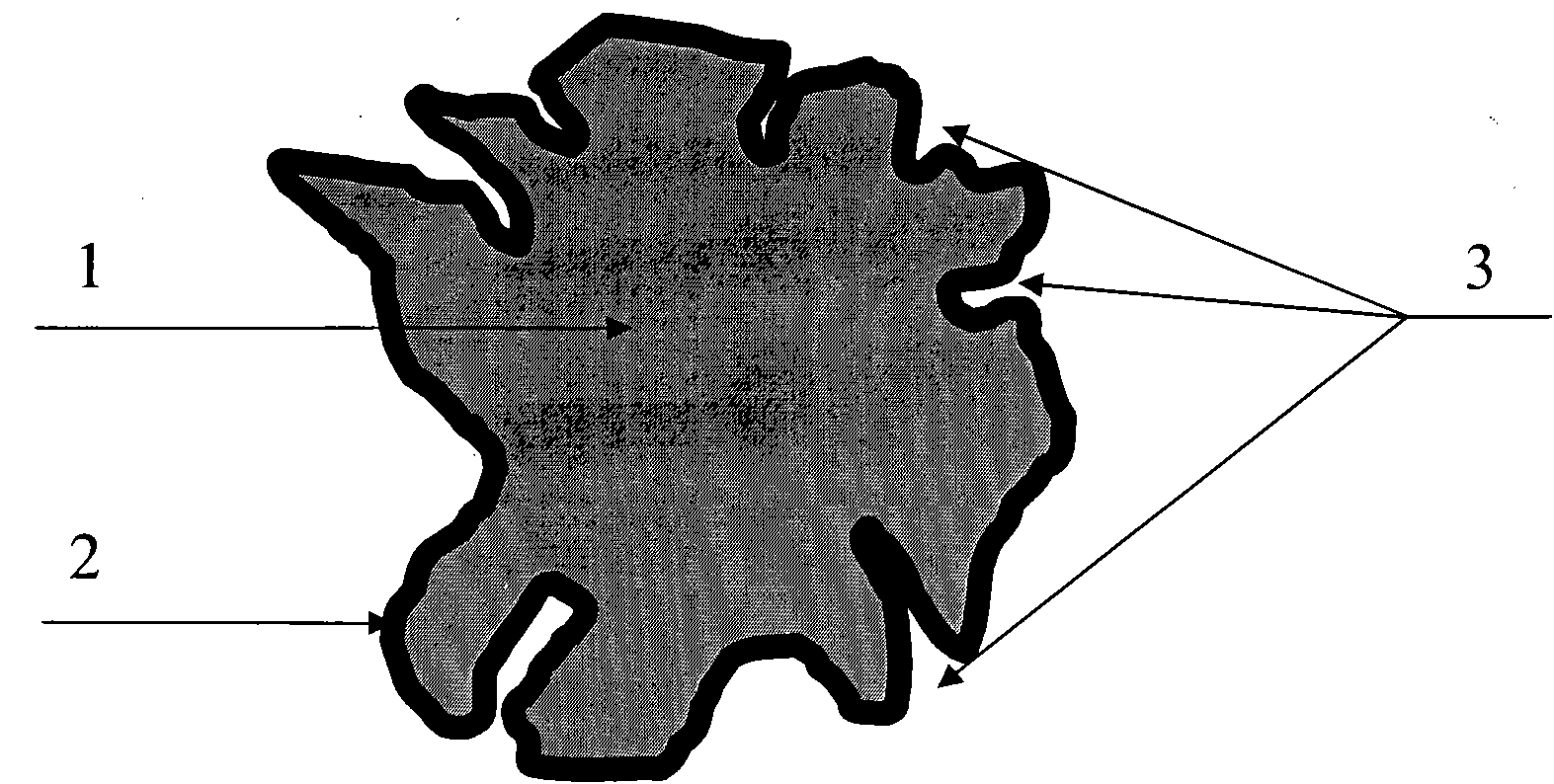

[0008] The porous ceramsite material used for building roof thermal insulation is crushed and screened to obtain irregular polyhedral ceramsite particles with pores on the surface. The particle size of the particles can be determined according to actual needs, usually in In the range of 0.5mm to 2.5mm, chemical methods or coating methods are used to make an adhesion layer containing iron oxide and manganese on the surface of the filter material particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com