Method for preparing liquid ferrous chloride for water treatment by taking waste hydrochloric acid as raw material

A technology of ferrous chloride and waste hydrochloric acid, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

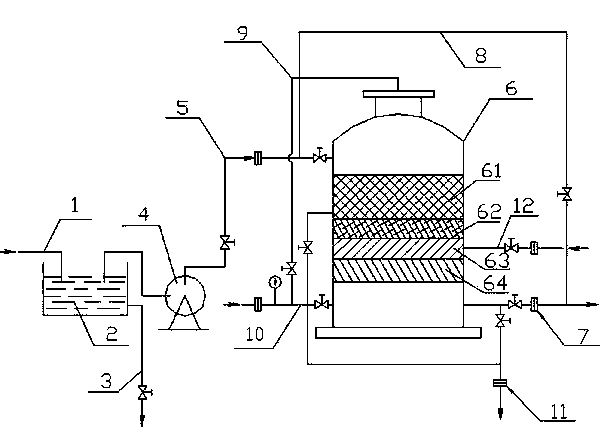

Image

Examples

Embodiment 1

[0035] A method for preparing liquid ferrous chloride for water treatment as raw material with waste hydrochloric acid, comprising the steps of:

[0036] (1) Choose to meet the national standard of GB320-2006 industrial synthetic hydrochloric acid, and at the same time meet the arsenic content ≤0.0005wt%, lead content ≤0.004 wt%, mercury content ≤0.00002 wt%, cadmium content ≤0.0005 wt%, chromium content ≤0.01 wt% %, zinc content ≤ 0.015 wt % standard hydrochloric acid (you can buy hydrochloric acid that meets the above standards from the market) as hydrochloric acid for strip pickling. In the pickling line of the workshop, in order to better handle waste hydrochloric acid, restrictions are imposed on the discharge of waste hydrochloric acid from pickling. The oily wastewater generated during maintenance, the strip washing wastewater, and the liquid waste generated in other links are not allowed to enter the waste hydrochloric acid storage tank.

[0037] (2) Detect the concentr...

Embodiment 2

[0043] A method for preparing liquid ferrous chloride for water treatment as raw material with waste hydrochloric acid, comprising the steps of:

[0044] (1) Choose to meet the national standard of GB320-2006 industrial synthetic hydrochloric acid, and at the same time meet the arsenic content ≤0.0005wt%, lead content ≤0.004 wt%, mercury content ≤0.00002 wt%, cadmium content ≤0.0005 wt%, chromium content ≤0.01 wt% %, zinc content ≤ 0.015 wt % standard hydrochloric acid (you can buy hydrochloric acid that meets the above standards from the market) as hydrochloric acid for strip pickling. In the pickling line of the workshop, in order to better handle waste hydrochloric acid, restrictions are imposed on the discharge of waste hydrochloric acid from pickling. The oily wastewater generated during maintenance, the strip washing wastewater, and the liquid waste generated in other links are not allowed to enter the waste hydrochloric acid storage tank.

[0045] (2) Detect the concen...

Embodiment 3

[0051] A method for preparing liquid ferrous chloride for water treatment as raw material with waste hydrochloric acid, comprising the steps of:

[0052] (1) Choose to meet the national standard of GB320-2006 industrial synthetic hydrochloric acid, and at the same time meet the arsenic content ≤0.0005wt%, lead content ≤0.004 wt%, mercury content ≤0.00002 wt%, cadmium content ≤0.0005 wt%, chromium content ≤0.01 wt% %, zinc content ≤ 0.015 wt % standard hydrochloric acid (you can buy hydrochloric acid that meets the above standards from the market) as hydrochloric acid for strip pickling. In the pickling line of the workshop, in order to better handle waste hydrochloric acid, restrictions are imposed on the discharge of waste hydrochloric acid from pickling. The oily wastewater generated during maintenance, the strip washing wastewater, and the liquid waste generated in other links are not allowed to enter the waste hydrochloric acid storage tank.

[0053] (2) Detect the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com