Method and apparatus for efficiently extracting or separating nano-grade matter in solution

A nano-scale, high-efficiency technology, applied in ultrafiltration and other directions, can solve the problems of high sealing and firmness requirements of pipelines and filter devices, prone to potential safety hazards, and increase manufacturing costs, etc., to increase solution fluidity and regeneration. Strong force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail by the following examples.

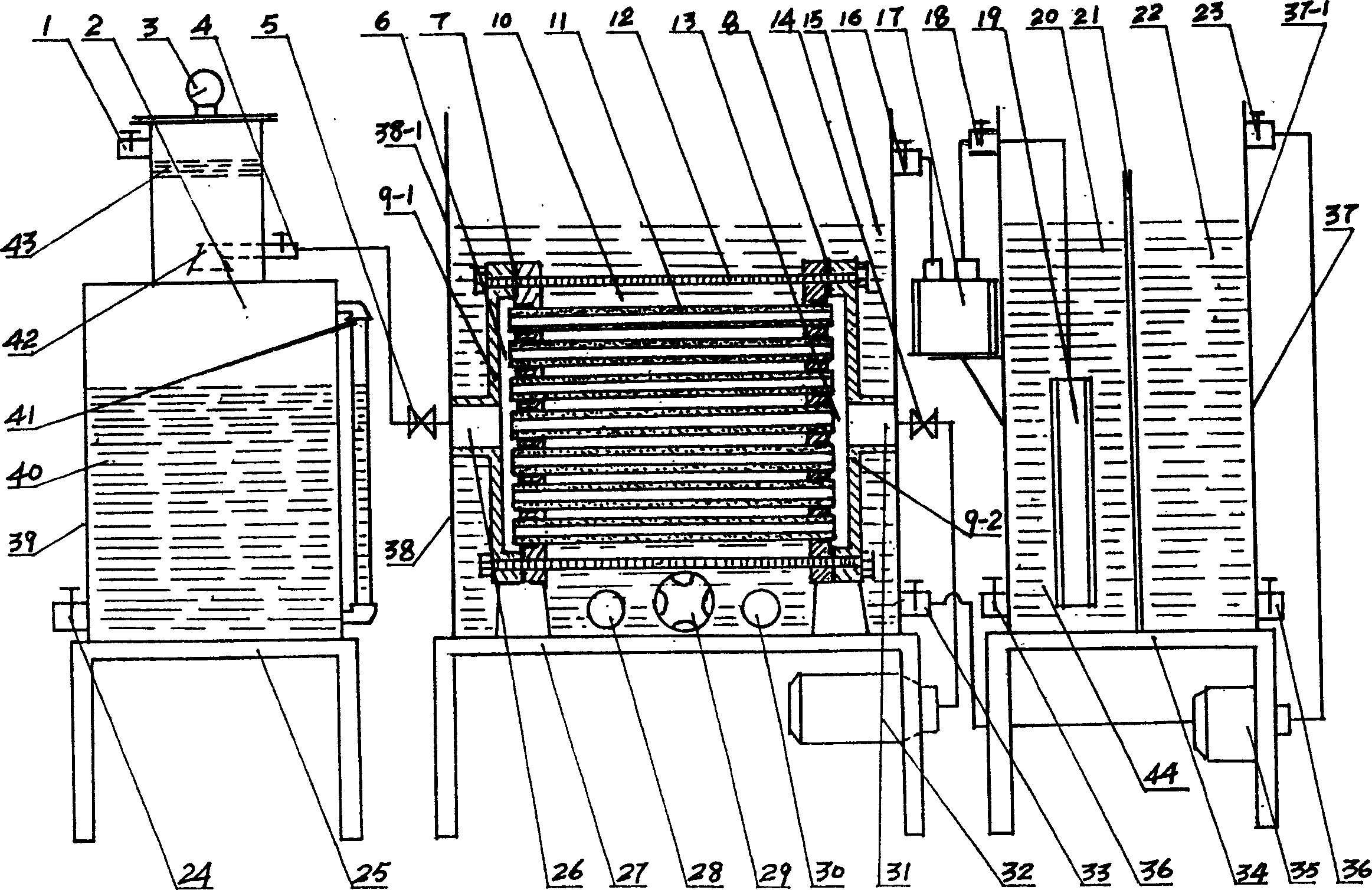

[0026] figure 1 Shown is a schematic diagram of the device structure used to realize the method for extracting or separating nano-scale substances in the solution of the present invention. The device consists of a fine filtration system 37, an ultrafiltration system 38, a negative pressure suction system 39, a filter tube backwashing system and the entire device The program controller is composed. Below in conjunction with process method and its device structure and working process are described in detail as follows:

[0027] After the solution to be treated is coarsely filtered or precipitated, the coarsely filtered solution 20 containing substances (impurities) with a particle size below 15-20 μ is injected into the open container 37-1 of the fine filtration system 37, and when the solution is filled, start self-priming Pump 17, the solution of substance (impurity) particle size below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com