Suspension ceramsite filter material for water treatment and production method thereof

A technology of ceramsite filter material and production method, which is applied in the field of water treatment, can solve the problems that the biological film is not strong enough, the biological film is easy to fall off, and the operation energy consumption is large, and achieves a light weight, strong hydrophilicity and uniform texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

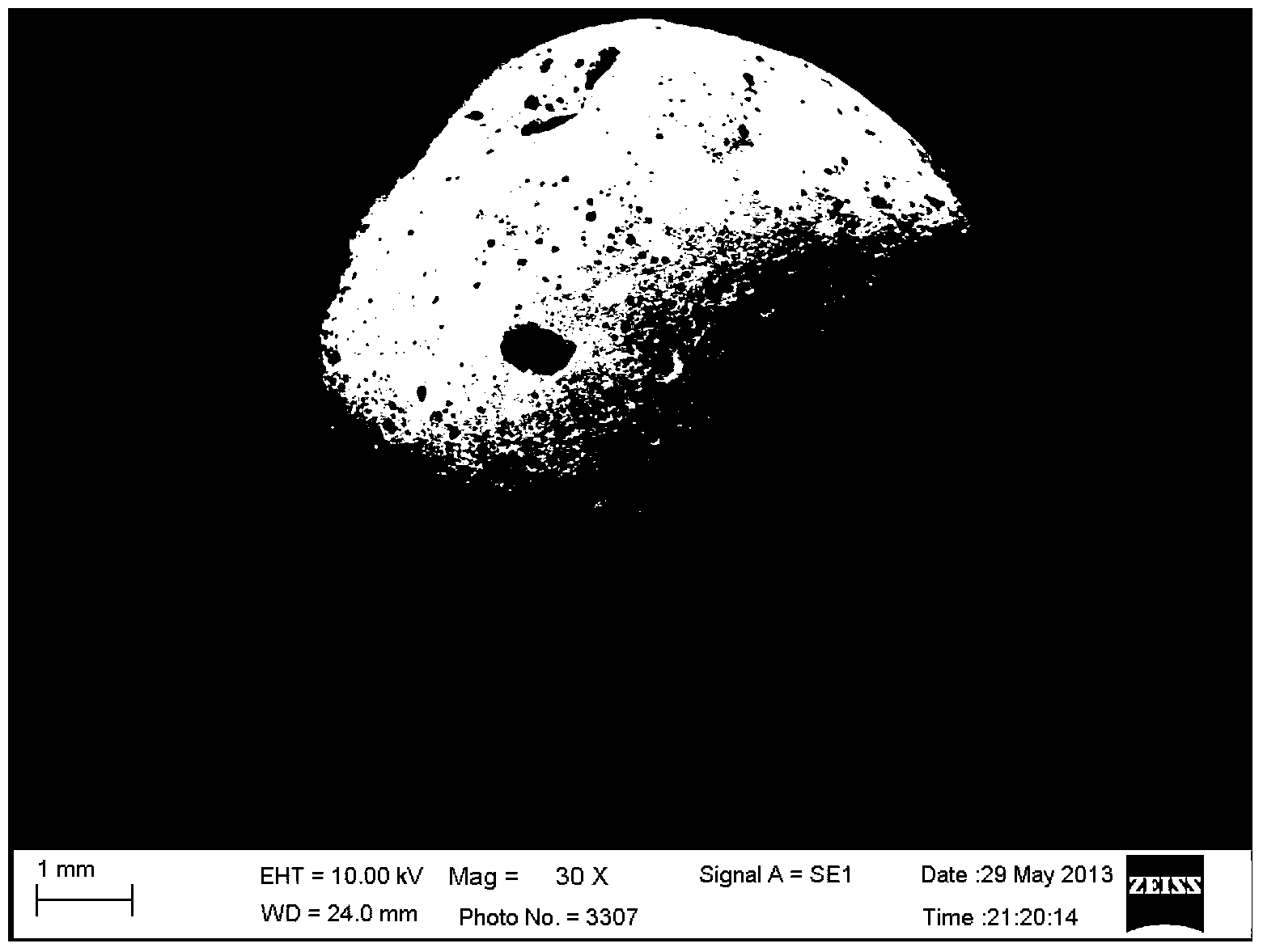

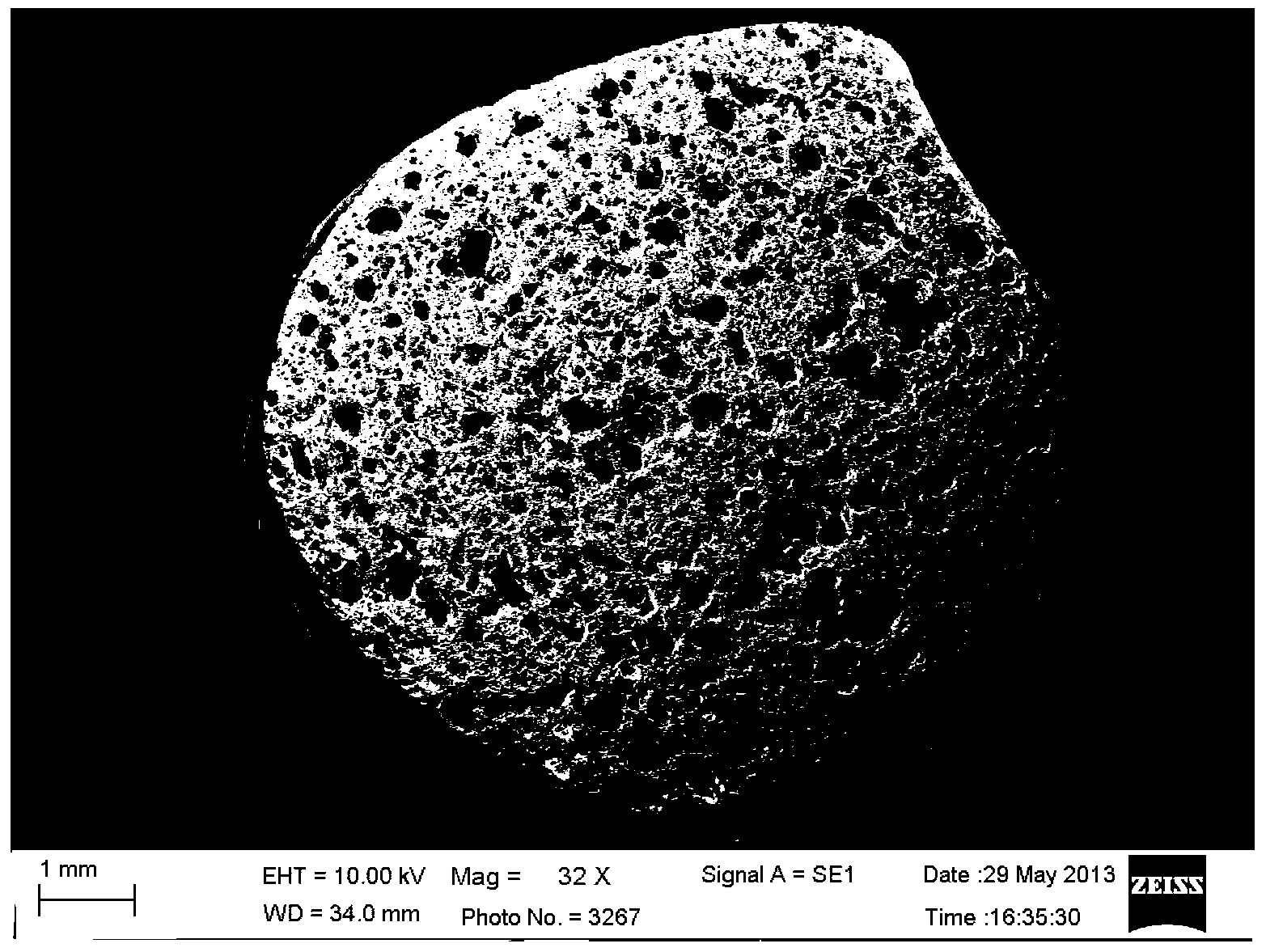

Image

Examples

Embodiment 1

[0018] Step 1, the initial production of shale ceramsite. Shale is selected as the raw material, and the shale mineral group is mainly illite, montmorillonite, kaolinite, and quartz, and the main component is Si0 2 The content is 57.7%, A1 2 o 3 The content is 18.4%, Fe 2 o 3 The CaO content is 7.2%, and the CaO content is 2.6%. Crush the shale to a particle size of 5-20mm, dry it in a drying oven at 100°C for 6 hours, put it into a ball mill for full grinding, and sieve to control the particle size range of 100-180 mesh, and send it to a rotary granulator for granulation , the particle size of the original filter material is 5-15mm; it is fired in a rotary kiln for 22 minutes at a firing temperature of 1200°C, and the fired ceramsite is naturally cooled to obtain the initial shale ceramsite product; the obtained shale ceramsite water-infiltrated particle density 3 The proportion is 2%, which can ensure that more than 95% of the ceramsite is suspended or sinks below the l...

Embodiment 2

[0024] Step 1: select shale as raw material, crush the shale to a particle size of 5-20mm, dry it in a drying oven at 100°C for 6 hours, put it into a ball mill for grinding, and then sieve to control the particle size range of 100-180 mesh, send After being granulated and shaped by a rotary granulator, the particle size of the original filter material is 5-15mm; it is fired in a rotary kiln for 20 minutes at a firing temperature of 1300°C, and the fired ceramsite is naturally cooled to obtain an initial shale ceramsite product; Shale ceramsite water soaked particle density 3 The ratio is 1.4%.

[0025]Step 2, sieve the ceramsite obtained in step 1, select a particle size of 8-12 mm, and put it into the pool for flotation; while transporting the ceramsite into the pool, replenish water to maintain 4-5 L / (m 2 .s) Aeration intensity, the floating ceramsite that flows out of the pool with the effluent is a qualified product, and the ceramsite in the storage tank does not meet the...

Embodiment 3

[0028] Step 1. Select suitable shale as raw material, crush the shale to a particle size of 5-20mm, dry it in a drying oven at 100°C for 6 hours, put it into a ball mill for grinding, and then sieve to control the particle size range of 100-180 mesh. Send it to the rotary disc granulator for granulation and shape, and the particle size of the original filter material is 5-15mm; it is fired in a rotary kiln for 18 minutes at a firing temperature of 1300°C, and the fired ceramsite is naturally cooled to obtain the initial shale ceramsite product; The obtained shale ceramsite water-soaked particle density is less than 0.9g / cm 3 The ratio is 1.7%.

[0029] Step 2, sieve the ceramsite obtained in step 1, select a particle size of 8-12 mm, and put it into the pool for flotation; while transporting the ceramsite into the pool, replenish water to maintain 4-5 L / (m 2 .s) Aeration intensity, the floating ceramsite that flows out of the pool with the effluent is a qualified product, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com