Method for installing fibre filter material in bulk

An installation method and a technology of fiber filtration, which are applied in the field of filtration equipment in the field of water treatment, can solve the problems that fiber filter materials are not easy to clean, easy to form mud balls, and difficult to clean thoroughly, so as to avoid short-circuit of water flow, ensure size consistency, cut off The effect of even amount of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

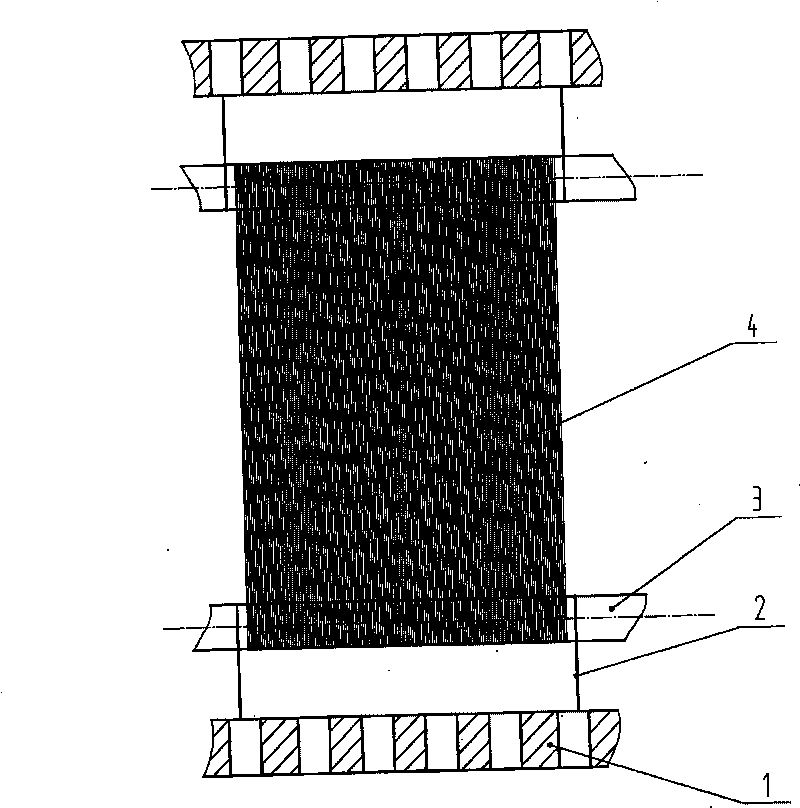

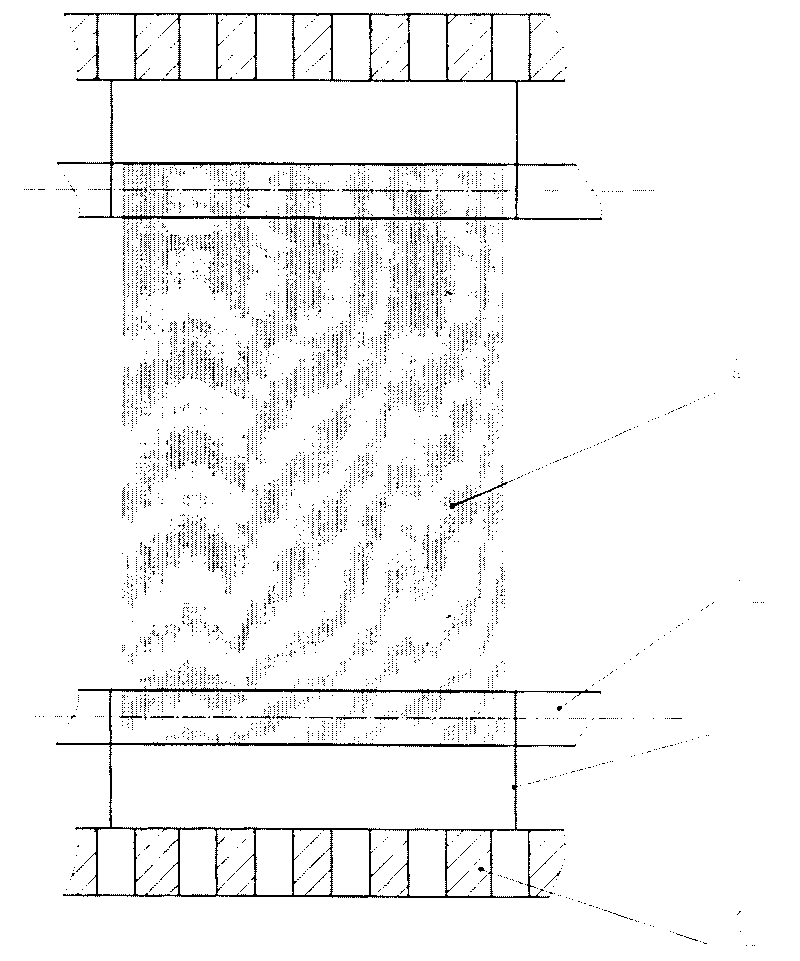

[0017] Embodiment 1: a filter tank of 2 meters in length and width, first the fiber filter material 4 is wound into a circular fiber filter material with a circumference of 2.4 meters and a weight of 0.35 kg. The specification of the rod 3 is a DN15 UPVC pipe with a length of 2 meters ; First, tie the ends of the two tubes to the ends of the upper and lower filter plates with nylon ropes, and then put a group of wound fiber filter materials into the upper and lower rods respectively, and place them on the upper and lower rods Tie a second nylon rope at a distance of 150mm from the first nylon rope on the rod, connect the rod 3 and the filter plate 1, and keep filling the fiber filter material 4 on the rod in this way, and hang it full of fiber The distance between each tube of the filter material 4 is 30 mm. In this way the whole filter tank is filled with fiber filter material.

[0018] After trial use, the fiber filter material installed in this way has an average suspended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com