Inorganic-organic composite film and preparation method thereof

A composite membrane and inorganic technology, applied in the field of filter materials, can solve the problems of composite membranes that cannot be used repeatedly and low filtration precision, and achieve the effects of good regeneration performance, high filtration precision and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

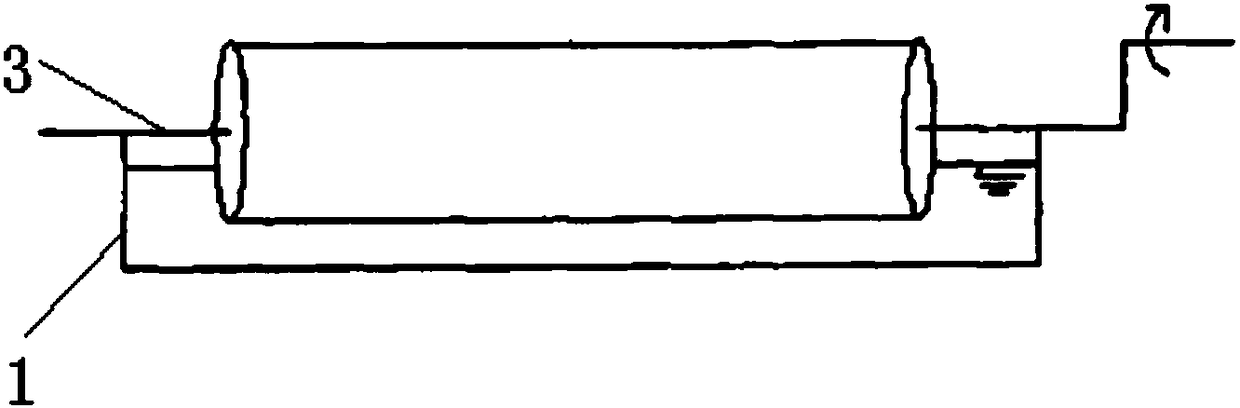

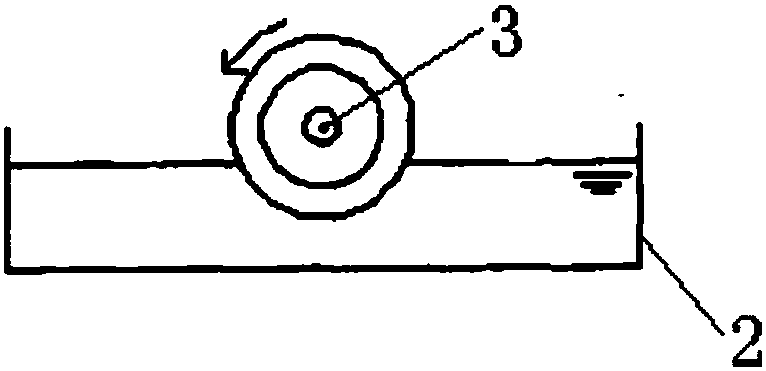

[0036] The preparation method of above-mentioned inorganic-organic composite film, this method adopts such as figure 1 with figure 2 The shown device includes a casting solution tank 1, a crosslinking agent tank 2 and a rotating rod 3, and is specifically implemented according to the following steps:

[0037] Step 1. Prepare organic material casting solution and crosslinking agent, pour the organic material casting solution into casting solution tank 1, and pour the crosslinking agent into crosslinking agent tank 2;

[0038] Among them, the preparation process of the organic material casting solution is as follows:

[0039] Weigh 3% to 25% of the organic material and 75% to 97% of the solvent according to the mass percentage, heat the solvent in a water bath to 50°C to 70°C, and add a pore-forming agent to the solvent while stirring (the mass of the pore-forming agent accounts for the mass of the solvent 0.1% to 0.5% of the pore-forming agent), to fully dissolve the pore-fo...

Embodiment 1

[0048]Weigh 15% of polyvinylidene fluoride and 85% of N-methylpyrrolidone respectively according to mass percentage, then heat N-methylpyrrolidone in a water bath to 50°C, and add 0.1%wt pore-forming agent to the solvent while stirring, so that The pore-forming agent is fully dissolved, then polyvinylidene fluoride is added, and the stirring is continued. After the polyvinylidene fluoride is fully dissolved, aging and defoaming are continued for 24 hours, and finally the organic material casting solution is obtained, and the prepared organic material is cast Pour the membrane solution into the casting solution tank 1; pour deionized water into the cross-linking agent tank 2; install the stainless steel filter element on the rotating rod 3, and the motor drives the rotating rod 3 to rotate at a rotation speed of 30r / min. Adhere to a layer of organic material casting liquid on the surface to obtain the initial composite film, then move the rotating rod 3 into the cross-linking ag...

Embodiment 2

[0051] Weigh 3% of polyvinyl alcohol and 97% of deionized water according to the mass percentage, then heat the polyvinyl alcohol in a water bath to 60°C, and add 0.2%wt pore-forming agent to the solvent while stirring to fully dissolve the pore-forming agent , then add polyvinyl alcohol, and keep stirring. When the polyvinylidene fluoride is fully dissolved, continue aging and defoaming for 24 hours, and finally obtain an organic material casting solution; weigh 0.5% glutaraldehyde, hydrochloric acid 0.1% and deionized water 99.4%, then add hydrochloric acid and glutaraldehyde successively to deionized water, stir and dissolve to obtain crosslinking agent after completely; Pour the prepared organic material casting solution into casting solution tank 1, The coupling agent is poured into the crosslinking agent tank 2; the stainless steel filter element is installed on the rotating rod 3, and the motor drives the rotating rod 3 to rotate at a rotation speed of 50r / min, and a lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com