Gradient-pore silicon nitride and silicon carbide combined film tube and preparation method therefor

A silicon carbide membrane and gradient pore technology, which is applied in the field of porous ceramic materials, can solve the problems of high sintering temperature and achieve the effects of firm bonding, high permeability and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

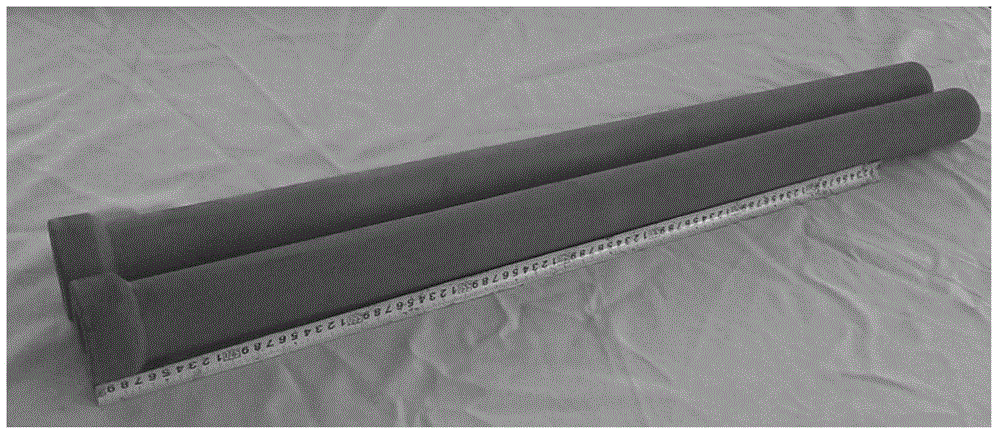

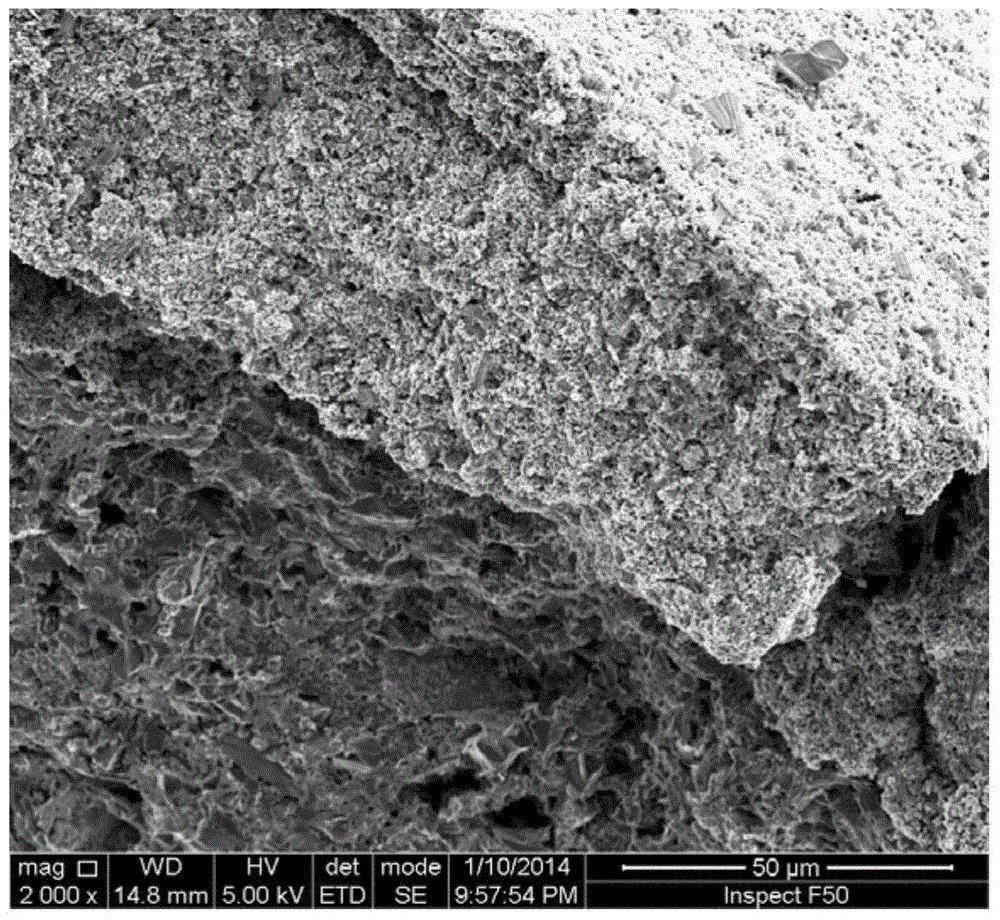

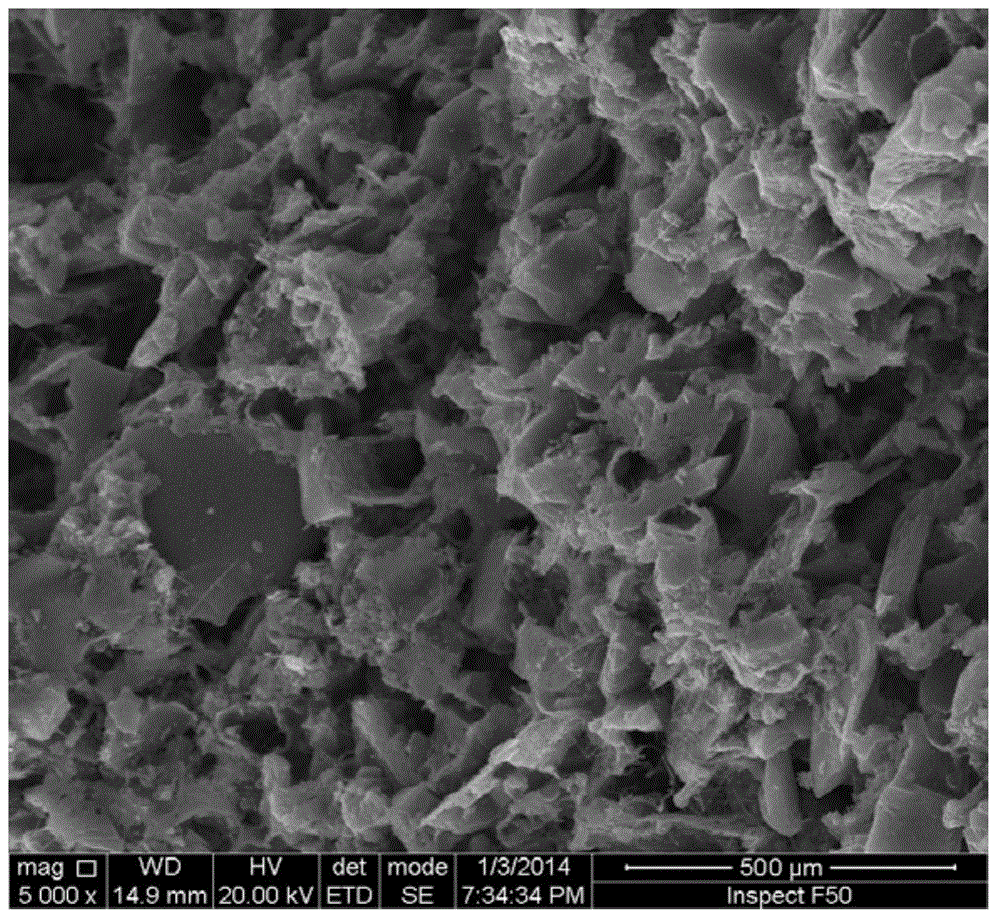

[0047] The preparation method of the gradient pore silicon nitride bonded silicon carbide film tube of the present invention uses coarse silicon carbide, silicon powder and pore-forming agent as basic materials, uses polymer resin and curing agent as binder, mixes ingredients, and uses cold isostatic Press the support body with the press sleeve, and then use fine-grained silicon carbide, silicon powder, fiber additives and organic polymer resin to prepare the film layer raw materials, and use the impregnation method to prepare the film layer on the surface. After drying, sintering to obtain the finished film tube, mainly including the following step:

[0048] (1) Raw material preparation for support molding

[0049] Raw material coarse silicon carbide, silicon powder, polymer resin, pore-forming agent, and curing agent are (10-6): (5-3): (2-1): (3-1): (0.06 ~0.02) blended in an organic solvent, the organic solvent content is between 20% and 30% of the total mass of raw materi...

Embodiment 1

[0065] Support raw material preparation and molding:

[0066] The raw materials 100μm silicon carbide particles, 10μm silicon powder, furfural resin, polyvinyl alcohol PVA, and p-toluenesulfonic acid are blended in ethanol at a mass ratio of 10:5:2:3:0.06, and the ethanol content accounts for 30% of the total mass of raw materials. %, after being mechanically stirred and ball milled for 2 hours to obtain a slurry, then dried and pulverized at 80°C to obtain a raw material composite powder.

[0067] Put the above-mentioned composite powder in the isostatic pressing sheath, and use mechanical vibration during the filling. The isostatic pressing sheath is designed to have a tube blank size of 1000mm long, 80mm inner diameter, and 100mm outer diameter, and then put it into the cold isostatic pressing machine. The pressurized pressure is 100MPa, the pressure is maintained for 12 minutes, and then the jacket is removed to obtain a prefabricated support, and then cured at 120° C. for...

Embodiment 2

[0086] The difference from Example 1 is:

[0087] The raw material 40μm silicon carbide particles, 20μm silicon powder, phenolic resin, polyvinyl alcohol, and p-toluenesulfonic acid are blended in ethanol at a mass ratio of 6:4:2:1:0.03, and the ethanol content accounts for 30% of the total mass of raw materials , After being mechanically stirred and ball milled for 2 hours to obtain a slurry, then dried and pulverized at 80° C. to obtain a raw material composite powder.

[0088] Put the above composite powder in the isostatic pressing sheath, and use mechanical vibration during the filling. The isostatic pressing sheath is designed to have a tube blank size of 1000mm long, 5mm inner diameter, and 20mm outer diameter, and then put it into the cold isostatic pressing machine. The pressurized pressure is 150MPa, the pressure is maintained for 5 minutes, and then the jacket is removed to obtain the prefabricated support, and then cured at 120°C for 1 hour to obtain the prefabrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com