Purification recovering method for sodium thiocyanate solution of acrylic fiber production

A technology of sodium thiocyanate and recovery methods, applied in the direction of thiocyanate, etc., can solve the problems of high energy consumption and material consumption, waste water, large quantities, etc., and achieve the reduction of desalinated water consumption, reduction of evaporated and concentrated water, and reduction of sewage discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

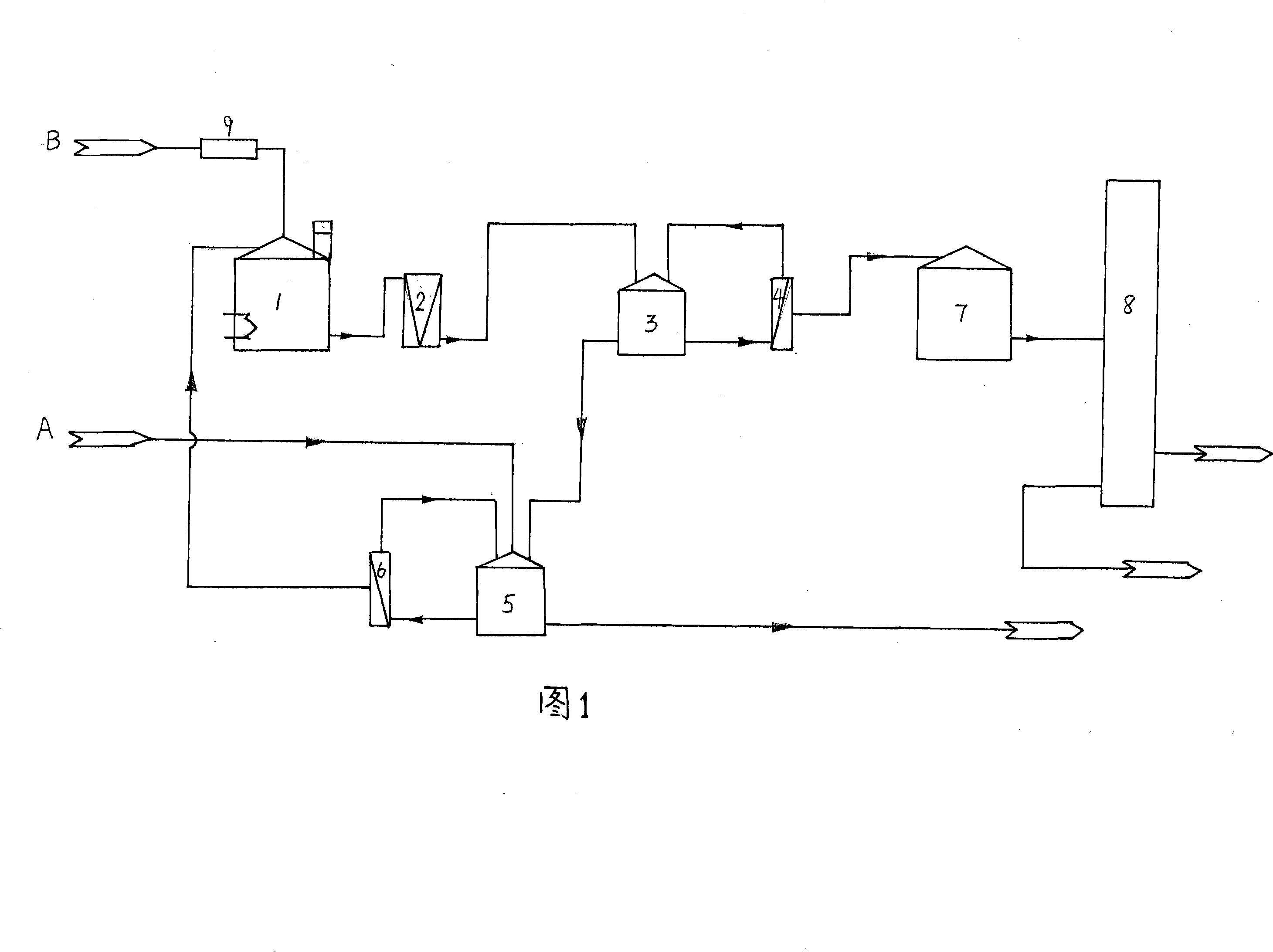

[0023] step one:

[0024] The high-heterothiocyanate-containing sodium thiocyanate solution B (control the sodium thiocyanate concentration to account for the solution weight percentage concentration of no more than 25%) produced by spinning and other production processes, after passing through the heat exchanger 9, the temperature is controlled at 20-40 ° C, the best The temperature is 25-35°C, and then it enters the buffer storage tank 1 to skim off the oily substances in the solution; after that, it is filtered through a bag filter 2 with a precision of 5-200 microns (preferably 10-50 microns) to intercept the solution The insoluble impurities in the solution will enter the first-level nanofiltration circulation tank 3 in one batch per 50 cubic meters of solution.

[0025] Step two:

[0026] After passing through a first-level nanofiltration device 4 circulating with the first-level nanofiltration circulation tank 3, filter out the qualified sodium thiocyanate solution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com