Efficient winder device for spinning

A coil-winding and high-efficiency technology, used in transportation and packaging, conveying filamentous materials, thin material handling, etc., can solve the problems of reducing work efficiency, slow work, low efficiency, etc., to improve efficiency, not easy to knot, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be further described in detail below.

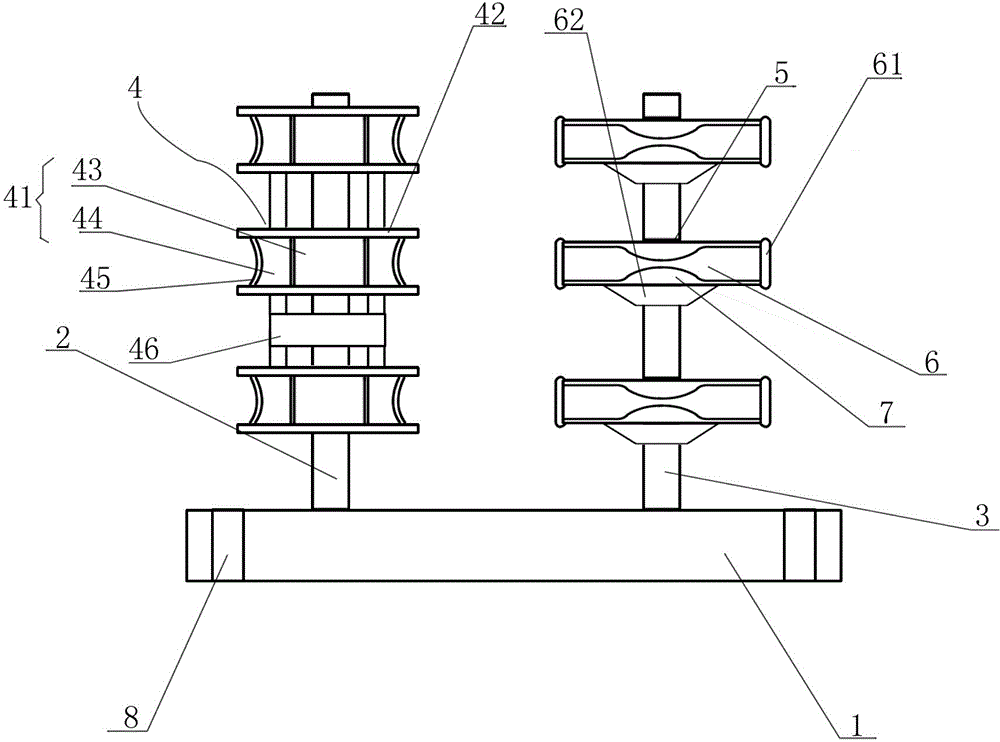

[0013] Such as figure 1 As shown, a kind of high-efficiency textile winding device 4 of the present invention includes a base 1, and is characterized in that: the base 1 is respectively provided with a first column 2 and a second column 3, and the first column 2 is sleeved with At least three reels 4, the same height of the second column 3 is provided with a through hole 5 corresponding to the reel 4, the through hole 5 is provided with a comb tube 6, and the inner wall of the comb tube 6 is provided with a middle inwardly protruding arc Shaped inner layer 7, inner layer 7 adopts pottery or plastics material to make, and reel 4 comprises a disc 41 and is arranged on the retaining ring 42 of disc 41 both sides, and first column 2 is provided with to drive revolving disc 4 to rotate motor46.

[0014] The disk 41 includes an inner disk 43 and an outer disk 44. The inner disk 43 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com