Automatic stretching, cutting and filamentation device for packaging bag processing

A packaging bag and filament-forming technology, which is applied in the field of automatic stretching and cutting filament-forming devices, can solve the problems of knotted braided lines, slow speed and poor collection effect, and achieve the effect of speeding up shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

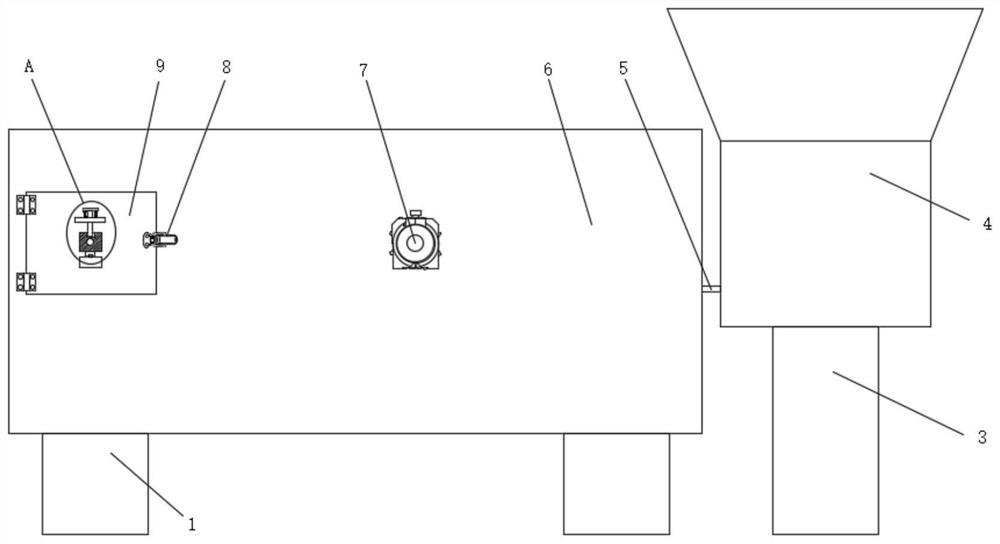

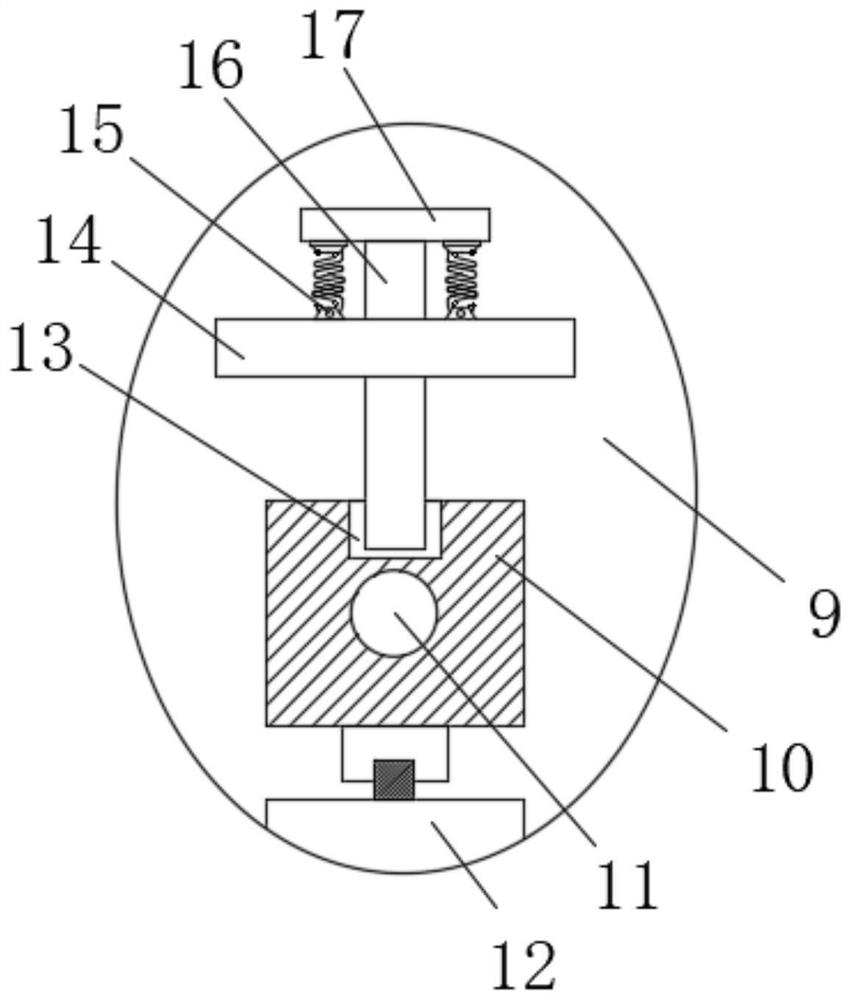

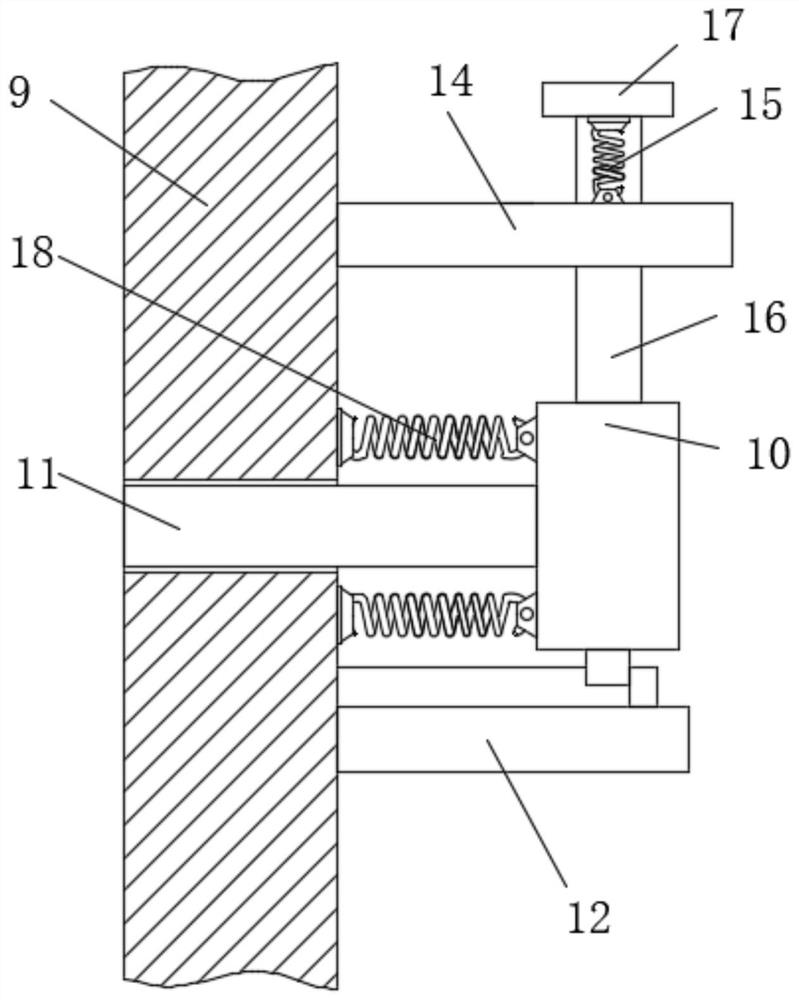

[0033] Refer Figure 1-10 , An automated tensile cutting of a packaging bag, including a processing box 6, an extruder 4, and a knitted wire 5, and the extruder 4 is located on one side of the processing box 6, and the bottom ferrous portion of the processing box 6 is fixed. The first base 1 is connected, the bottom of the extruder 4 is fixedly connected to two second base 3, the knitting line 5 outputs from the extruder 4, and the internal setting of the processing box 6 is used for collecting knitting lines 5 The collecting assembly, the inside of the processing box 6 is provided with a stretch assembly for stretching the knitted line 5, and the bottom inner wall of the processing box 6 is fixedly connected to the heating box 27, and the internal setting of the heating box 27 is used to quickly and form the knitted line 5. The top inner wall of the processing box 6 is provided with a compression assembly for compressing the braid 5.

[0034]In the present invention, the collectin...

Embodiment 2

[0041] Based on the first embodiment, the present embodiment is improved: one end of the rotating roller 29 is fixedly coupled to two L-plate 46 provided with symmetrical arrangement, and the two L-plate 46 is fixed to each other, and the second block 47 is fixedly connected to each other. The second card slot 48 having a symmetric setting is provided on one side of one of the respective partitions 45 located in the innermost side.

[0042] Working principle: When used, the braided line 5 generated by the extruder 4 enters the processing box 6, bypasses the first tunnel 23, the second tape plate 25, and the voltage line roller 31 and fixes around the winding roller 30. The start motor 7, the output shaft of the motor 7 drives the fourth axis 50, and the fourth axis 50 is rotated through the chain 2 and the sprocket 49, and the second axis 26 and the first shaft 24 rotate, fourth The rotating shaft 50 droves the second tunnel 25 and the half gear 32, and the first rotating shaft 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com