Pay-off spool for steel wire rope

A pay-off reel and wire rope technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of easy accidents, difficult to grasp the degree of pay-off, etc. The effect of labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

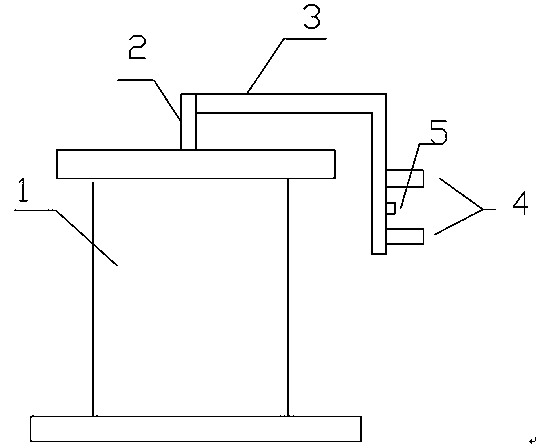

[0010] Such as figure 1 As shown, a wire rope pay-off reel includes a pay-off reel 1, a rotating shaft 2 is set through the top of the pay-off reel 1, and an L-shaped bracket 3 is welded on the rotating shaft 2, and the L-shaped bracket The outer side of 3 is welded two chute 4 from top to bottom on the outer side of described L-shaped support 3, between two chute 4 a length measuring sensor is installed.

[0011] The above is only a specific implementation of the present invention, but the scope of protection of the present invention is not limited thereto, and any changes or replacements that do not come to mind through creative work shall be covered within the scope of protection of the present invention. Therefore, the protection scope of the present invention should be determined by the protection scope defined in the claims.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com