Electromagnetic automatic line throwing appliance for recycling underwater robot

An underwater robot and electromagnetic technology, which is applied in the salvage, transportation and packaging of ships and ships, can solve the problems that the rope throwing device cannot be used underwater, the influence of individual differences in pyrotechnics, and cumbersome operation, etc., and achieves simple structure, The effect of high space utilization and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

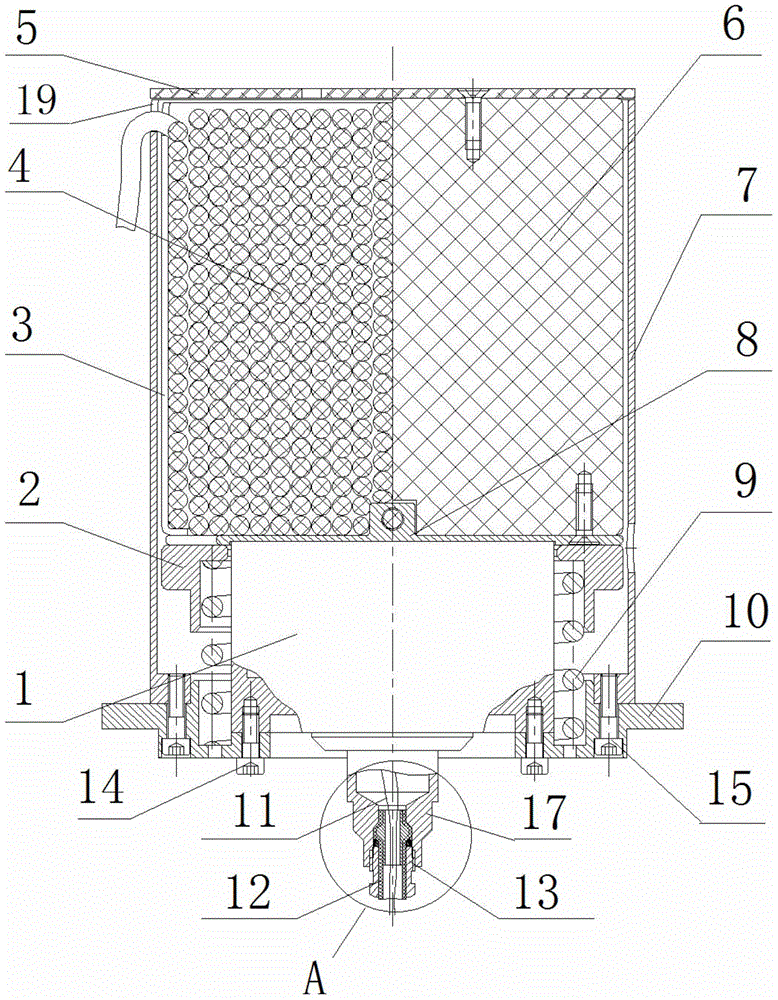

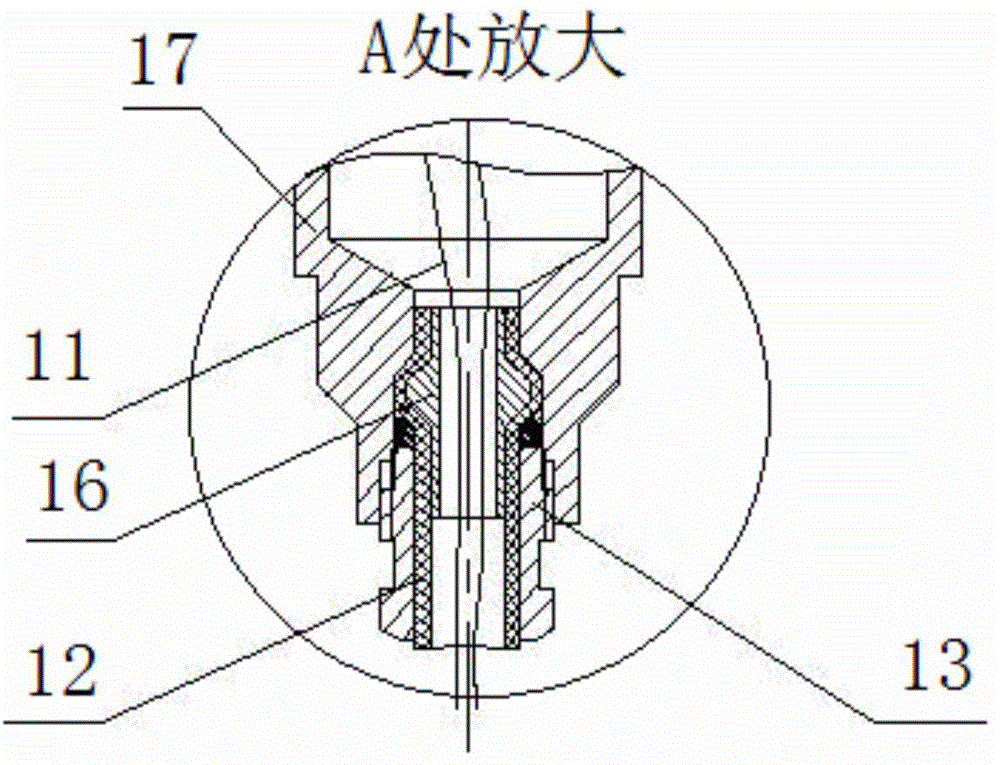

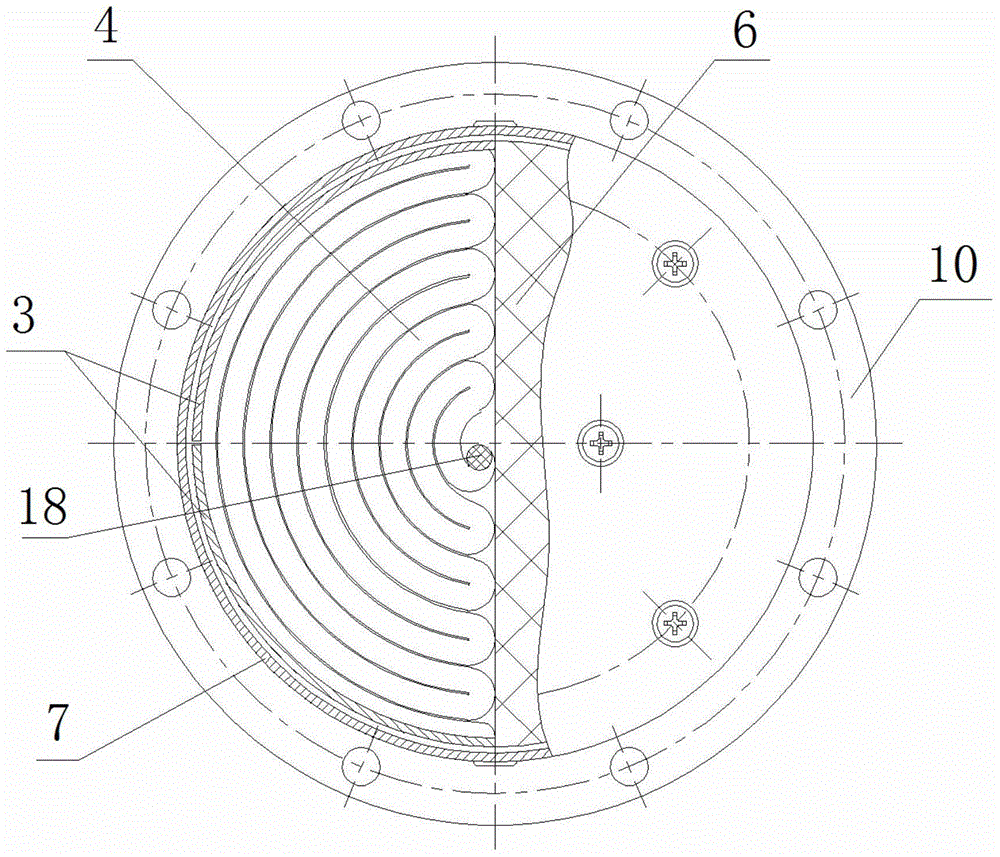

[0025] Such as figure 1 and image 3 As shown, the present invention comprises an electromagnet 1, a spring collar 2, a side baffle 3, a cable 4, an end cover 5, a buoyancy block 6, a launching tube 7, a bottom steel plate 8, a spring 9 and a base 10, wherein the base 10 is fixed On the main body of the underwater robot, a flange is provided on the outside of the circumference of the base 10, a groove is provided in the middle of the base 10, a through hole is provided at the center of the groove, and the launching tube 7 is installed on the said base 10 by screws 15. On the flange of the base 10, and the fixed end of the launch tube 7 is matched with the slit of the base 10, the electromagnet 1 is arranged in the launch tube 7, and is fixed in the recess of the base 10 by screws 14. In the groove, the signal input end 17 of the electromagnet 1 protrudes fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com