Slurry spraying machine

A shotcrete machine and shell technology, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of uneven discharge and easy accumulation of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

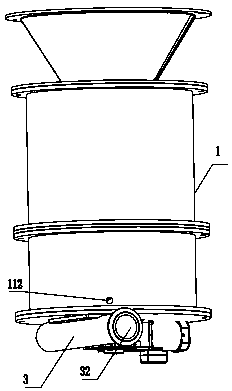

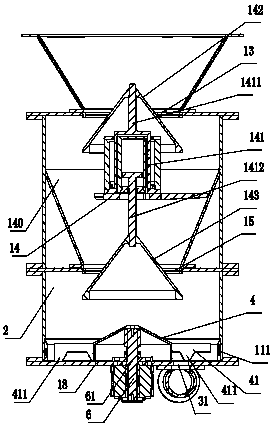

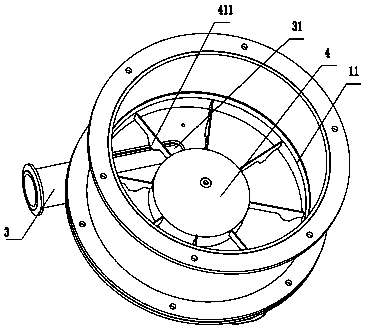

[0020] The present invention will be further described below in conjunction with the accompanying drawings: as shown in the figure, a spraying machine includes a casing 1, a discharge chamber 2 is provided in the casing, and a discharge pipe 3 connected to the first air source is also included. , the bottom of the housing is provided with a feed port 31 communicated with the discharge pipe, and the discharge pipe is also provided with a discharge port 32 communicated with the feed port, and the discharge chamber is provided with There is a rotor 4 that is connected to the first power source and can rotate along its own axis. A push plate 41 is provided on the outer wall of the rotor, and the push plate is used to push the slurry to the discharge port. One section of the discharge pipe is connected to the first air source, and the other end is provided with the discharge port. When in use, the material will be accumulated at the bottom after falling into the discharge chamber, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com