Temperature controlled and pressure controlled formation method of lithium ion battery

A technology of lithium-ion battery and formation method, which is applied in the field of power batteries, can solve problems such as electrolyte loss, cost increase, and environmental pollution, and achieve the effects of improving high-temperature performance, slowing down exhaust speed, and reducing ambient air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

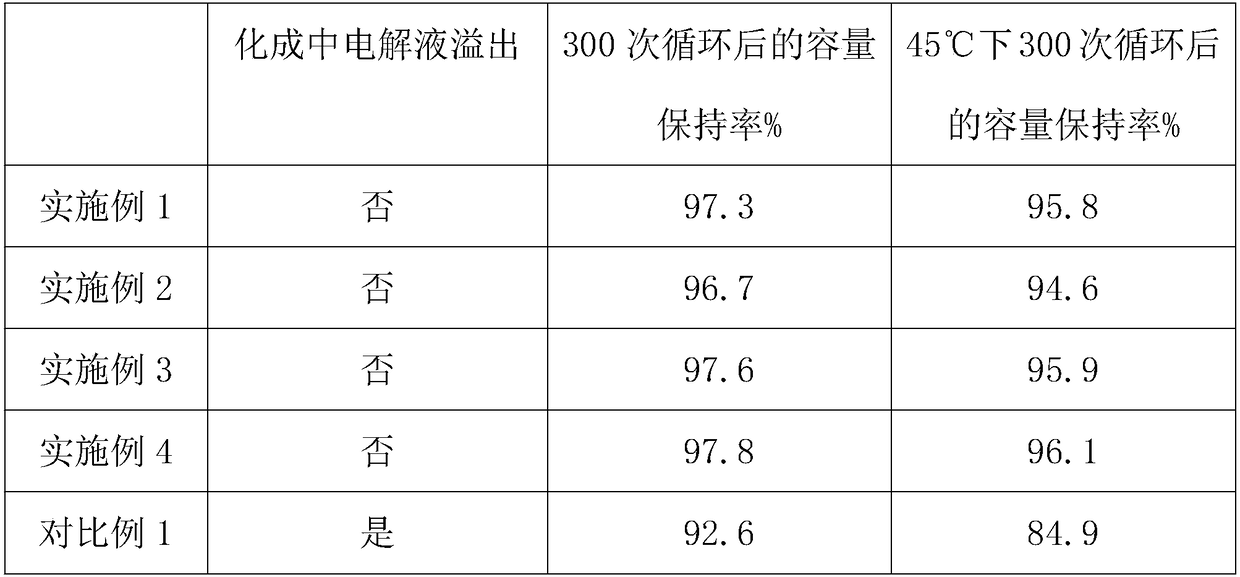

Examples

Embodiment 1

[0038] 1), place the lithium-ion battery injected with the electrolyte in a sealed formation device, vacuumize, adjust the air pressure in the sealed formation device to 0.04MPa, and let it stand for 0.3h; Adjust the air pressure in the sealed chemical formation device to 0.001MPa, and let it stand for 0.3h; the electrolyte includes a non-aqueous solvent, 0.6M LiPF 6 , and the LiBOB of 0.4M; And the mass fraction is the vinyl sulfite of 2% and the biphenyl of 1%; Described non-aqueous solvent is the ethyl carbonate of 65 volume % and the dimethyl carbonate of 35 volume %;

[0039] 2) Lowering the temperature inside the chemical conversion device to 8°C, while feeding nitrogen containing carbon dioxide, the volume fraction of the carbon dioxide is 5%, and adjusting the air pressure in the chemical conversion device to 0.1 MPa;

[0040] 3), using a current of 0.01C to adjust the voltage of the lithium-ion battery to a first voltage, the first voltage is 2.65V; stand still for 0....

Embodiment 2

[0056] 1), place the lithium-ion battery injected with the electrolyte in a sealed formation device, vacuumize, adjust the air pressure in the sealed formation device to 0.06MPa, and let it stand for 1h; continue to vacuumize, vacuumize the described The air pressure in the sealed chemical conversion device is adjusted to 0.01MPa, and it is left to stand for 1h; the electrolyte includes a non-aqueous solvent, 0.8M LiPF 6 , and the LiBOB of 0.6M; And the mass fraction is the vinyl sulfite of 4% and the biphenyl of 2%; Described non-aqueous solvent is the ethyl carbonate of 65 volume % and the dimethyl carbonate of 35 volume %;

[0057] 2) Lower the temperature inside the chemical conversion device to 12°C, and at the same time feed nitrogen containing carbon dioxide, the volume fraction of the carbon dioxide is 8%, and adjust the air pressure in the chemical conversion device to 0.1 MPa;

[0058] 3), using a current of 0.02C to adjust the voltage of the lithium-ion battery to t...

Embodiment 3

[0074] 1), place the lithium-ion battery injected with the electrolyte in a sealed formation device, vacuumize, adjust the air pressure in the sealed formation device to 0.05MPa, and let it stand for 0.5h; The air pressure in the sealed chemical formation device is adjusted to 0.005MPa, and left to stand for 0.5h; the electrolyte includes a non-aqueous solvent, 0.7M LiPF 6 , and the LiBOB of 0.5M; And the mass fraction is the vinyl sulfite of 3% and the biphenyl of 2%; The non-aqueous solvent is the ethyl carbonate of 65 volume % and the dimethyl carbonate of 35 volume %;

[0075] 2) Lower the temperature in the chemical conversion device to 10°C, and at the same time feed nitrogen containing carbon dioxide, the volume fraction of the carbon dioxide is 6%, and adjust the air pressure in the chemical conversion device to 0.1 MPa;

[0076] 3), using a current of 0.01C to adjust the voltage of the lithium-ion battery to a first voltage, the first voltage is 2.7V; stand still for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com