Tyre rubber slitter

A slitting and rubber technology, which is applied in the field of slitting machines, can solve problems such as low efficiency, inability to cut rubber in strips, and easily damaged knives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

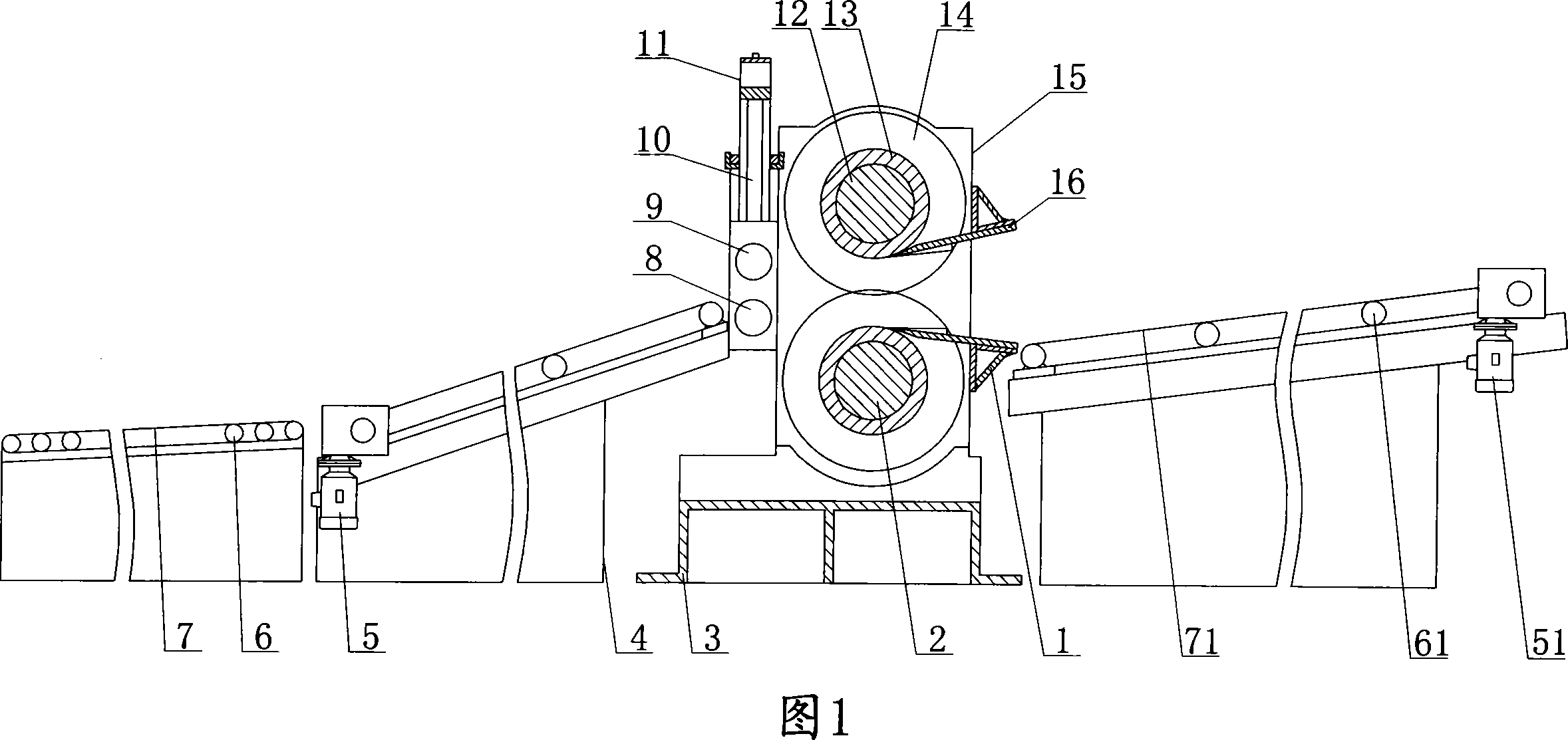

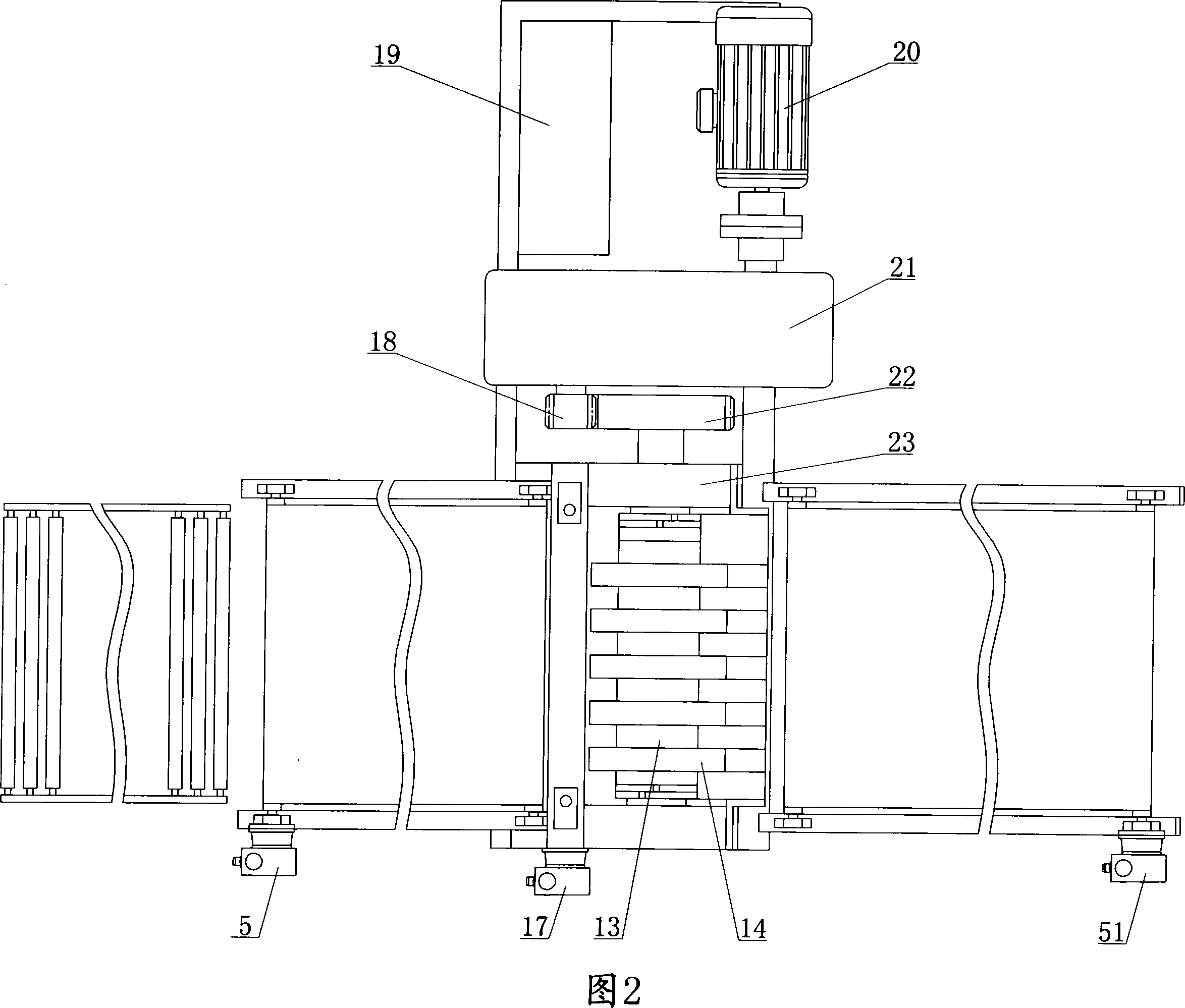

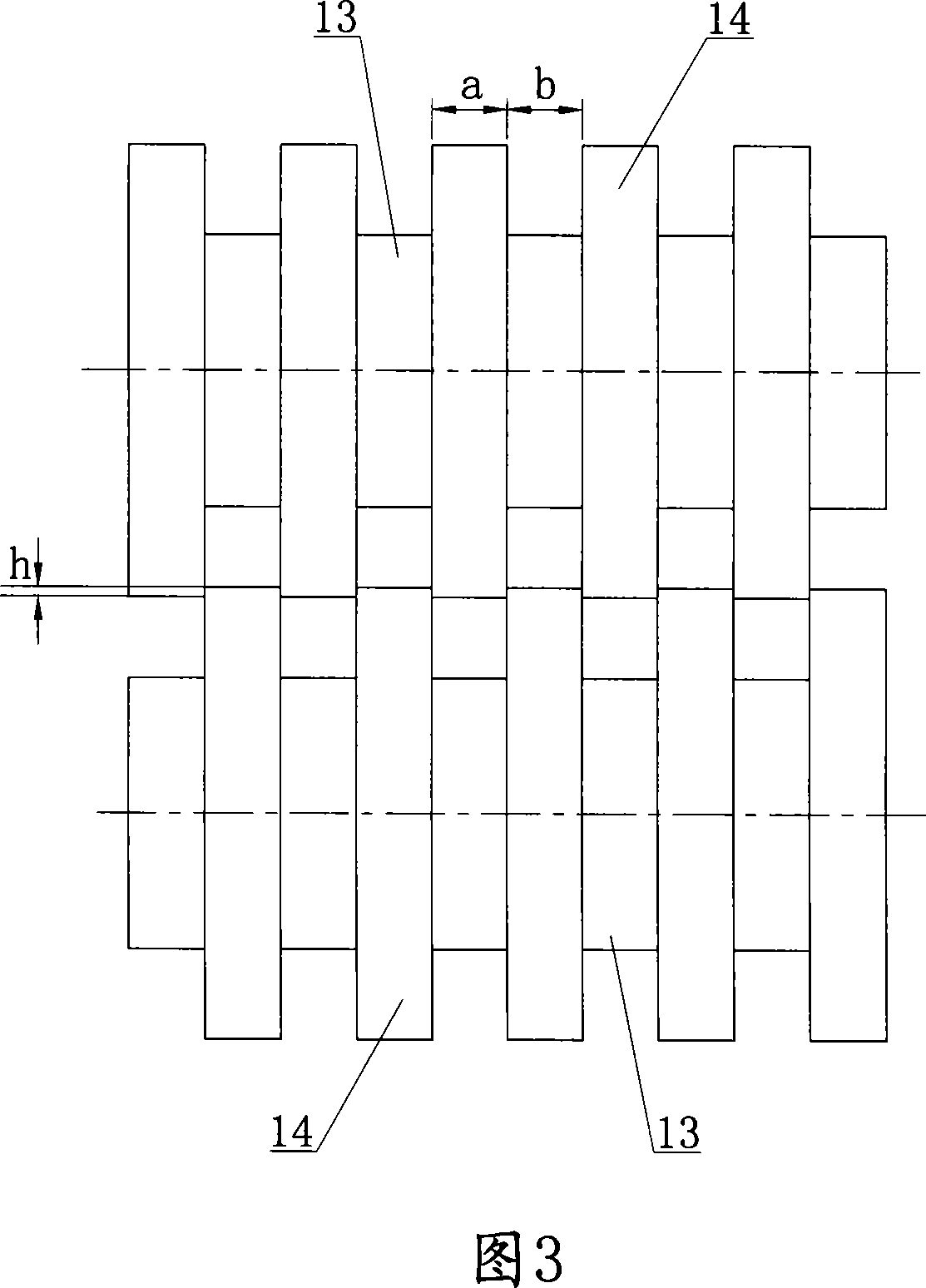

[0012] In Figures 1 and 2, the tire rubber slitting machine is composed of a feeding conveying mechanism, a hydraulic forced feeding mechanism, a slitting mechanism, a discharging conveying mechanism and an electric control box 19, and the feeding conveying mechanism is installed on the feeder of the slitting mechanism. The front end of the outlet, the discharge conveying mechanism is installed at the rear end of the discharge outlet of the slitting mechanism. The feeding conveying mechanism and the discharging conveying mechanism include bracket 4, stepless speed regulating reducer 5, 51, conveying roller 6, 61, conveyor belt 7, 71, stepless speed regulating reducer 5, 51 drives conveying roller 6, 61 Drive the conveyor belt 7,71 to run, and the conveying speed is arbitrarily adjusted within a certain range by the stepless speed regulation red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com