Environment-friendly coating mixing device

A technology of mixing device and environmental protection coating, applied in mixers, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problems of low product quality, long time consumption, uneven distribution of coating raw materials, etc. High quality, full and even mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

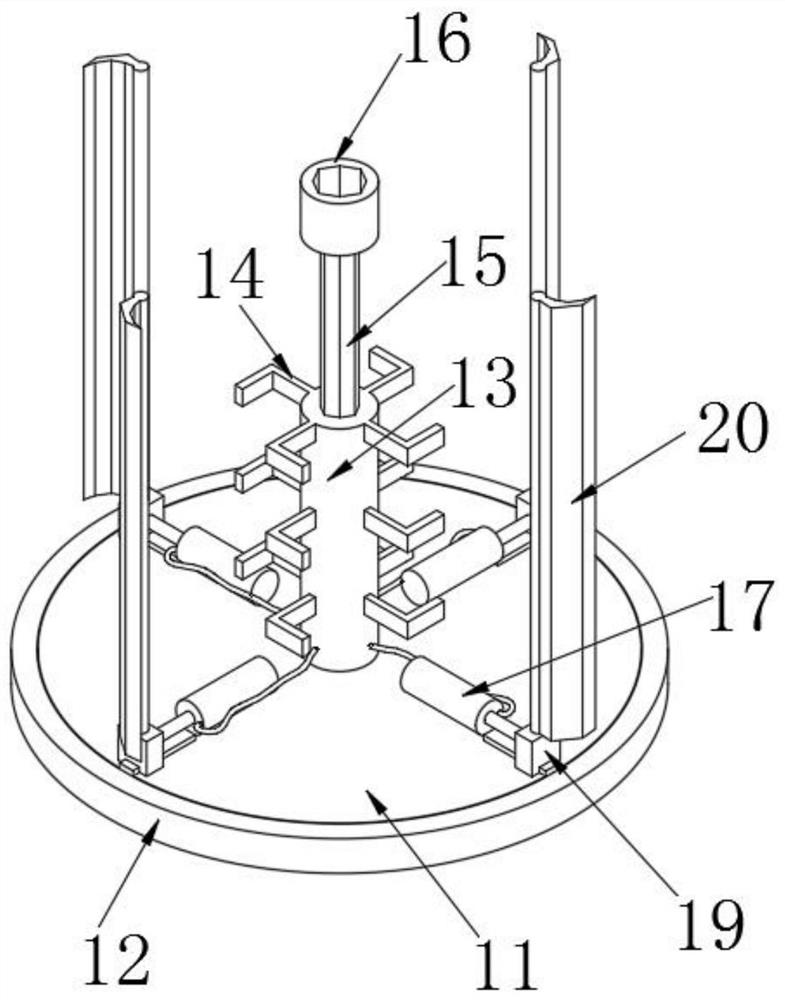

[0039] As an embodiment of the present invention, in the normal state of the mixing cylinder 2, the stirring blade 20 is in contact with the inner wall of the mixing cylinder 2, and when the stirring blade 20 rotates, the paint on the inner wall of the mixing cylinder 2 is scraped off.

[0040] As an embodiment of the present invention, the specific operation steps of the mixing device are as follows;

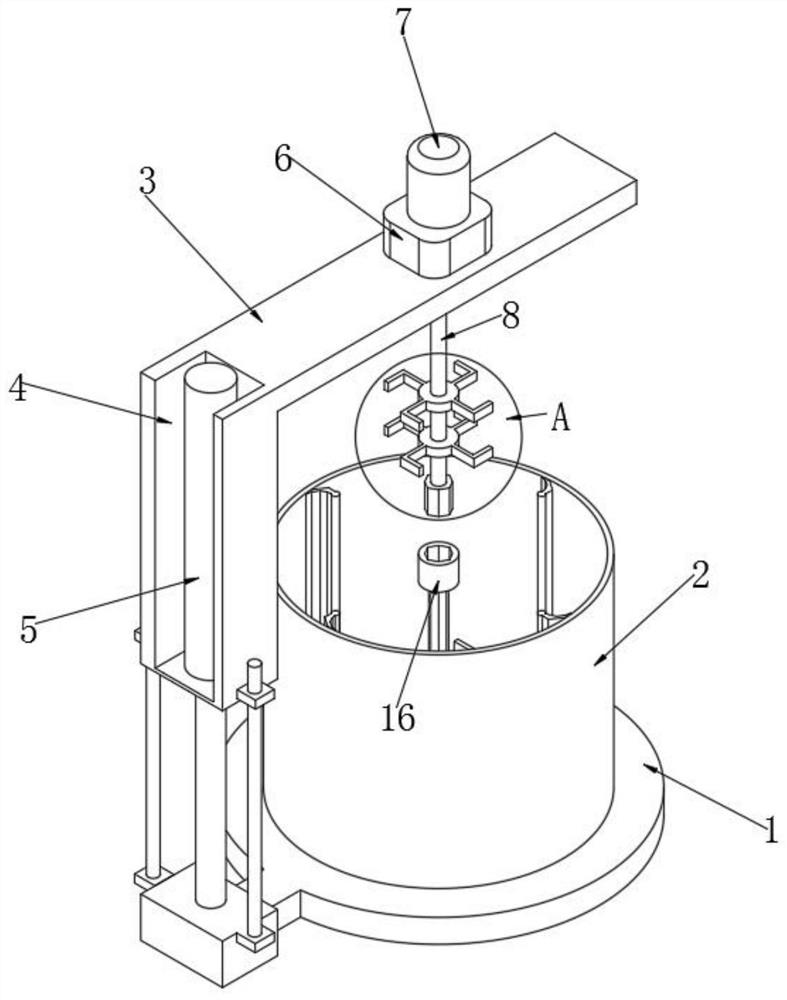

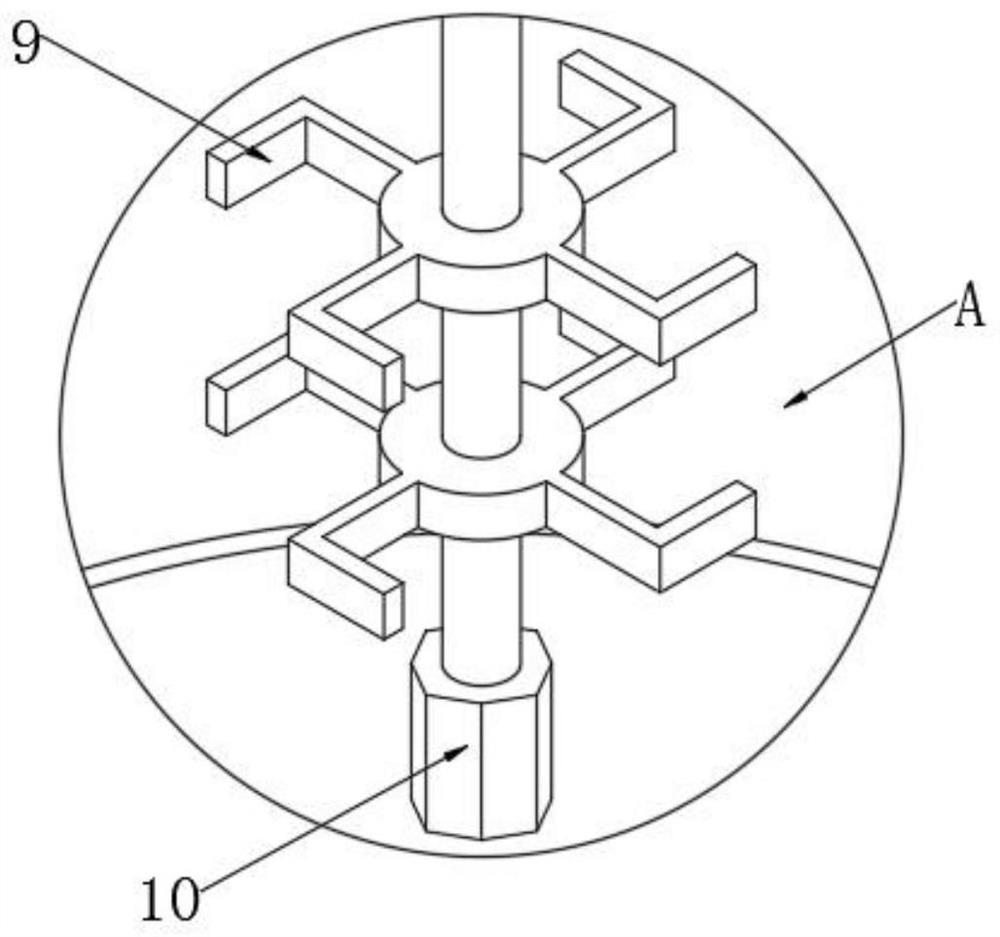

[0041] Step 1: Add the paint into the mixing cylinder 2, and then place the mixing cylinder 2 on the base 1. At this time, the hydraulic rod 5 in the installation groove 4 works and stretches to drive the lifting frame 3 to move up and down until the connecting head at the bottom of the stirring shaft 8 10 is clamped with the hexagonal hole of the connecting seat 16;

[0042] Step 2: At this time, the servo motor 7 works, the reducer 6 decelerates to drive the stirring shaft 8 to rotate, and at the same time, the cooperation between the first movable rod 15 and the first cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com