Cement mixer

A mixer and cement slurry technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of uneven mixing of cement slurry, slow mixing speed, and inability to meet construction specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

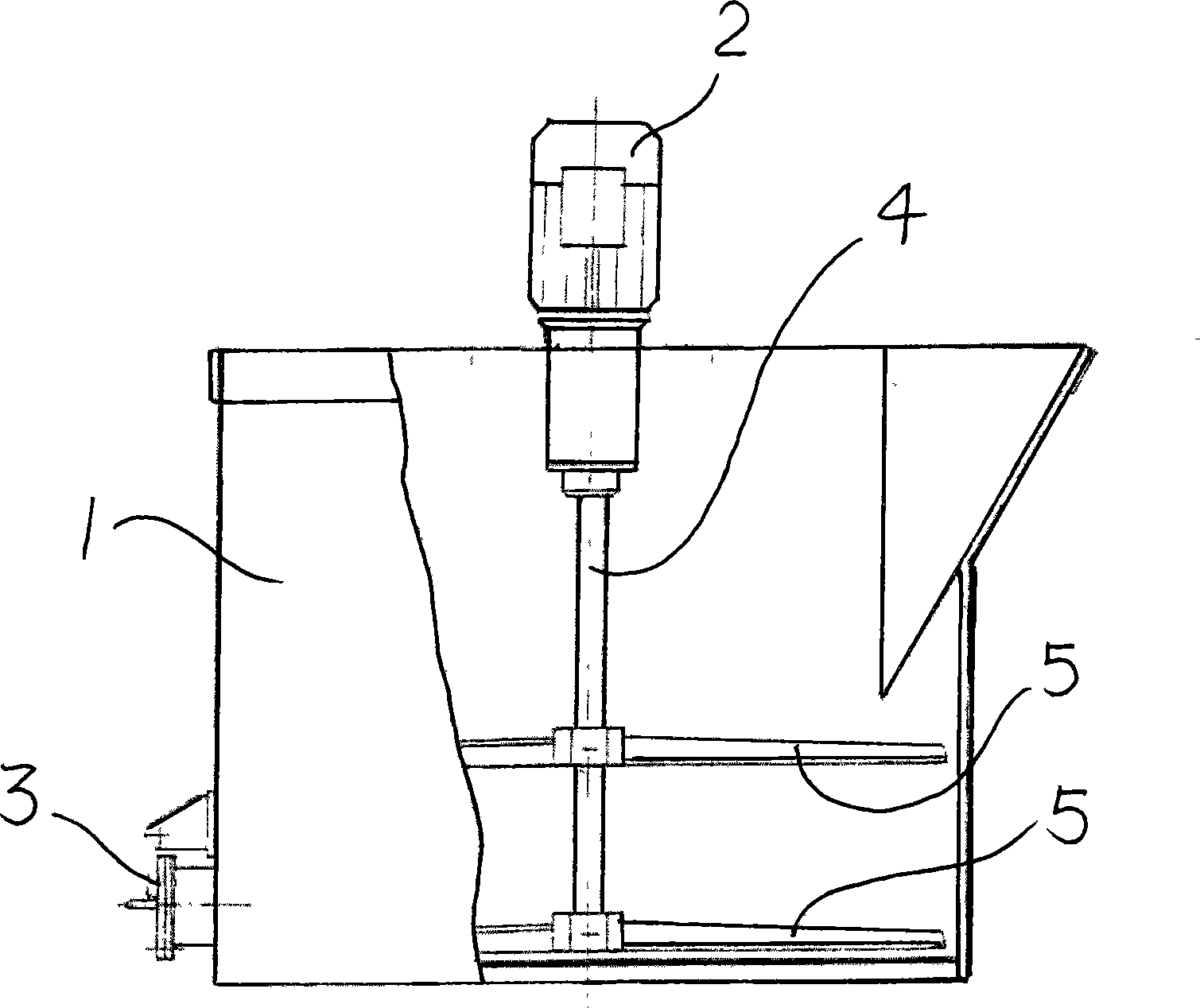

[0007] Example 1: Refer to the accompanying drawings. Inject water (tap water) and cement into the mixing drum. When the motor works, it drives the vertical shaft and drives the mixing blades to rotate. Because the upper and lower sets of mixing blades on the vertical shaft simultaneously affect the water and cement in the mixing drum After stirring, the water and cement are fully and evenly mixed to make it into cement slurry, and the mixed cement slurry flows out from the slurry outlet to provide a cement slurry with a water-cement ratio of about 0.4 that meets the requirements of my country's construction specifications. The purpose of the invention is achieved by the use of the grouting operation of the pipe orifice.

Embodiment 2

[0008] Example 2: refer to the accompanying drawings. In this embodiment, on the basis of Embodiment 1, the angle between the stirring blade and the horizontal plane is selected to be 30°, which can achieve the better purpose of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com