High-efficiency hull breaking integrated system for performing anaerobic fermentation on livestock and poultry excrement and straw mixture

A technology of mixing raw materials and anaerobic fermentation, which is applied in the direction of bioreactor/fermentation tank combination, specific-purpose bioreactor/fermentation tank, biochemical equipment, etc. Reasonable, low biogas production rate and other problems, to achieve the effect of fully and evenly mixed raw materials, increased processing capacity, and advanced processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with specific examples.

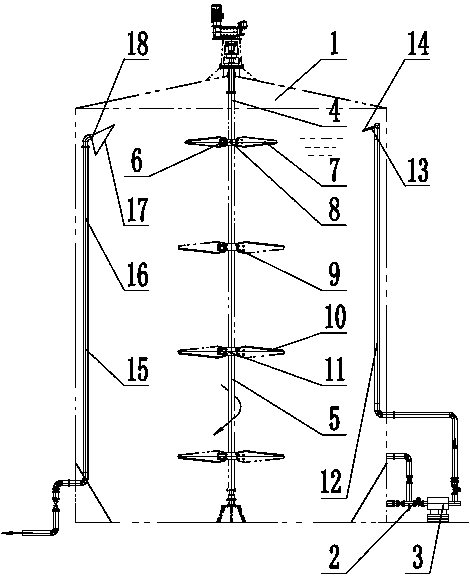

[0023] see figure 1 , The invention provides an integrated system for high-efficiency shell breaking of livestock and poultry manure and straw mixed raw materials for anaerobic fermentation. Large-scale wet fermenter, motor deceleration transmission device mechanical stirring, fermenter diameter 18m, fermenter body height-to-diameter ratio 1:1, fermenter 1 animal manure and straw mixed raw material capacity 5000-5500m³, constant temperature continuous feeding or semi-continuous feeding Feeding, the temperature of the material is 35-38°C, the concentration of the material in the fermentation tank 1 reaches 10%, and the temperature of the liquid in the tank reaches 35-40°C.

[0024] The motor deceleration transmission device is installed on the fermentation tank 1, and the stirring shaft 4 is installed longitudinally in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com