Production process of engineering fibre for polyester road

An engineering fiber and production process technology, which is applied in the high-performance asphalt reinforced mixed material-polyester road engineering fiber and its production field, can solve the problems such as not involving polyester fiber, achieve simple and convenient operation, improve strength and Service life, the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

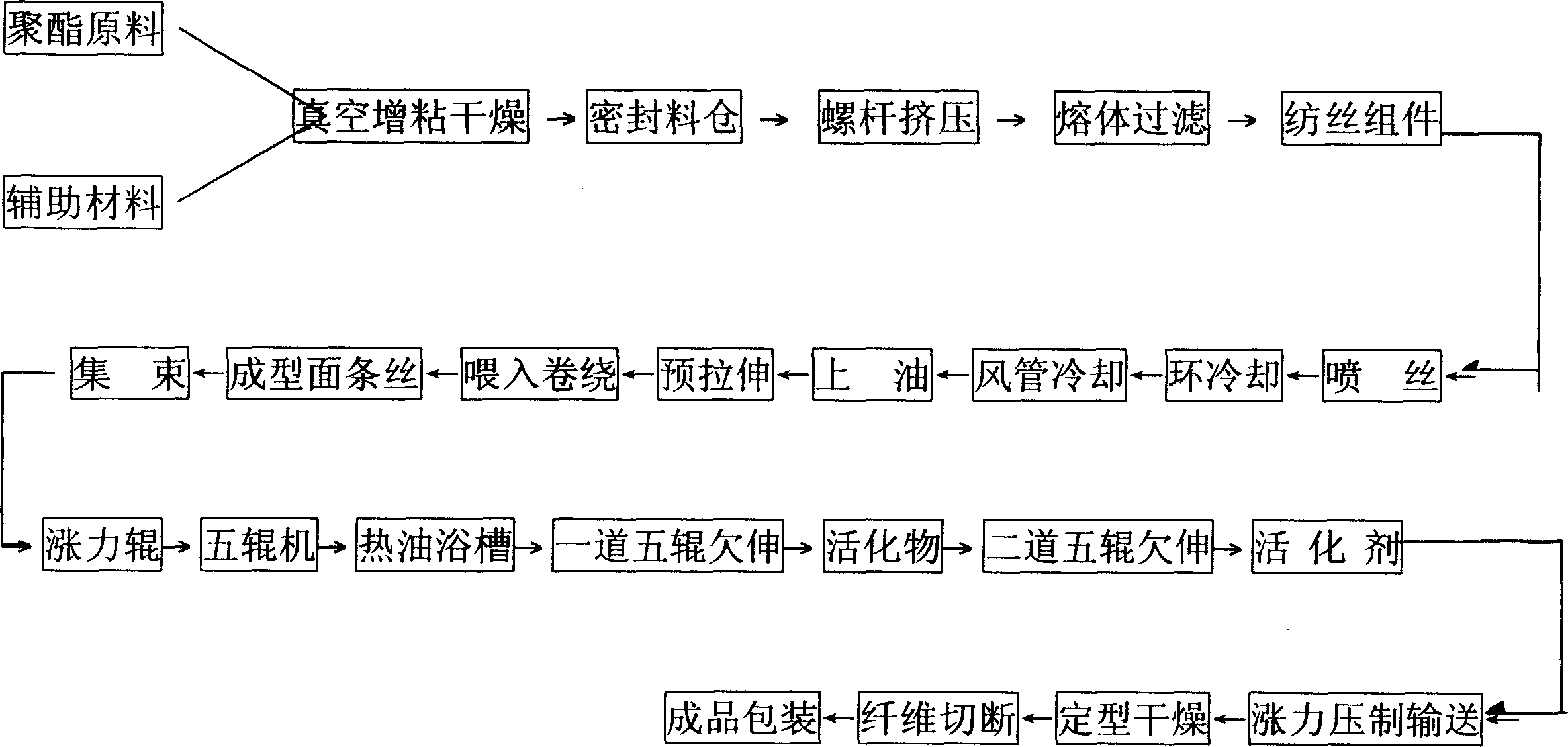

Method used

Image

Examples

Embodiment Construction

[0027] The process parameters of the pre-spinning part are as follows:

[0028] ①Drying requirements for polyester raw materials, dry moisture content less than 0.2‰, viscosity-increasing intrinsic viscosity above 0.8.

[0029] ②Screw melt extrusion temperature and speed: screw heating zone 1 is 300°C, zone 2 is 320°C, zone 3 is 345°C, zone 4 is 365°C, zone 5 is 350°C, zone 6 is 345°C. The screw extrusion force is 80 kilograms, and the speed is 65 rpm.

[0030] ③ Melt filtration adopts 220-mesh filter element, metering pump 10CC / 40 rpm, spinneret Φ0.5 / 600 holes, and the cooling wind speed of the ring blowpipe is 0.4 seconds. The air temperature is 18℃~22℃, and the winding speed is 650m / min.

[0031] The post-understretching production process parameters are as follows:

[0032] ①It is more appropriate for the formed noodle silk to be bundled at 600,000 to 700,000 deniers after stretching.

[0033] ②The temperature of the hot oil tank is 85℃~90℃, and the concentration of oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com