Construction Method of Anti-seepage Crack Protection Layer of Roof Structure

A protective layer and seepage cracking technology, which is applied to the roof covering layer, roof, and roof using flexible materials, etc., can solve the problem of high polymer materials' low tensile and tear resistance, reduced roof impermeability effect, and tear resistance. Insufficient performance and other problems, to achieve the effect of durable protection of building structures, improvement of quality stability, and strong tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

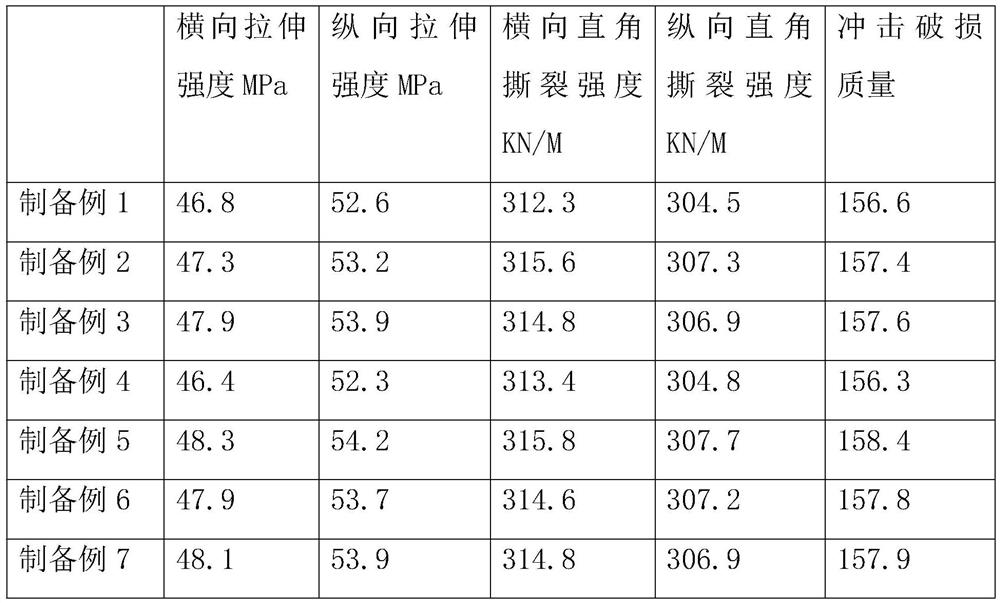

Examples

preparation example 1-5

[0048] A waterproof and heat-insulating film, comprising the following components:

[0049] Chlorotrifluoroethylene, polyvinyl alcohol, polyetherimide, antioxidant.

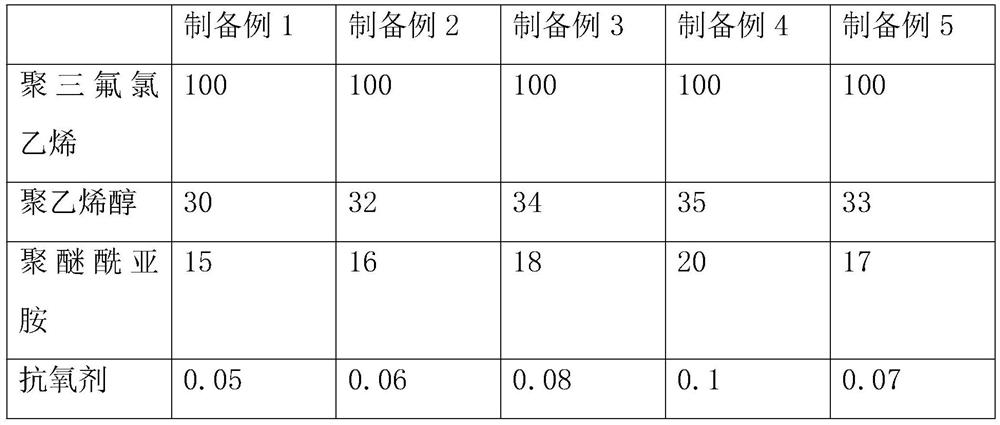

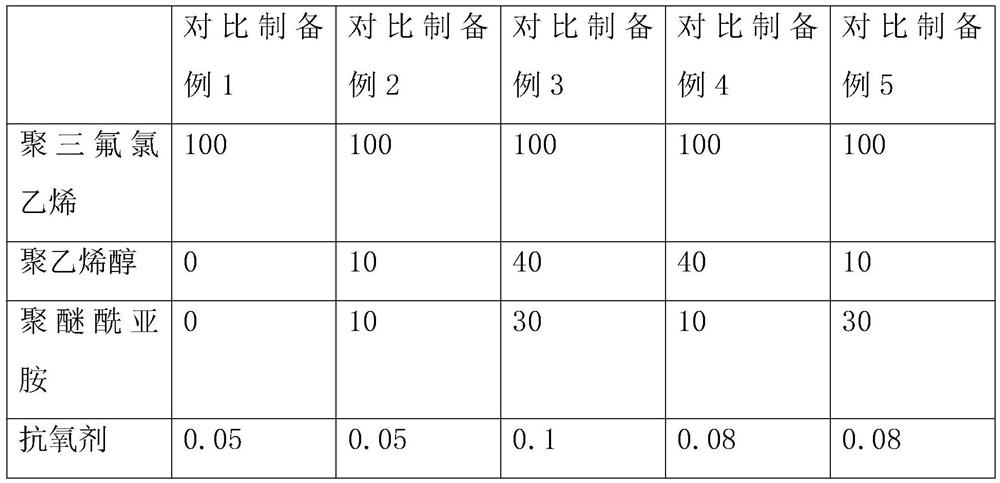

[0050] In Preparation Examples 1-5, see Table 2 for the specific input amount (unit: Kg) of each component.

[0051] Table 2

[0052]

[0053] In Preparation Example 1-5, the preparation method of waterproof and heat-insulating film is as follows:

[0054] Put polychlorotrifluoroethylene, polyvinyl alcohol, polyetherimide, and antioxidant into a stirred tank, rotate at a speed of 1200r / min, stir for 3 minutes to obtain a mixture, put the mixture into a film blowing machine, and blow it into a film. A waterproof and heat-insulating film was obtained, wherein the extrusion temperature of the mixture was 250° C., and the thickness of the waterproof and heat-insulating film was 0.08 mm.

preparation example 6-8

[0056] A waterproof and heat-insulating film, compared with Preparation Example 5, the only difference is:

[0057] Also includes the following components:

[0058] Aluminum powder.

[0059] In Preparation Examples 6-8, see Table 3 for the specific input amount (unit: Kg) of aluminum powder.

[0060] table 3

[0061] Preparation example 6 Preparation Example 7 Preparation example 8 Aluminum powder 1 2 1.5

[0062]Preparation Examples 6-8 In summary, aluminum powder, polychlorotrifluoroethylene, polyvinyl alcohol, polyetherimide, and antioxidant are put into a stirring tank and stirred evenly.

Embodiment 1

[0072] A construction method for a roof structure anti-crack protective layer, comprising the following steps:

[0073] Step 1), clean the roof structure, build the pouring formwork, pour cement mortar on the roof structure, compact it to form a leveling layer, and let the leveling layer stand for 1 hour.

[0074] Step 2), sprinkle water mist on the leveling layer with a nozzle to make the surface of the leveling layer wet.

[0075] Step 3), use a sponge stick to roll on the leveling layer once to absorb excess water droplets on the surface of the leveling layer, so that the surface of the leveling layer has no water droplets but is in a wet state, and then cover the surface of the leveling layer with a waterproof and heat-insulating film, and the adjacent waterproof and heat-insulating The edges of the film connection overlap each other, and the overlapping width is 1cm. A polypropylene sheet is placed in the overlapping place. The length of the polypropylene sheet is the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com