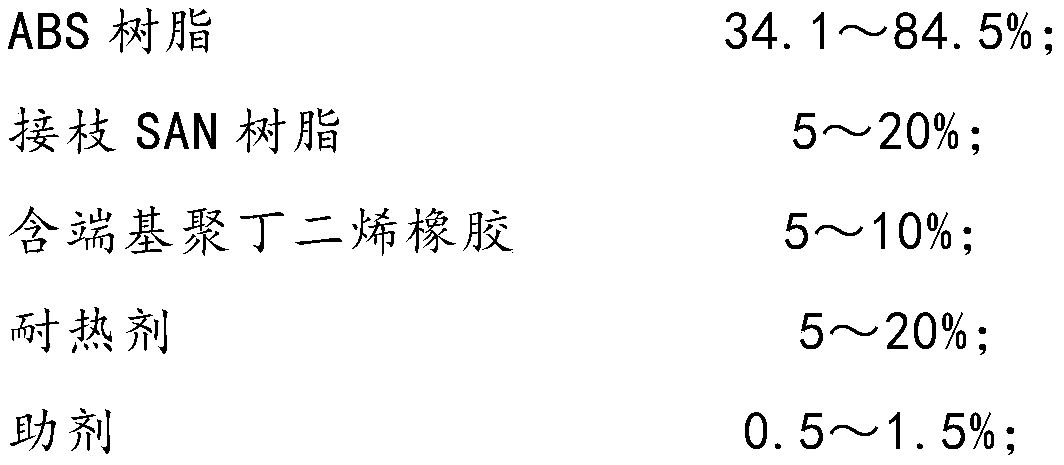

A kind of abs resin composition with high melt strength and good appearance for blow molding

An ABS resin, high melt strength technology, applied in the field of polymer materials, can solve the problems of limited improvement of melt strength, difficulty in achieving system uniformity for ABS resin, low equipment requirements, good uniformity, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

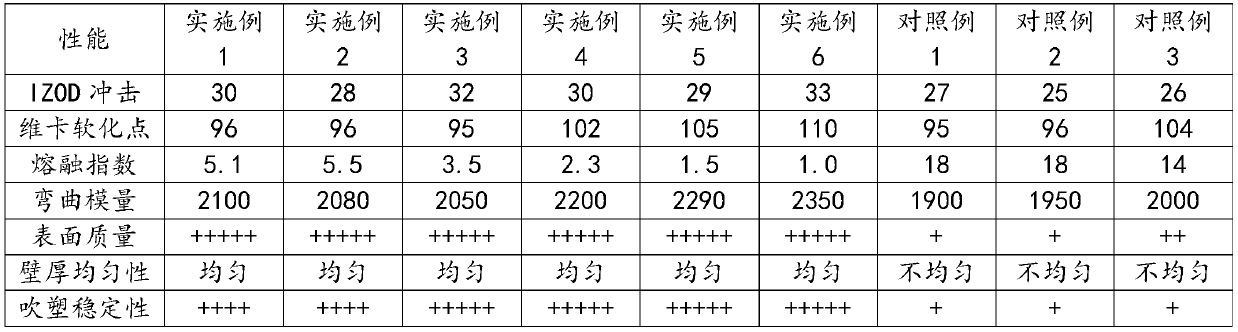

Examples

Embodiment 1~6 and comparative example 1~3

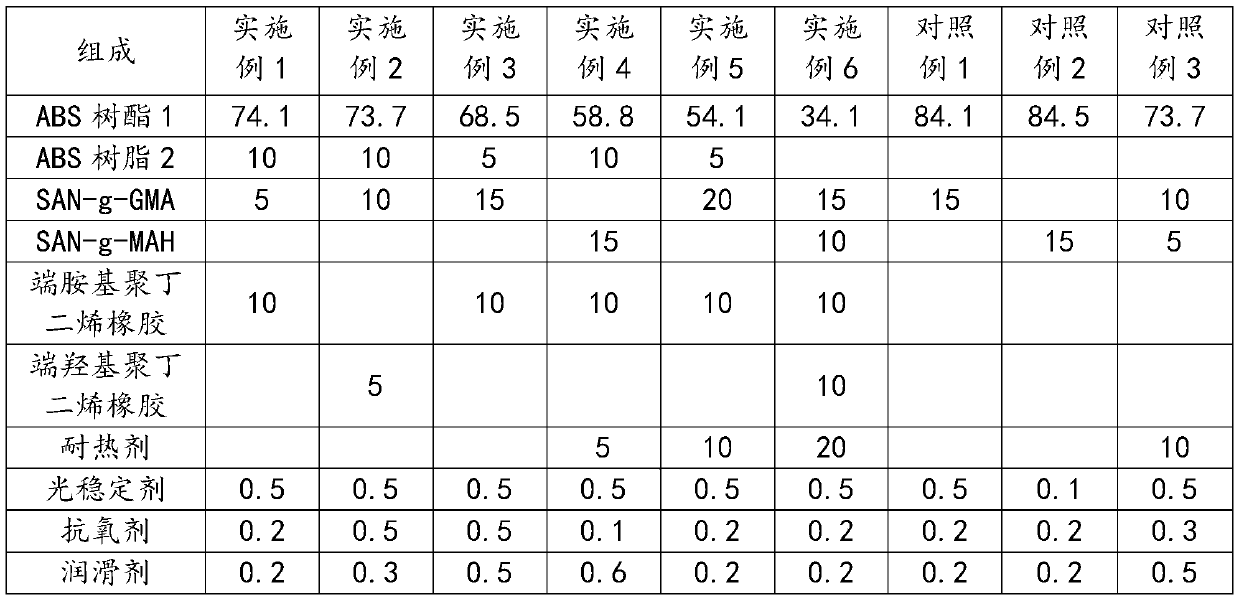

[0029] Prepare the raw materials of Examples 1~6 and Comparative Examples 1~3 respectively according to the formula in Table 1, prepare according to the following steps, join the twin-screw extruder (screw diameter is 35mm, aspect ratio L / D=48) in the main barrel. The temperature control of each section of the main barrel (from the feeding port to the nozzle outlet) is 220°C, 235°C, 245°C, 255°C, and 250°C respectively, and the twin-screw speed is 300 rpm. grains.

[0030] The formula of table 1 embodiment 1~6 and comparative example 1~3

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com