Long-acting glass hydrophobic agent and preparation and use method thereof

A technology of hydrophobic agent and glass, applied in the field of long-term glass hydrophobic agent, can solve the problems of high equipment requirements, complex process, inability to use, etc., to achieve the effect of strengthening the adhesion effect, ensuring driving safety, and convenient secondary cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

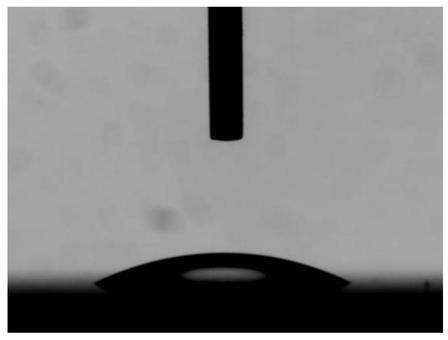

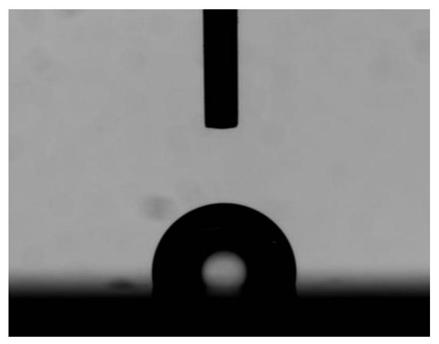

Image

Examples

Embodiment 1

[0041] Prepare the long-acting glass hydrophobic agent of the present invention according to the following formula and ratio:

[0042]

[0043] Preparation:

[0044] a) Add 1 g of hydrochloric acid to the mixture of 79 g of absolute ethanol and 15 g of isopropanol, and stir for 30 min.

[0045] b) Slowly add 5 g of polysiloxane to the solution in step a) while stirring, and continue stirring at room temperature for 3 hours to obtain the required long-lasting glass hydrophobic agent.

Embodiment 2

[0047] Prepare the long-acting glass hydrophobic agent of the present invention according to the following formula and ratio:

[0048]

[0049]

[0050] Preparation:

[0051] a) Slowly add 1 g of sulfuric acid to the mixture of 85 g of absolute ethanol and 4 g of isopropanol, and stir for 30 min.

[0052]b) Slowly add 10 g of polysiloxane to the solution in step a) while stirring, and continue stirring at room temperature for 6 hours to obtain the required long-lasting glass hydrophobic agent.

Embodiment 3

[0054] Prepare the long-acting glass hydrophobic agent of the present invention according to the following formula and ratio:

[0055]

[0056] Preparation:

[0057] a) Slowly add 1 g of sulfuric acid to a mixture of 95 g of absolute ethanol and 1 g of water, and stir for 30 min.

[0058] b) Slowly add 3 g of polysiloxane to the solution in step a) while stirring, and continue stirring at 40° C. for 4 hours to obtain the required long-lasting glass hydrophobic agent.

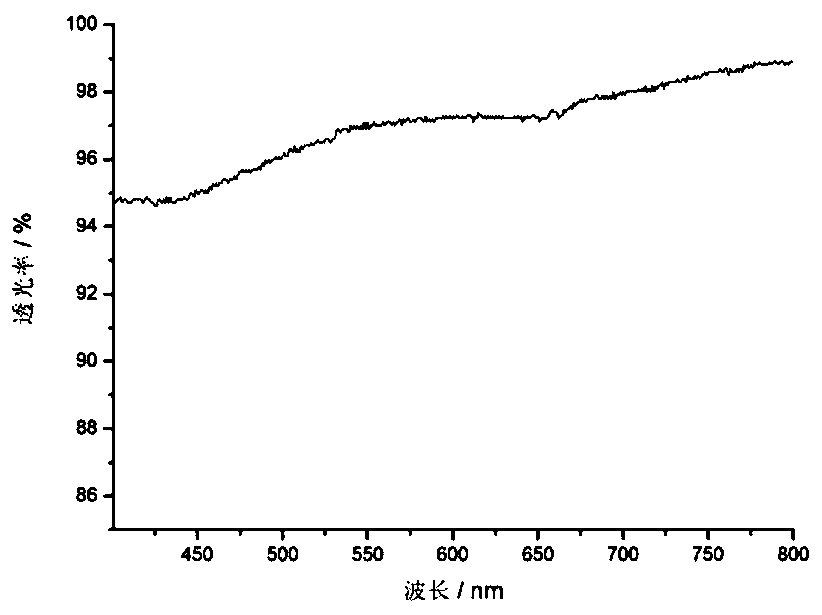

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com