Semi-solid slurry preparation and feeding device for surface repair integrated equipment

A semi-solid slurry and surface repair technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problem of inability to realize the integration of semi-solid slurry preparation and supply, difficult to control the temperature in sections, and low production efficiency. Low-level problems, to achieve the effect of simple structure, uniform and sufficient mixing, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to detail the technical content, structural features, achieved objects and effects of the present invention, the following will be described in detail with reference to the accompanying drawings.

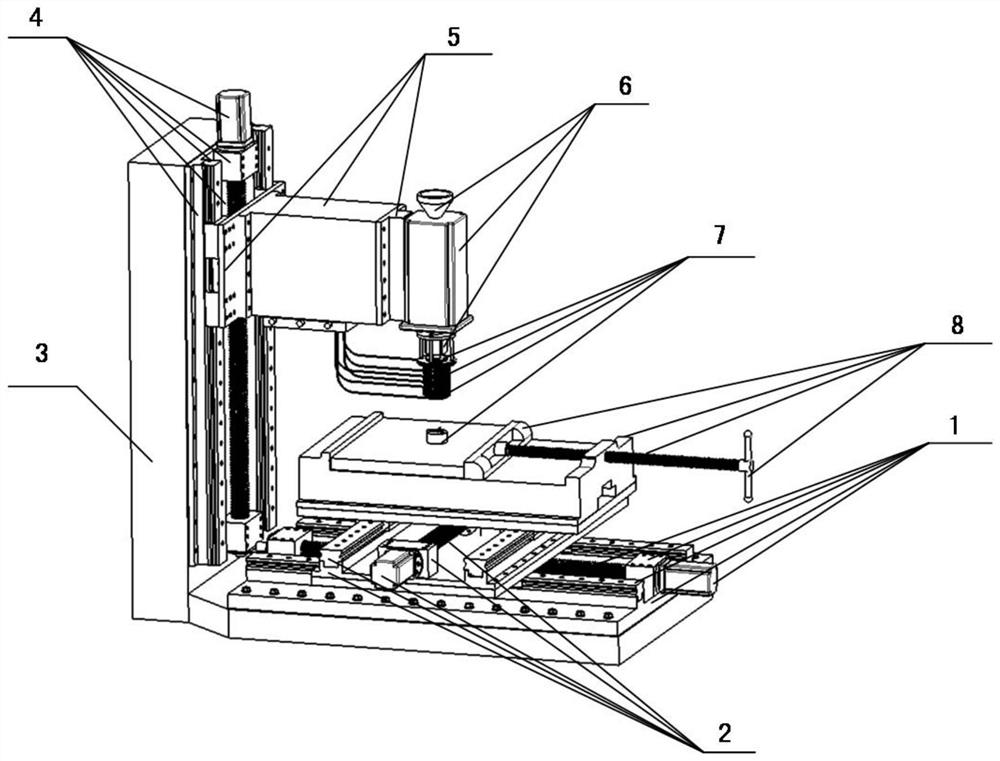

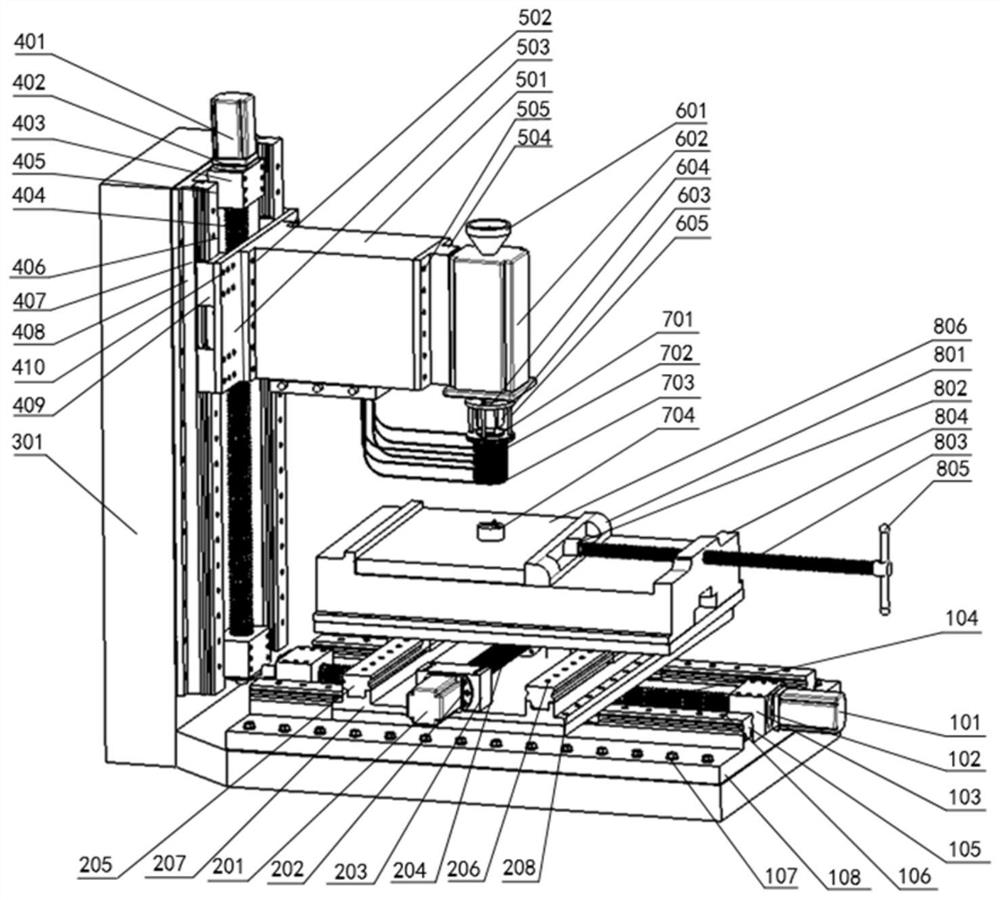

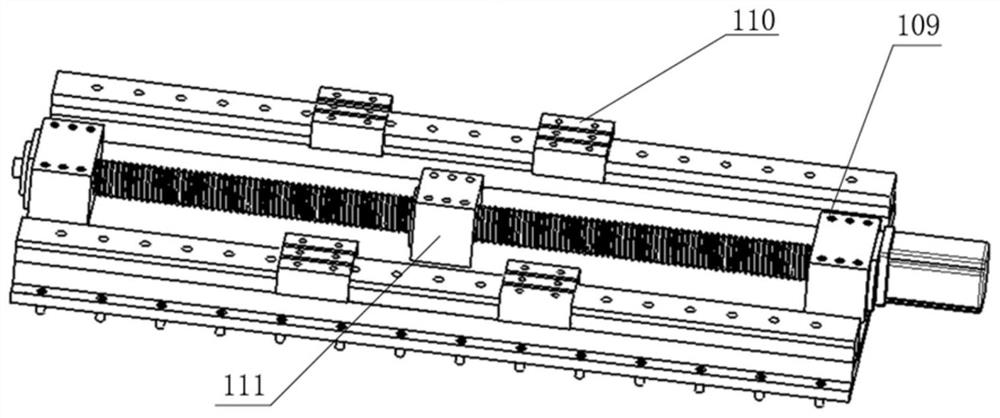

[0049] The invention provides a semi-solid slurry preparation and feeding device for surface repair integrated equipment based on metal powder, such as figure 1 As shown, it includes X-axis direction feeding assembly 1, Y-axis direction feeding assembly 2, machine tool base 3, Z-axis direction feeding assembly 4, servo motor support assembly 5, hollow shaft continuous feeding assembly 6, semi-solid slurry Material preparation and feeding assembly 7 and steel plate workpiece clamping assembly 8 to be repaired. The X-axis direction feed component 1 is connected to the machine tool base 3, the Y-axis direction feed component 2 is connected to the X-axis direction feed component 1, the Z-axis direction feed component 4 is connected to the machine tool base 3, and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com