PPM environmentally friendly material and preparation method thereof

A technology of environmental protection materials and raw materials, applied in the field of plastic environmental protection, can solve the problems of easy to become brittle, poor flexibility, unsuitable for low temperature environment, etc., and achieve the effect of easy stirring and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

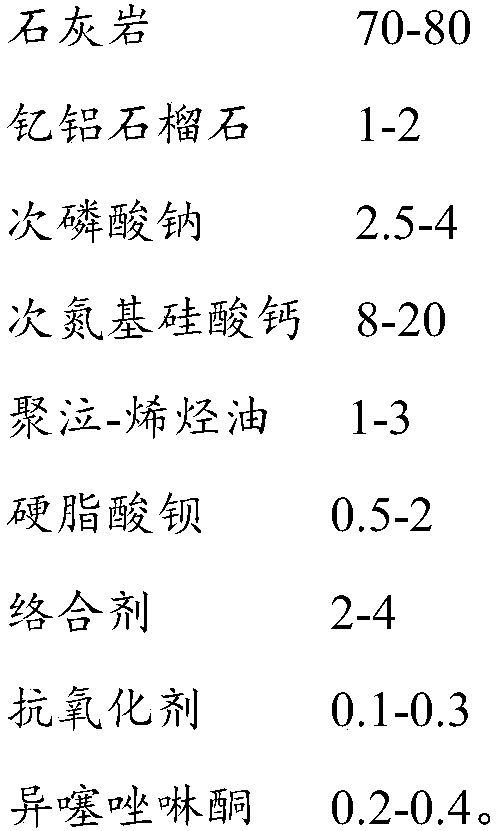

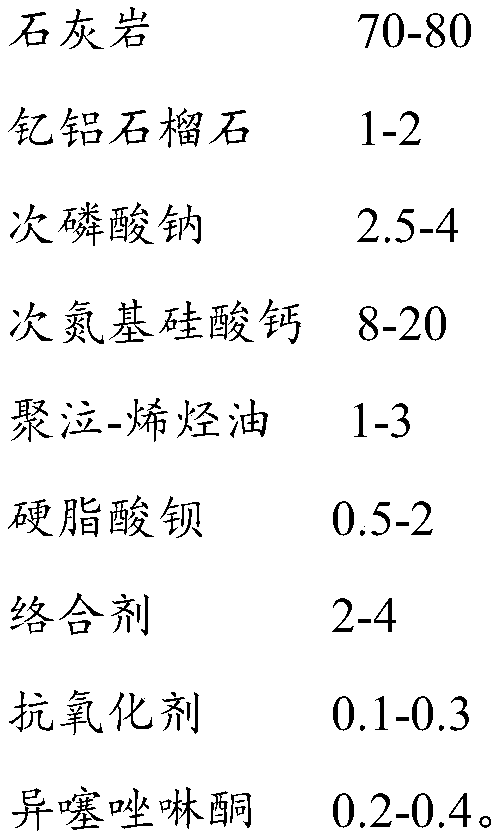

[0016] A preparation method of PPM environment-friendly material, comprising the following steps:

[0017] a. 70 kilograms of limestone, 2.5 kilograms of sodium hypophosphite, 8 kilograms of nitrilocalcium silicate, 1 kilogram of yttrium aluminum garnet and 0.5 kilogram of barium stearate are mixed uniformly to obtain mixture A with a particle diameter of 2-4 nanometers;

[0018] b. Add 1 kilogram of poly(ethylene oxide)-olefin oil and stir in mixture A, obtain mixture B;

[0019] c. Add 2 kg of titanate coupling agent, 0.1 kg of antioxidant, and 0.2 kg of isothiazolinone to mixture B in sequence, and place in a 50°C-60°C water bath to stir evenly to obtain PPM environmental protection material A.

Embodiment 2

[0021] A preparation method of PPM environment-friendly material, comprising the following steps:

[0022] a. 80 kilograms of limestone with a particle diameter of 2-4 nanometers, 4 kilograms of sodium hypophosphite, 20 kilograms of calcium nitrilosilicate, 2 kilograms of yttrium aluminum garnet and 2 kilograms of barium stearate are mixed uniformly to obtain mixture C;

[0023] B. add 3 kilograms of poly(ethylene oxide)-olefin oils and stir in mixture C, obtain mixture D;

[0024] c. Add 4 kg of titanate coupling agent, 0.3 kg of antioxidant, and 0.4 kg of isothiazolinone to mixture D in sequence, and place in a 50°C-60°C water bath to stir evenly to obtain PPM environmental protection material B.

Embodiment 3

[0026] A preparation method of PPM environment-friendly material, comprising the following steps:

[0027] a. mixing 80 tons of limestone with a particle size of 2-4 nanometers, 4 tons of sodium hypophosphite, 20 tons of calcium nitrilosilicate, 2 tons of yttrium aluminum garnet and 2 tons of barium stearate to obtain mixture E;

[0028] b. Add 3 tons of poly(ethylene oxide)-olefin oil in the mixture E and stir evenly, obtain the mixture F;

[0029] c. Add 4 tons of titanate coupling agent, 0.3 tons of antioxidant and 0.4 tons of isothiazolinone to the mixture F in sequence, and put it in a 50°C-60°C water bath and stir evenly to obtain the PPM environmental protection material C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com