Cleaning solution for removing light resistance residue

A technology of photoresist residue and cleaning liquid, applied in the direction of photosensitive material processing, can solve problems such as increasing metal corrosion, and achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

[0023] The reagents and raw materials used in the present invention are all commercially available. The cleaning solution of the present invention can be prepared by simply and uniformly mixing the above components.

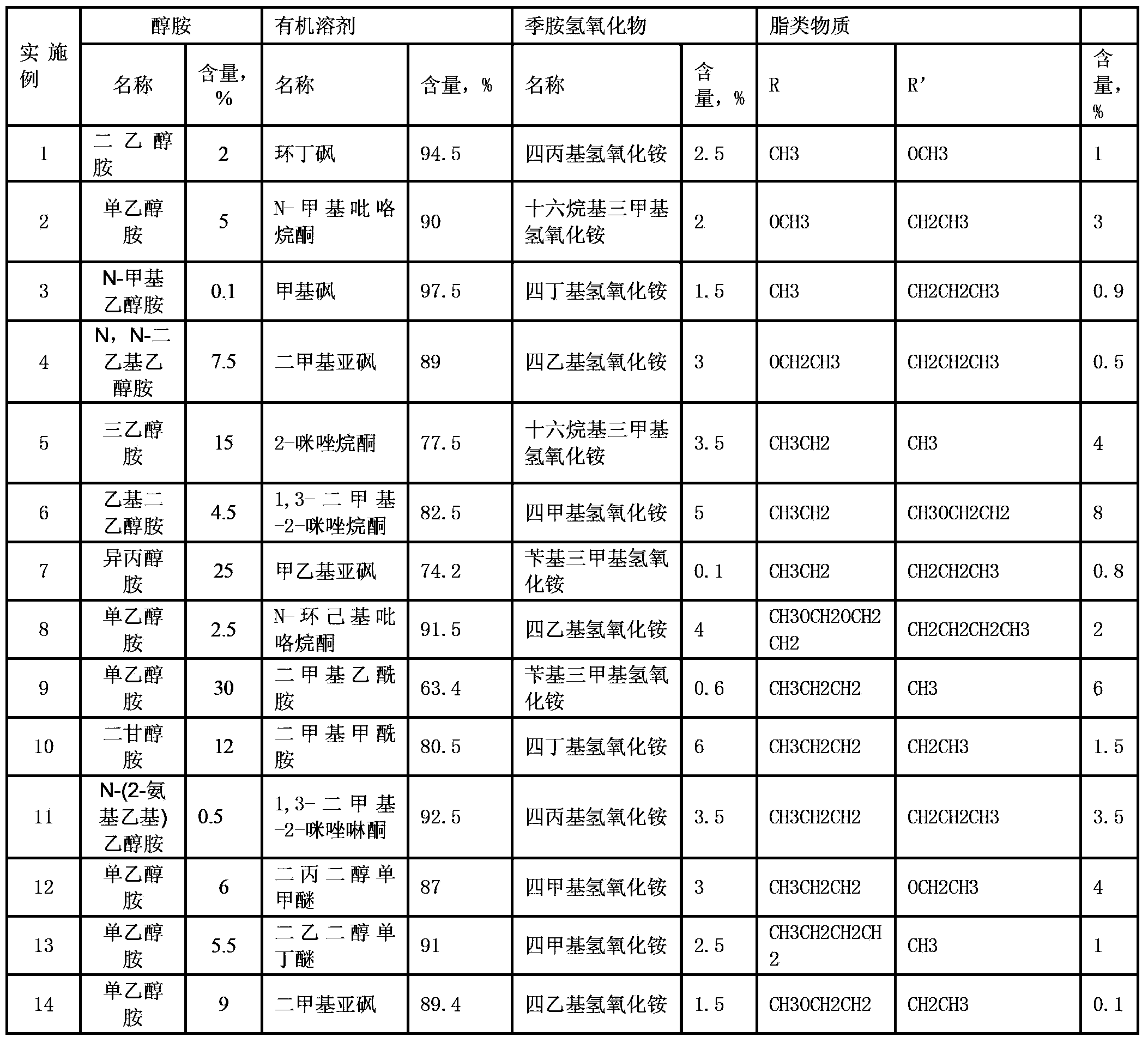

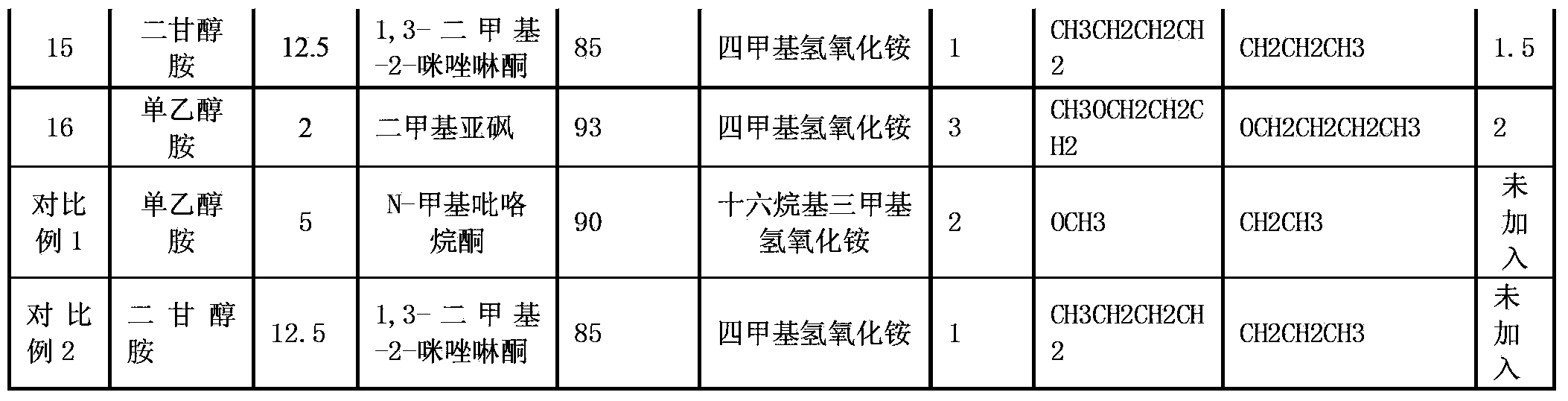

[0024] Table 1 embodiment and the composition and content of comparative example cleaning solution

[0025]

[0026]

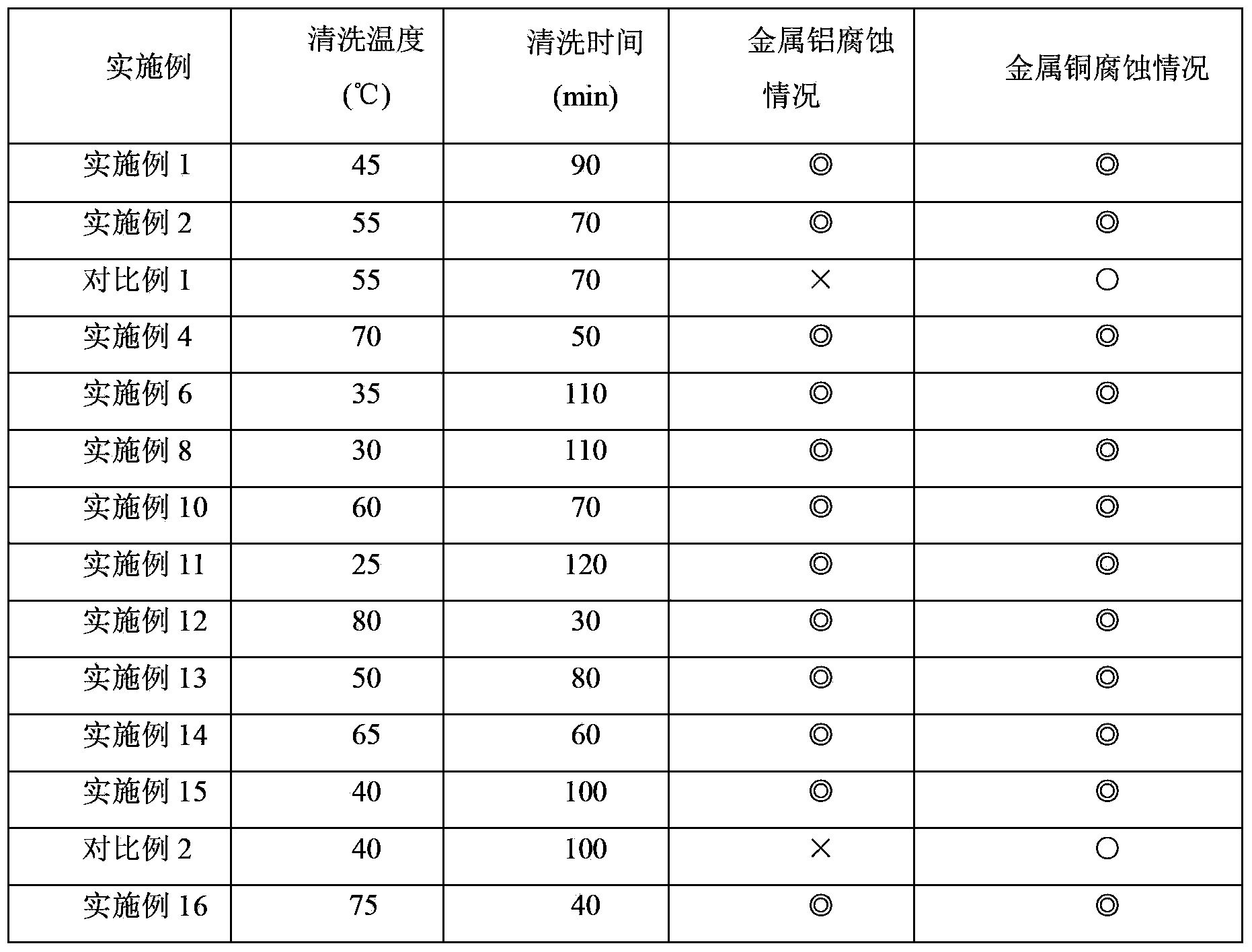

[0027] In order to further investigate the cleaning situation of this type of cleaning solution, the present invention adopts the following technical means: the wafers containing photoresist residues after the convex balls have been electroplated in the wafer microsphere implantation process are respectively immersed in the cleaning solution for 25 Use a constant temperature oscillator to vibrate at a vibration frequency of about 60 rpm for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com