Photoresist cleaning liquid with extremely-low corrosion to metals

A technology of cleaning solution and photoresist, which is applied in the processing of photosensitive materials, etc., can solve the problems of increasing metal corrosion and achieve good application prospects

Inactive Publication Date: 2015-06-03

ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, increasing the alkalinity and operating temperature of the cleaning solu

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

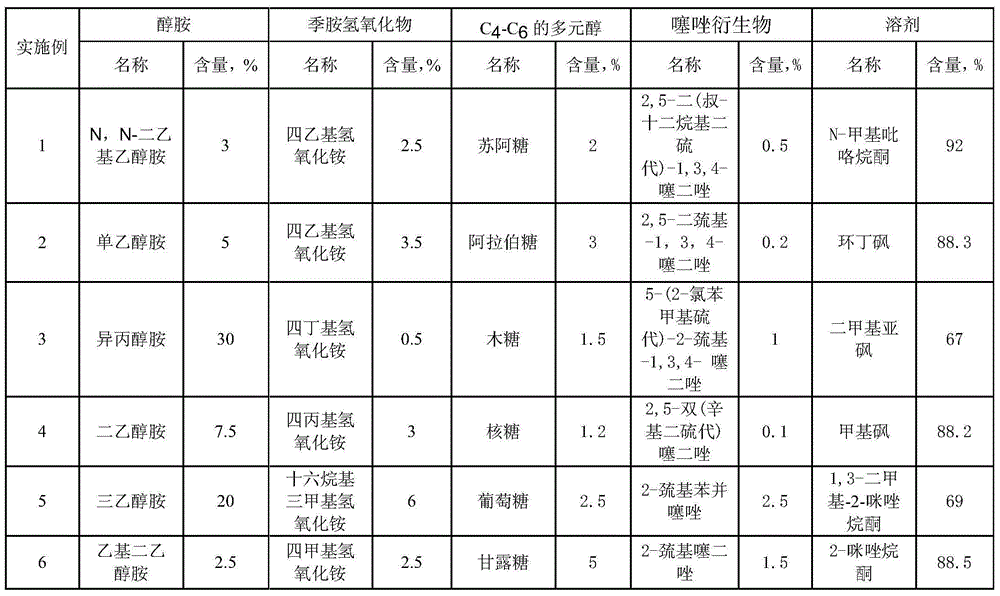

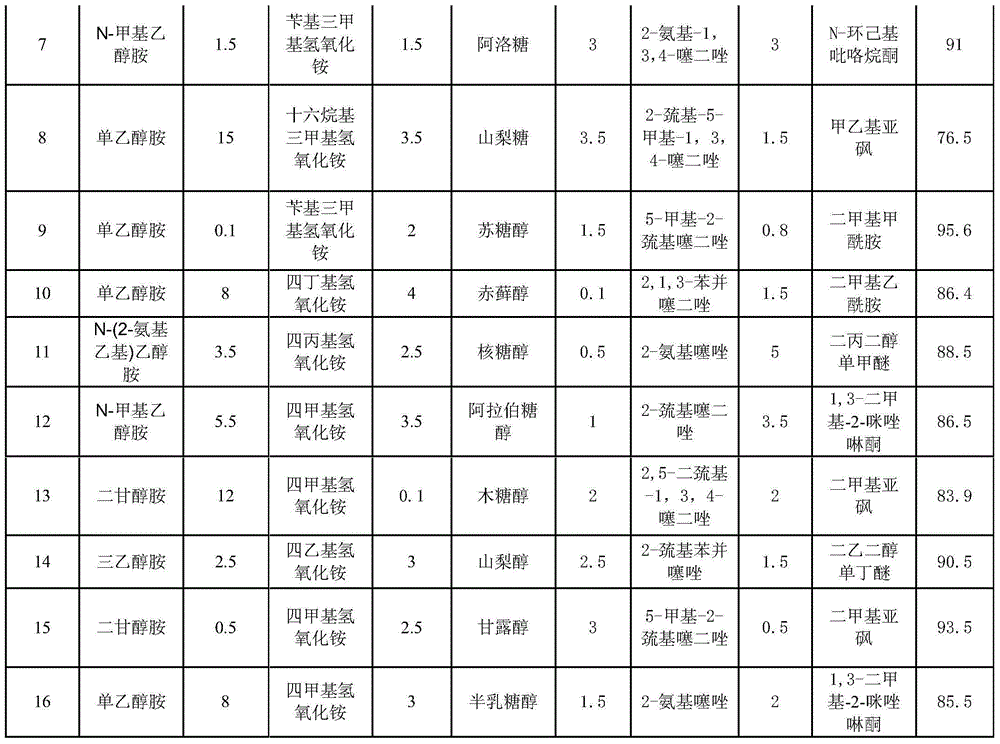

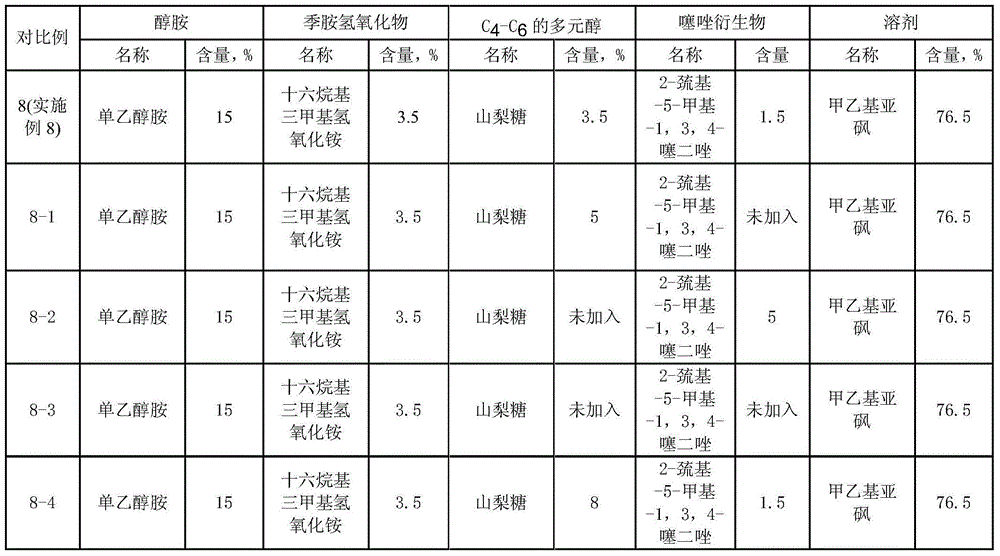

The invention discloses photoresist cleaning liquid for removing the photoresist residues and with extremely-low corrosion to metals and composition thereof. The photoresist cleaning liquid contains (a) quaternary ammonium hydroxide; (b) alkylol amine; (c) solvent; (d) C4-C6 polyhydric alcohol; and (e) thiazole derivative. The photoresist cleaning liquid disclosed by the invention has the advantages that the photoresist photoresistance residues on wafers can be effectively removed, and the corrosion to metals such as copper and aluminium is ultra-low; and the application prospect in the fields of cleaning of semiconductor chips and the like is good.

Description

technical field [0001] The invention discloses a photoresist cleaning solution with extremely low corrosion to metal. Background technique [0002] In the usual semiconductor manufacturing process, a photoresist mask is formed on the surface of some materials, and the pattern is transferred after exposure. After the required pattern is obtained, the remaining photoresist needs to be peeled off before the next process. . This process requires complete removal of unwanted photoresist without etching any substrate. [0003] At present, the photoresist cleaning solution is mainly composed of polar organic solvents, strong alkali and / or water, and the photoresist on the semiconductor wafer is removed by immersing the semiconductor wafer in the cleaning solution or rinsing the semiconductor wafer with the cleaning solution. [0004] For example, JP1998239865 discloses a cleaning solution for an aqueous system, which consists of tetramethylammonium hydroxide (TMAH), dimethylsulfo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03F7/42

Inventor 孙广胜刘兵何春阳黄达辉

Owner ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com