Stirring mechanism of asphalt stone mixing and stirring heating tank

A technology of mixing and stirring mechanism, applied in the direction of roads, road repair, roads, etc., can solve the problems of poor mixing effect, low efficiency, single mixing function, etc., and achieve the effect of convenient implementation, uniform mixing and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

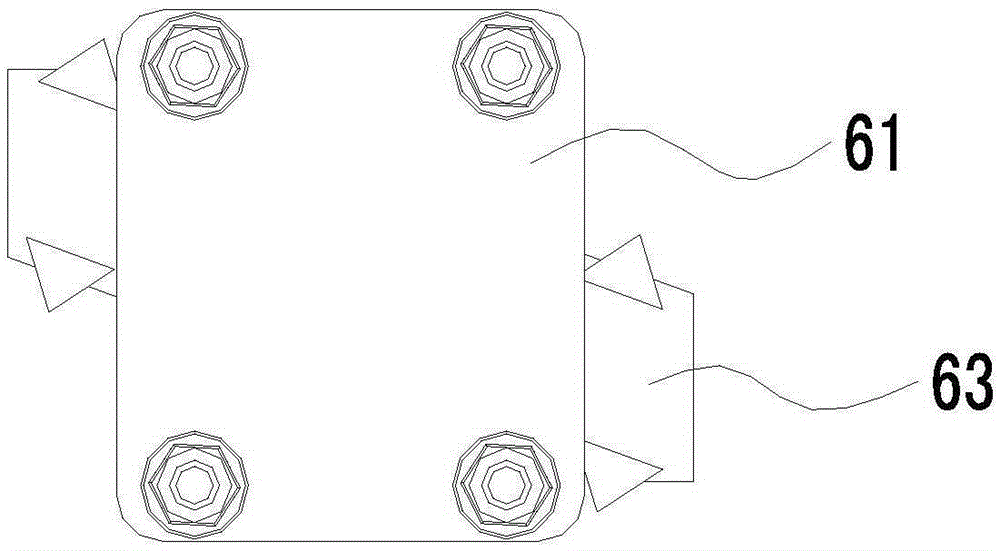

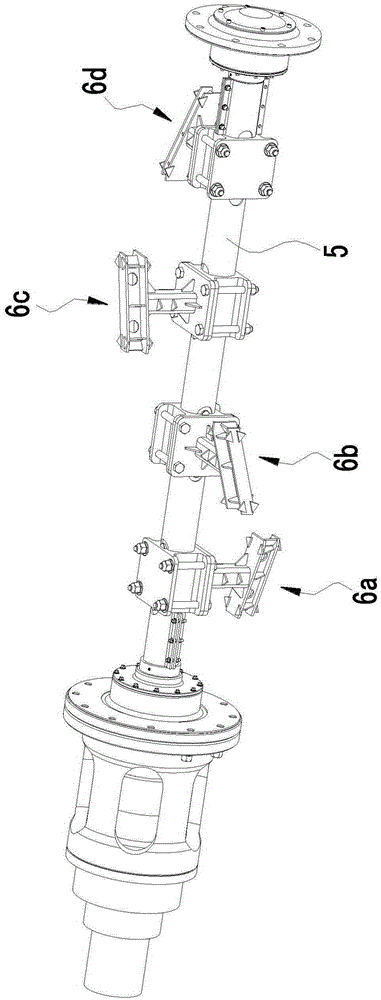

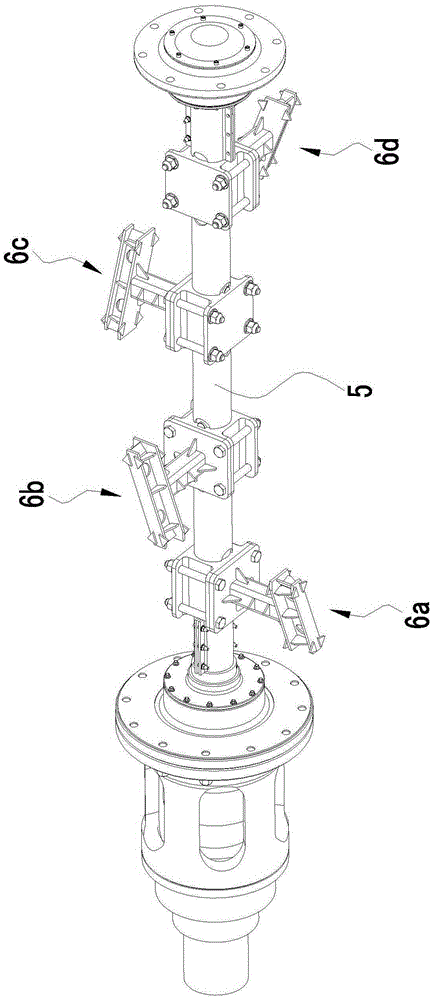

[0036] like Figure 1 to Figure 12 As shown, a stirring mechanism of an asphalt stone mixing and stirring heating tank includes a stirring shaft 5 and a plurality of stirring blades 6 installed on the stirring shaft. 5 are arranged at intervals in the axial direction, each stirring blade 6 includes a base 61, a stirring arm 62 and a blade portion 63, one end of the stirring arm 62 is connected to the base 61, the other end of the stirring arm 62 is connected to the blade portion 63, and the base 61 is installed on On the stirring shaft 5, the projections of two adjacent stirring blades 6 on a plane perpendicular to the axis M of the stirring shaft form a "V" shape, and the blade parts 63 of all the stirring blades are spatially arranged in a helical shape. The stirring shaft 5 can be driven by the power mechanism of the stirring heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com