Double-tube dry-shotcrete cement soil pile-forming method

A pile-forming and soil-forming technology, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of difficult foundation treatment, uneven ash spraying, small treatment depth, etc., achieve large pile diameter and improve pile quality , The effect of increasing the pile depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be defined more clearly.

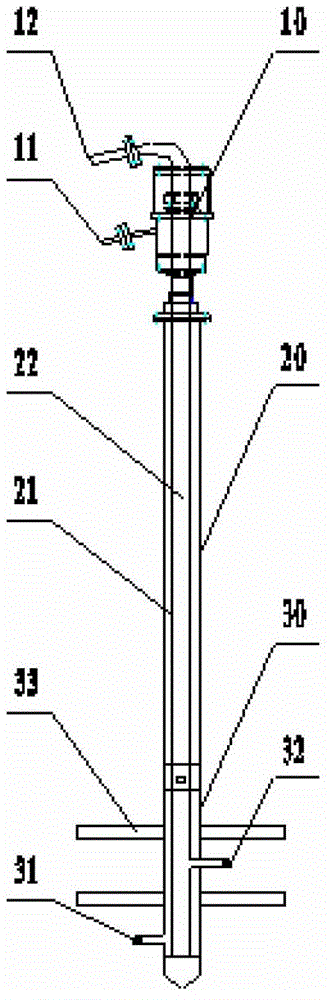

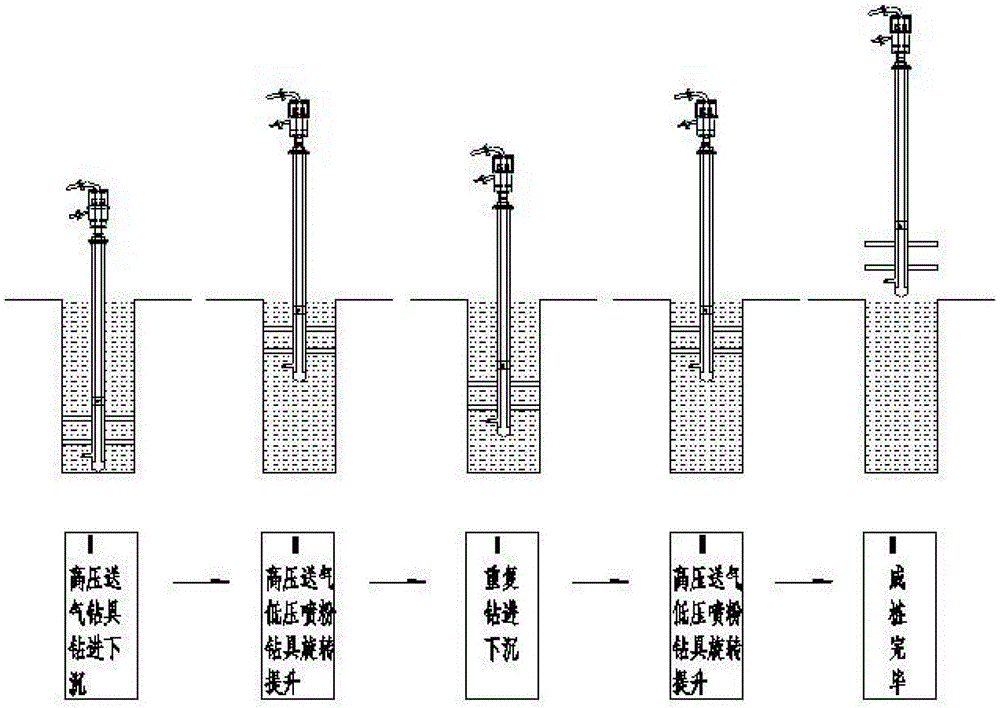

[0025] In the construction process of the pile forming method of the present invention, the key component used in conjunction with the drilling rig construction is a double-tube dry jet mixing drilling tool (see figure 1 As shown), it is composed of a faucet 10, a drill pipe 20 and a drill bit 30, wherein the faucet 10 has a high-pressure gas input port 11, a low-pressure gas, and a low-pressure cement powder input port 12; the drill pipe 20 includes a gas pipe 21 and a core pipe 22; the drill bit 30 has a high-pressure gas outlet 31, a low-pressure gas, a low-pressure cement powder outlet 32 and a stirring blade 33.

[0026] Among them, the high-pressure gas is inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com