Equipment and method for constructing high-pressure rotary jet stiffening pile by using ribbed drilling method

A technology of high-pressure rotary spraying and construction equipment, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of fast mechanical wear, increased steel ball rotation resistance, and labor-intensive, etc., and achieves reduced pile-forming time, shearing The effect of improving shear strength and reducing cement waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

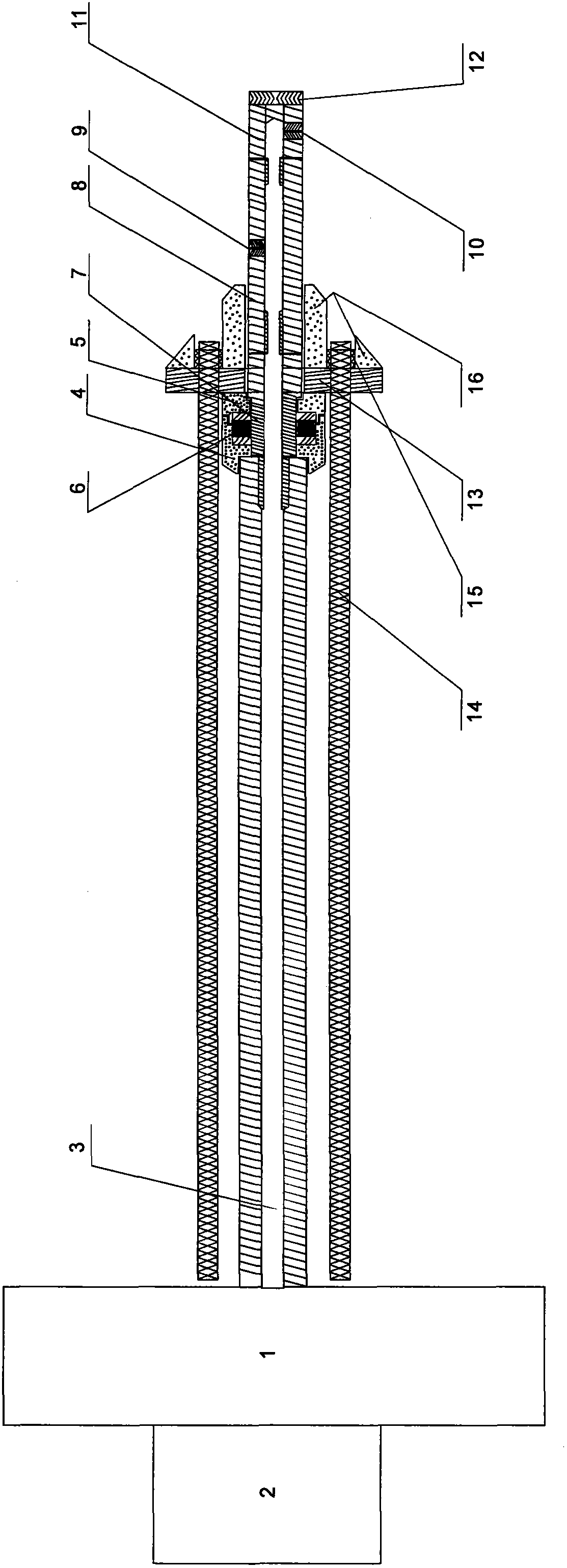

[0048] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0049] An end bearing disc 13 is included which adjoins the bearing 6 which has a protective cover. Described bearing 6 has protective cover. The protective cover can effectively protect the bearing.

[0050] The further technical solution of the present invention is: the protective cover is divided into two parts that can be spliced, that is, the rear shell 4 of the bearing protective cover and the front shell 5 of the bearing protective cover. Dividing into two parts allows the inner bearing 6 to be replaced.

[0051] The further technical solution of the present invention is that: the splicing surface between the rear shell 4 of the bearing protection cover and the front shell 5 of the bearing protection cover is a folded surface. The folded surface can effectively prevent sand from entering the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com