Weak perturbation inclined rotary jet group pile occlusion strengthening method used for shield passing underneath house

A kind of micro-disturbance, housing technology, applied in the direction of foundation structure engineering, foundation structure repair, sheet pile wall, etc., can solve the problems of stratum disturbance, long-term downtime, housing cracking engineering economy, etc., to achieve protection hysteresis, reduce disturbance effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0032] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

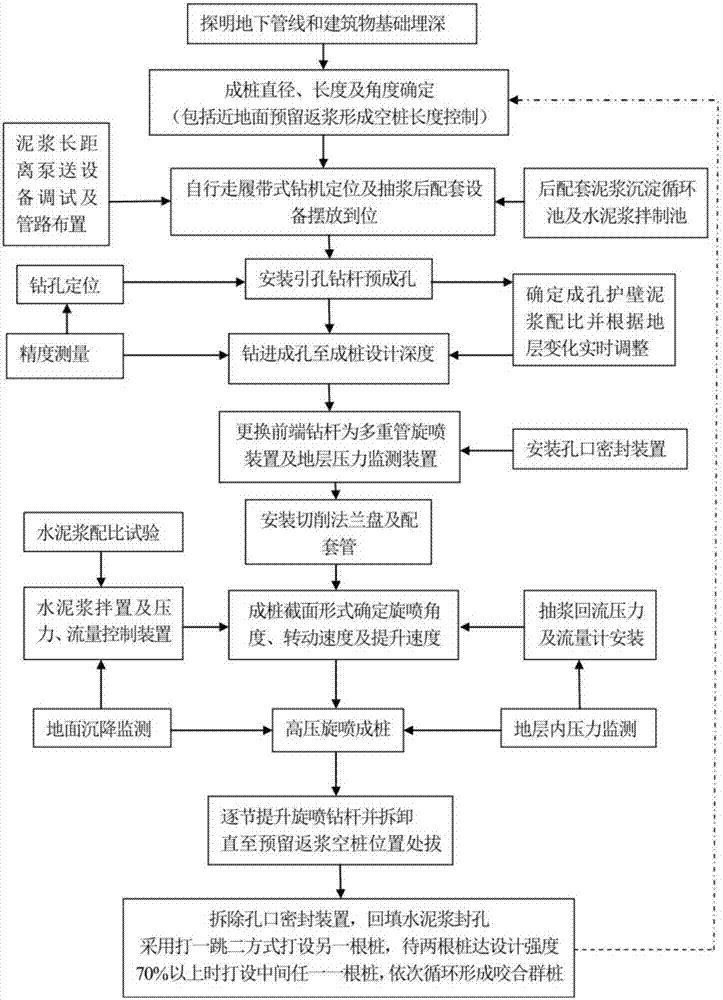

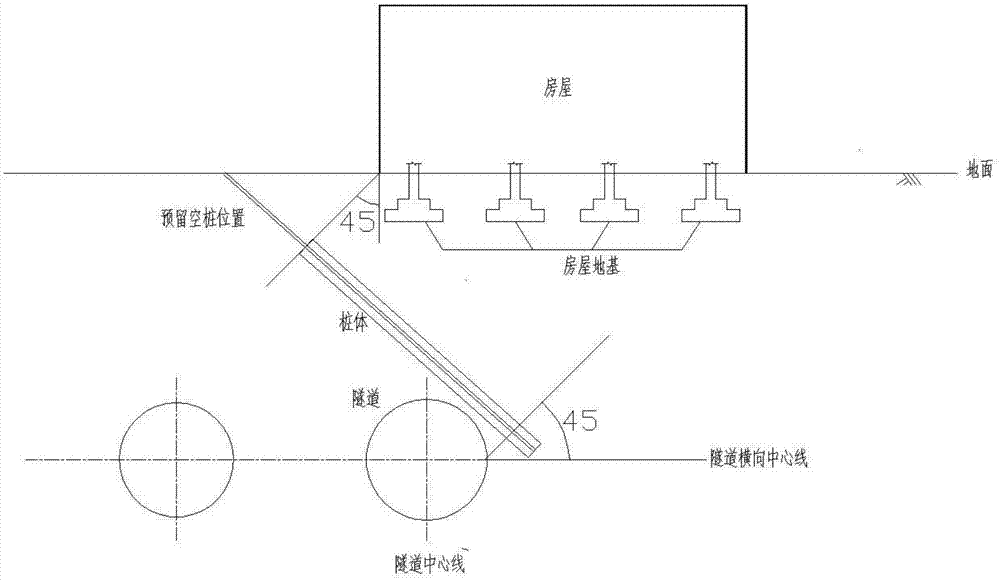

[0033] like figure 1 , 2 As shown, the present invention provides a kind of micro-disturbance inclined rotary spraying pile group occlusal reinforcement method for the shield tunneling under the house, including:

[0034] According to the positional relationship between the house and the tunnel, determine the location of the jet grouting pile, the angle of pile formation, the depth of driving, and the location of the reserved empty pile;

[0035] Determine the drilling parameters according to the driving position, pile forming angle, driving depth and reserved empty pile positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com