Patents

Literature

35results about How to "Reduce shear deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

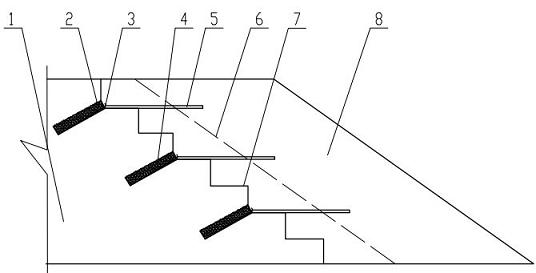

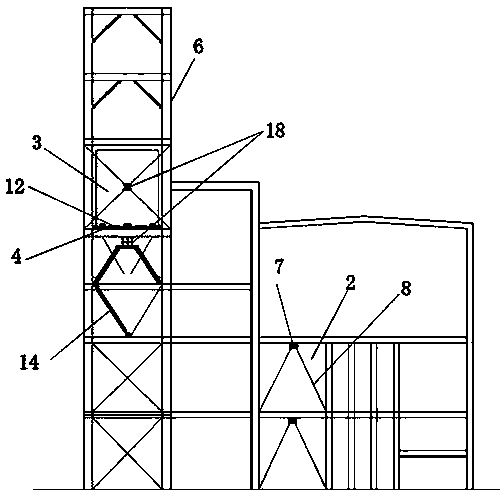

Anchored roadbed widening method

InactiveCN102619150AReduce shear deformationGuaranteed carrying capacityRoadwaysVertical planeEngineering

The invention discloses an anchored roadbed widening method, which belongs to the technical field of road construction. The anchored roadbed widening method comprises the following steps of: firstly performing slope cutting on an old roadbed slope, then excavating a step on the old roadbed slope from the ground, obliquely drilling an anchorage hole into an old roadbed at the joint of the vertical plane of the step and the horizontal plane, placing a steel bar into the anchorage hole, and casting the steel bar and the old roadbed into a whole by pouring cement grout; laying a new roadbed in layers, rolling, flatly laying a geogrid on the step of the old roadbed when the new roadbed is filled to be aligned with the step of the old roadbed provided with the anchorage drilled hole, connecting a transverse rib of the geogrid with an end hook which is bent upwards of the exposed part of the steel bar, tensing the geogrid, fixing with the lower layer of a soil body, and finally filling soil on the geogrid and rolling. According to the anchored roadbed widening method disclosed by the invention, an anchor rod technology is used for reinforcing the old roadbed slope, the geogrid and the old roadbed are connected into a whole, the geogrid can be prevented from sliding on the step of the old roadbed, the stability of the new roadbed and the old roadbed is improved, and non-uniform sedimentation can be effectively controlled.

Owner:SHIJIAZHUANG TIEDAO UNIV

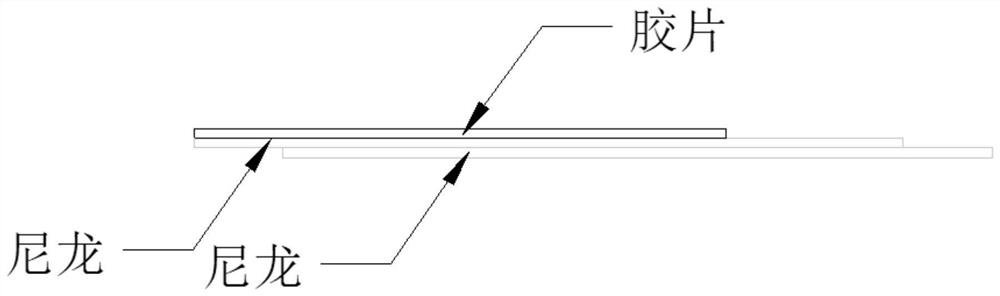

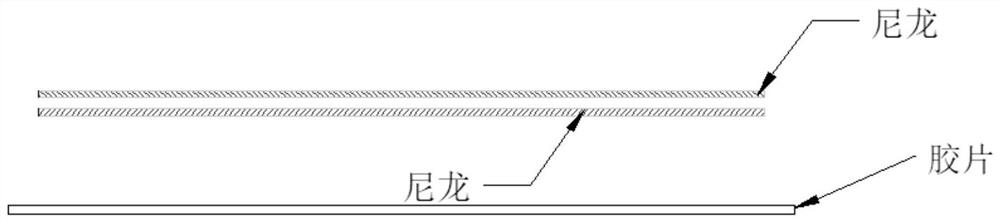

Rubber composition for coating radial ply tyre steel wire cord

InactiveCN101451041AGood stickinessReduce shear deformationConjugated diene hydrocarbon coatingsNatural rubber coatingsOrganic acidButadiene-styrene rubber

The present invention discloses a rubber composition used for coating steel wire cords of radial ply tyres, which comprises: 1) a rubber component containing natural rubber, or the natural rubber and cis-butadiene rubber, or the natural rubber and butadiene styrene rubber, or the natural rubber, the cis-butadiene rubber and the butadiene styrene rubber; and 2) an adhesion system comprising 0.5 to6 weight portions of triazine adhesive, 5 to 20 weight portions of white carbon black and organic acid cobalt salt with 0.03 to 1 weight portion of cobalt which take 100 weight portions of the rubbercomponent as a reference. On the basis of 100 weight portions of the rubber component, the rubber composition also comprises various auxiliary agents. The rubber composition used for coating the steel wire cords of the radial ply tyres has good viscosity, liquidity and penetrability, is not only suitable for the steel wire cords of ordinary all-steel load or all-steel engineering radial ply tyres, but also particularly suitable for large-diameter steel wire cords of which the diameter is larger than 2 millimeters.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

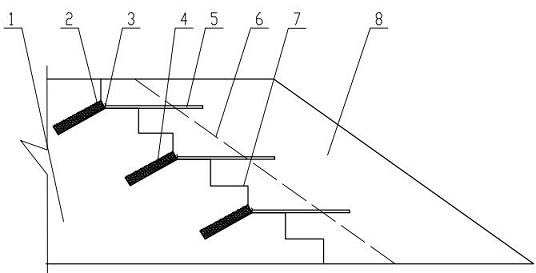

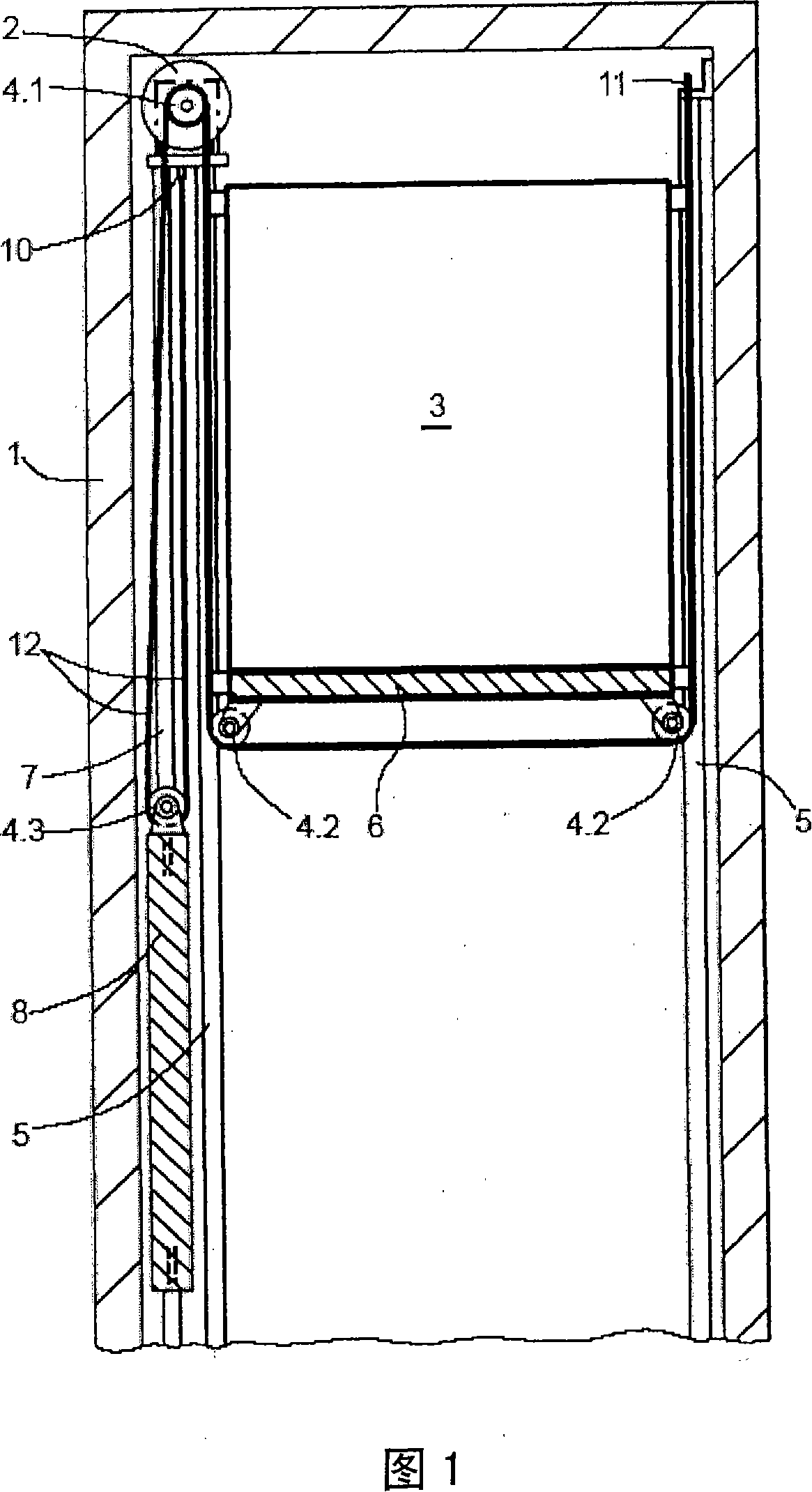

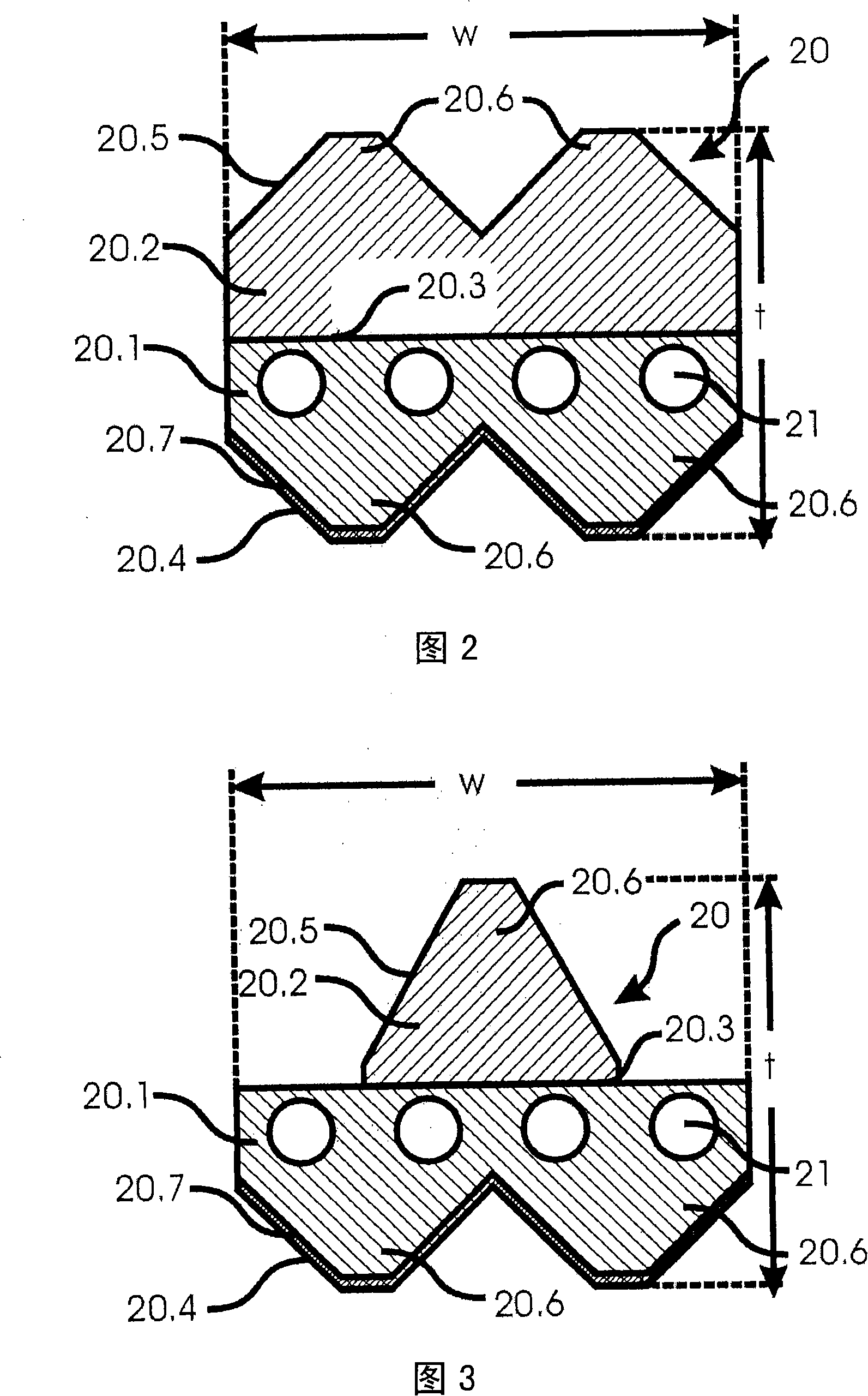

Lift facility, belt for such a lift facility, method for manufacturing such a belt, combination of such a belt and method for assembling such a combination in a lift facility

InactiveCN101121487AReduced risk of getting stuckLarge geometric moment of inertiaElevatorsBeltsEngineeringMechanical engineering

Owner:INVENTIO AG

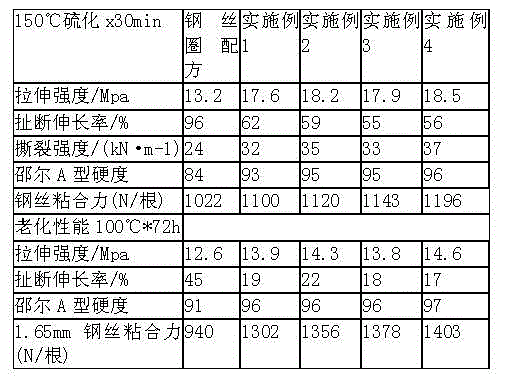

Rubber composition for tire bead ring

The invention relates to the technical field of rubber, in particular to a rubber composition for a tire bead ring. The rubber composition is characterized by being prepared from the following raw materials in parts by weight through mixing: 0-40 parts of natural rubber, 60-100 parts of butadiene styrene rubber, 5-40 parts of high styrene resin, 60-120 parts of carbon black, 0-15 parts of reinforcing phenolic resin, 3.0-5.0 parts of zinc oxide, 1.0-3.0 parts of stearic acid, 5-15 parts of tackifying resin, 0.5-1.5 parts of protecting wax, 15-25 parts of sulphur powder, 10-25 parts of softening oil, 0.8-1.5 parts of an accelerant DM and 0.1-0.2 part of an accelerant DPG. According to the rubber composition, under the condition that the structure of the tire bead ring keeps unchanged, the adhesive force of the bead ring modulus and coating is improved, and the problems of tire wiredrawing explosion, bead hollowness and bead break are solved.

Owner:TRIANGLE TIRE

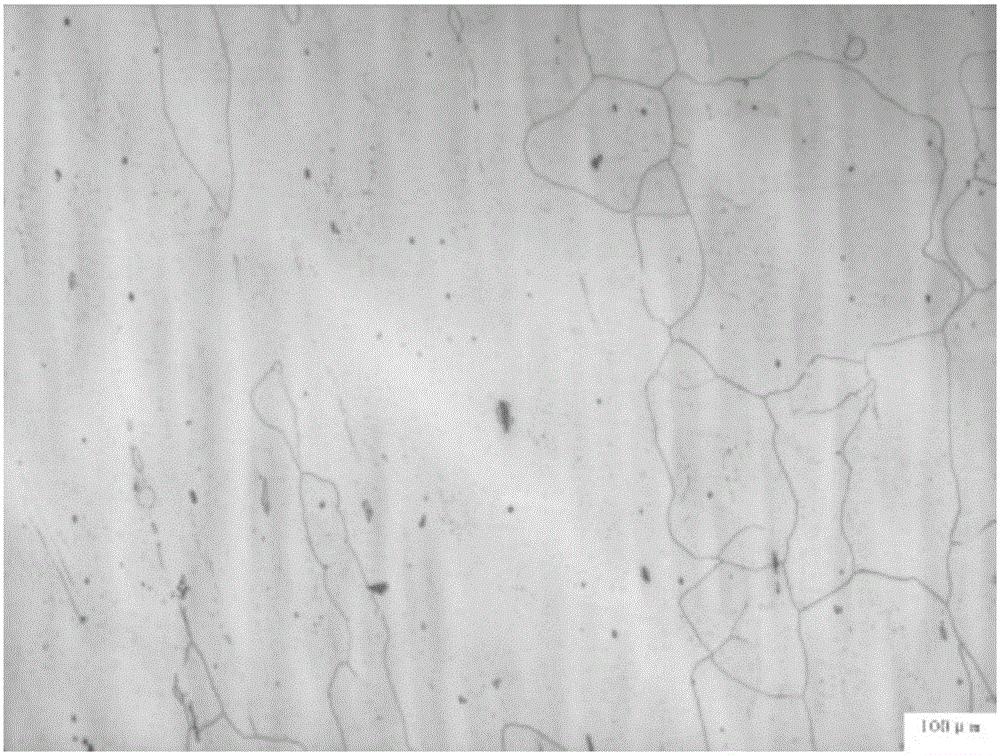

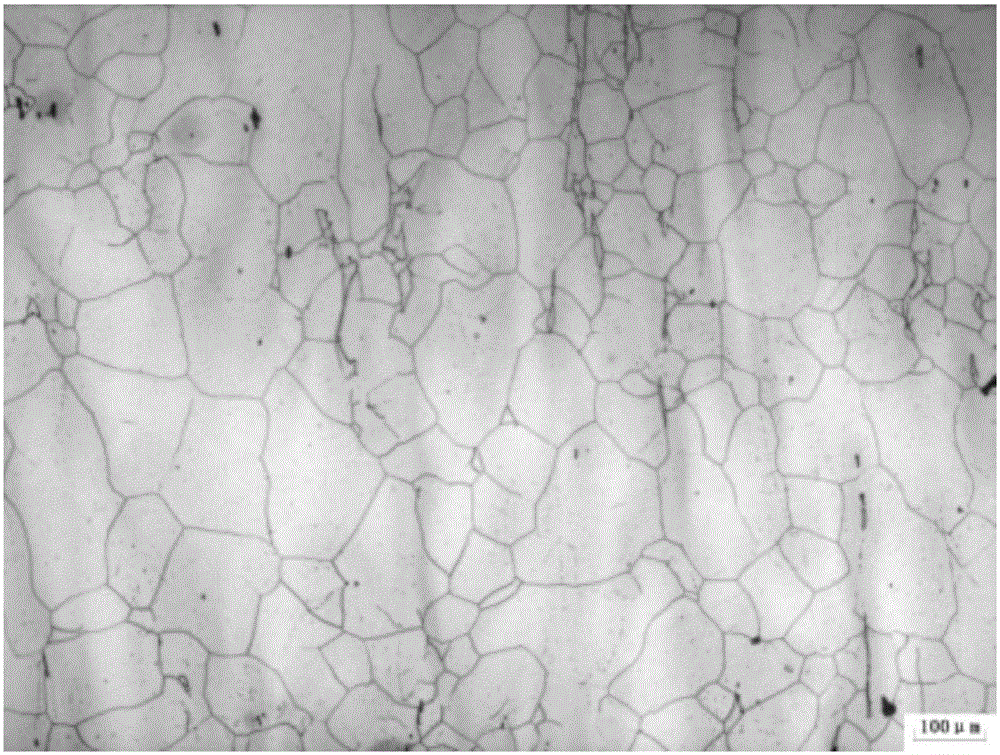

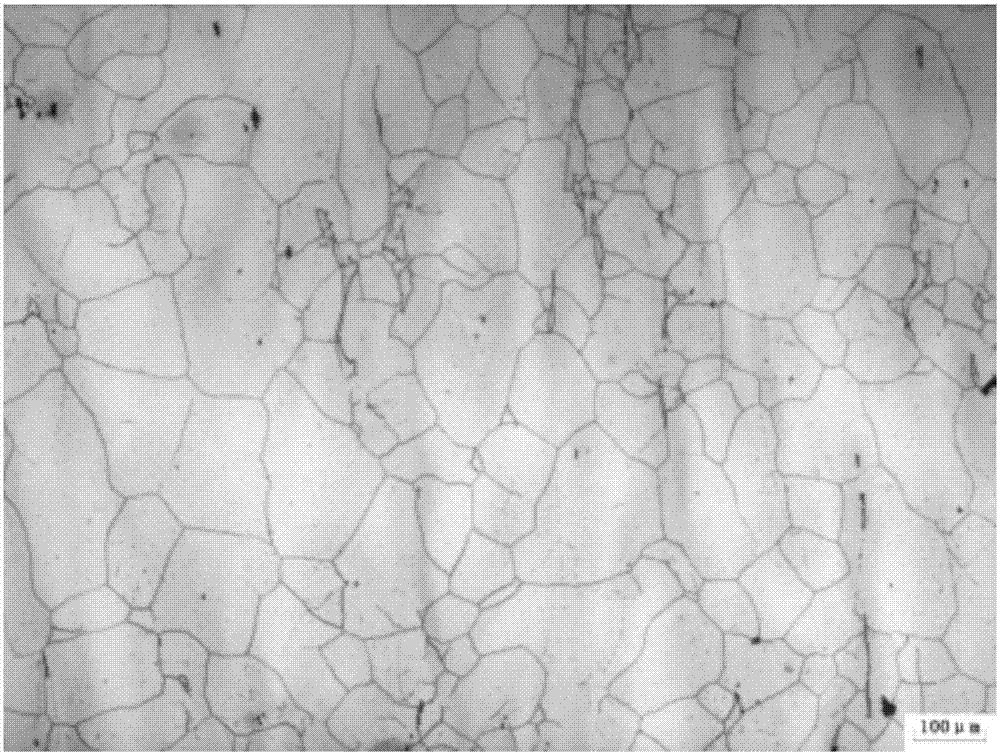

Coarse ring-free aluminum alloy bar and preparation method thereof

InactiveCN106011564AReduce shear deformationReduce material flow dead zoneShearing deformationCrystallite

The invention discloses a coarse ring-free aluminum alloy bar. The coarse ring-free aluminum alloy bar is prepared from the following components in percentage by weight: 0.62 to 0.7 percent of Si, 0.3 to 0.4 percent of Fe, 0.2 to 0.35 percent of Cu, 0.1 to 0.15 percent of Mn, 0.9 to 0.98 percent of Mg, 0.15 to 0.25 percent of Cr, 0.25 percent of Zn, 0.06 to 0.13 percent of Ti and the balance of Al. According to the coarse ring-free aluminum alloy bar disclosed by the invention, the addition range of Cr and Mn elements is strictly controlled on the basis of 6061 aluminum alloy specified in the national standard GB / T3191-2010, and the Cr and Mn elements have a function of inhibiting grain expansion in the aluminum alloy; the temperatures of a die, a cast ingot and an extrusion container can be controlled during a follow-up extrusion process, so that the shear deformation of a material during extrusion is reduced; an arc-shaped die bearing is adopted, so that the material flowing dead zone of an extrusion die is reduced; by using the produced 6061 aluminum alloy bar, a coarse ring cannot be fundamentally seen, the mechanical performance of a material and the oxidation performance of a product are greatly increased, the color of the material is consistent after an anode is oxidized, and the coarse ring-free aluminum alloy bar has no defects of piebaldness and the like.

Owner:无锡海特铝业有限公司

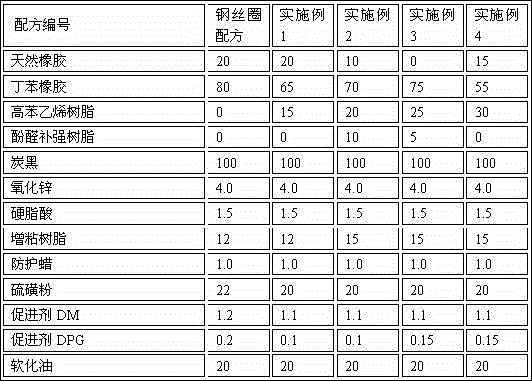

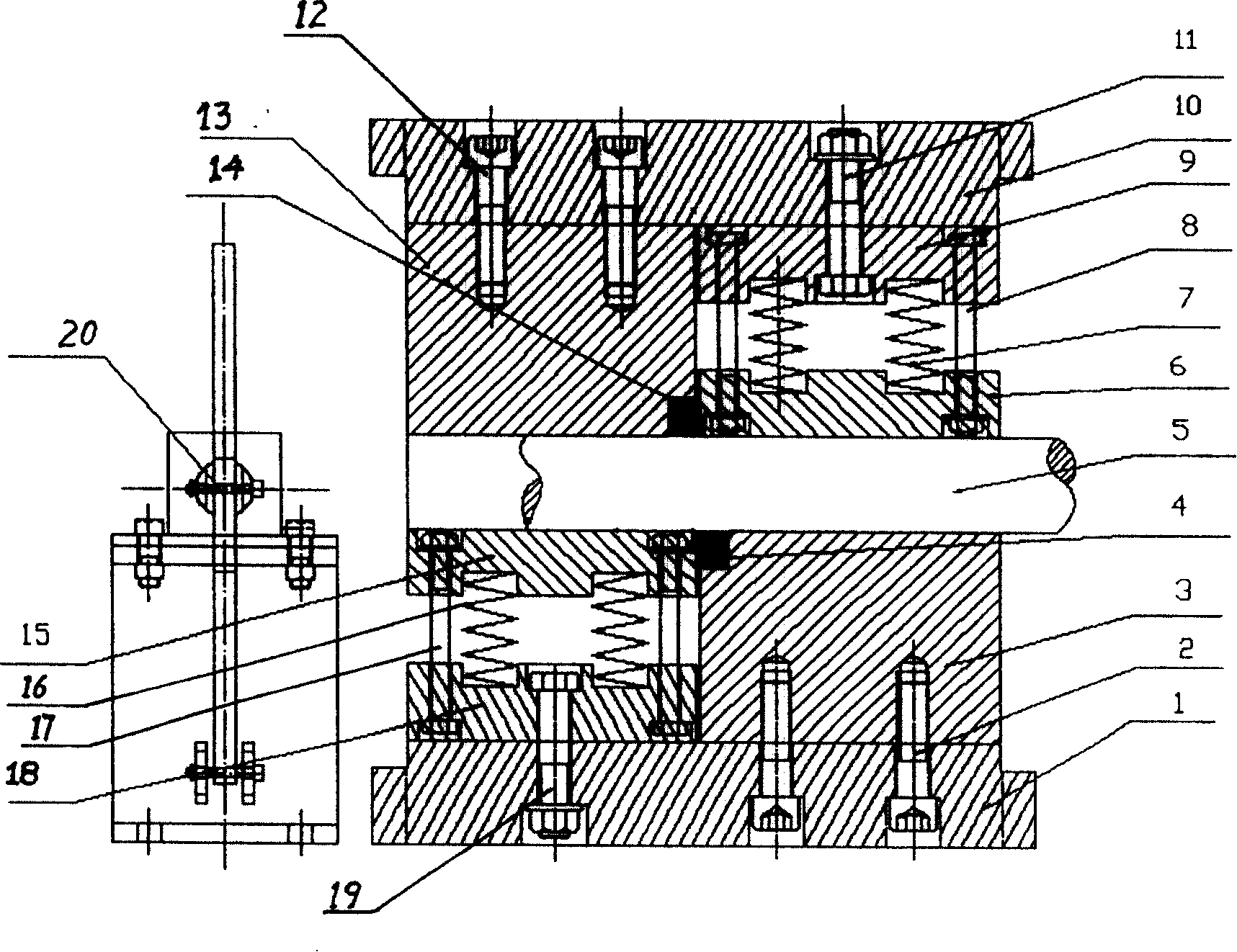

Rod material precision shear mould

InactiveCN1597208AReduce manufacturing costImprove cutting efficiencyShearing machine accessoriesMachine press

A precision shearing die of rod material for press is composed of upper and lower die plates, upper and lower fixed cutter carriers, upper and lower cutting blades, and the upper and lower clamp units consisting of clamping block, clamping spring, screw bolt and fixed block.

Owner:JINXI AXLE CO LTD

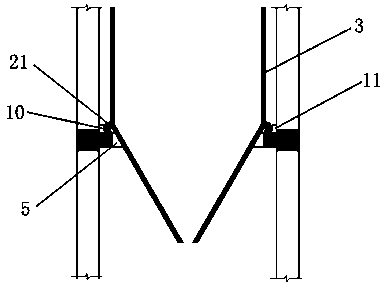

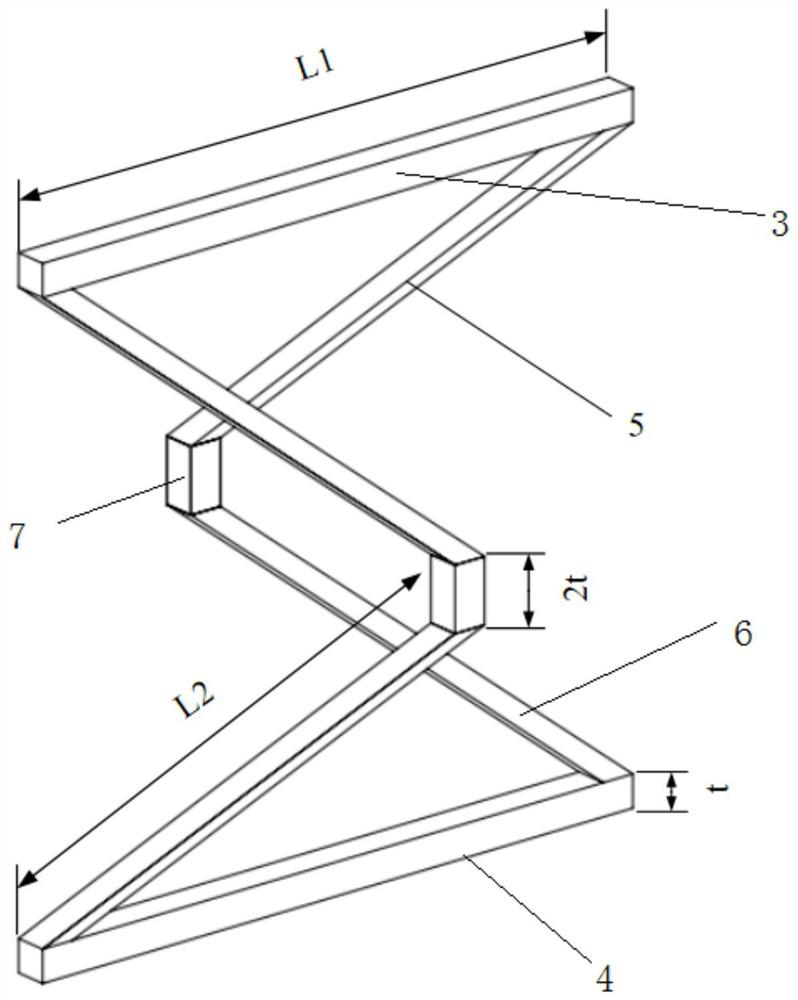

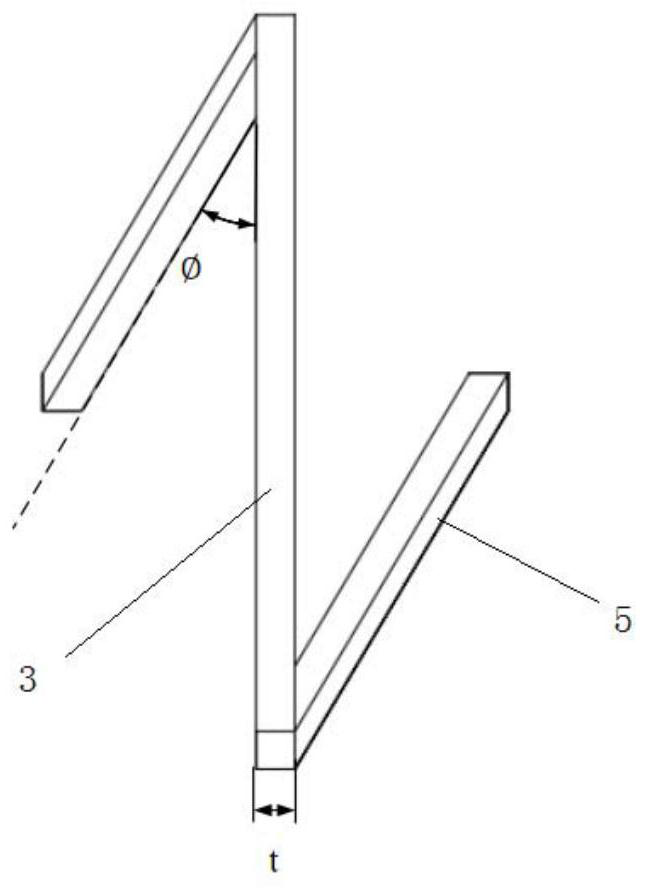

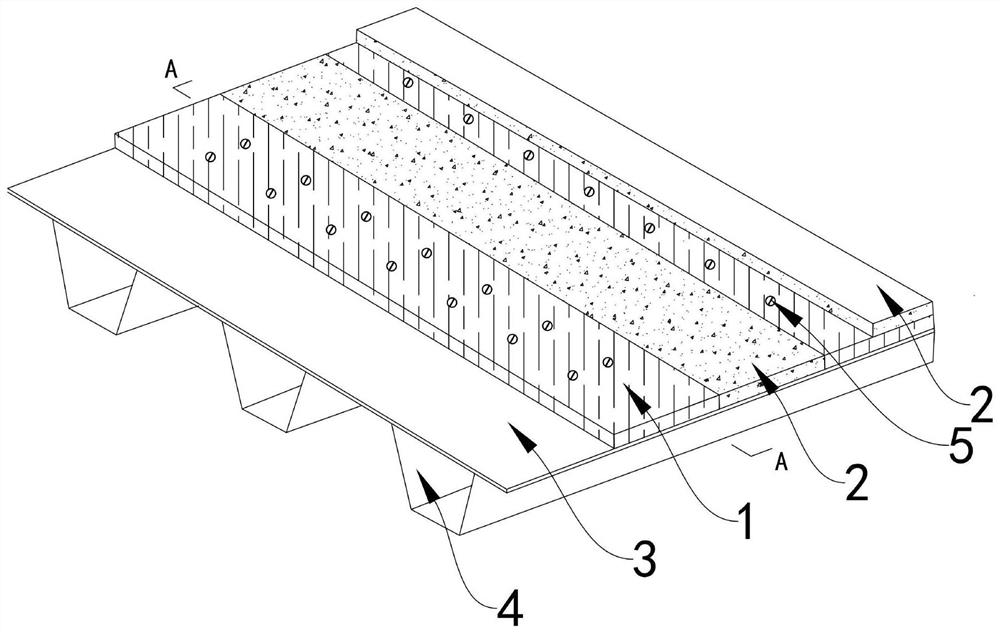

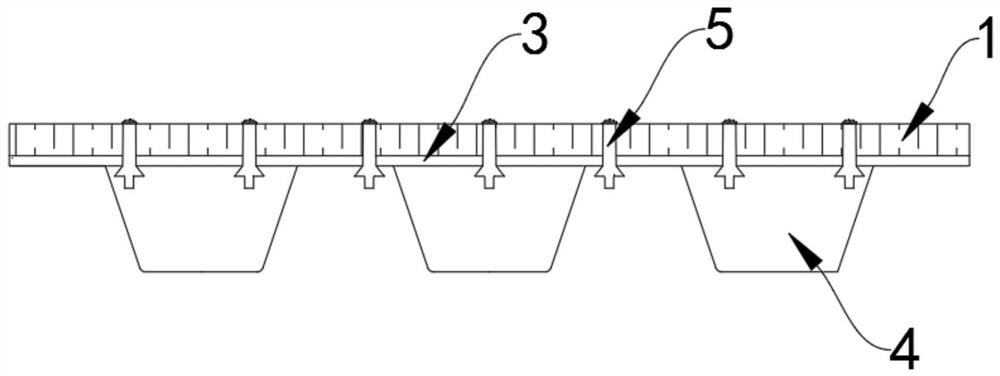

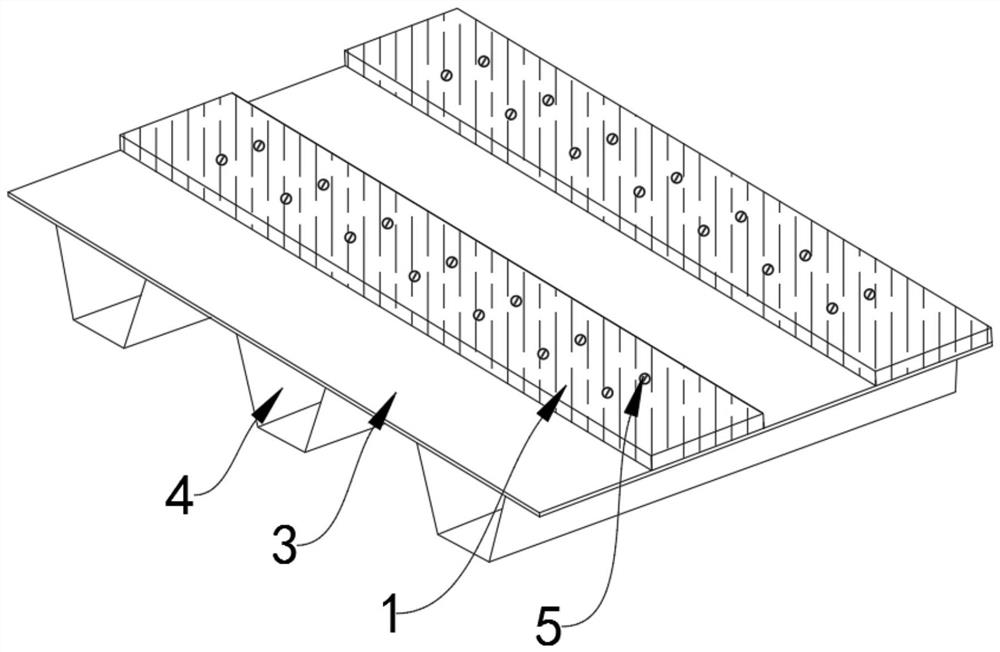

Wood-concrete composite beam shear connector pushing-out testing sample

PendingCN108412049AIncreased shear strengthIncrease stiffnessBridge structural detailsBuilding constructionsSocial benefitsMesh reinforcement

The invention discloses a wood-concrete composite beam shear connector pushing-out testing sample. The wood-concrete composite beam shear connector pushing-out testing sample comprises a wood beam, concrete slabs, a shear connector, anchoring parts and a steel mesh reinforcement. The shear connector is anchored on the upper portion of the wood beam through the anchoring parts, the steel mesh reinforcement is laid on the upper portion of the wood beam through a supported template piece, transverse reinforcements in the steel mesh reinforcement penetrate through through-holes reserved in the shear connector, the concrete slabs are poured into the template piece with the steel mesh reinforcement and the shear connector used as a skeleton, and a wood-concrete composite beam is formed. The wood-concrete composite beam shear connector pushing-out testing sample improves the shear strength and shear stiffness of the shear connector, has good fatigue resistance performance, reduces the shear deformation of the shear connector, and overall deformation of wood-concrete composite beam is reduced; and while resisting relative slip, the raising effect between the concrete slabs and the wood beam can be effectively restrained, and good social benefits and transformation prospects are achieved.

Owner:SUZHOU UNIV OF SCI & TECH

Anti-seismic toughness plant structural system comprehensively adopting seismic isolation and absorption technologies

PendingCN110259205AReduce energy consumptionImprove energy consumptionProtective buildings/sheltersIndustrial buildingsRelative displacementEarthquake intensity

The invention belongs to the technical field of industrial civil structures, and relates to a high-performance toughness structural system comprehensively applying seismic solation and energy dissipation seismic absorption technologies to improve anti-seismic performance of a plant. The anti-seismic toughness plant structural system comprehensively adopting seismic isolation and absorption technologies comprises a large-mass-ratio tuning mass damper and an energy dissipation sub-frame which are connected to a plant main structure. Buckling-restrained braces are adopted to replace parts of ordinary steel supporting components, and the damper is adopted on a structural floor with large horizontal relative displacement to replace an ordinary supporting structural system so as to achieve the effect of energy dissipation seismic absorption; a coal hopper of the plant is subjected to seismic isolation design through a seismic isolation support, the adopted seismic isolation support is optimally calculated, and thus movement of the coal hopper under the seismic effect and movement of the main body structure are tuned to form the large-mass-ratio tuning mass damper; and the anti-seismic toughness plant structural system can be applied to structural design and seismic reinforcement of the high seismic intensity field underground plant, and can also be applied to other similar industrial structures.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

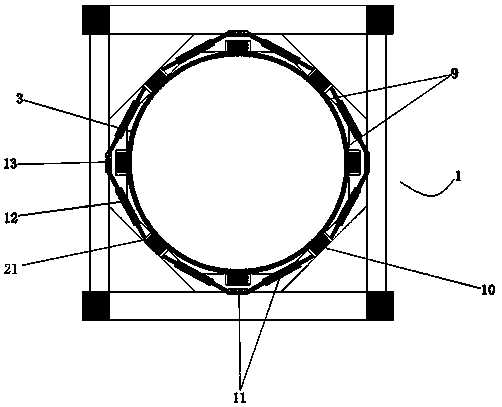

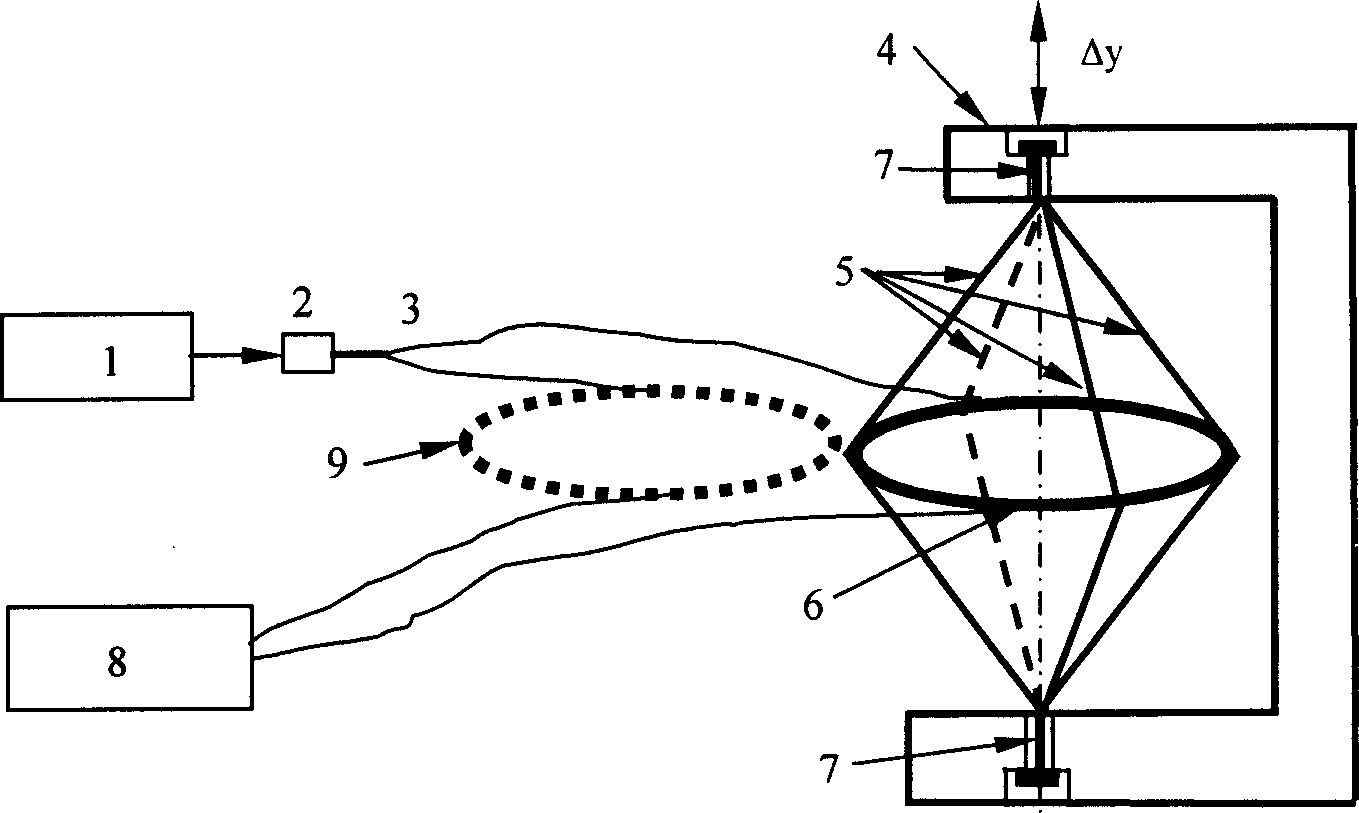

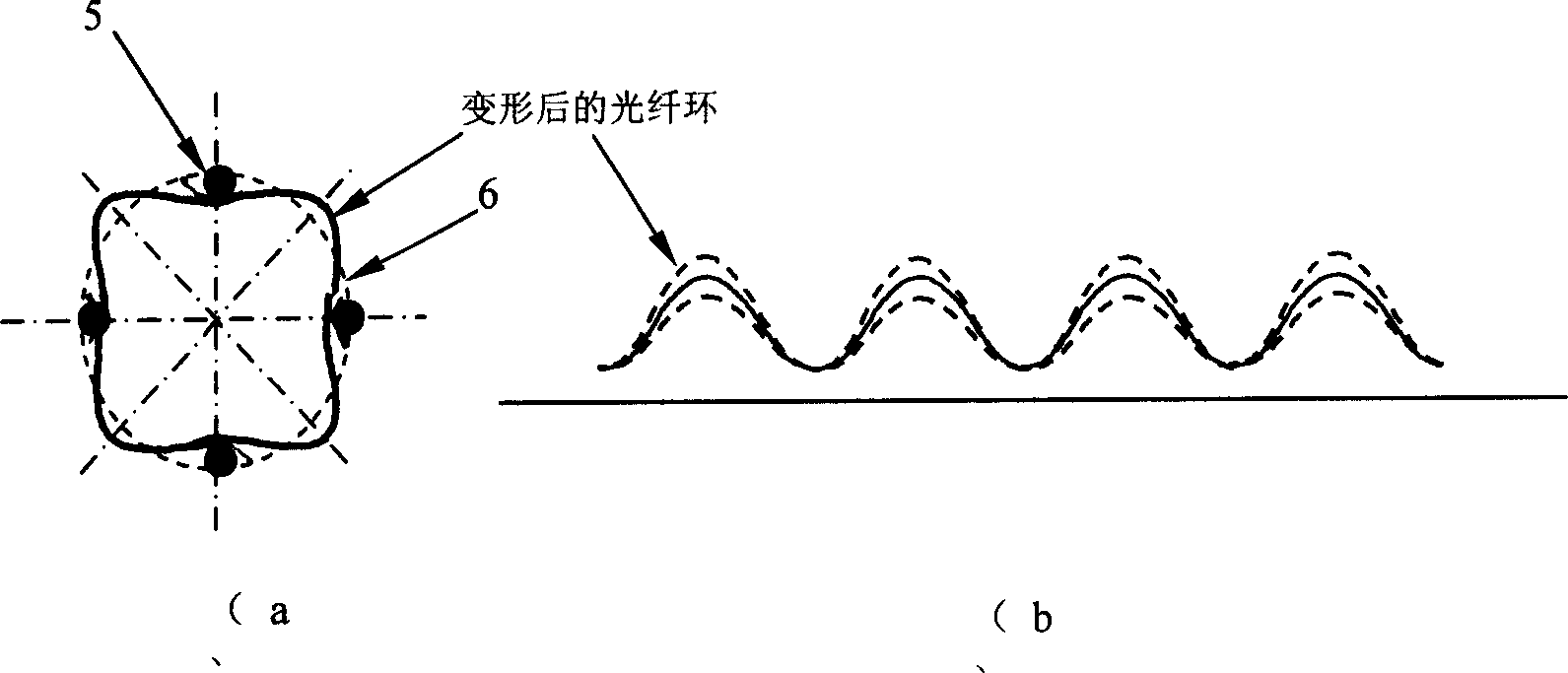

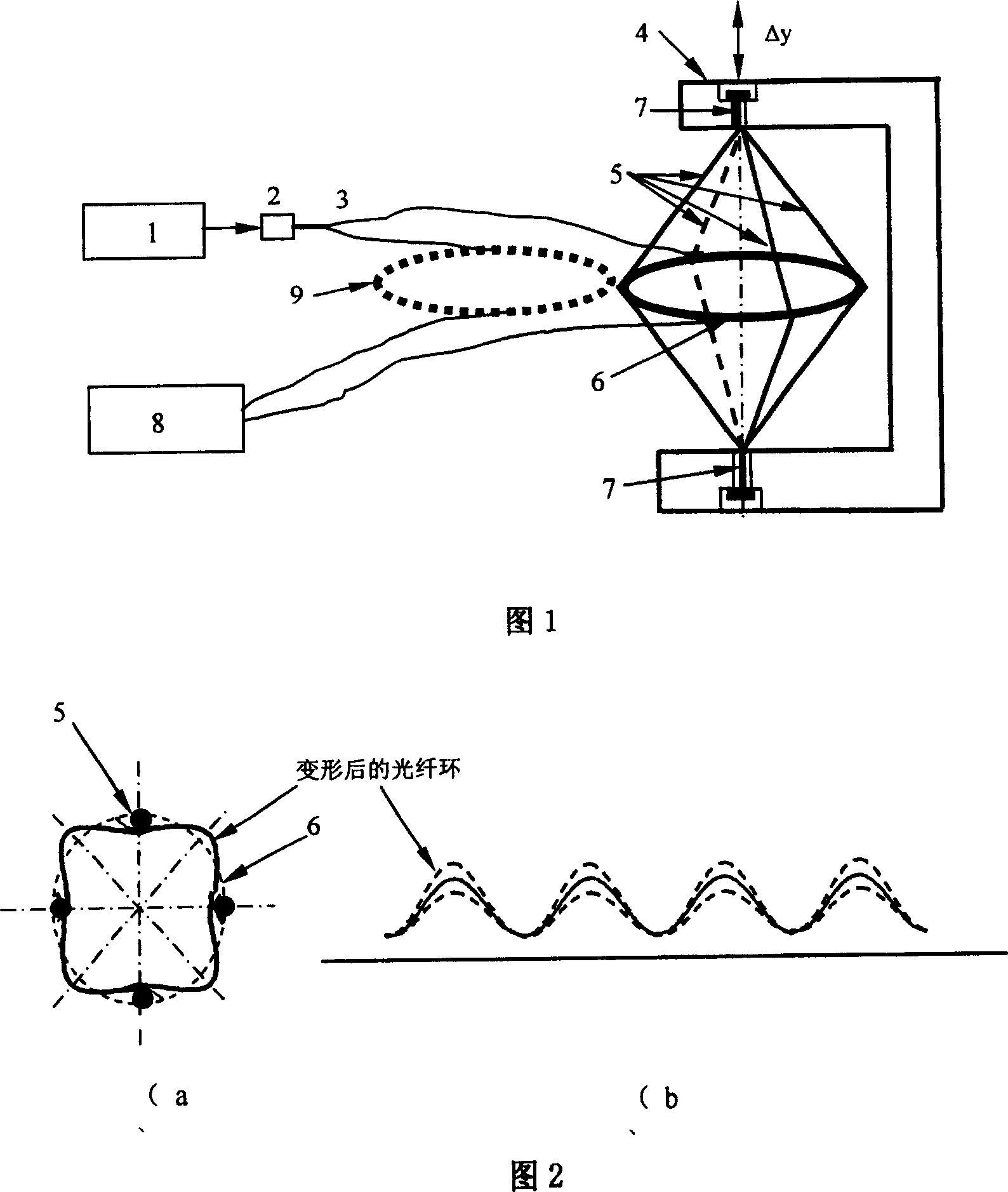

Optical fiber micro-bending displacement sensor

InactiveCN1743812AImprove dynamic performanceHigh sensitivityUsing optical meansConverting sensor output opticallyOptical power meterOptical fiber coupler

An optical fiber micro bent displacement sensor, which contains light source, optical fiber coupler, Y type optical fiber, integral distortion device, optical micro bent distortion device, two optical rings, two pretension screw and optical power meter. Said invention adopts separated integral distortion device and optical fiber micro distortion device, can design the rigidity and strength of integral distortion according to need for adapting different frequency and amplitude signal measurement.

Owner:SHANGHAI JIAO TONG UNIV

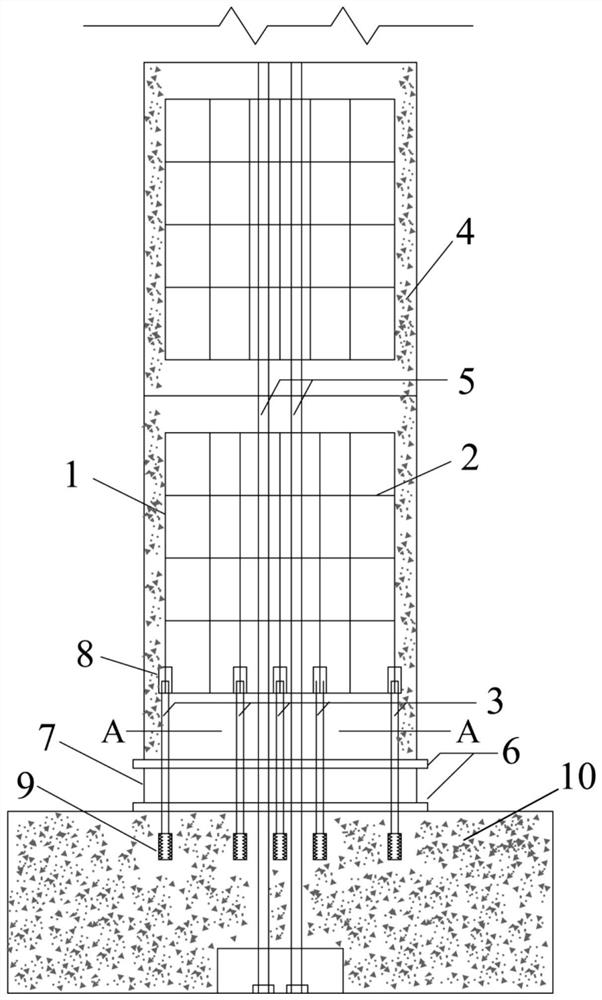

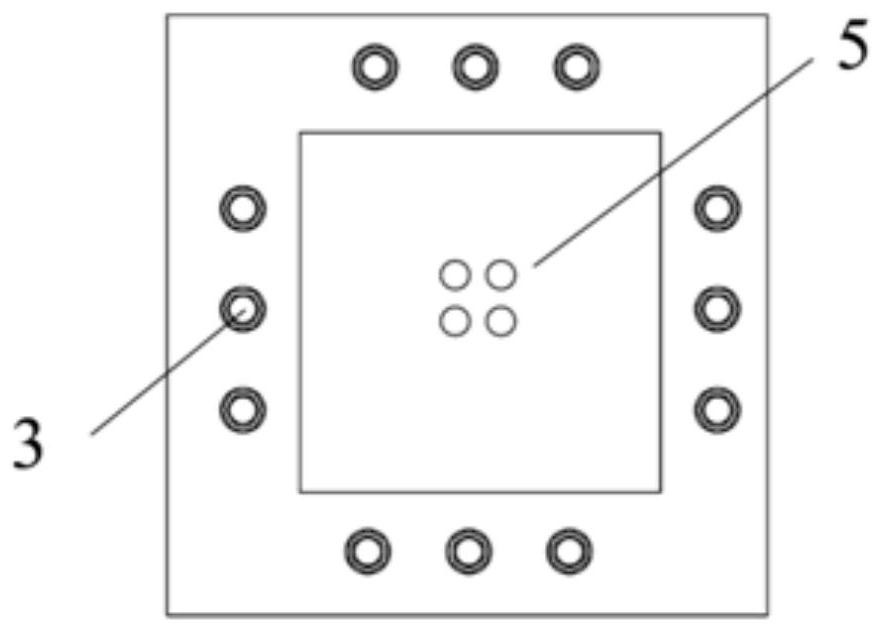

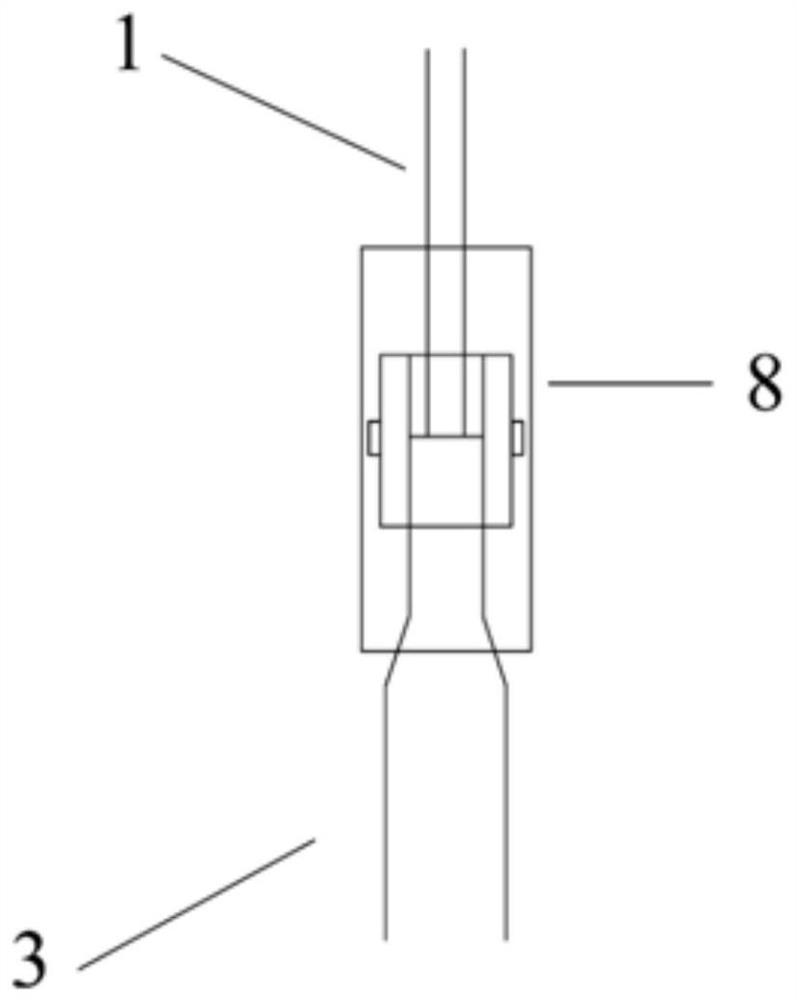

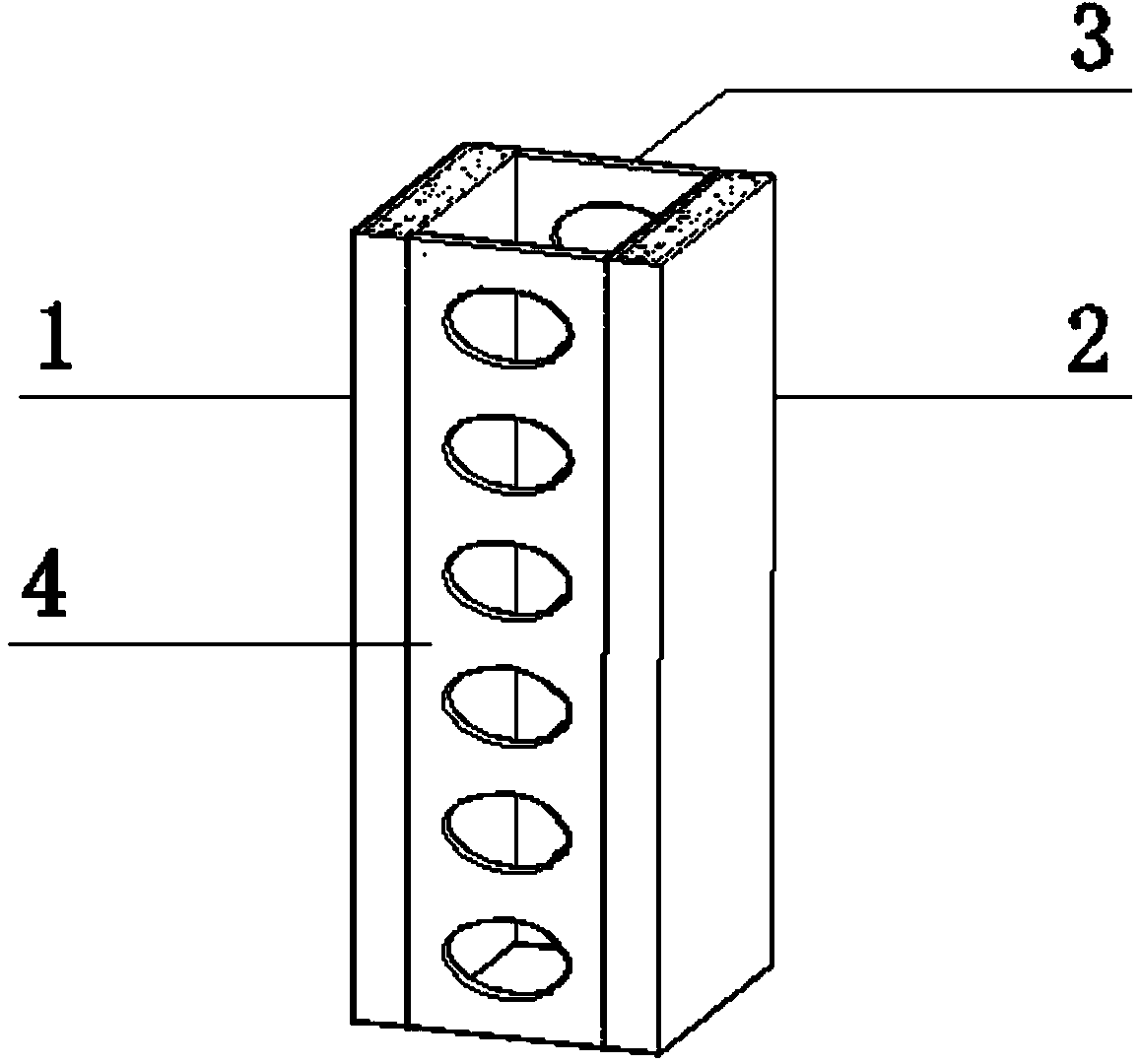

Prestressed segment assembled pier with SMA energy-consuming reinforcing steel bars at bottom and assembling method

InactiveCN113186812AAvoid shear damageReduce shear deformationBridge structural detailsBridge erection/assemblyBridge engineeringPre stress

The invention belongs to the field of bridge engineering, and particularly relates to a prestressed segment assembled pier with SMA energy-consuming reinforcing steel bars at the bottom and an assembling method. The structure comprises a bearing platform, prestressed steel bars, reinforced concrete segments, SMA energy-consuming steel bars, steel base plates, rubber pads, steel bar connectors and anchoring devices, wherein a reinforced concrete bottom section is connected with a bearing platform in the pier, a layer of rubber pad with double functions of energy consumption and protection is placed between the bottom section and the bearing platform, and the upper side and the lower side of the rubber pad are each provided with a steel base plate. Longitudinal bars in the bottom section are connected with SMA energy dissipation steel bars through steel bar connectors, the SMA energy dissipation steel bars are located in a reserved PVC pipeline; then the PVC pipeline sequentially and downwards penetrates through a steel base plate, a rubber pad, the steel base plate and a hole channel reserved in a bearing platform from a plastic hinge area of the bottom section; and finally the tail ends of the SMA energy dissipation steel bars are anchored to an anchoring device in the bearing platform. The structure has the advantages of being high in energy dissipation capacity, high in self-resetting capacity, small in residual displacement, small in pier bottom concrete damage and the like, and is suitable for being popularized and used in medium and high intensity areas.

Owner:NANJING UNIV OF SCI & TECH

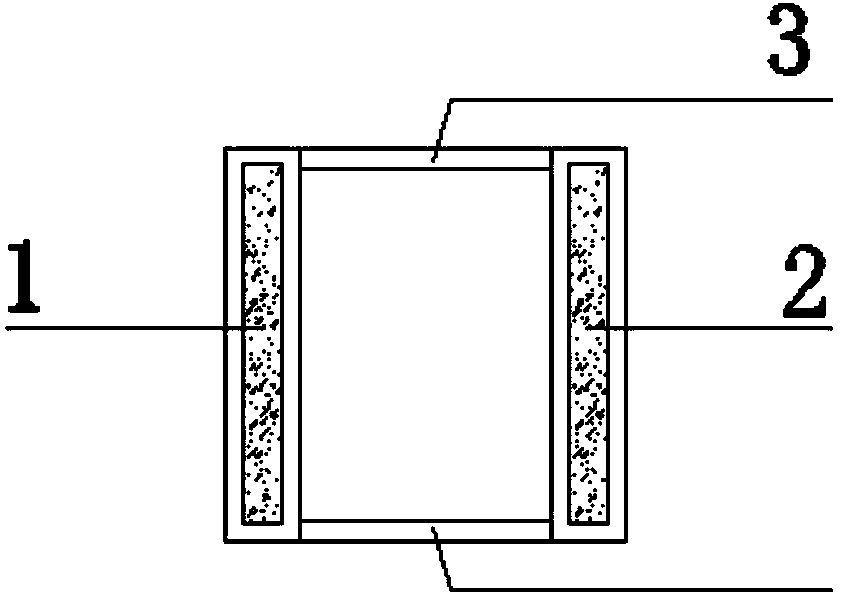

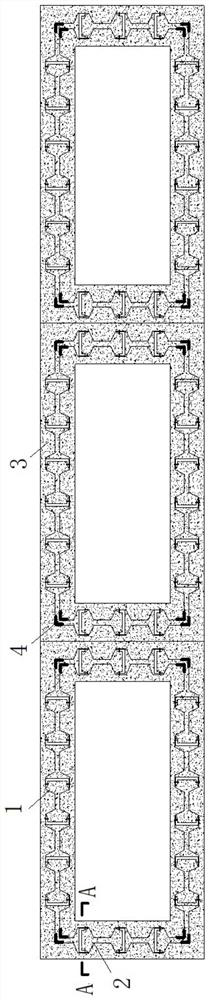

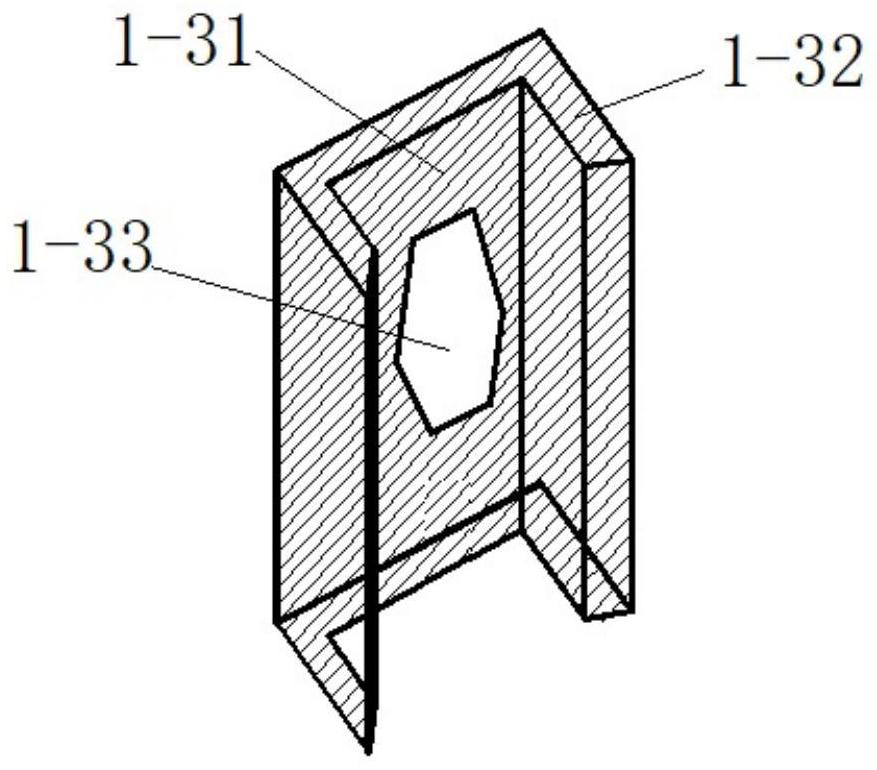

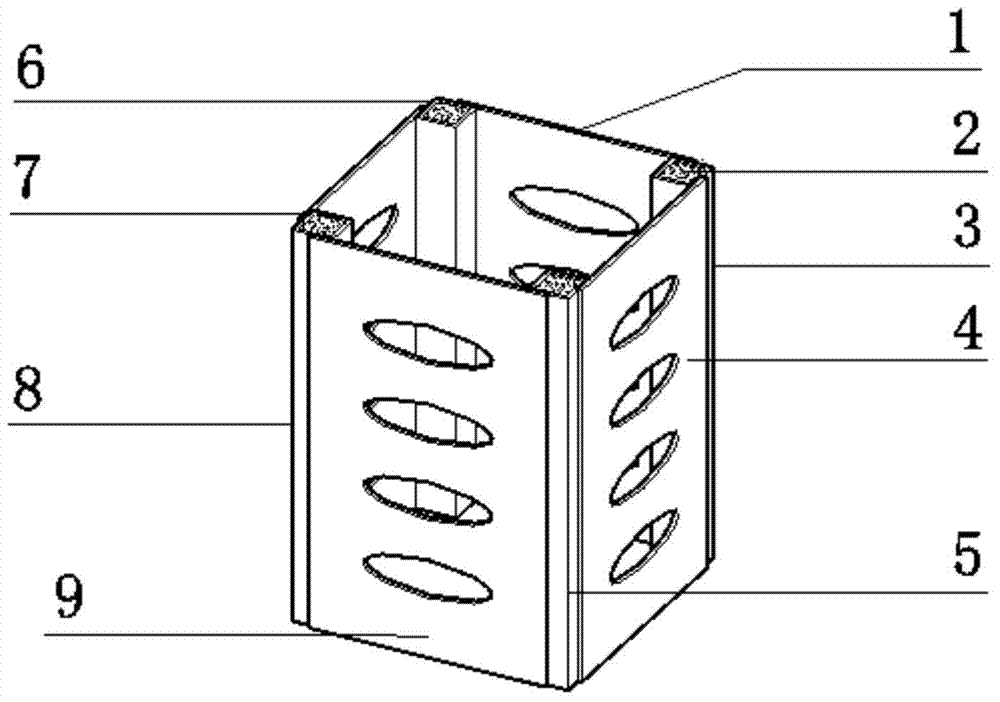

Cellular connection steel plate-double-limb steel pipe concrete composite column

The invention discloses a cellular connection steel plate-double-limb steel pipe concrete composite column, comprising a steel pipe concrete limb part 1, a steel pipe concrete limb part 2, a steel connection plate 1 and a steel connection plate 2, wherein two ends of the steel pipe concrete limb part 1 and the steel pipe concrete limb part 2 are respectively connected with each other through the steel connection plate 1 and the steel connection plate 2 to form a battened steel column; the steel connection plate 1 and the steel connection plate 2 are cellular connection plates with holes in the centers; the steel connection plate 1 and the steel connection plate 2 are respectively composed of two steel plates which are the same in shape and are provided with gaps in the edges; and the two steel plates are welded through a butt weld joint to form the cellular connection plate. According to the cellular connection steel plate-double-limb steel pipe concrete composite column, the mechanical behavior is improved, and the stability performances of a real axis and a virtual axis are fully approximate, so that the materials in the directions of two principal axes can bring into full play, the steel consumption is lowered, and the comprehensive cost of engineering is reduced.

Owner:NANJING UNIV OF TECH

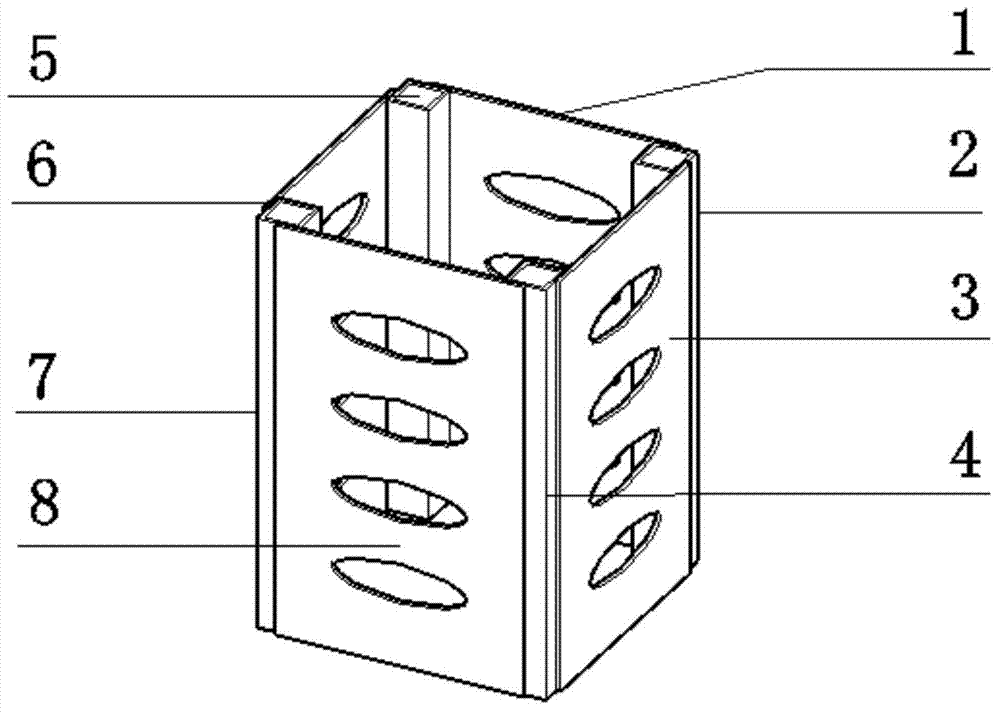

Four-limb steel column for connection of cellular connection plates

The invention discloses a four-limb steel column for connection of cellular connection plates. The four-limb steel column for connection of cellular connection plates comprises a steel tube limb I, a steel tube limb II, a steel tube limb III, a steel tube limb IV, a steel connection plate I, a steel connection plate II, a steel connection plate III and a steel connection plate IV, wherein the steel tube limb I, the steel tube limb II, the steel tube limb III and the steel tube limb IV are connected together through the steel connection plate I, the steel connection plate II, the steel connection plate III and the steel connection plate IV to form a rectangular section column; the steel connection plate I, the steel connection plate II, the steel connection plate III and the steel connection plate IV are cellular connection plates, the middles of which are provided with holes; the steel connection plate I, the steel connection plate II, the steel connection plate III and the steel connection plate IV are respectively formed by two steel plates which are provided with gaps at the boundary zones and of the same shape; every two steel plates are welded through butt welds to form each cellular connection plate. The four-limb steel column for connection of cellular connection plates is capable of improving the stress property of the latticed columns and improving the rigidity and the buckling strength of the steel columns in a relatively economic manner.

Owner:NANJING UNIV OF TECH

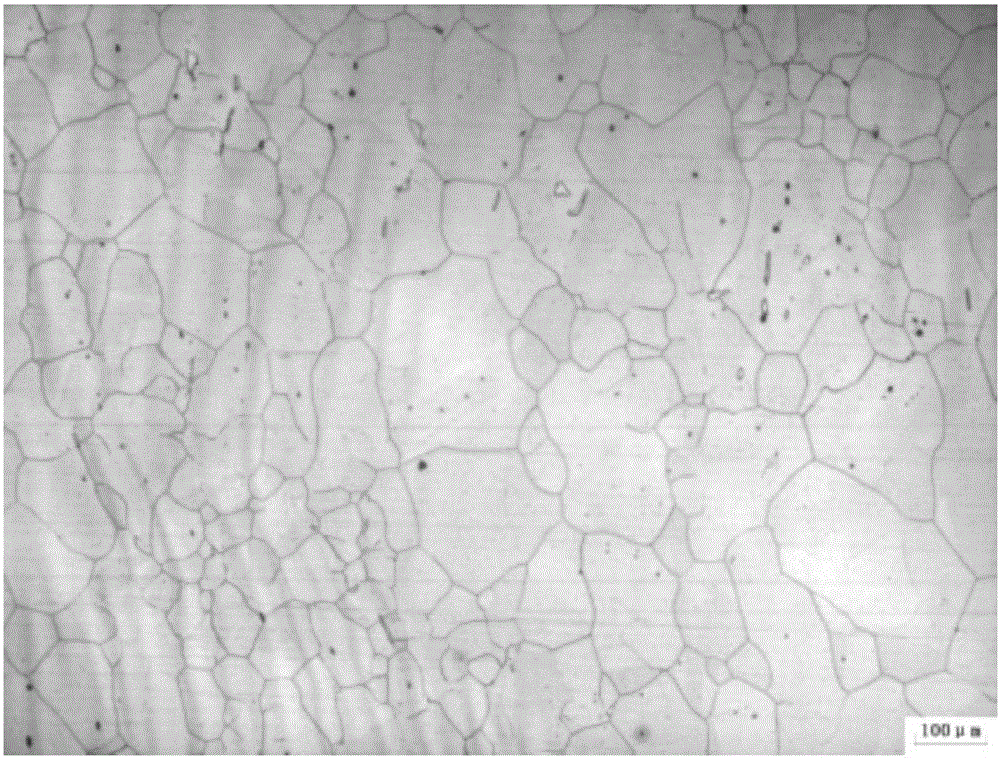

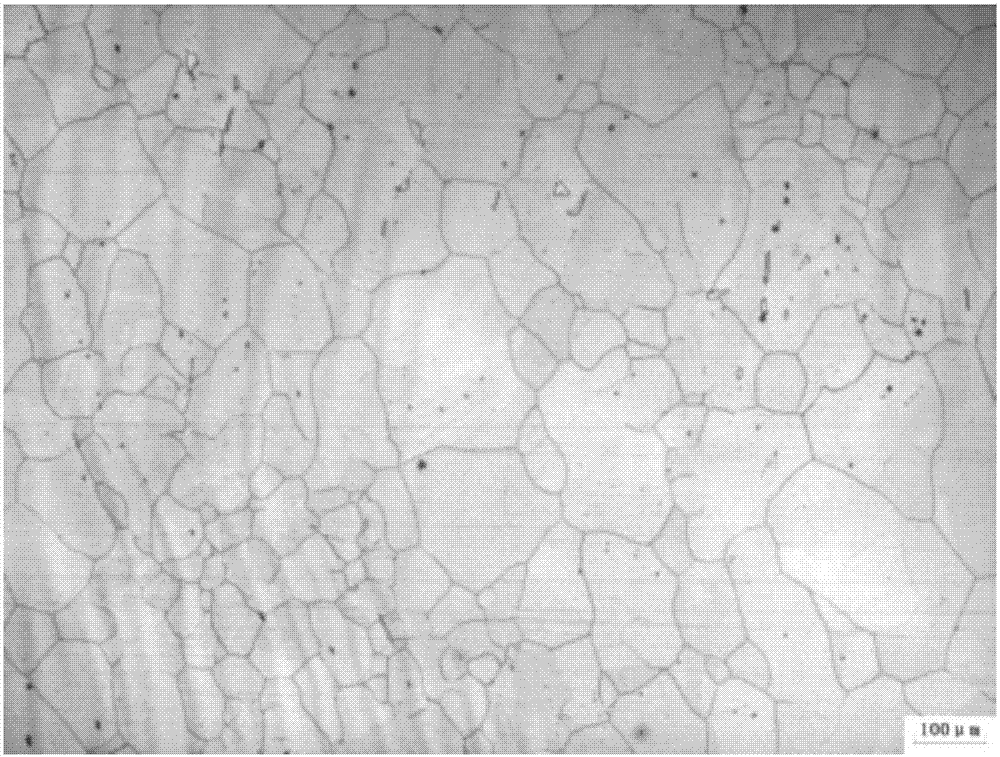

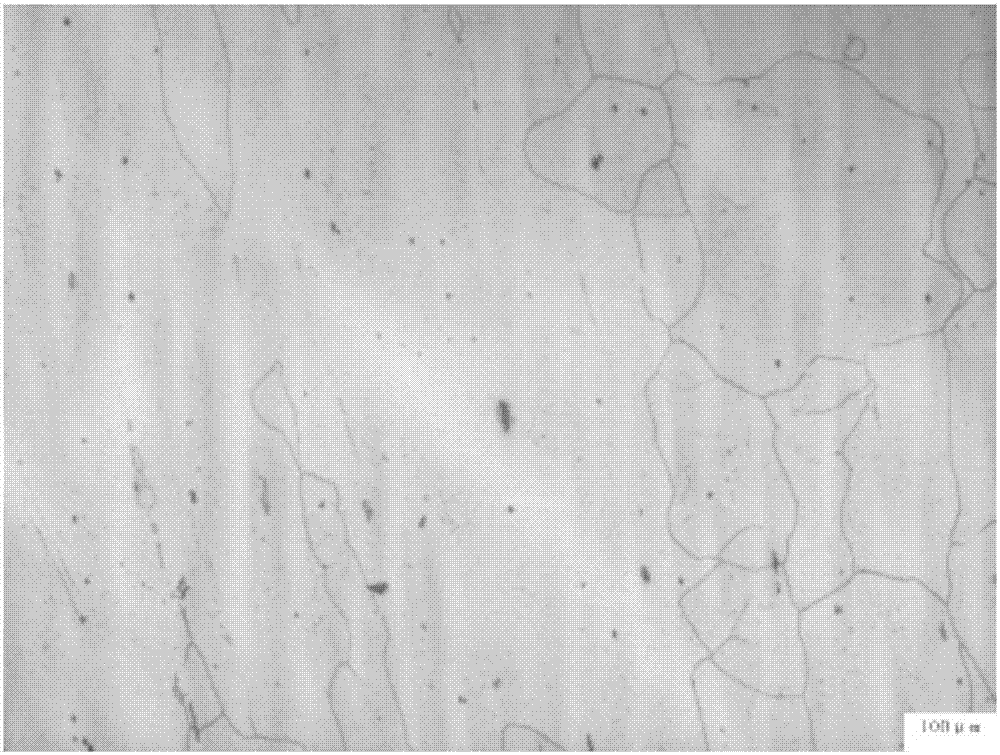

Manufacturing method for large-diameter austenitic stainless steel thick-wall pipe

ActiveCN106694606AReduce production processImprove uniformityRoll mill control devicesMetal rolling arrangementsThick wallSS - Stainless steel

The invention provides a manufacturing method for a large-diameter austenitic stainless steel thick-wall pipe, and belongs to the technical field of stainless steel machining. The manufacturing method includes the steps of integration of an electric furnace, AOD and centrifugal casting, hot rolling, homogenized heat treatment, primary cold rolling, structure regulation heat treatment, finished pipe cold rolling, solid solution heat treatment and the like. A large-wall-thickness centrifugal casting hollow pipe blank is used as a billet pipe, so that the manufacturing procedure of a billet pipe is omitted, and the yield is increased. The uniformity of the structure and performance in the pipe wall thickness direction is improved through high-temperature homogenized heat treatment of the hot-rolled pipe blank, and the deformation uniformity in the wall thickness direction in the follow-up cold rolling deformation process is improved. Through structure regulation annealing heat treatment and the pinning effect of the second phase, the cold-rolled pipe blank with the uniform and fine grain structure is obtained, so that the large-diameter thick-wall finished pipe with the grain size being higher than the 4.0 level is obtained. Furthermore, the finished pipe is rolled through a superlarge-diameter roller, the better uniform deformation in the wall thickness direction is achieved, and thus the large-diameter thick-wall finished pipe with the grain size being higher than the 5.0 level is obtained.

Owner:CENT IRON & STEEL RES INST

Novel cutting machine

InactiveCN107538073AHigh torqueImprove work efficiencyMetal sawing devicesMaintainance and safety accessoriesHead movementsQuality of work

The invention discloses a novel cutting machine. The novel cutting machine comprises a cutting machine body and a cutter blade, and the cutting machine body moves downwards while the cutter blade operates. A hydraulic spray head is installed at the bottom of the cutting machine body, dust is blocked by installing a baffle while the cutting machine operates, and the hydraulic spray head sprays water out through operating of a hydraulic pump. The novel cutting machine has the beneficial effects that the novel cutting machine is a handheld belt type electric cutting machine and belongs to the technical field of handheld electric cutting tools provided with disc-shaped cutter blades; the cutting machine is large in torsion, high in working efficiency and simple and convenient in machining mode, after a dust guard plate is installed, the safety performance during working is greatly improved, and the working quality is ensured; and when the cutting machine operates, the hydraulic pump suckswater, the water is sprayed out from the spray head, thus, a cooling effect can be achieved, the working quality can be improved, and cutting-off deformation is reduced.

Owner:JIANGYIN SHENGYUAN COPPER MATERIAL

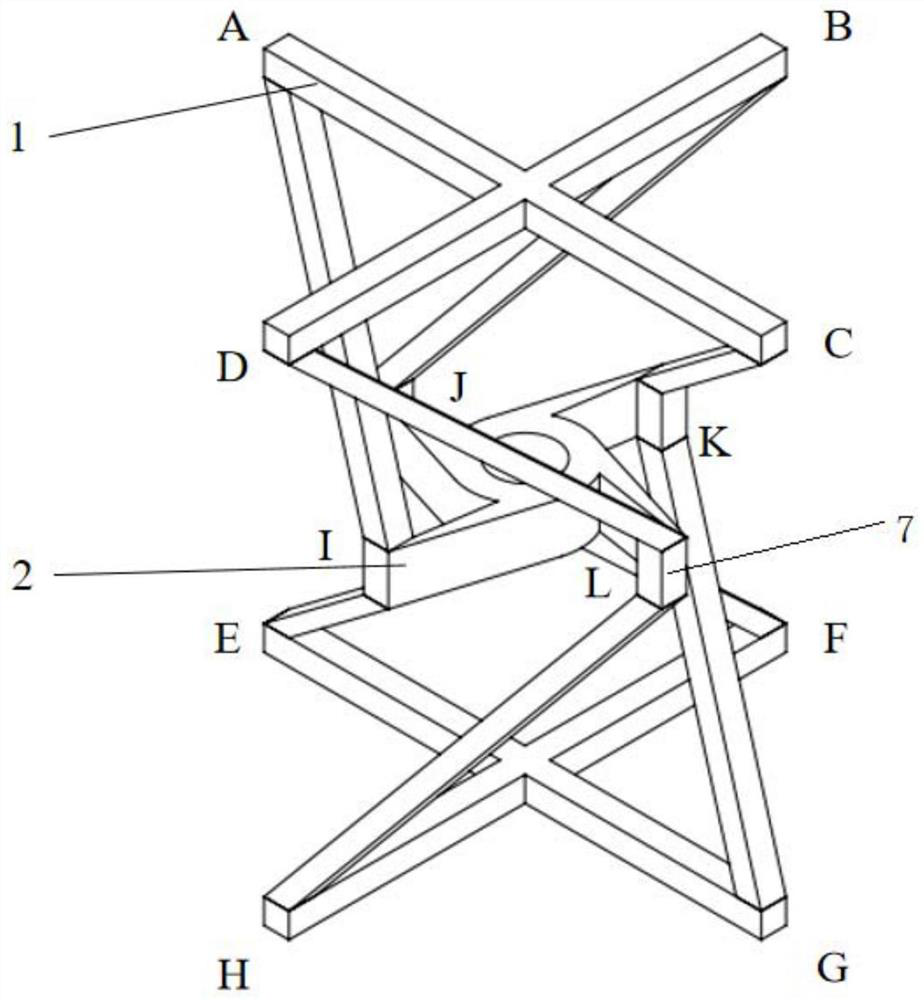

Three-dimensional structure with negative Poisson's ratio characteristic and combination method thereof

ActiveCN113525273AHigh densityStable structureSustainable transportationBumpersEngineeringAutomobile safety

The invention relates to a three-dimensional structure with a negative Poisson's ratio characteristic, which comprises a plurality of three-dimensional structure units. Each three-dimensional structure unit comprises a four-chiral structure unit and two torsion structure units; the torsion structure unit comprises an upper cross rod, a lower cross rod, an upper inclined rod and a lower inclined rod, the upper cross rod is connected with the upper inclined rod, the lower cross rod is connected with the lower inclined rod, the upper inclined rod is connected with the lower inclined rod, the horizontal projection of the upper inclined rod coincides with the horizontal projection of the lower inclined rod, and an included angle phi is formed by the horizontal projection of the upper cross rod and the horizontal projection of the upper inclined rod; the two torsion structure units are perpendicular to each other; the four-chiral structure unit comprises a circular ring and a connecting rod; one end of the connecting rod is tangent to the circular ring, and the other end of the connecting rod is connected with the connecting point of the upper inclined rod and the lower inclined rod. The invention further relates to a combination method of the three-dimensional structure with the negative Poisson's ratio characteristic. The structure is stable, can achieve the negative Poisson's ratio characteristic in multiple directions, and belongs to the field of automobile safety equipment.

Owner:GUANGZHOU UNIVERSITY

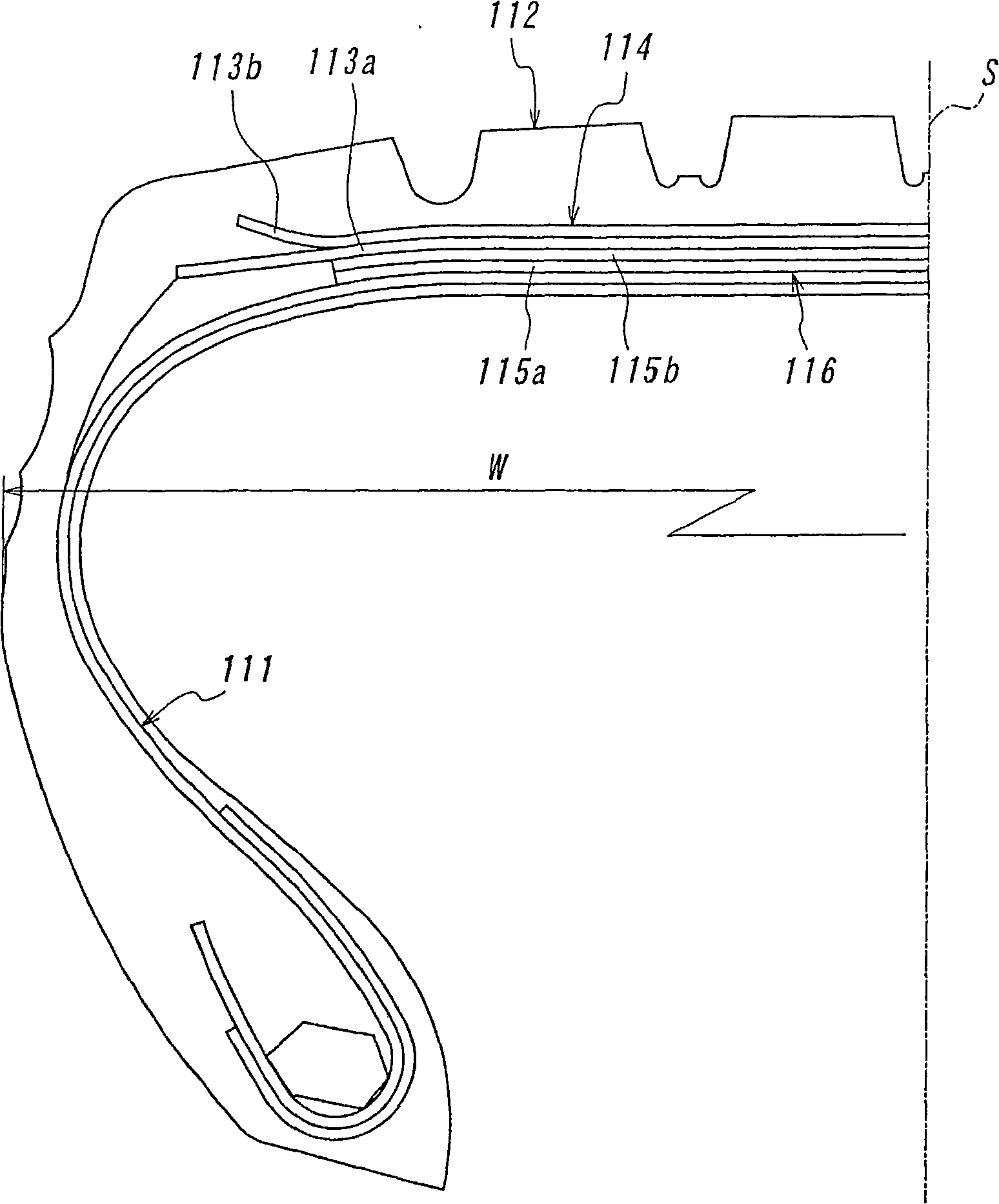

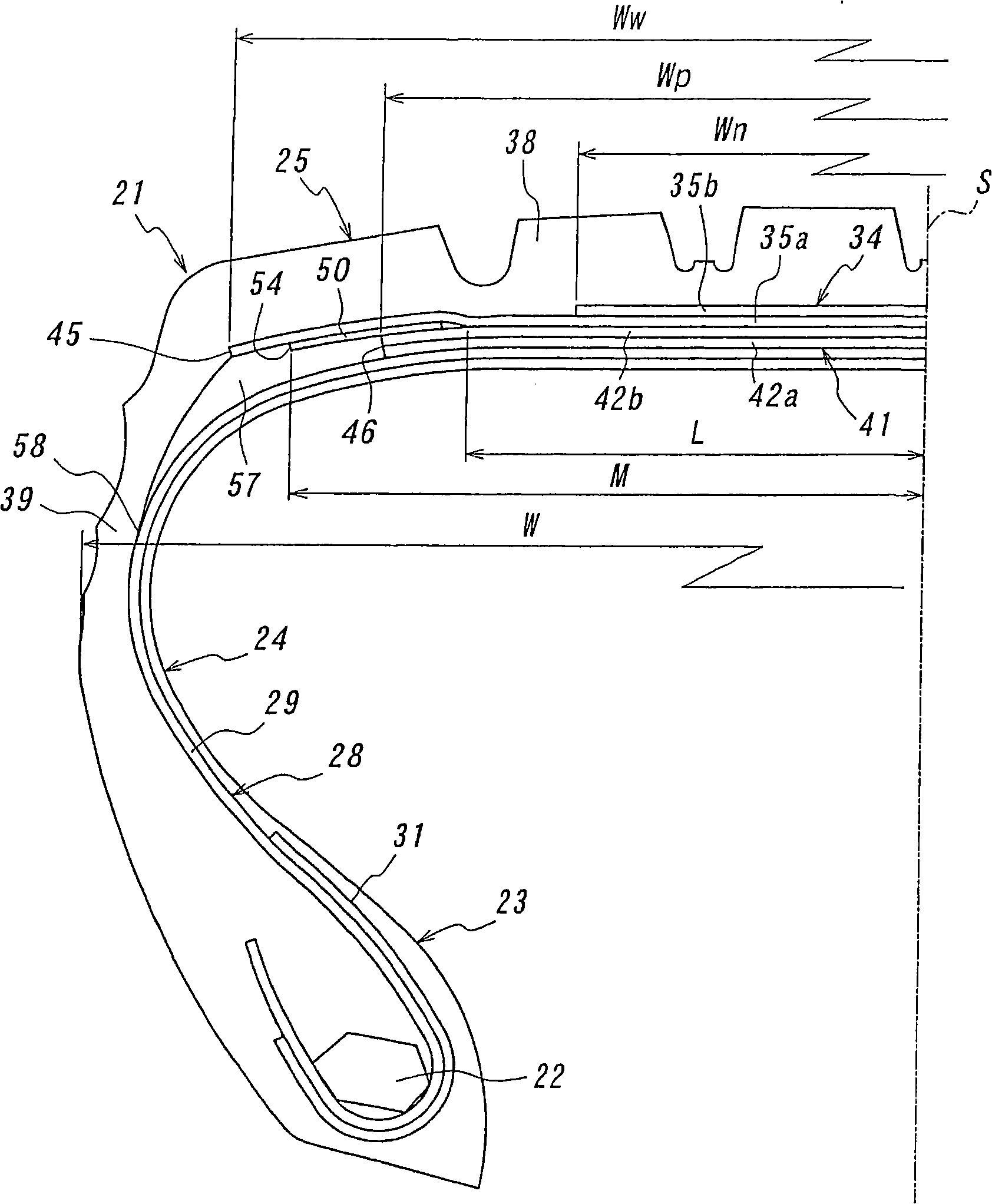

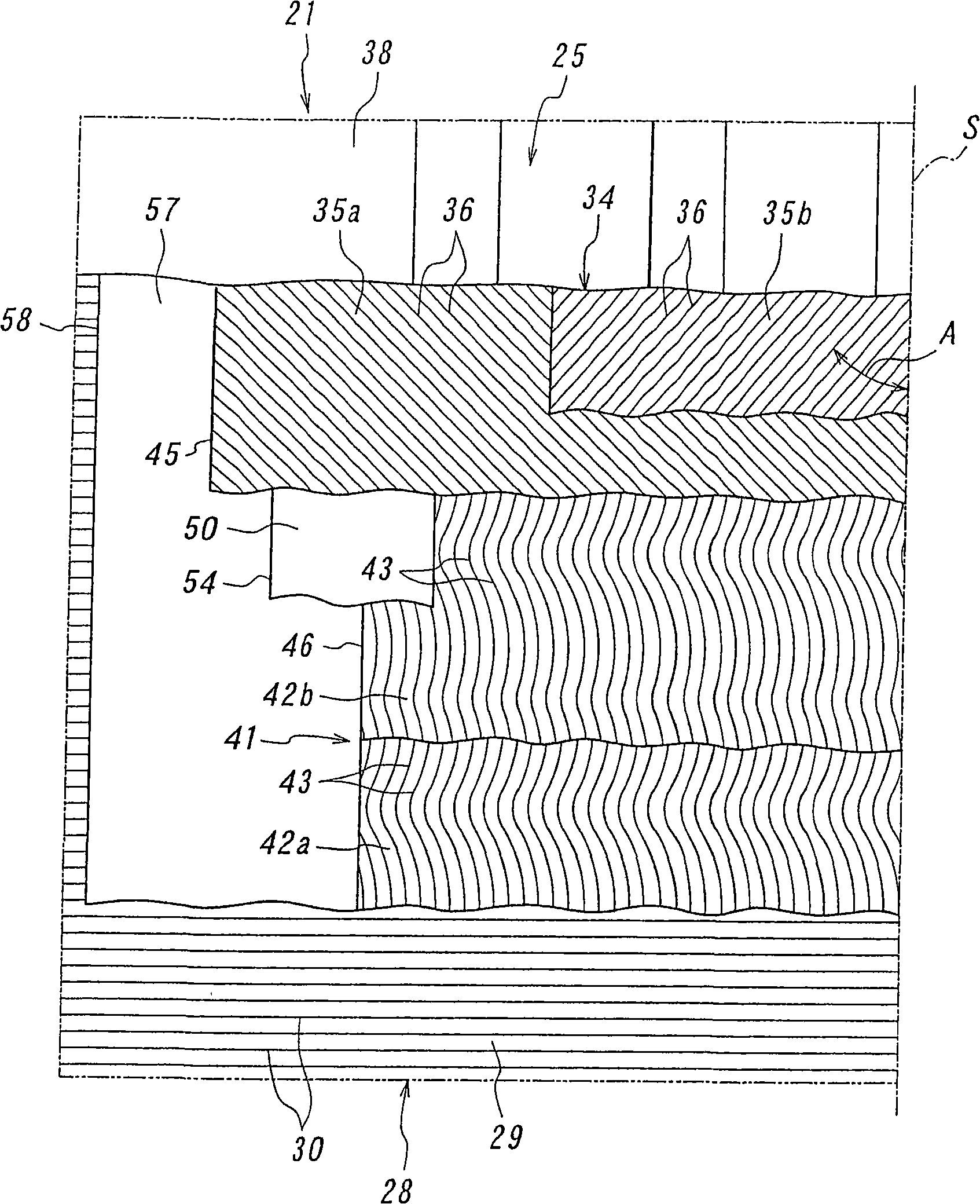

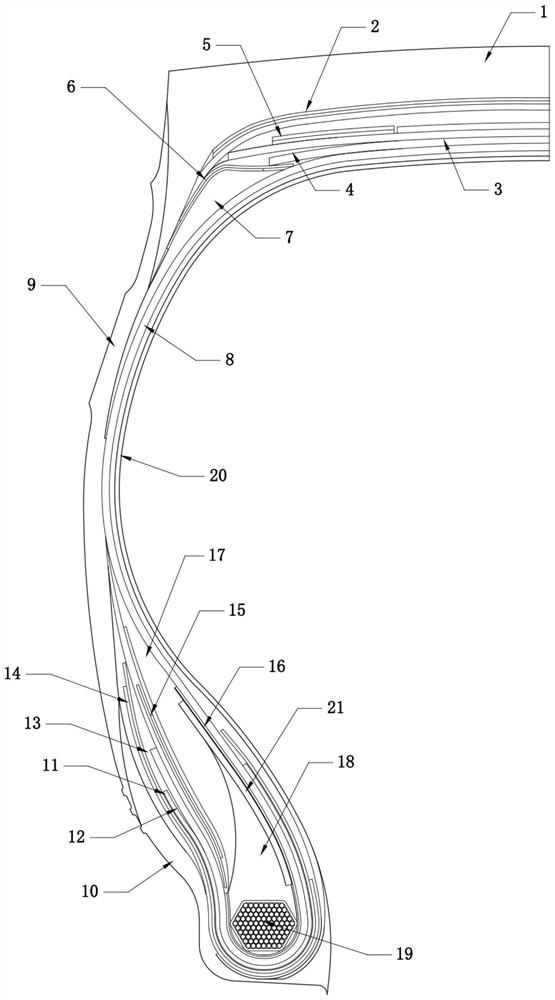

Pneumatic radial tire

InactiveCN101306629AReduce shear deformationEnsuring inclusionHeavy duty tyresHeavy duty vehicleShearing deformationMechanical engineering

A belt durability is improved by effectively suppressing an interlayer separation between each widthwise outer end portion of a belt reinforcing layer 41 and a belt layer 34, in which each widthwise outer end 45 of one widest-width inner belt ply 35a is located outward from each widthwise outer end 46 of widest-width reinforcing plies 42a, 42b in the widthwise direction and hence reinforcing elements of the belt plies are not crossed with each other at the outside from the each widthwise outer end 46 in the widthwise direction. Therefore, the each widthwise outer end portion of the inner belt ply 35a is easily reduced in the widthwise direction, whereby shearing deformation in section to the each widthwise outer end portion of the reinforcing ply 42a, 42b is reduced.

Owner:BRIDGESTONE CORP

Optical fiber micro-bending displacement sensor

InactiveCN100360905CImprove dynamic performanceHigh sensitivityUsing optical meansConverting sensor output opticallyOptical power meterOptical fiber coupler

An optical fiber micro bent displacement sensor, which contains light source, optical fiber coupler, Y type optical fiber, integral distortion device, optical micro bent distortion device, two optical rings, two pretension screw and optical power meter. Said invention adopts separated integral distortion device and optical fiber micro distortion device, can design the rigidity and strength of integral distortion according to need for adapting different frequency and amplitude signal measurement.

Owner:SHANGHAI JIAO TONG UNIV

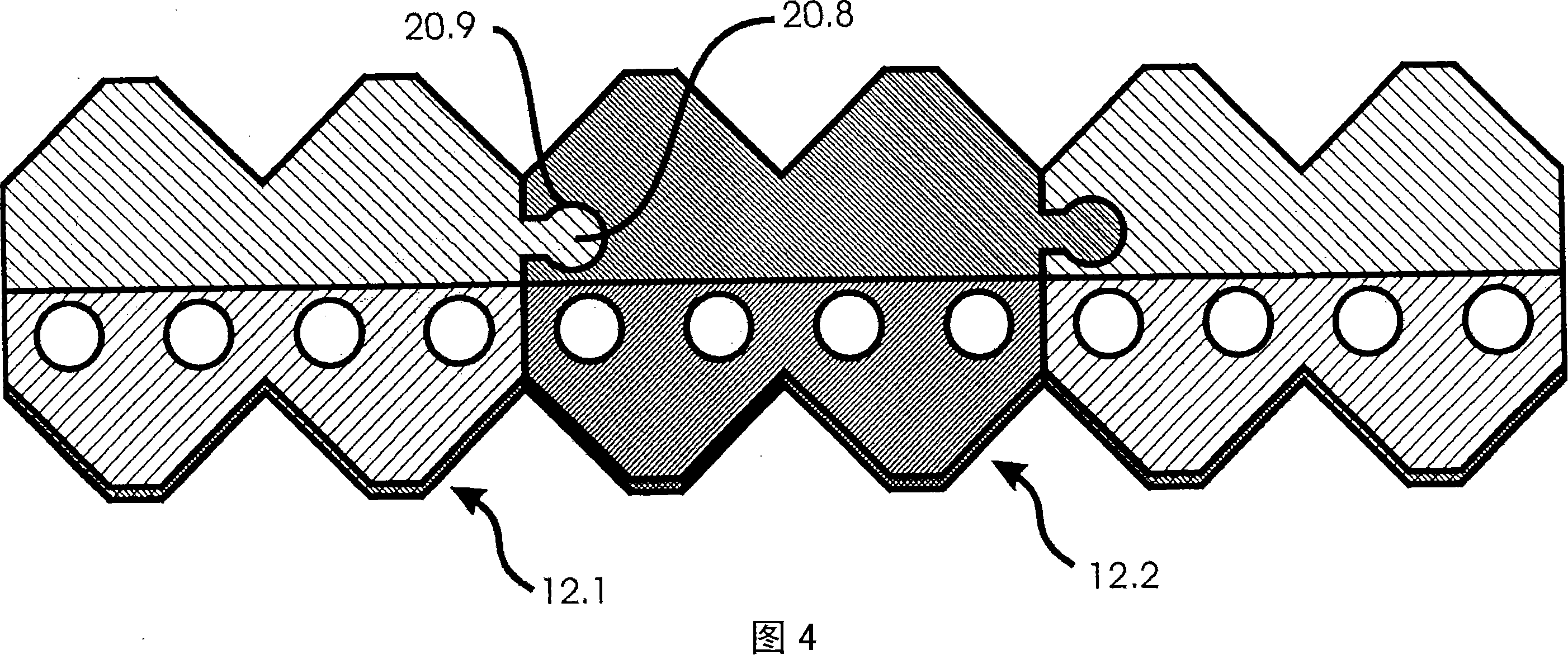

A prefabricated corrugated steel plate lattice enclosure structure and construction method thereof

ActiveCN112983116BPlay the role of tension reinforcementIncrease contact surfaceFencingClassical mechanicsAxial force

The invention discloses a prefabricated corrugated steel plate lattice-type enclosure structure and a construction method thereof. The structure includes a number of frame-structured enclosure units, each enclosure unit includes a transverse enclosure portion and a longitudinal enclosure portion filled with concrete, and a truss as a bending component is arranged inside the transverse enclosure portion. The interior of the enclosure is provided with a lattice column as an axial force-bearing member. The truss and the lattice column are connected to each other and bonded with the concrete to form a whole. It is composed of channel steel, a channel steel is arranged in the cavity formed by each peak-to-peak part, the flange of the channel steel is connected with the wave crest in the cavity, and the opening direction of the channel steel in the adjacent cavity is opposite. The invention solves the problem that the envelope structure is only regarded as a non-structure in the traditional building form, is convenient for timely replacement when damaged, and ensures that the structure has good mechanical properties.

Owner:CHANGZHOU INST OF TECH

Heavy-load radial tire and manufacturing method thereof

PendingCN114851781AHigh strengthImproved material modulus transitionHeavy duty tyresHeavy duty vehicleLap jointHeavy load

The invention provides a heavy-load radial tire and a manufacturing method, and relates to the field of radial tires, the heavy-load radial tire comprises a tread, a sidewall and a tire body, the sidewall is connected with the tread and toe wear-resistant rubber, and the toe wear-resistant rubber is connected with a lining after bypassing a steel wire ring; a belted layer outer reinforcing layer, a belted layer and a belted layer inner reinforcing layer are sequentially arranged between the tread and the tire body; one end of the belted layer inner reinforcing layer is in lap joint with the belted layer, and the other end extends to the sidewall; the belted layer is covered with the belted layer outer reinforcing layer, the end of the belted layer outer reinforcing layer extends to the tire shoulder, and the belted layer outer reinforcing layer and the belted layer inner reinforcing layer are attached to the tire shoulder. In order to solve the problem of shoulder empty disease at the tire shoulder position under heavy load at present, the inner reinforcing layer and the outer reinforcing layer are respectively arranged on two sides of the belted layer and are attached to the tire shoulder position, one end of the inner reinforcing layer is in lap joint with the belted layer, and the other end of the inner reinforcing layer extends to the tire side, so that the strength of the tire shoulder is improved, and the occurrence risk of shoulder crown empty quality disease is reduced.

Owner:TONGLI TIRE CO LTD +1

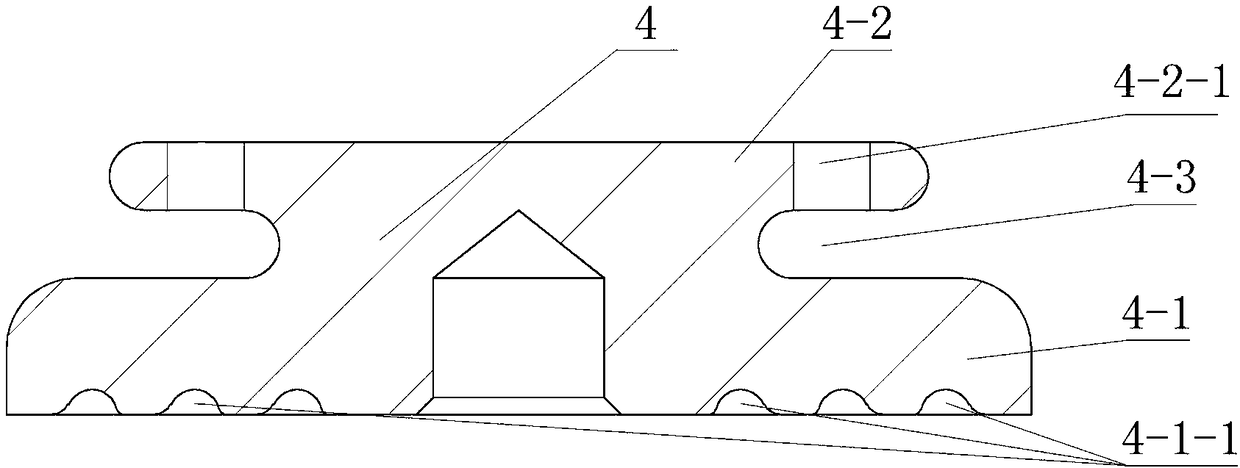

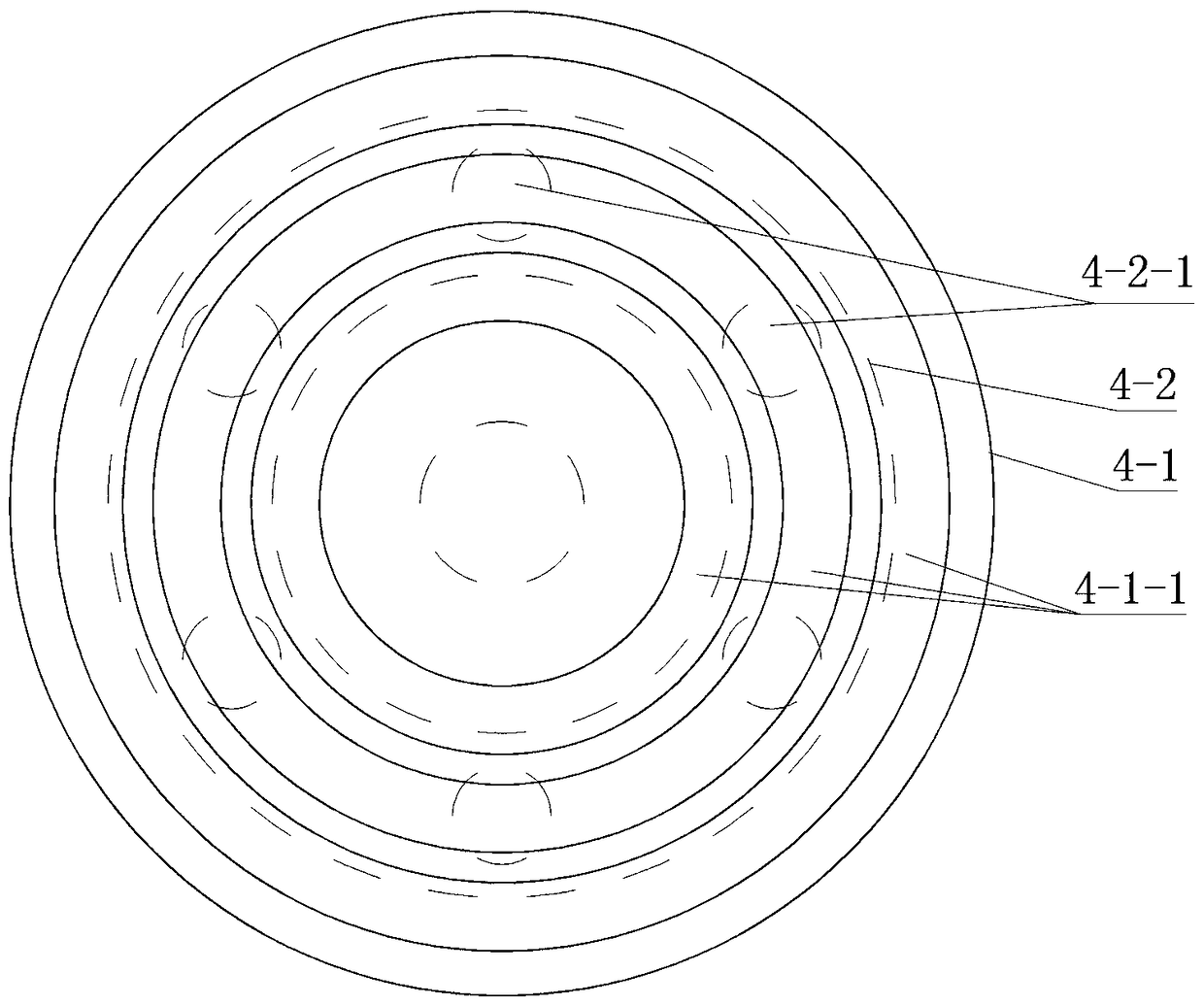

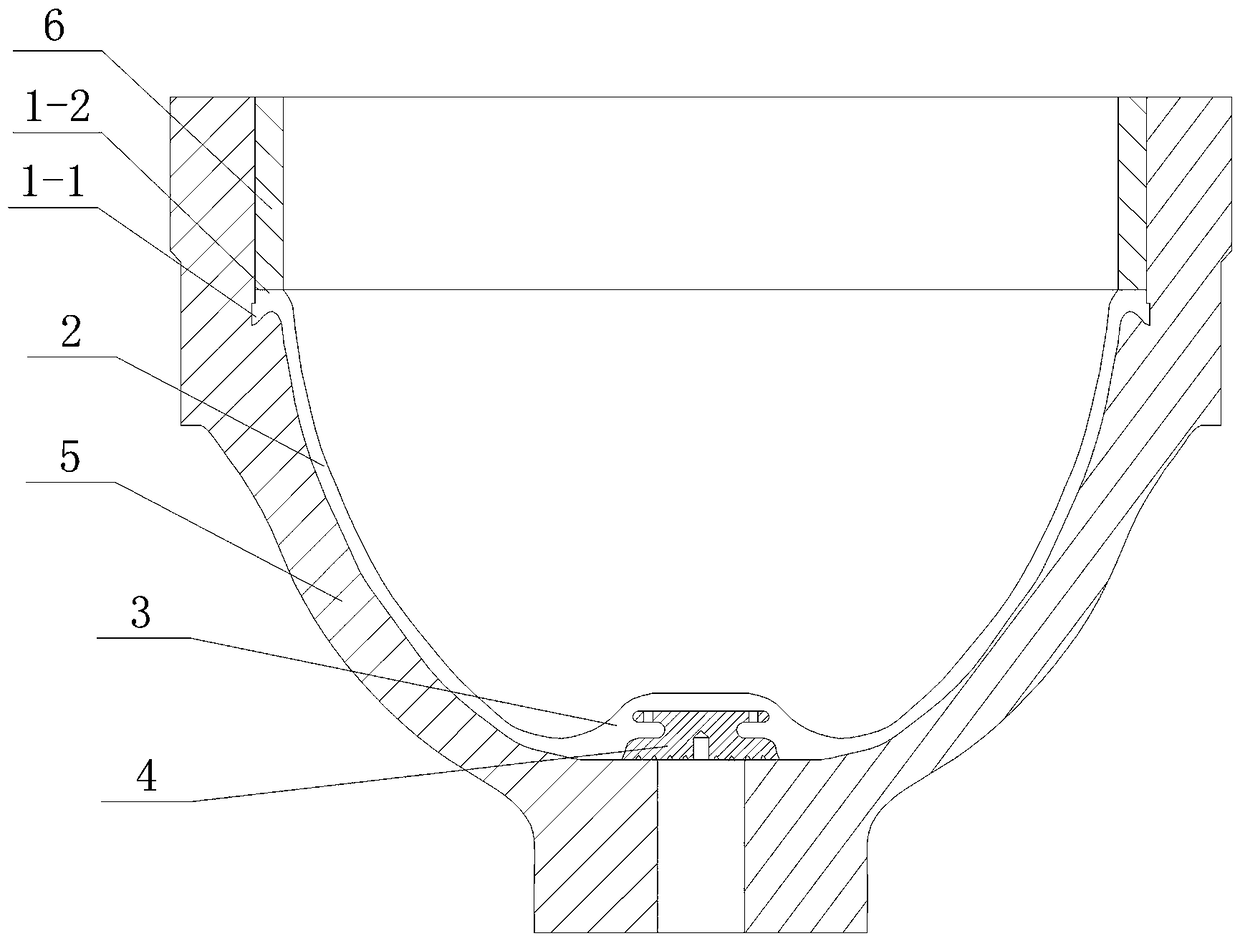

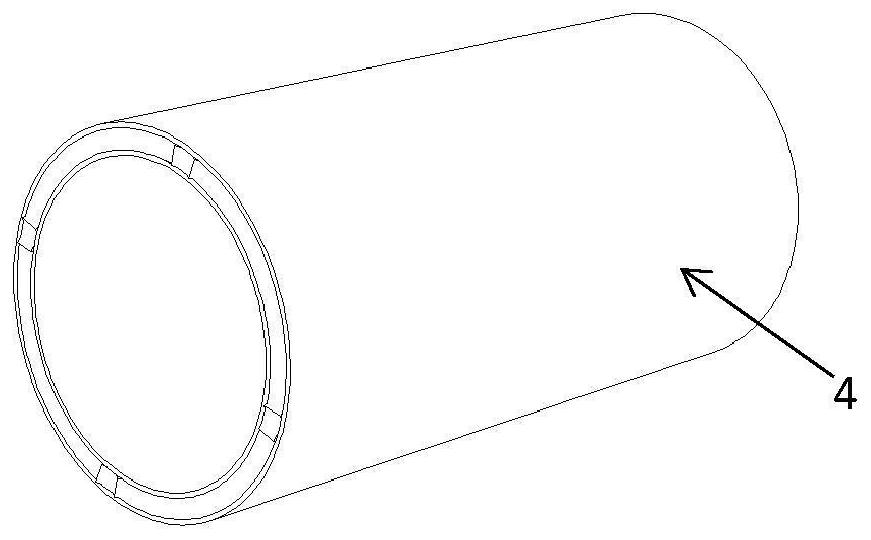

Bowl type rubber diaphragm for accumulator

ActiveCN106989172BHigh strengthStrengthen the perfect combinationEngine diaphragmsEngineeringUltimate tensile strength

The invention provides a bowl-shaped rubber diagram for an energy accumulator and belongs to the technical field of hydraulic accessories. The bowl-shaped rubber diagram structurally comprises a bowl mouth sealing part, a bowl bottom thickening part and an arc bowl wall connected between a sealed bowl mouth and a thickened bowl bottom. The key lies in that the vertical section of the bowl bottom thickening part is in a circular-truncated-cone shape; the side surface of a circular truncated cone and the inner surface of the arc bowl wall are in uniform smooth transition to form an arc surface; and a special-shaped buffering core piece with the vertical section being in an inverted tray shape is inset in the bottom of the thickened bowl bottom. According to the bowl-shaped rubber diagram for an energy accumulator, the inverted-tray-shaped special-shaped buffering core piece is inset in the thickened part of the bottom of the bowl-shaped rubber diagram, and by means of the buffering structure and the elastic modulus characteristic of the core piece, the impact resistance strength and the high-frequency deformation capacity of the rubber diagram are improved, and the service life of the rubber diagram is prolonged.

Owner:SHIJIAZHUANG SIMKER TECH CO LTD

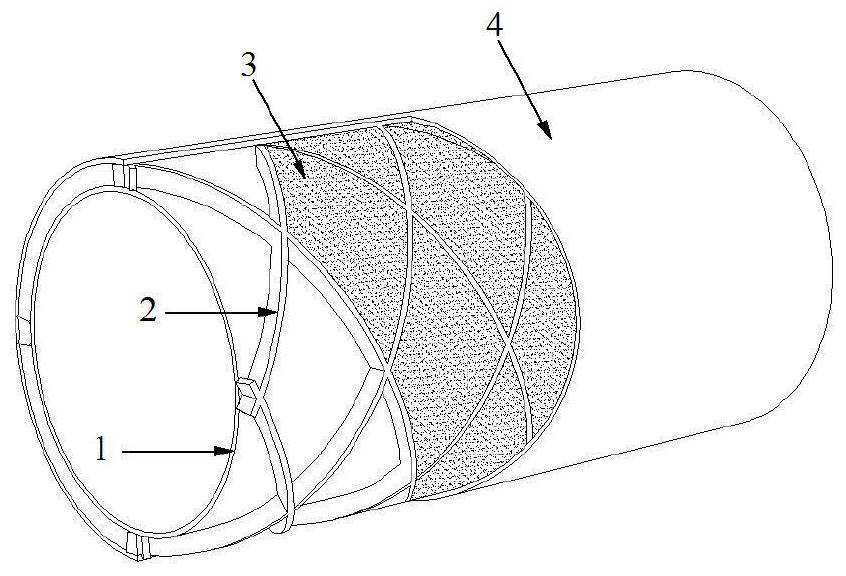

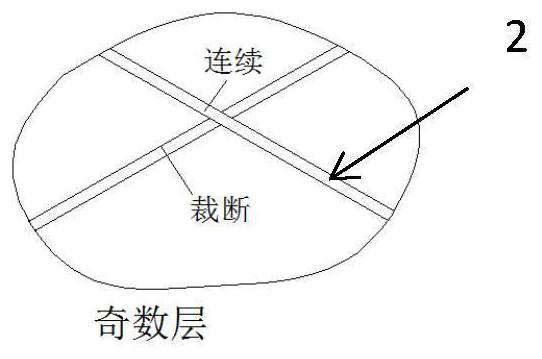

A processing method for a light-weight and high-rigidity composite pressure-resistant shell structure of an underwater vehicle

ActiveCN109795611BImprove battery lifeReduce shear stressWaterborne vesselsDomestic articlesCarbon fibersCrazing

Owner:NAVAL UNIV OF ENG PLA

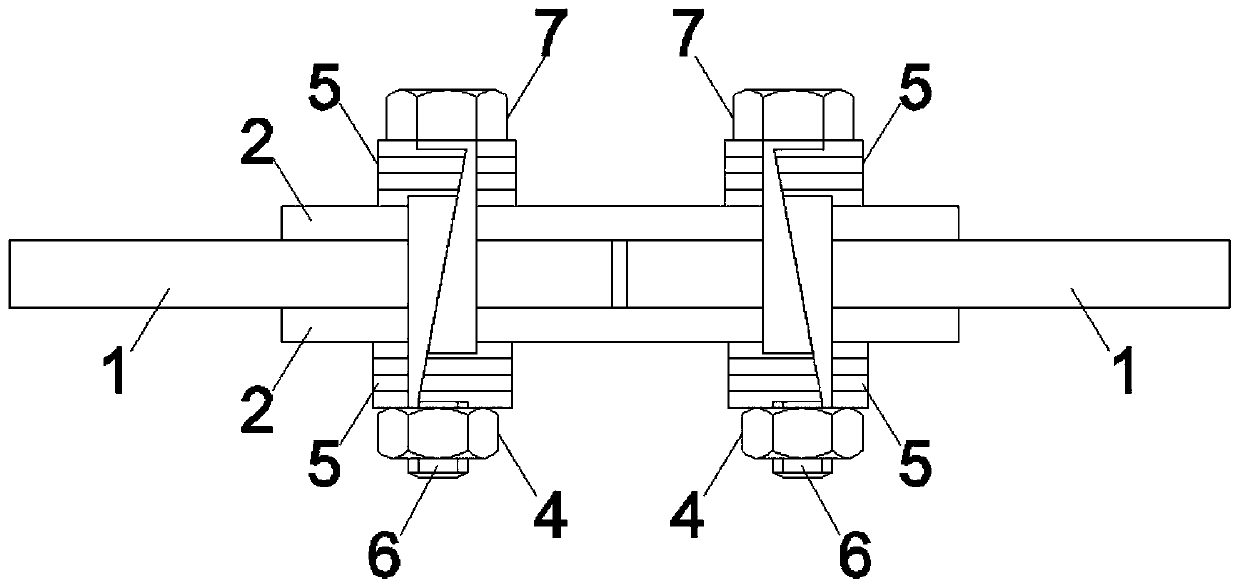

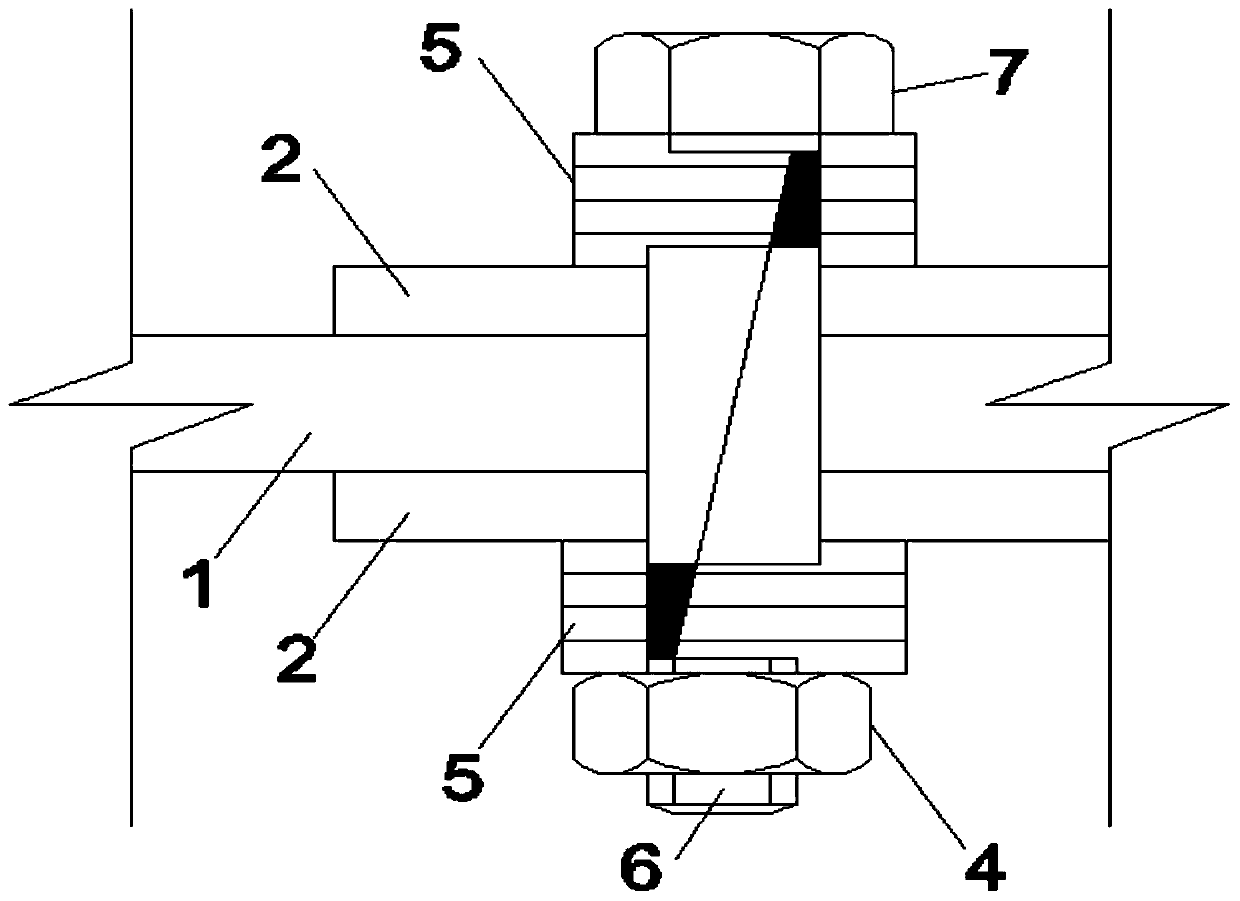

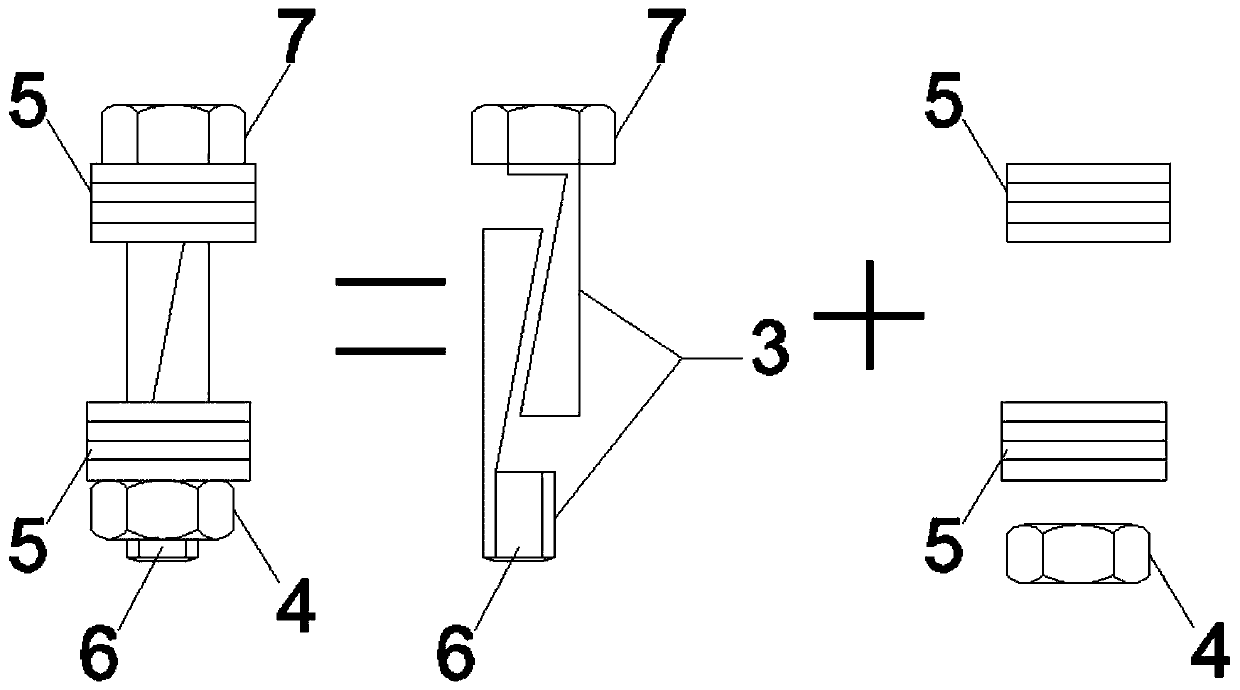

Connecting joint for self-compaction wedge-shaped spliced type pressure-bearing type high-strength bolts

PendingCN109944326AAvoid partial material becoming brittleAvoid askingSheet joiningScrewsEngineeringWedge shape

The invention discloses a connecting joint for self-compaction wedge-shaped spliced type pressure-bearing type high-strength bolts. A wedge-shaped screw of the connecting joint and a wedge-shaped screw with a nut are each provided with a certain number of gaskets. When the bolts are screwed down and pre-tension force is exerted, pressing force is generated between contact surfaces of connected plate pieces, and the bolts are tensioned axially, so the wedge-shaped screw and the wedge-shaped screw with the nut relatively slide, the actual diameter of the bolts is accordingly increased, the gaps,in the tension direction of the connected plate pieces, between reserved bolt holes and the bolts are filled. After the connected plate pieces are connected, the gaskets should make sectional weakened sections of the screws located on the upper side and the lower side of upper and lower spliced plates respectively, so the non-sliding connecting joint suitable for steel structure connecting partsfor bearing the reciprocating load effect in the tension direction of the connected plate pieces is formed.

Owner:TIANJIN UNIV

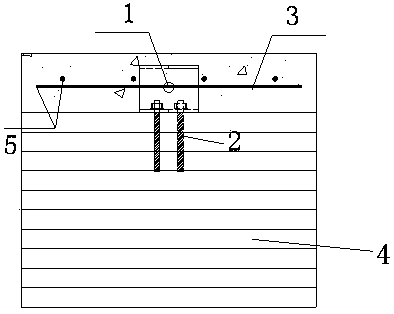

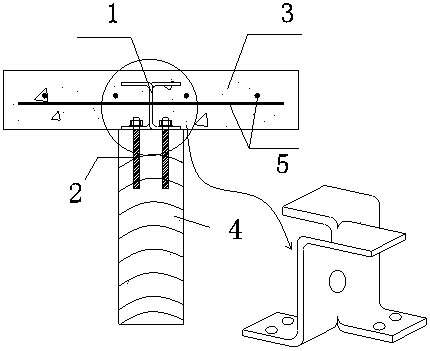

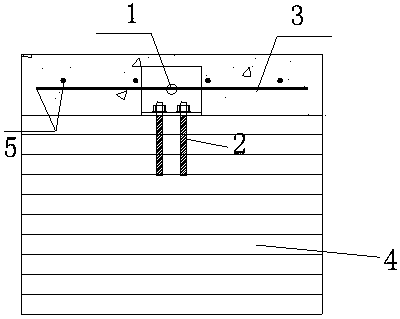

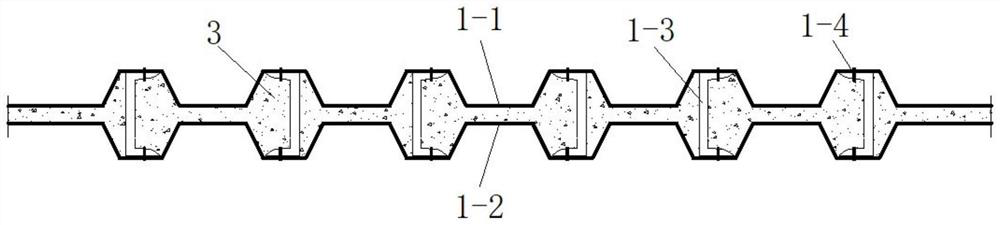

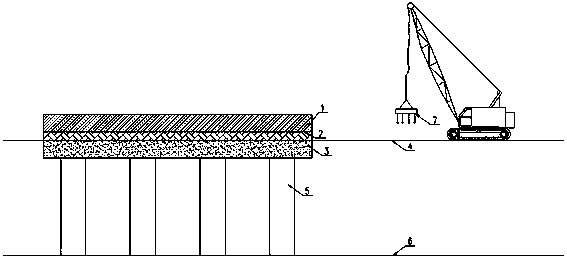

Warehousing terrace sedimentation control system and construction method thereof

PendingCN108411886AReduce shear deformationReduce settlementBulkheads/pilesSoil preservationSurface layerControl system

The invention discloses a warehousing terrace sedimentation control system and a construction method thereof. The warehousing terrace sedimentation control system comprises a terrace surface layer, aleveling layer, a ribbed mattress layer and a reinforced composite foundation; the ribbed mattress layer, the leveling layer and the terrace surface layer are arranged on the reinforced composite foundation in sequence; and the warehousing terrace sedimentation control system can effectively solve the problem of nonuniform sedimentation of a warehousing terrace of a deep new-soil-filled foundation, and meets use requirements of the warehousing terrace. Compared with a conventional engineering pile scheme, a dynamic consolidation method and a deep stirring pile method are lower in production cost, and are both conventional foundation treatment methods; and a deep cement stirring pile adopting the ribbed mattress layer is combined with the dynamic consolidation method to reinforce the deep new-soil-filled foundation, so that the effects of reducing the foundation sedimentation and nonuniform sedimentation and homogenizing the foundation stress are more obvious.

Owner:中交物流规划设计研究院有限公司

A method for manufacturing austenitic stainless steel large-diameter thick-walled pipe

ActiveCN106694606BReduce production processImprove uniformityRoll mill control devicesMetal rolling arrangementsSS - Stainless steelThick wall

The invention provides a manufacturing method for a large-diameter austenitic stainless steel thick-wall pipe, and belongs to the technical field of stainless steel machining. The manufacturing method includes the steps of integration of an electric furnace, AOD and centrifugal casting, hot rolling, homogenized heat treatment, primary cold rolling, structure regulation heat treatment, finished pipe cold rolling, solid solution heat treatment and the like. A large-wall-thickness centrifugal casting hollow pipe blank is used as a billet pipe, so that the manufacturing procedure of a billet pipe is omitted, and the yield is increased. The uniformity of the structure and performance in the pipe wall thickness direction is improved through high-temperature homogenized heat treatment of the hot-rolled pipe blank, and the deformation uniformity in the wall thickness direction in the follow-up cold rolling deformation process is improved. Through structure regulation annealing heat treatment and the pinning effect of the second phase, the cold-rolled pipe blank with the uniform and fine grain structure is obtained, so that the large-diameter thick-wall finished pipe with the grain size being higher than the 4.0 level is obtained. Furthermore, the finished pipe is rolled through a superlarge-diameter roller, the better uniform deformation in the wall thickness direction is achieved, and thus the large-diameter thick-wall finished pipe with the grain size being higher than the 5.0 level is obtained.

Owner:CENT IRON & STEEL RES INST

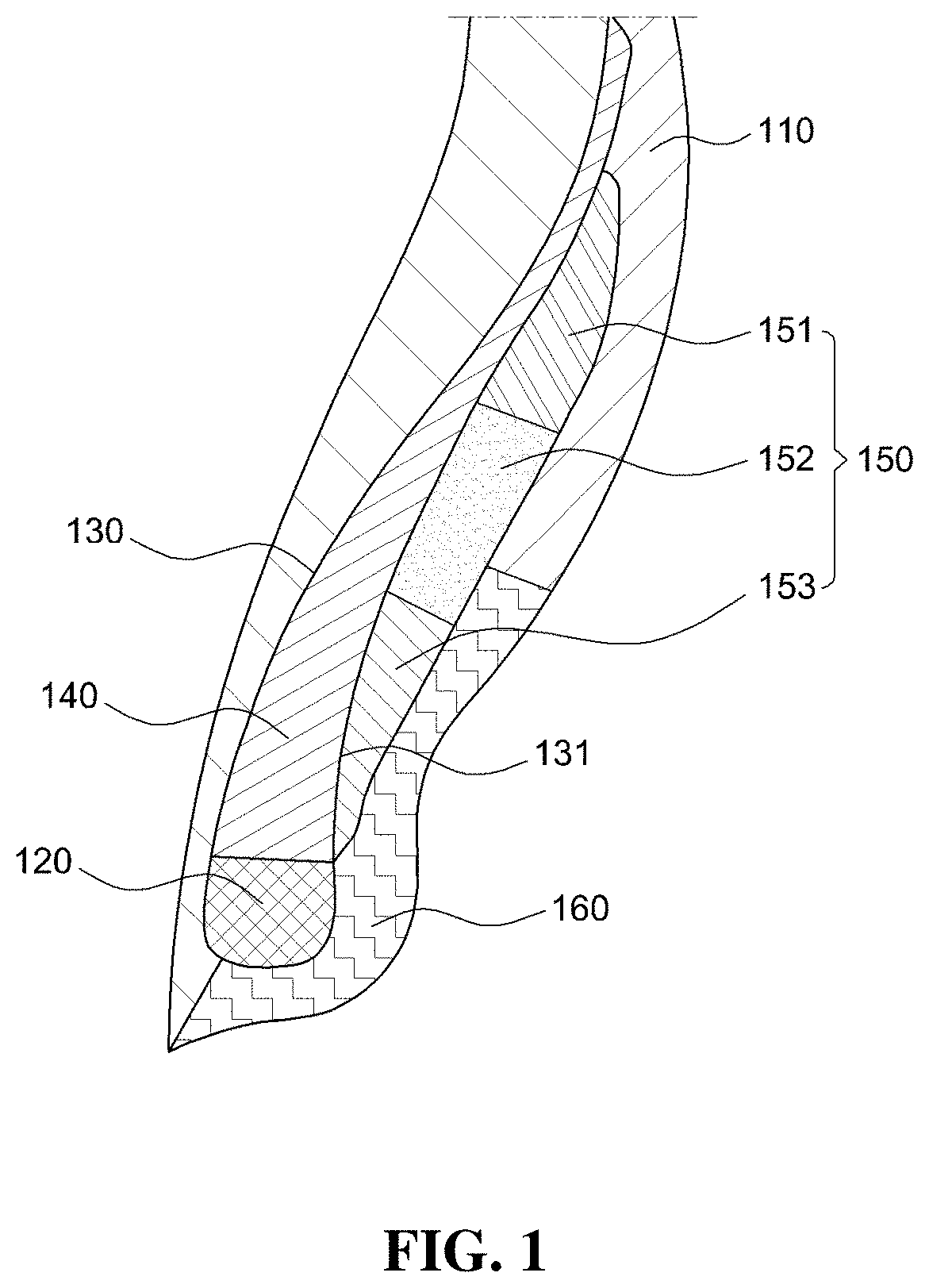

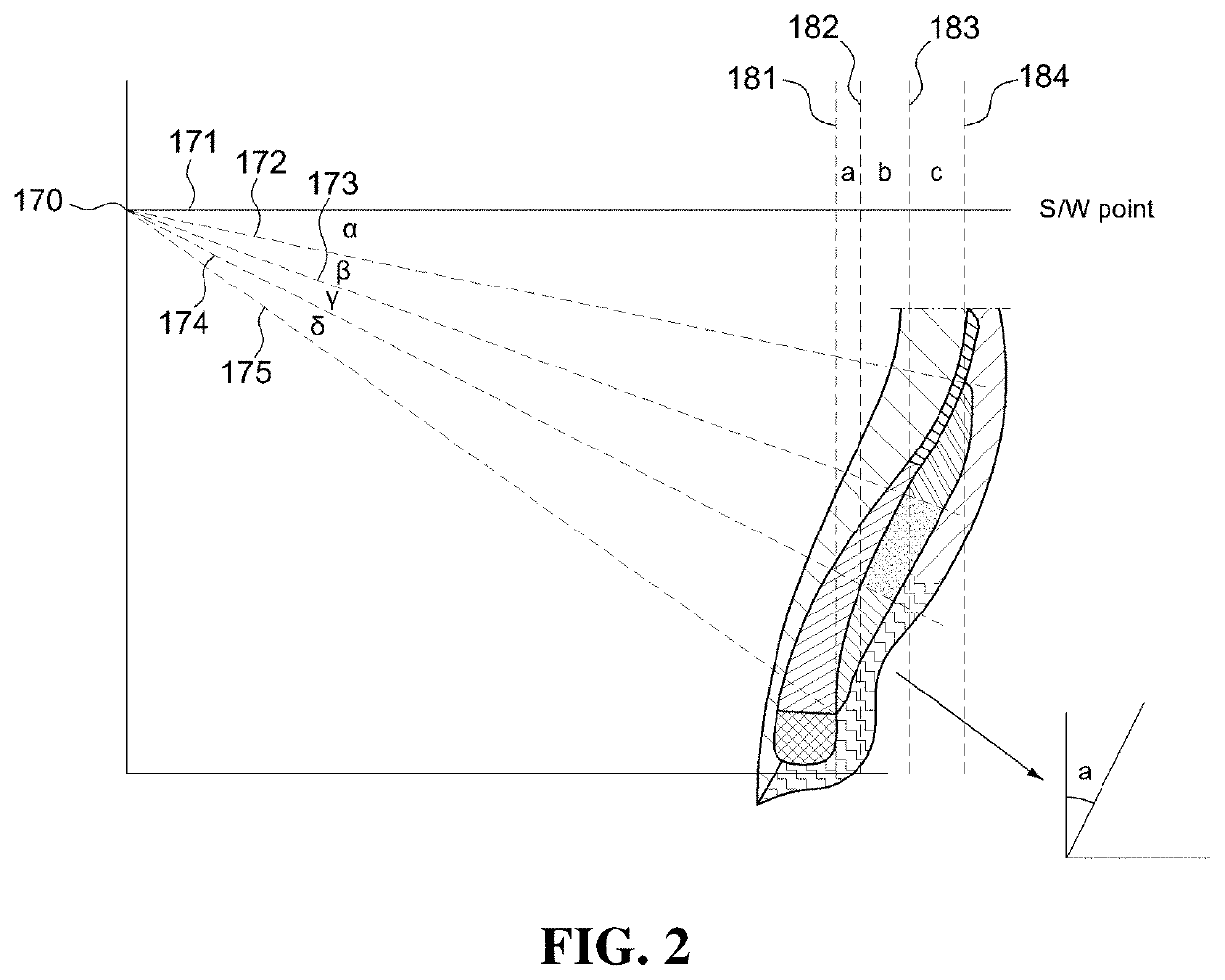

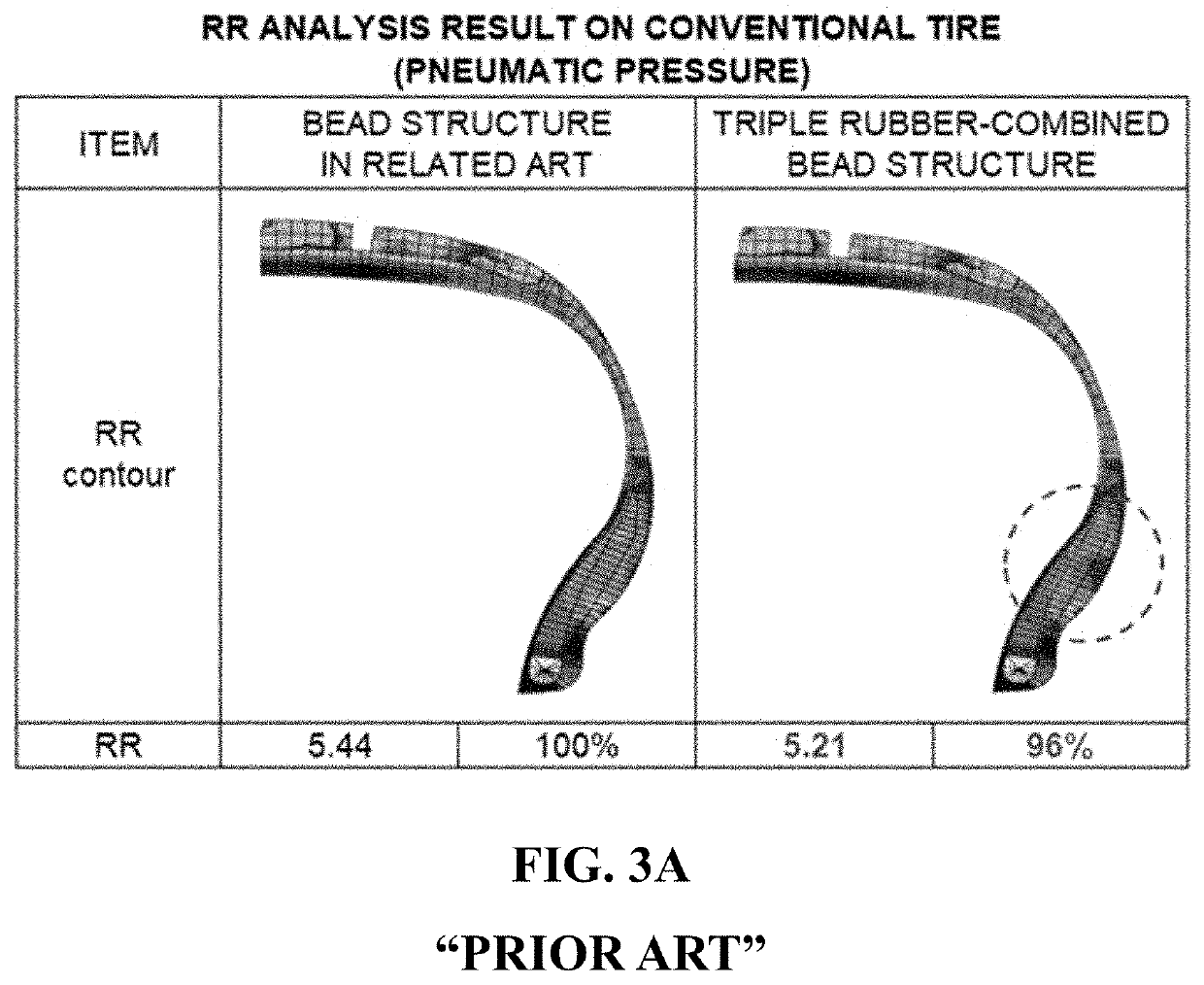

Pneumatic tire with bead filler applied with multiple rubber layer

ActiveUS11485177B2Reduce weightImprove rolling resistanceTyre beadsRolling resistance optimizationTire beadPolymer science

Owner:HANKOOK TIRE & TECH CO LTD

Rod material precision shear mould

InactiveCN100398239CReduce manufacturing costImprove cutting efficiencyShearing machine accessoriesEngineeringMachine press

A precision shearing die of rod material for press is composed of upper and lower die plates, upper and lower fixed cutter carriers, upper and lower cutting blades, and the upper and lower clamp units consisting of clamping block, clamping spring, screw bolt and fixed block.

Owner:JINXI AXLE CO LTD

Steel-wood combined bridge deck structure and paving method thereof

ActiveCN114000424AHas a buffering effectReduce fatigue damageIn situ pavingsBridge structural detailsFatigue damageArchitectural engineering

The invention belongs to the technical field of bridge engineering, and relates to a steel-wood combined bridge deck structure and a paving method thereof. The steel-wood combined bridge deck structure comprises a steel bridge deck slab, a plurality of U-shaped ribs are evenly distributed and fixed to the bottom end of the steel bridge deck slab, the adjacent U-shaped ribs are arranged at intervals, and a plurality of wood laths are further evenly distributed and fixed to the upper surface of the steel bridge deck slab; the adjacent wood laths are arranged at intervals, and asphalt concrete is laid between the adjacent wood laths and on the upper sides of the adjacent wood laths. Through the structural design, the bridge deck has a certain buffering effect, fatigue damage to the steel bridge deck is reduced, and the asphalt concrete is fixed through the wood laths, so that interlayer separation caused by insufficient interlayer bonding force can be prevented; as the wood laths are relatively flexible materials, a part of shear deformation can be absorbed, and the shear deformation of the bridge deck caused by vehicle braking can be effectively reduced.

Owner:中铁建大桥工程局集团南方工程有限公司 +1

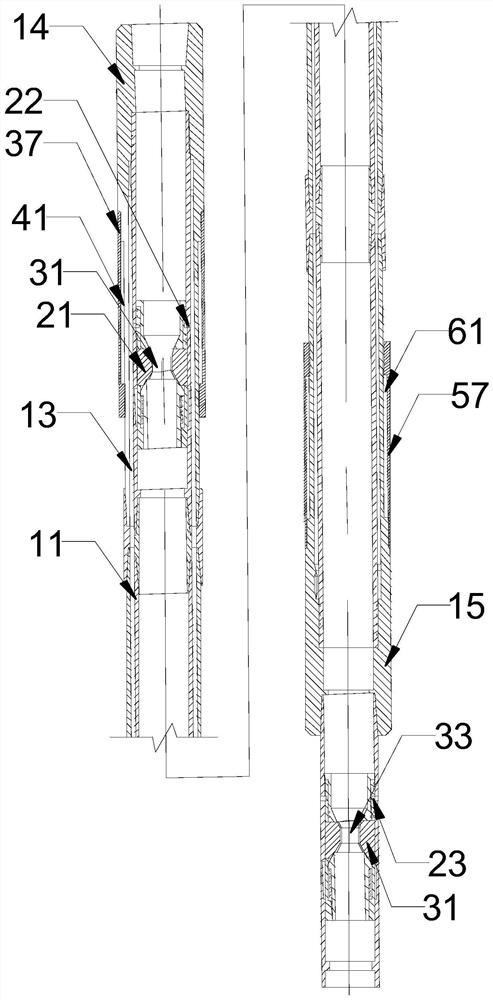

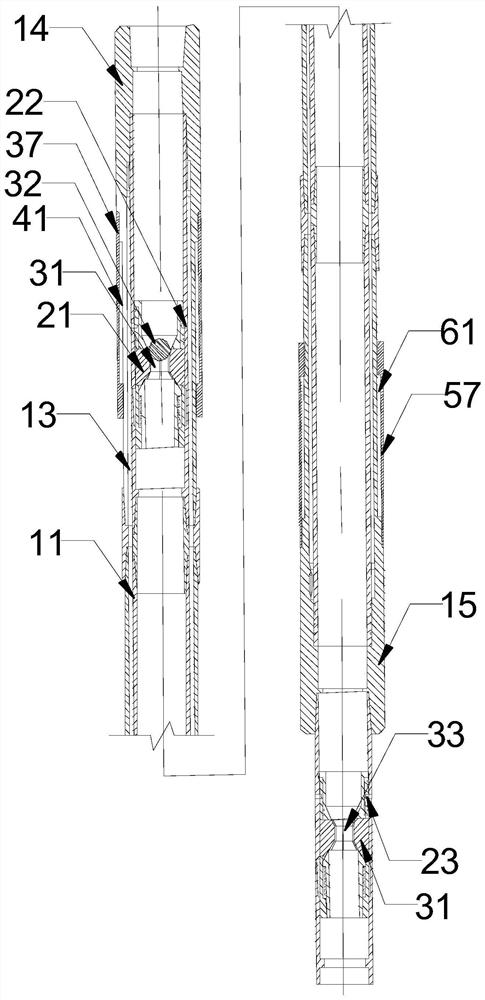

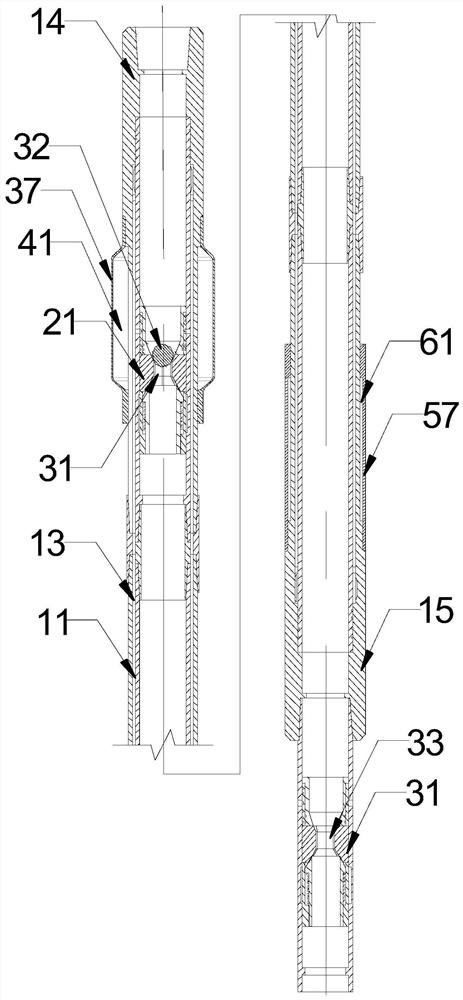

Well cementing device for controlling shear deformation of casing pipes

InactiveCN111852389AReduce shear deformationImproved shear deformation capabilityWell/borehole valve arrangementsSealing/packingWell cementingEngineering

The invention provides a well cementing device for controlling shear deformation of casing pipes. The well cementing device comprises a concentric pipe column, a first packer, a second packer and a control valve system. The concentric pipe column comprises the inner casing pipe and the outer casing pipe. The first packer is connected to the upper end of the concentric pipe column. First through holes are formed in the side wall of the first packer. The second packer is connected to the lower end of the concentric pipe column. Second through holes are formed in the side wall of the second packer. The control valve system comprises a first control valve and a second control valve. The well cementing device for controlling shear deformation of the casing pipes is provided with a first workingstate of sealing a first liquid inlet by the first control valve, a second working state of opening the first liquid inlet by the first control valve, a third working state of opening the first liquid inlet by the first control valve and sealing a second liquid inlet by the second control valve and a fourth working state of opening the first liquid inlet by the first control valve and opening thesecond liquid inlet by the second control valve. The well cementing device for controlling shear deformation of the casing pipes is capable of reducing the shear deformation of the casing pipes.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

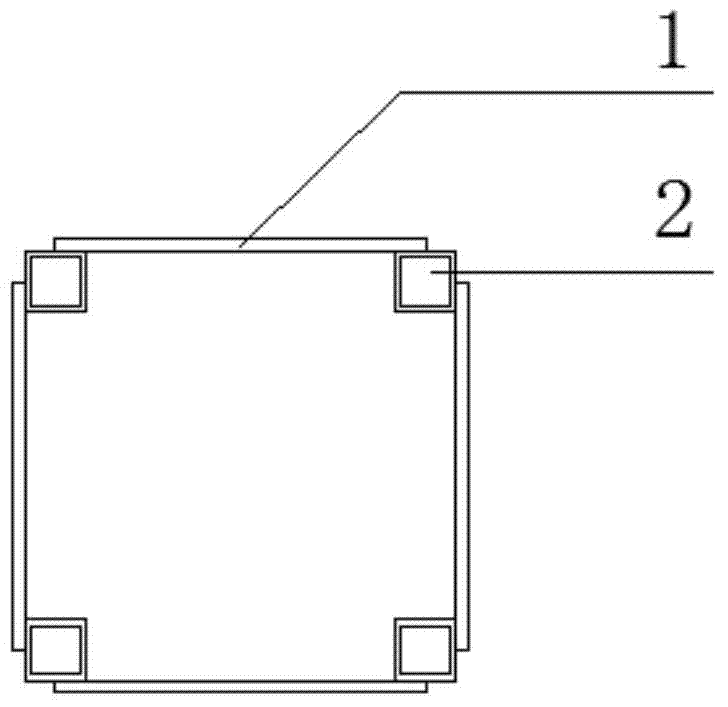

Cellular connection steel plate-four-limb concrete filled steel tube composite column

InactiveCN104234319AReasonable section compositionLight weightStrutsPillarsSheet steelFully developed

The invention discloses a cellular connection steel plate-four-limb concrete filled steel tube composite column which comprises a steel tube limb I, a steel tube limb II, a steel tube limb III, a steel tube limb IV, a steel connection plate I, a steel connection plate II, a steel connection plate III, a steel connection plate IV and concrete, wherein the steel tube limb I, the steel tube limb II, the steel tube limb III and steel tube limb IV are connected together through the steel connection plate I, the steel connection plate II, the steel connection plate III and the steel connection plate IV to form a rectangular section column; the steel tube limb I, the steel tube limb II, the steel tube limb III and steel tube limb IV are internally filled with the concrete; the steel connection plate I, the steel connection plate II, the steel connection plate III and the steel connection plate IV are respectively formed by two steel plates which are provided with gaps at the boundary zones and of the same shape; every two steel plates are welded through butt welds to form each cellular connection plate. According to the cellular connection steel plate-four-limb concrete filled steel tube composite column, the materials in two main shaft directions can be fully developed, so that the dosage of the steel is reduced and the comprehensive cost of the projects is lowered.

Owner:NANJING UNIV OF TECH

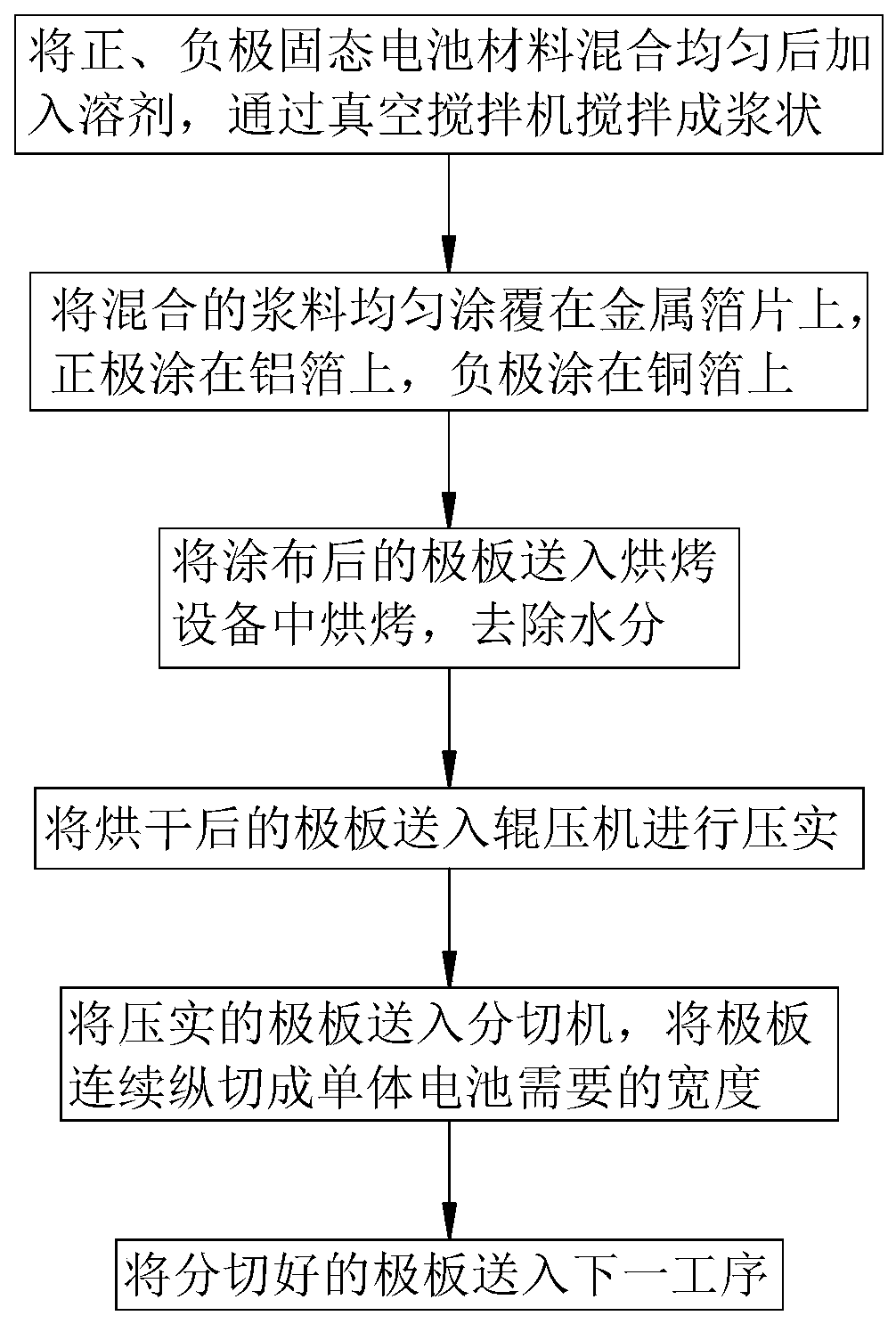

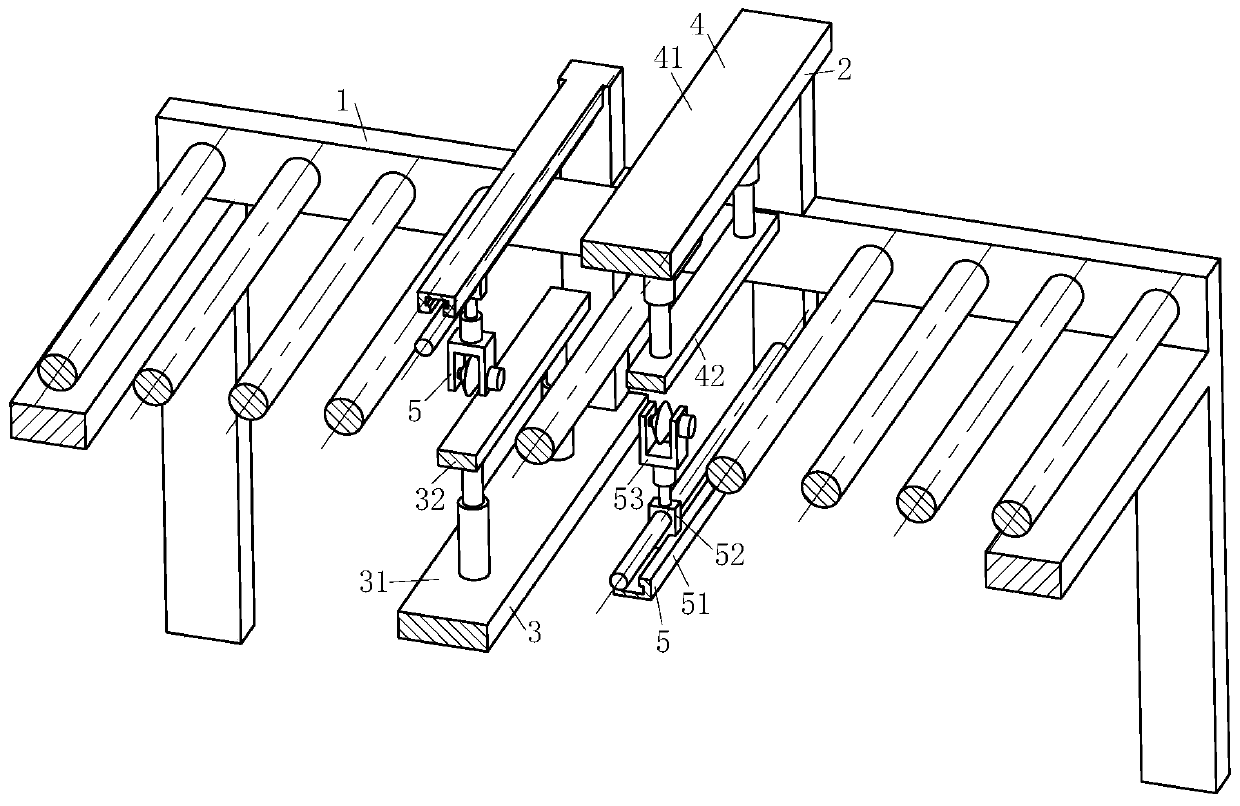

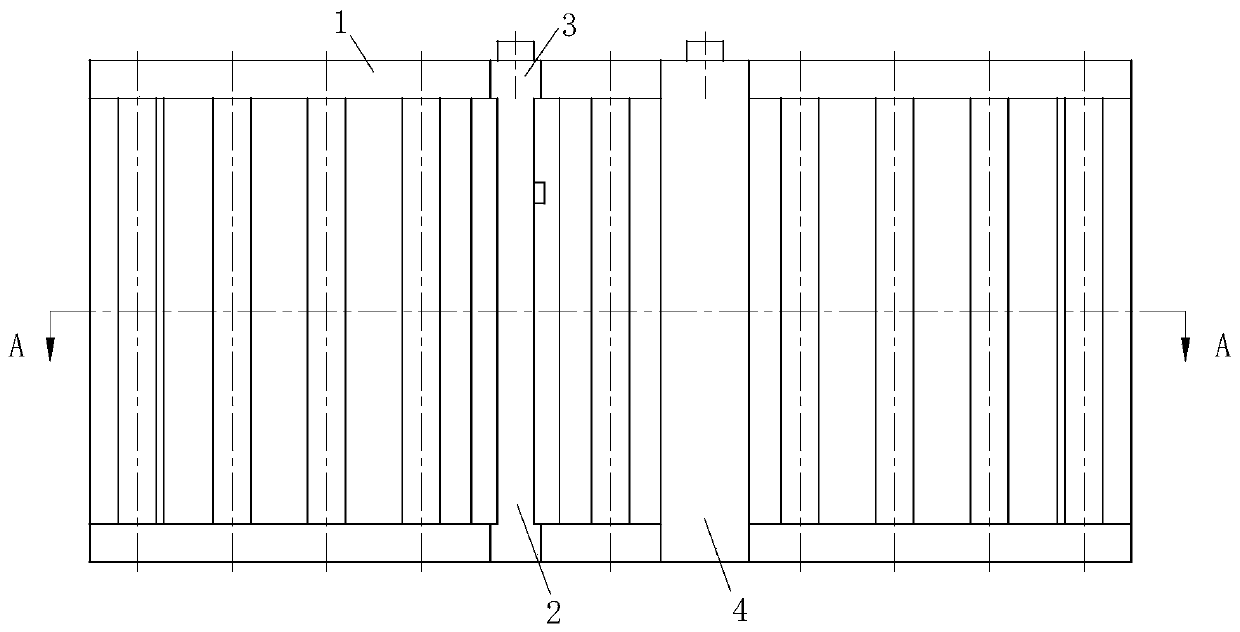

A kind of lithium battery production process

ActiveCN108511808BReduce shear deformationQuality improvementFinal product manufactureElectrolyte accumulators manufactureShearing deformationPetroleum engineering

The invention belongs to the technical field of lithium batteries, and specifically relates to a lithium battery production process. The process uses a slitting machine, the slitting machine includes a workbench and a shearing mechanism, and the shearing mechanism includes a primary cutting unit and a re-cutting unit; The initial cutting unit is set in the middle of the workbench. The initial cutting unit includes the lower support plate, the lower pressing plate and the cutting assembly. The initial cutting unit is used to score the pole plate; On the table; the re-cutting unit includes an upper support plate, an upper pressing plate and a cutting assembly. The re-cutting unit is used to cut off the pole plate. There is a notch at the bottom of the upper pressing plate, and an adjusting unit is arranged in the notch; the adjusting unit includes a left slider, Right slider and lead screw. The invention adopts the method of notching one side of the polar plate first, and then cutting from the other side of the polar plate, so as to reduce the amount of shearing deformation of the polar plate, improve the quality of the polar plate slice, and avoid the winding leakage of the subsequent polar plate, and the positive and negative Pole contact causes an internal short circuit.

Owner:自贡市泰威科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com