Prestressed segment assembled pier with SMA energy-consuming reinforcing steel bars at bottom and assembling method

An energy-dissipating steel bar and prestressing technology, which is applied in the field of prestressed section assembled bridge piers and assembly, can solve the problems of excessive opening of the joint at the bottom of the pier, damage to the concrete at the foot of the column at the bottom concrete section, and poor energy dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

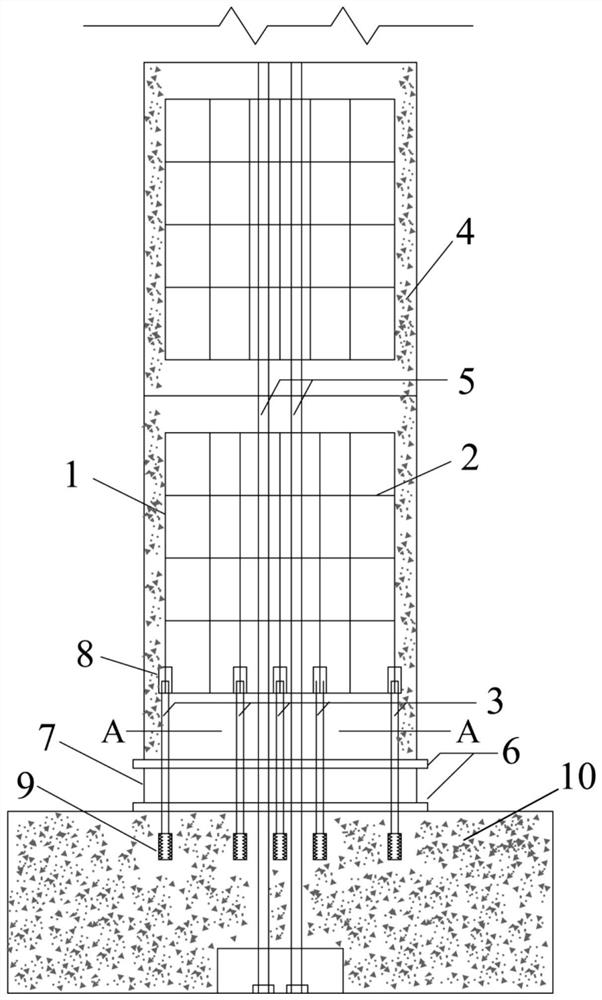

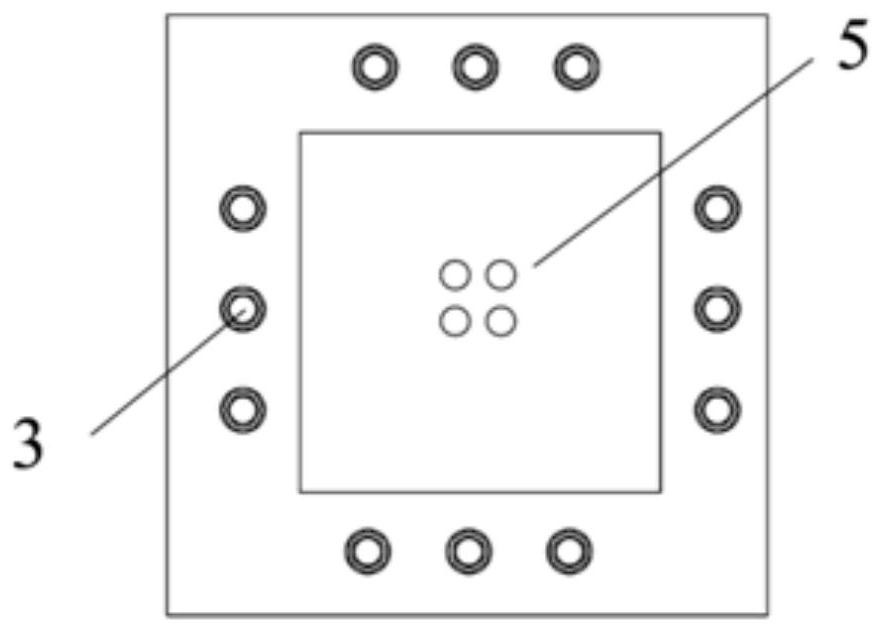

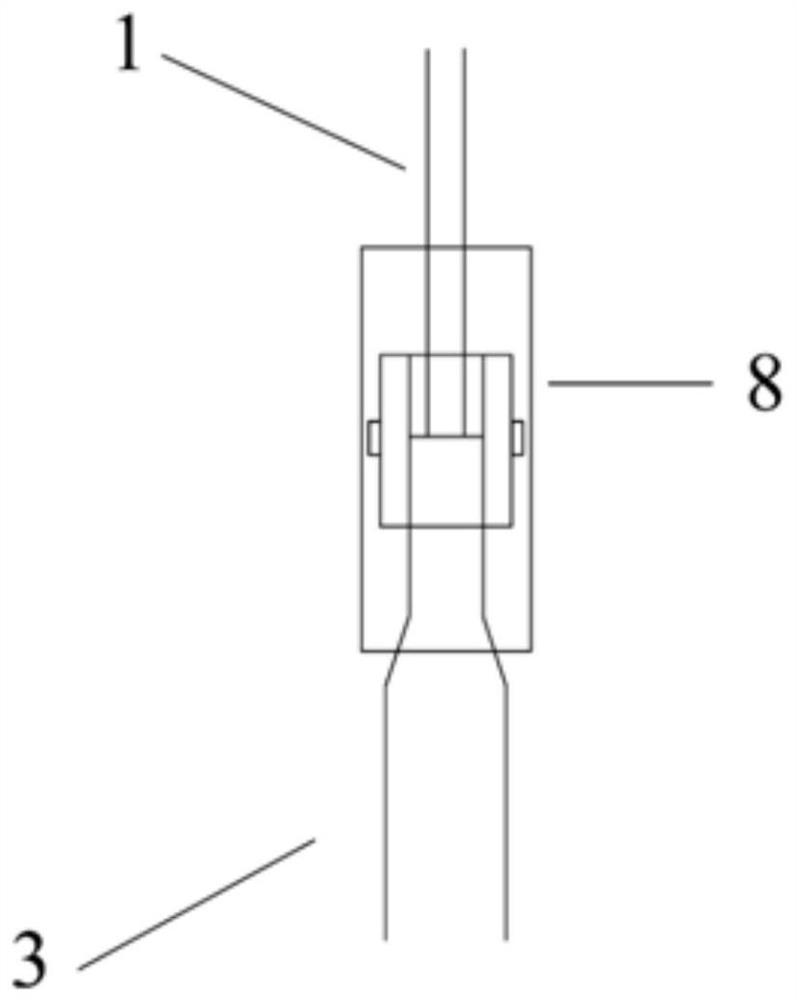

[0023] The following is attached with the manual Figure 1-3 A specific implementation of the prestressed section assembled bridge pier with SMA energy-dissipating steel bars at the bottom of the present invention is described:

[0024] as attached figure 1 As shown, the present invention provides a prestressed section assembled bridge pier with SMA energy-dissipating steel bars at the bottom, which mainly includes: longitudinal bars 1, horizontal stirrups 2, SMA energy-dissipating bars 3, hollow concrete sections 4, and prestressed bars 5 , Steel backing plate 6, rubber pad 7, steel bar connector 8, anchoring device 9 and platform 10.

[0025] The bearing platform 10 is fixed on the ground, a rubber pad 7 is placed on the bearing platform 10, and a steel backing plate 6 is respectively placed on the upper and lower sides of the rubber pad. and the SMA energy-dissipating steel bar 3 quantity and position leave the channel.

[0026] The bottom hollow concrete segment 4 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com