Anti-seismic toughness plant structural system comprehensively adopting seismic isolation and absorption technologies

A technology of workshops and technologies, applied in earthquake-proof, building components, industrial buildings, etc., can solve problems such as poor earthquake-resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

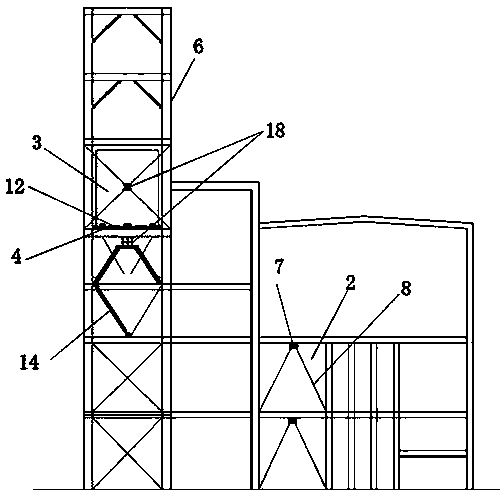

[0033] Example 1 as figure 1 , 2 As shown in and 3, the anti-seismic and resilient plant structure system of this embodiment comprehensively adopts the shock-absorbing technology, mainly including a large mass ratio tuned mass damper 1 connected to the main structure of the plant and an energy-dissipating sub-frame 2 containing the damper.

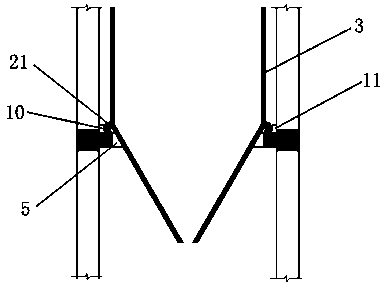

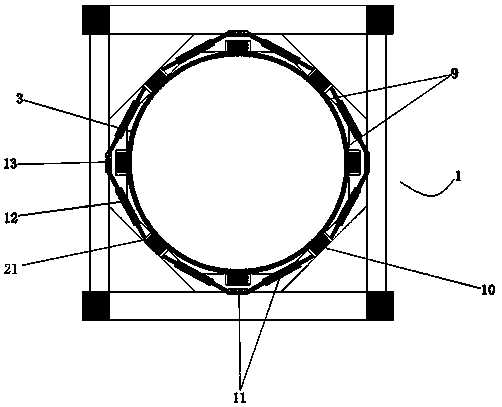

[0034]Through the design, the coal hopper equipment in thermal power plants is designed as a large mass ratio tuned mass damper 1, which mainly includes a coal hopper 3, an isolation layer 4, and a support system 5. Wherein the coal hopper seismic isolation layer 4 includes a horizontal seismic isolation support 10 and a horizontal limiting device 11 . Support system 5 comprises polygonal planar frame structure 9, and the number of sides of polygonal planar frame structure 9 depends on specific circumstances, and polygonal planar frame structure 9 is an octagon in the present embodiment, as image 3 shown. Each side of the polygonal pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com