Bowl type rubber diaphragm for accumulator

A technology of rubber diaphragms and accumulators, applied in the direction of diaphragms, mechanical equipment, etc., can solve problems such as joint edge damage and peeling, trouble technicians, failure, etc., to reduce shear deformation, avoid shear deformation, and improve efficiency. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

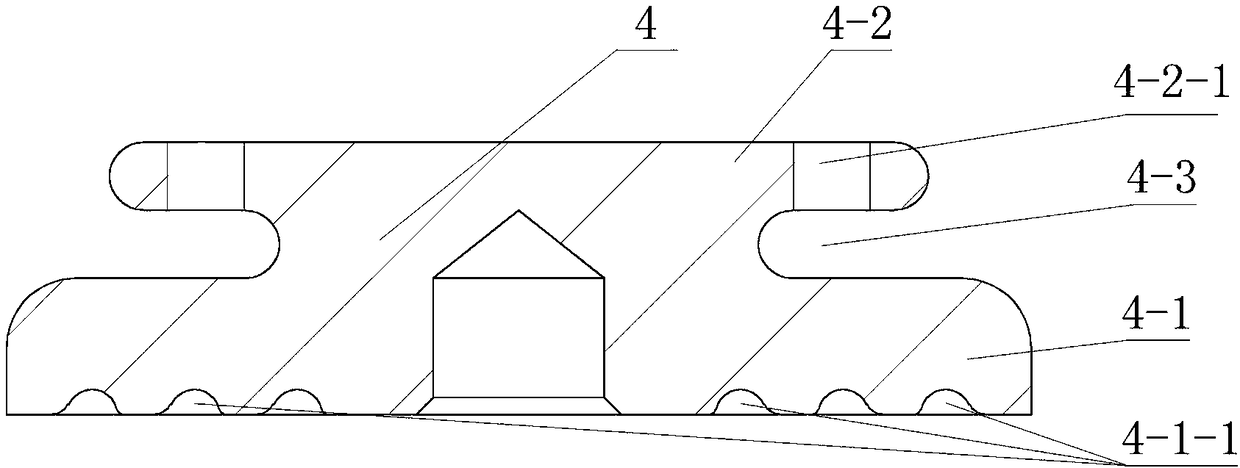

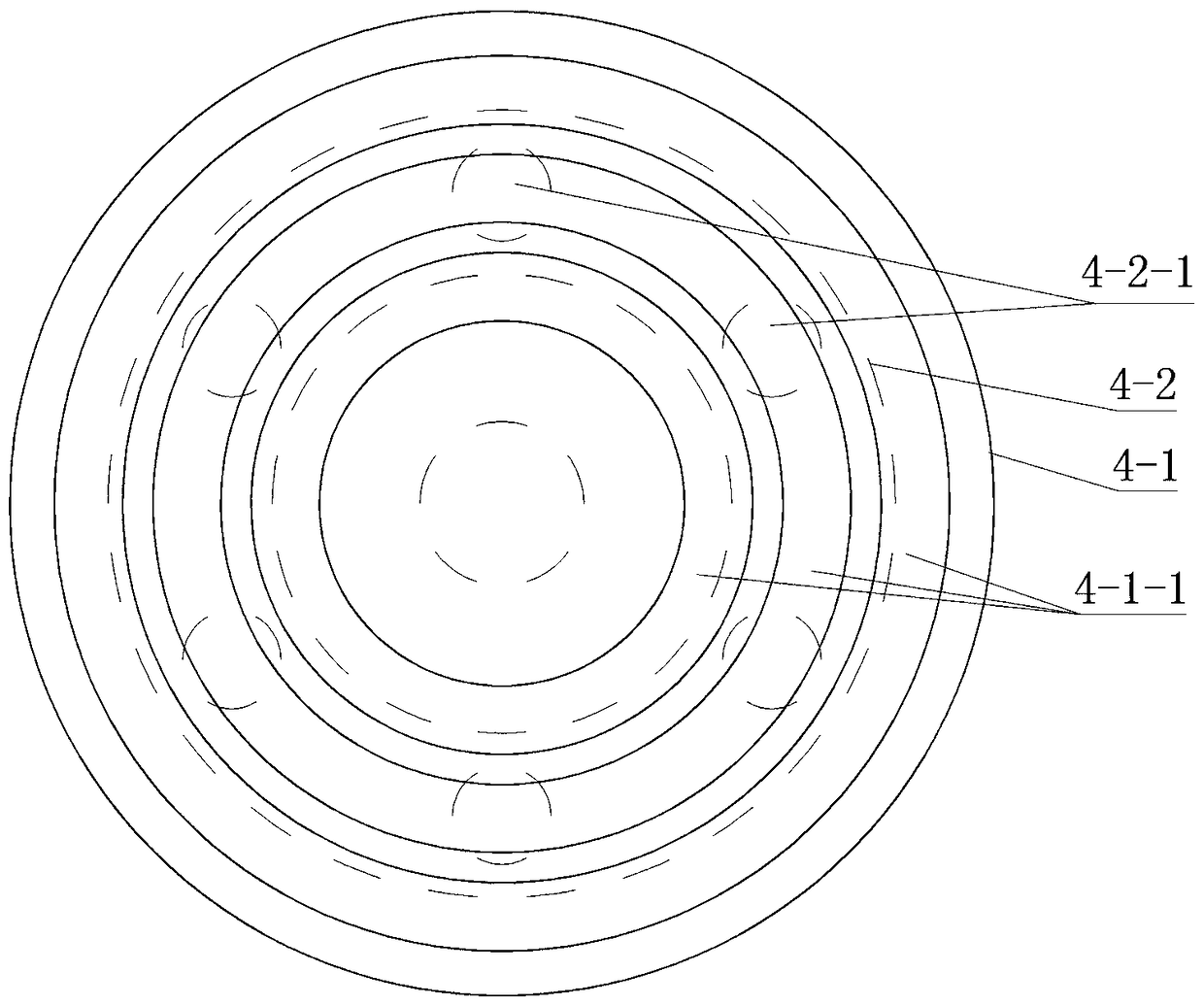

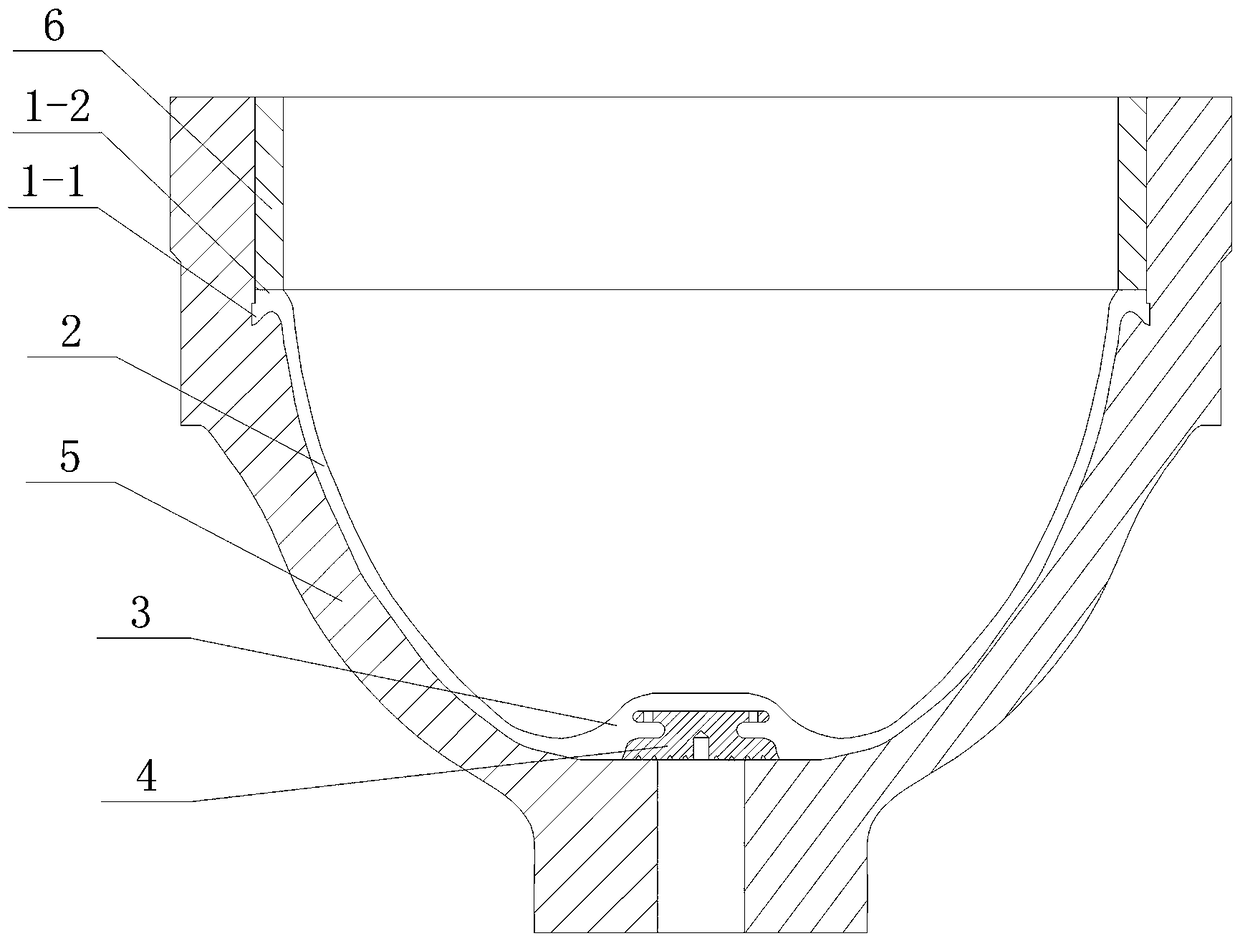

[0020] A bowl-shaped rubber diaphragm for an accumulator, referring to the accompanying drawings, includes a bowl mouth seal 1, a thickened bowl bottom, and an arc-shaped bowl wall 2 connected between the sealed bowl mouth and the thickened bowl bottom. The vertical section at the bottom of the thickened bowl is in the shape of a circular platform 3, and the side surfaces of the circular platform 3 and the inner surface of the arc-shaped bowl wall 2 are smoothly and evenly transitioned to form an arc surface. The bottom of the thickened bowl is inlaid with a special-shaped buffer chip 4 whose vertical section is an "inverted tray type". The buffer chip 4 is made of space aluminum, including a circular bottom support 4-2, a tray 4-1 and an annular groove 4-3 arranged between the two parts, a tray 4-1, an annular groove 4-3 and a bottom support 4-2 The junction with the rubber is arc-shaped. Six positioning buffer holes 4-2-1 are evenly distributed circularly along the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com