Patents

Literature

45results about How to "Avoid shear stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

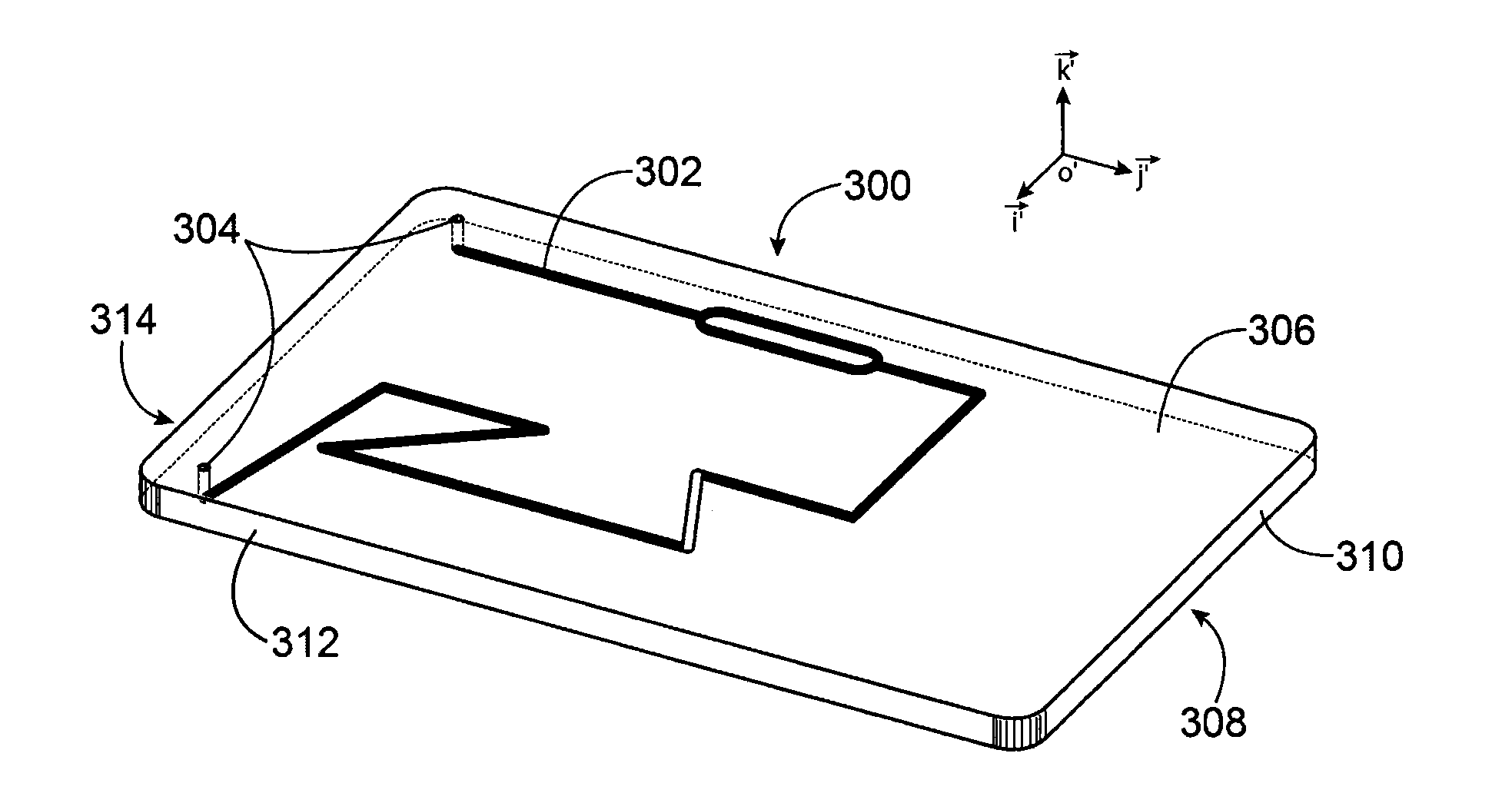

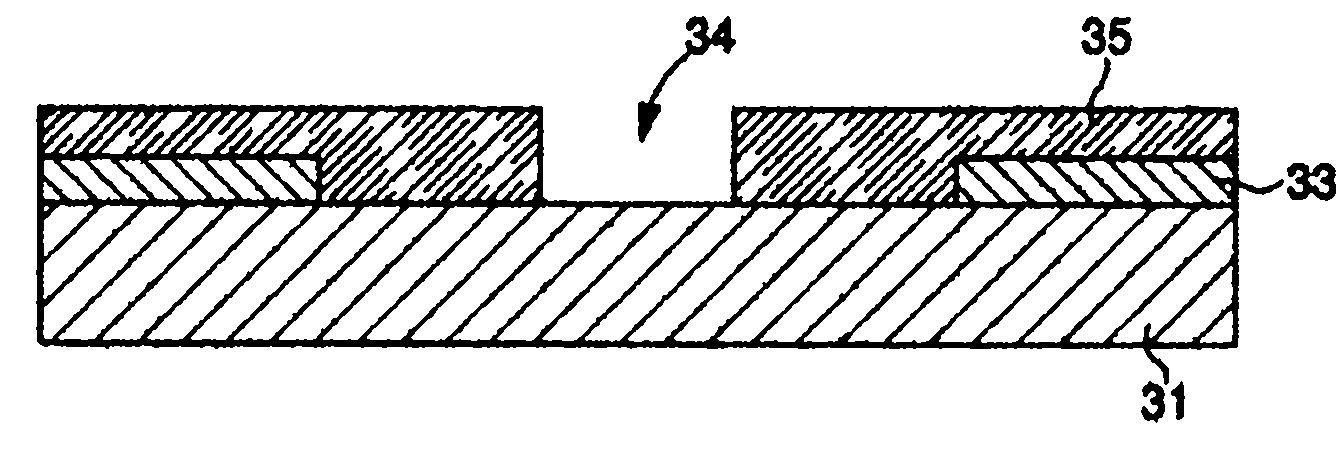

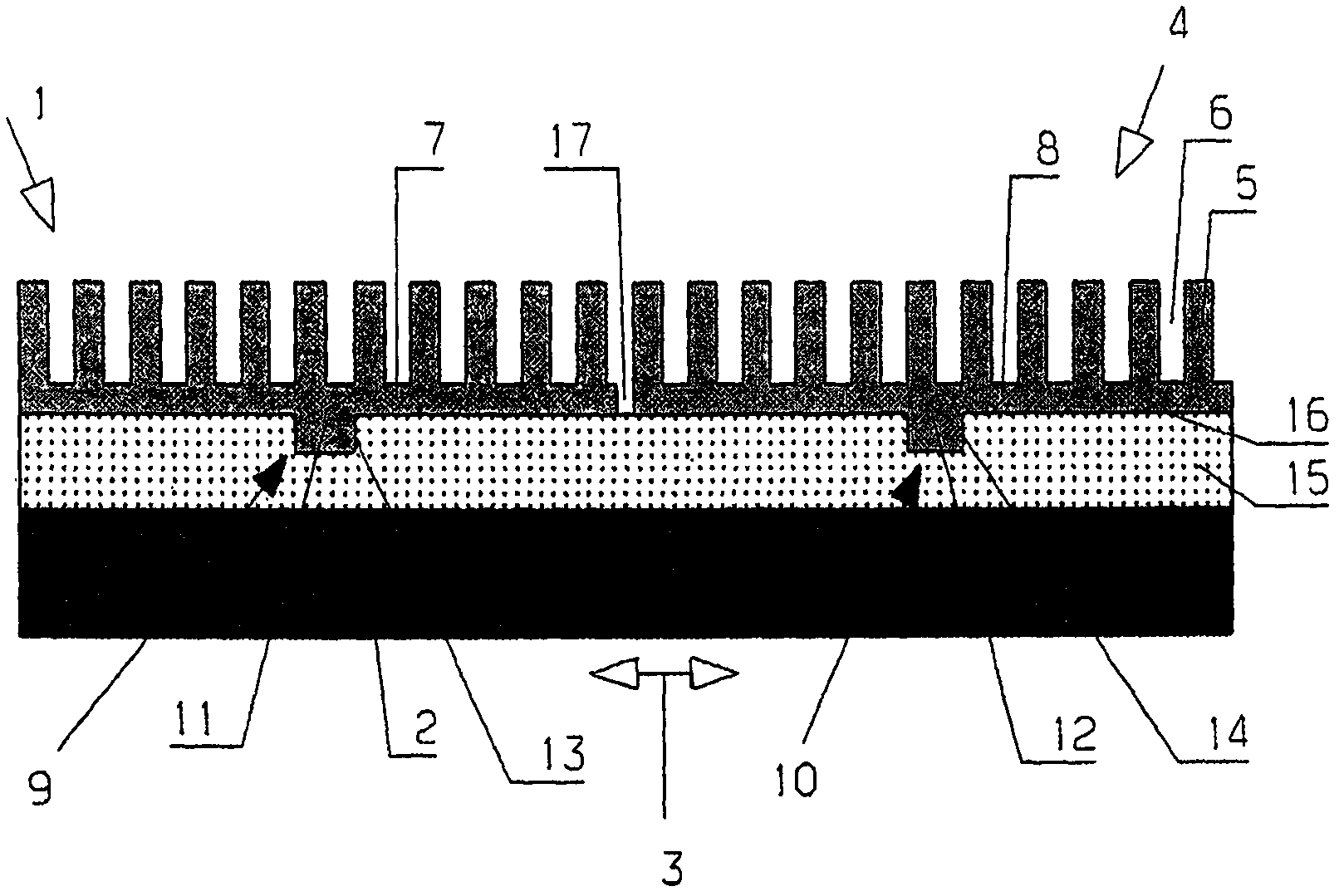

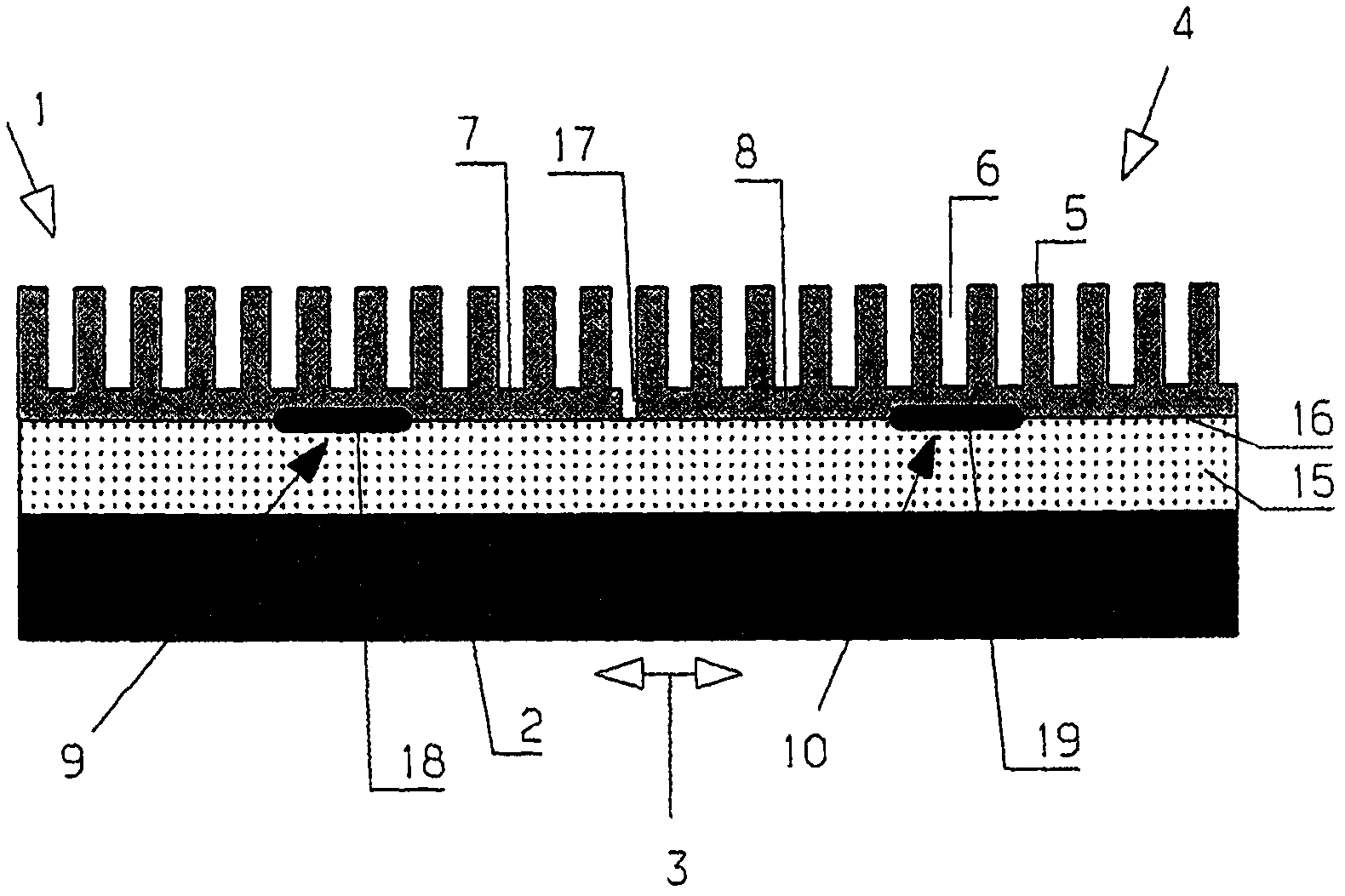

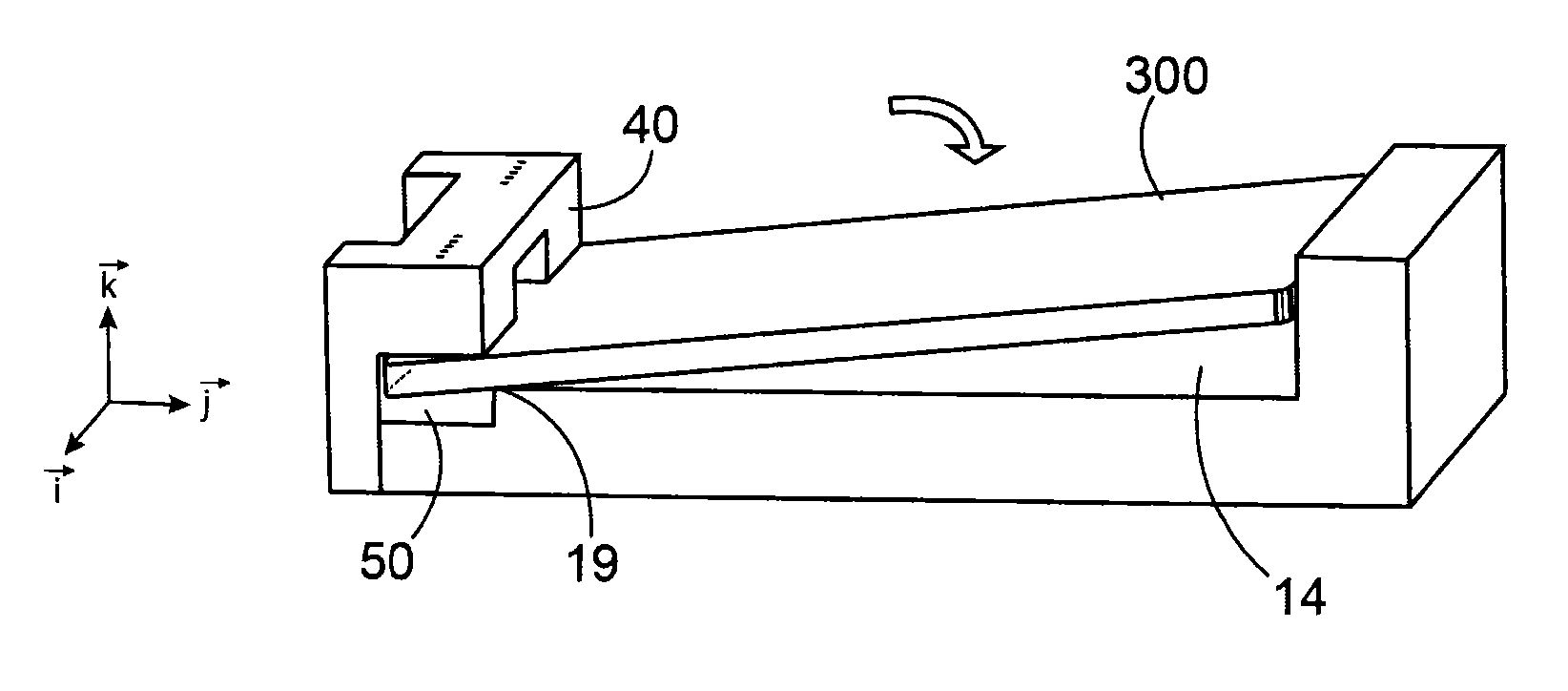

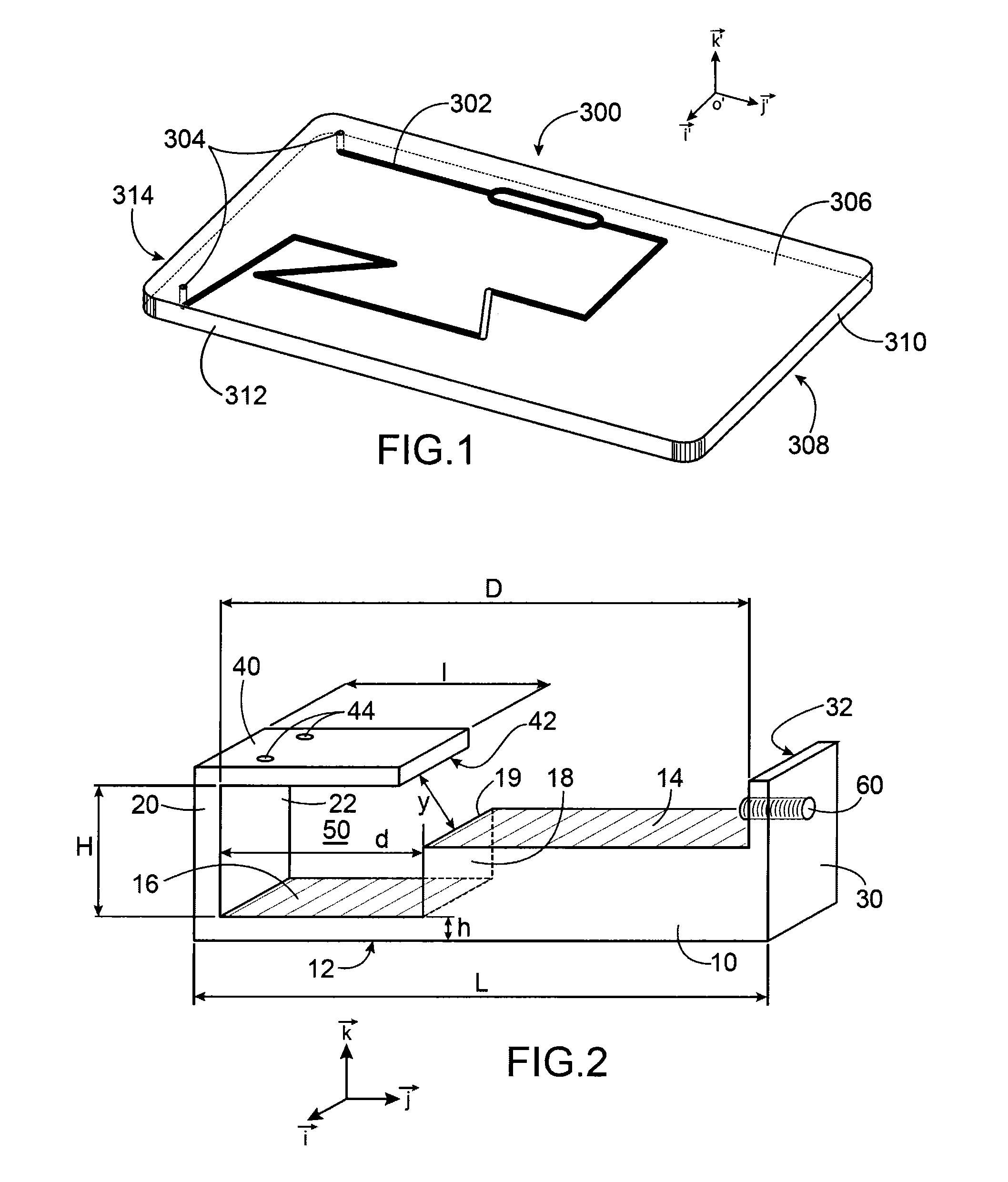

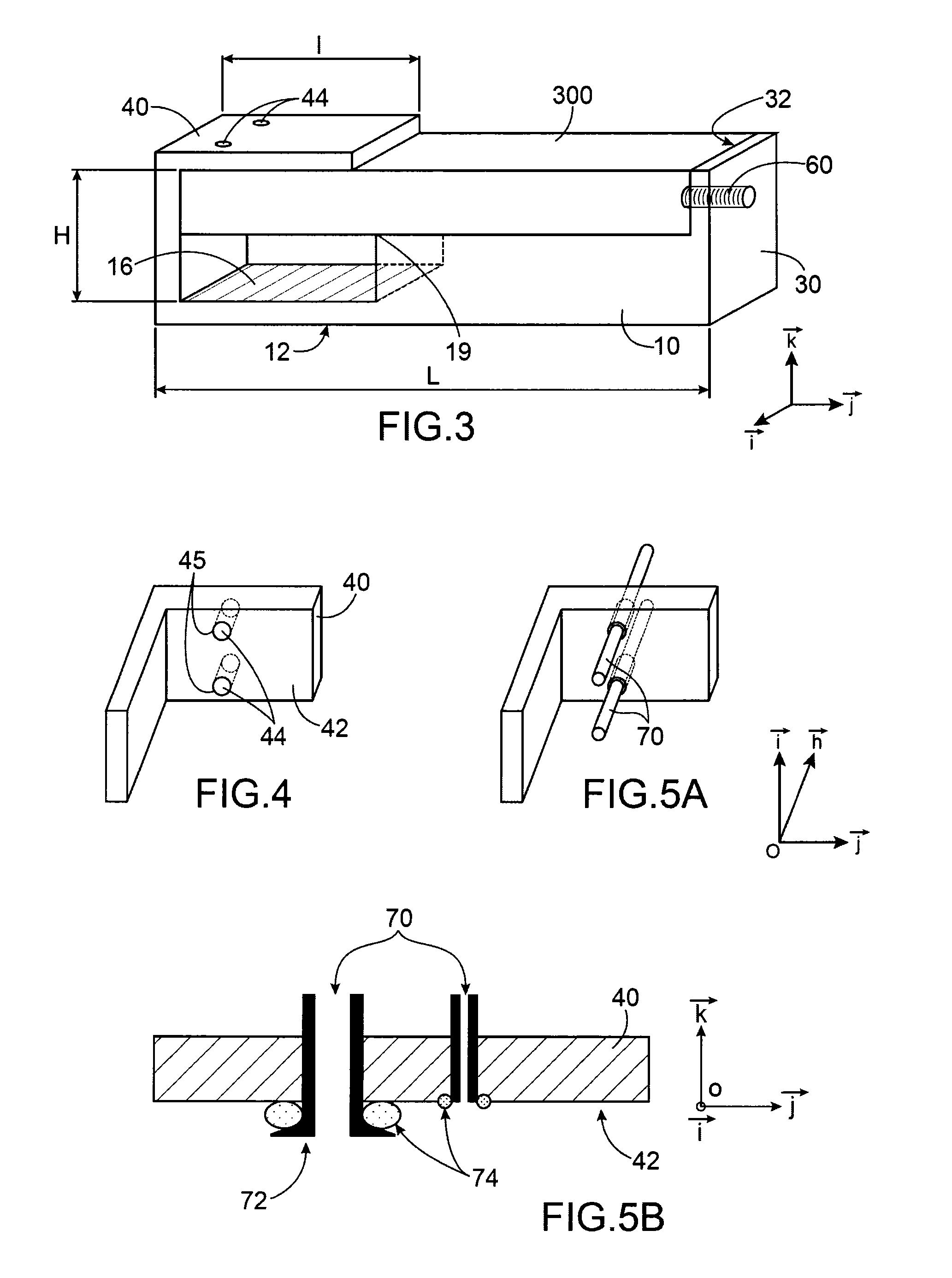

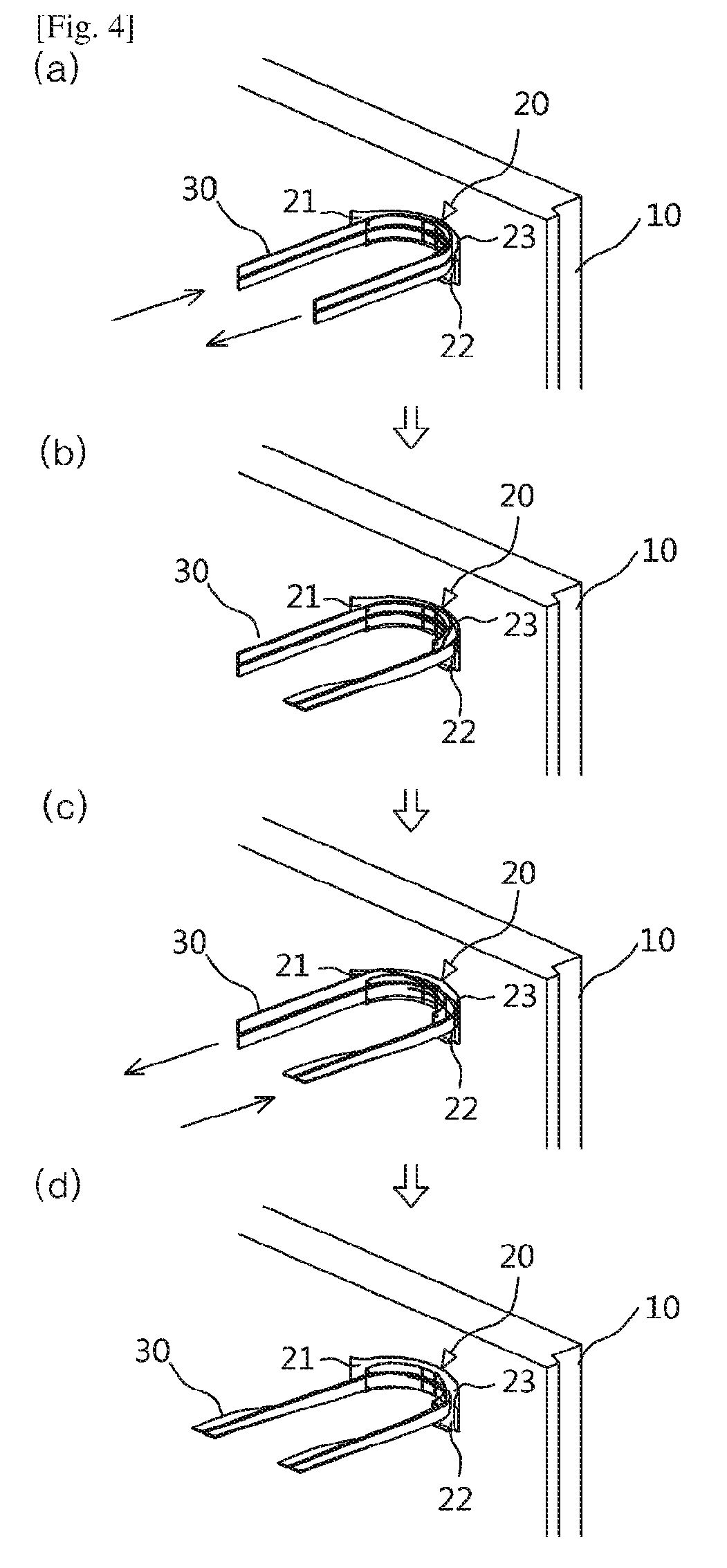

Microfluidic card connection device

ActiveUS20140037515A1Avoid shear stressEasy to introduceWave amplification devicesLaboratory glasswaresEngineeringInterconnection

A device for interconnecting a card including at least one first fluid channel, emerging from a connection side parallel to a support side, the interconnection device including: a first surface configured to receive the support side of the card; a second surface parallel to the first surface, from which a second fluid channel emerges; and a mechanism to hold the card in place, configured to hold a connection side of the card pressed against the second surface of the device, such that first fluid channel is in fluid connection with the second fluid channel.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

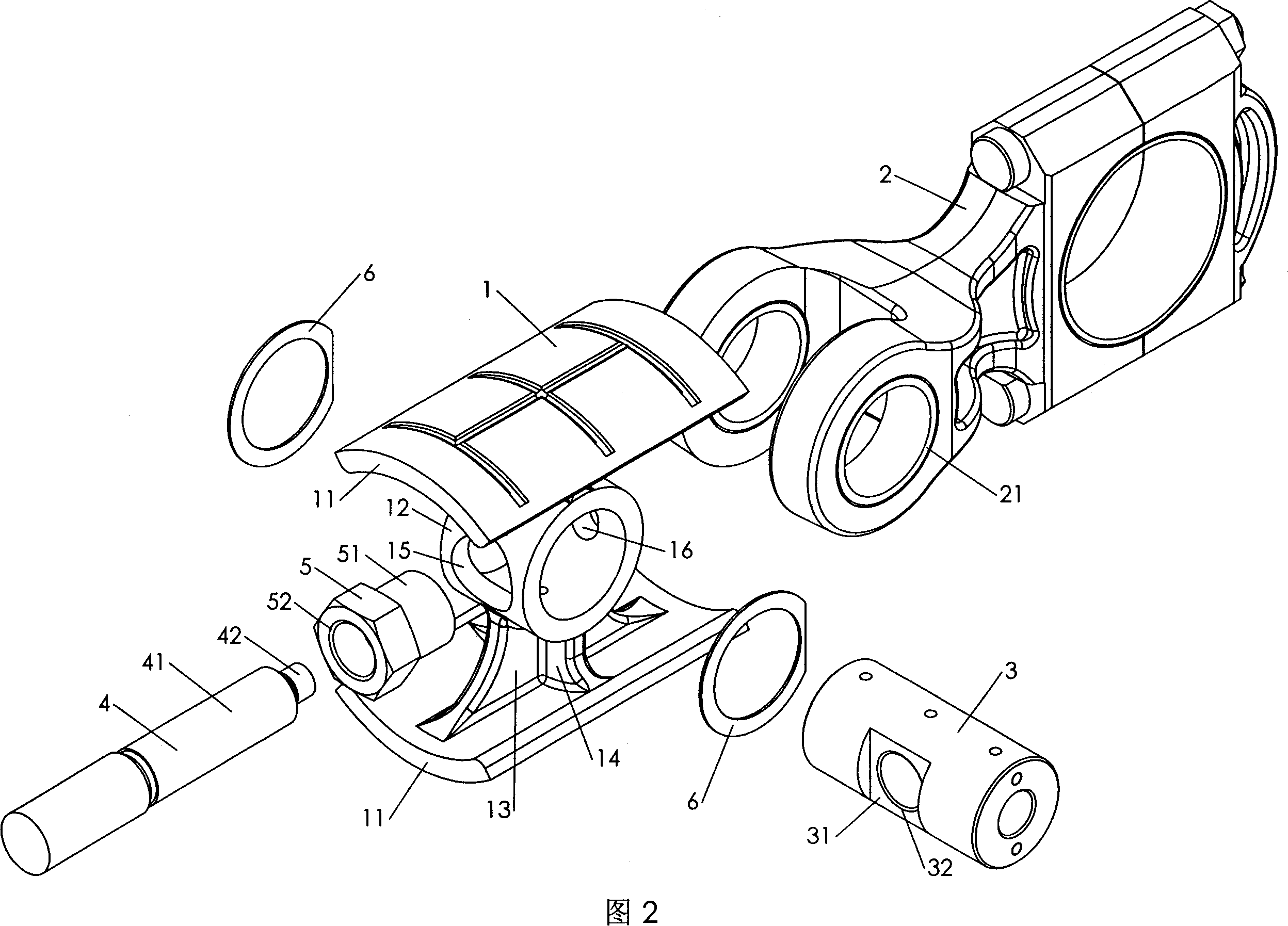

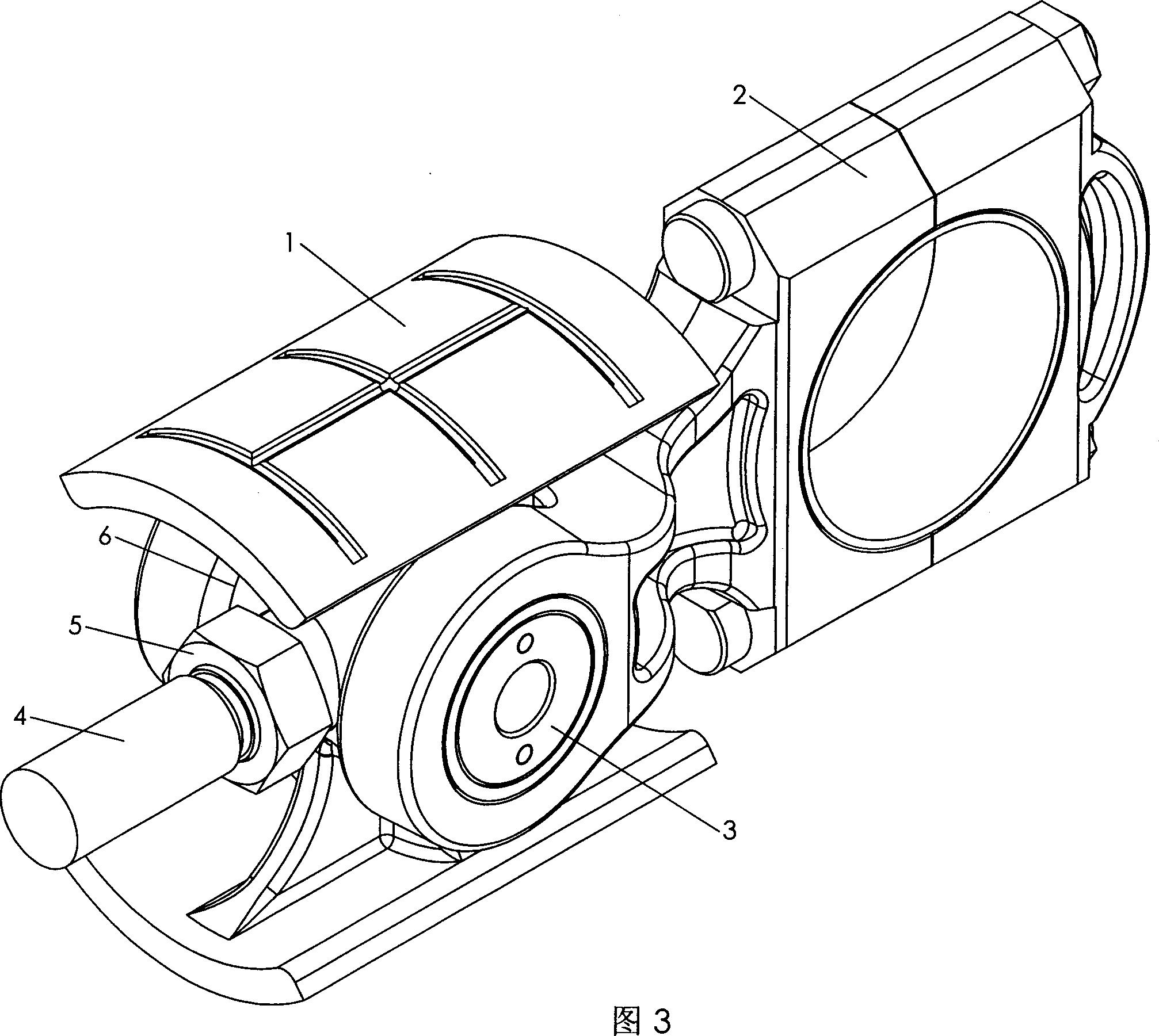

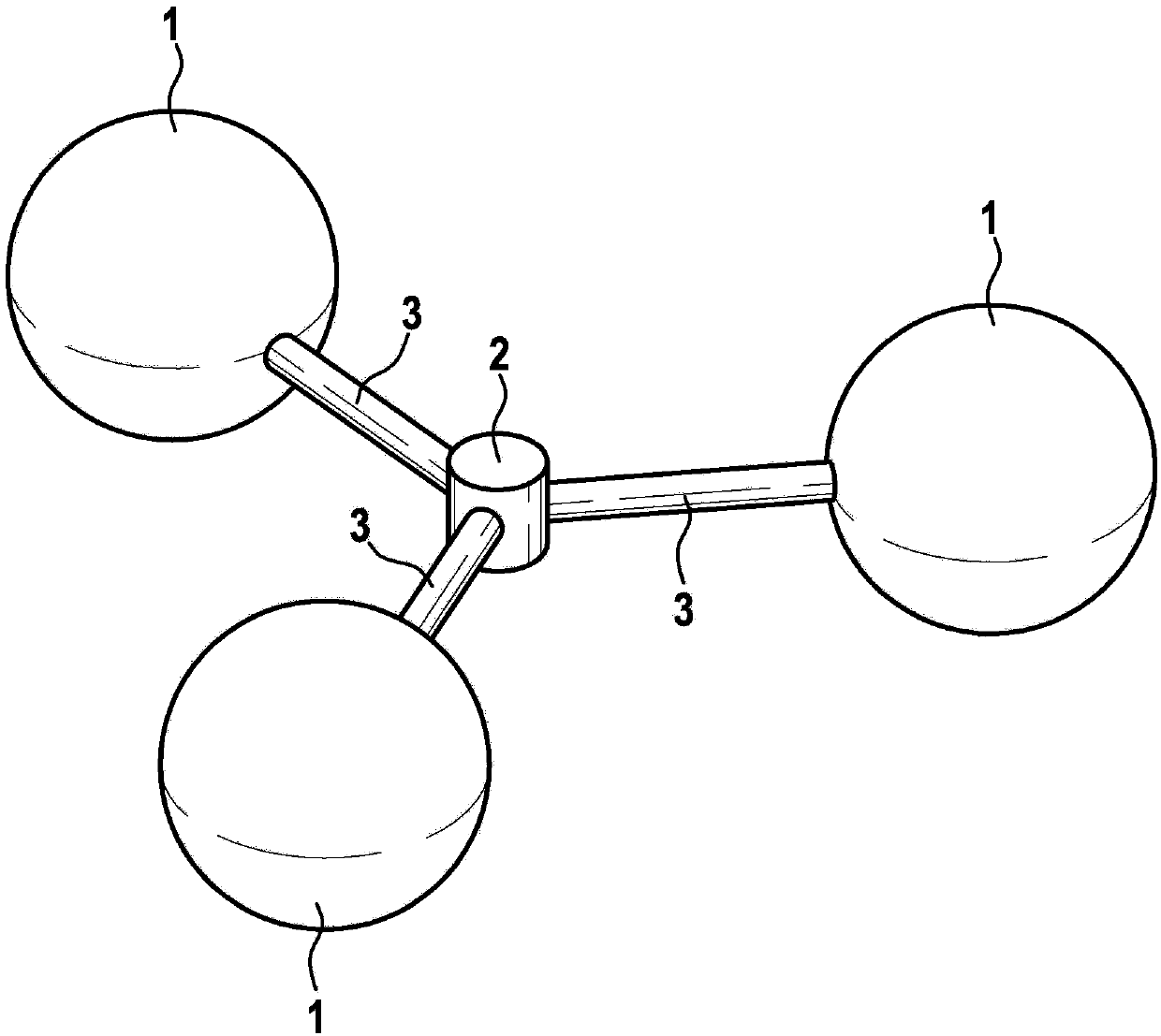

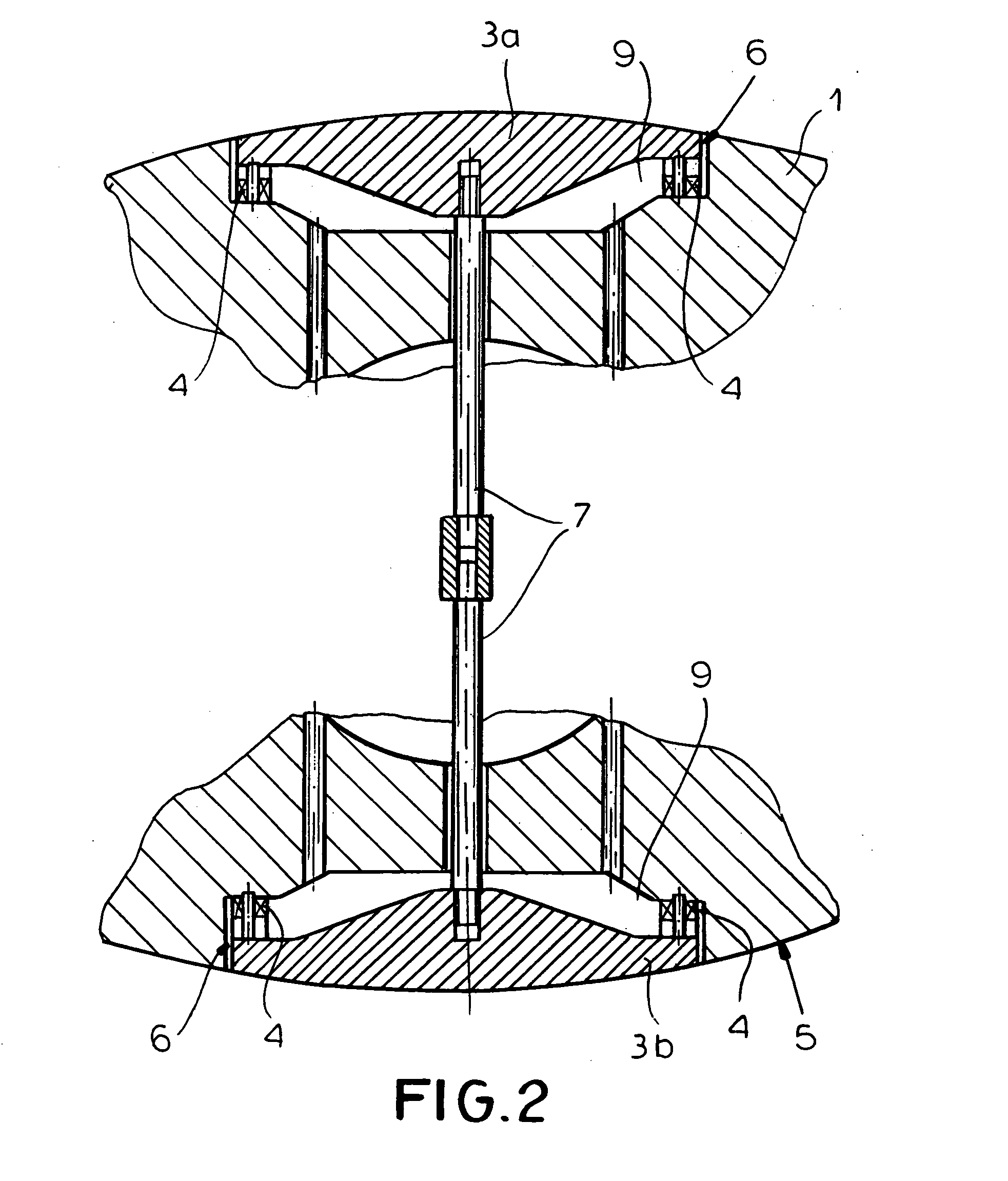

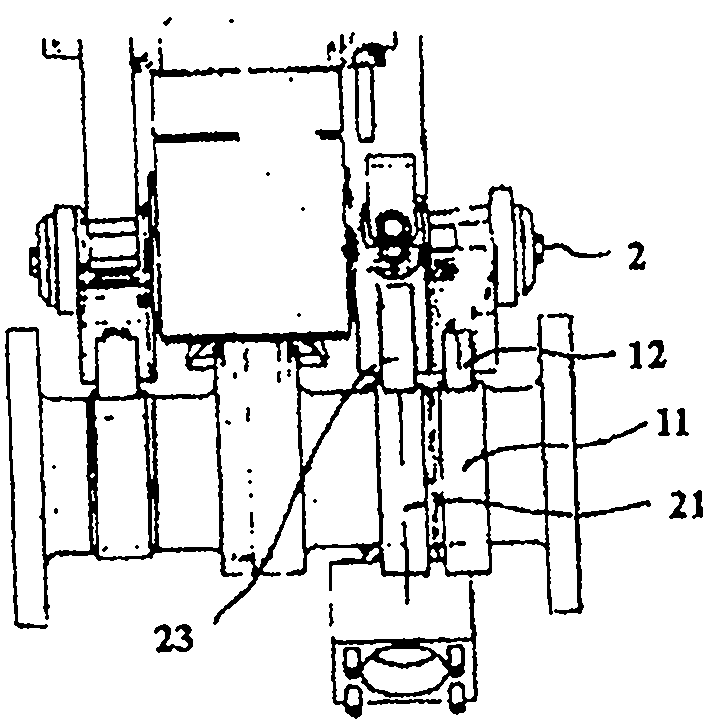

Cross head of crank rod type piston compressor

InactiveCN1445463AReduced strength requirementsEasy to manufactureCrossheadsMulti-stage pumpsCross-linkCoupling

A cross-linked coupling for crank-connecting rod piston compressor is disclosed. A short cylindrical cross pin with screwed through hole perpendiculart to its basic line is used to pivot a cross bodyhaving a single pin hole seat to the connecting rod with smaller fork end. Said pin hole seat has two through holes coaxial with the sliding cylindrical surface. The piston rod whose end has externalscrew passes through the bigger hole on pin hole seat and then is turned into the screwed through hole on cross pin. A short cylinder at the end is inserted in another hole to locate the cross-linkedcoupling. A cross nut has a cylindrical end, which is also inserted said bigger hole to lock the piston rod to the cross-linked coupling.

Owner:XI AN JIAOTONG UNIV

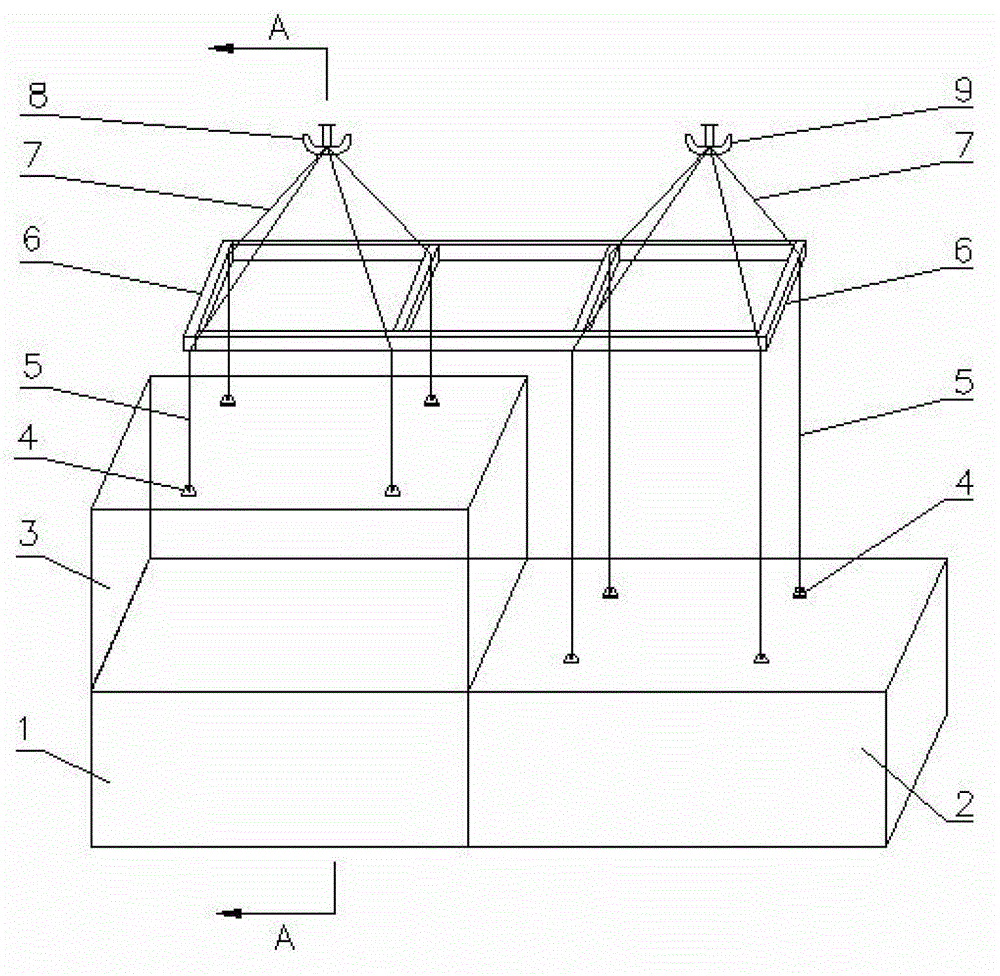

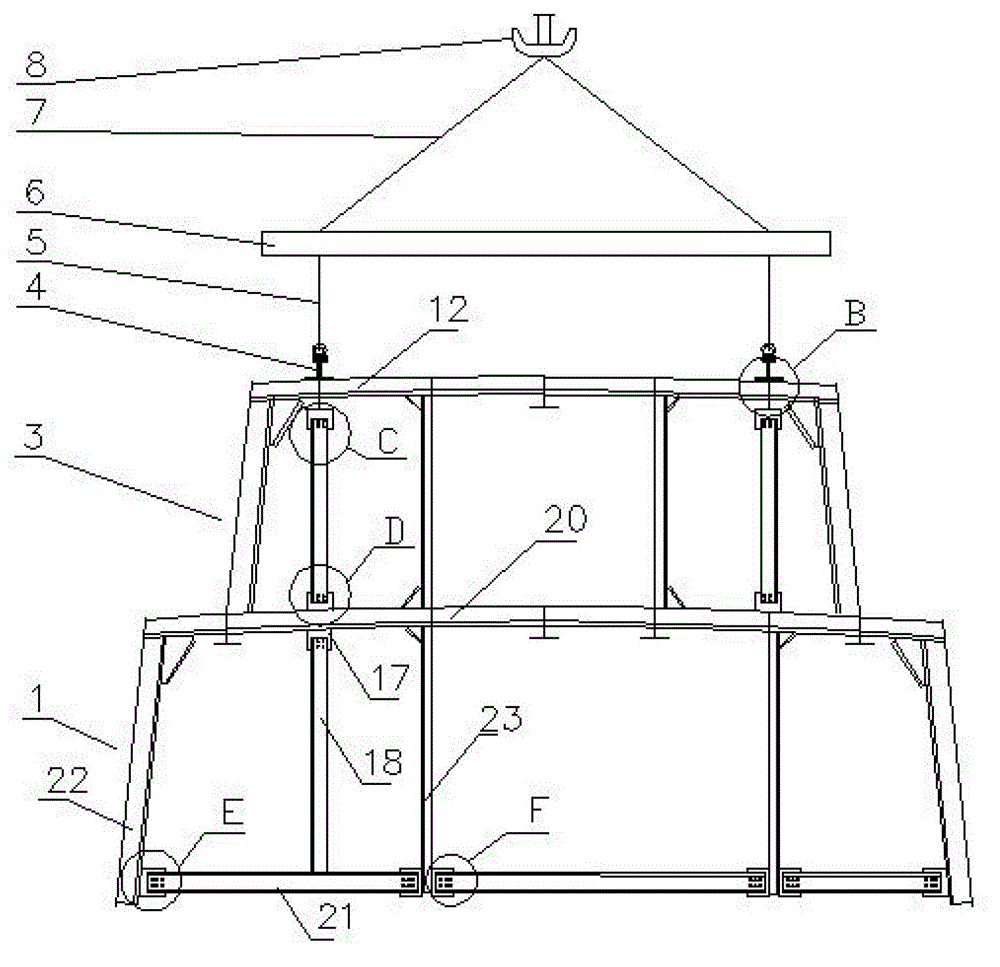

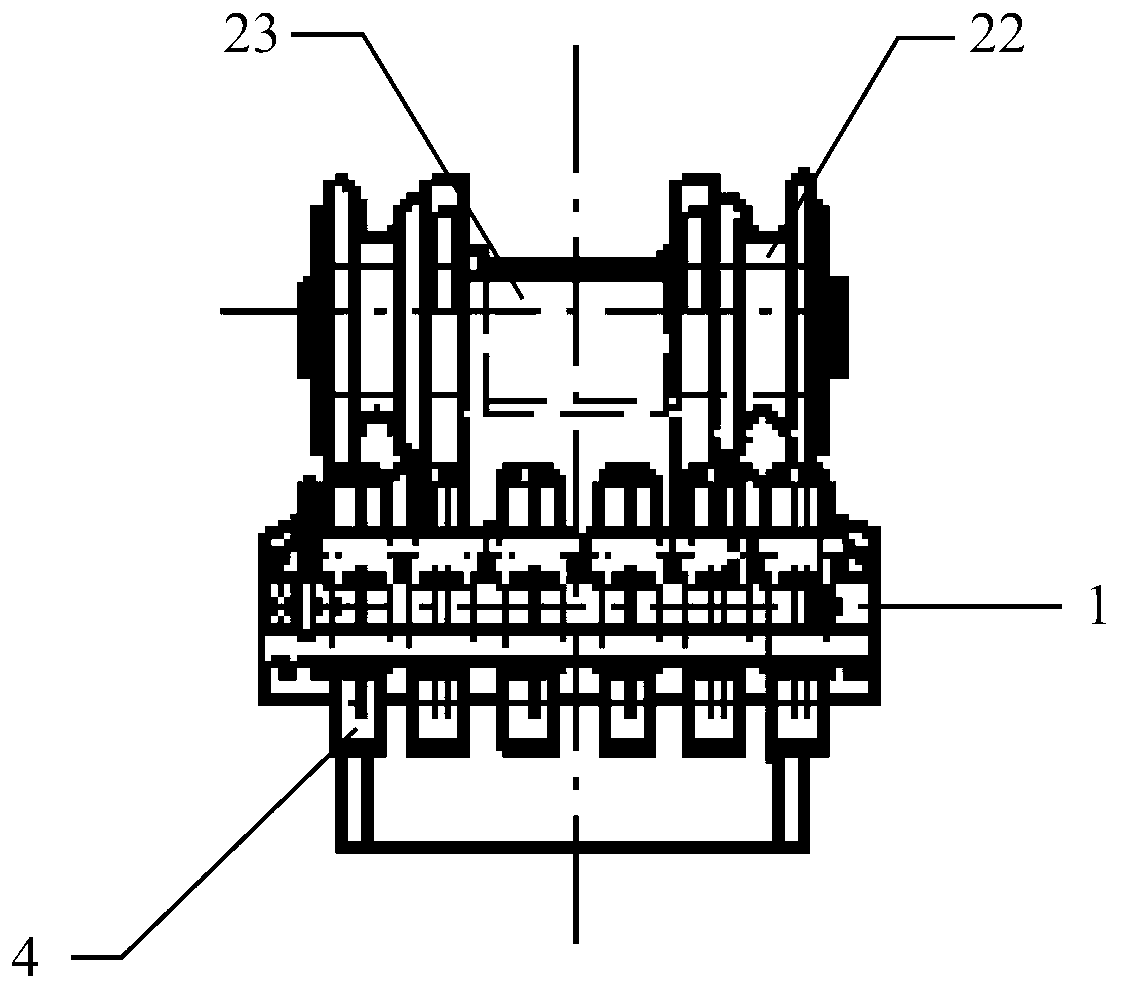

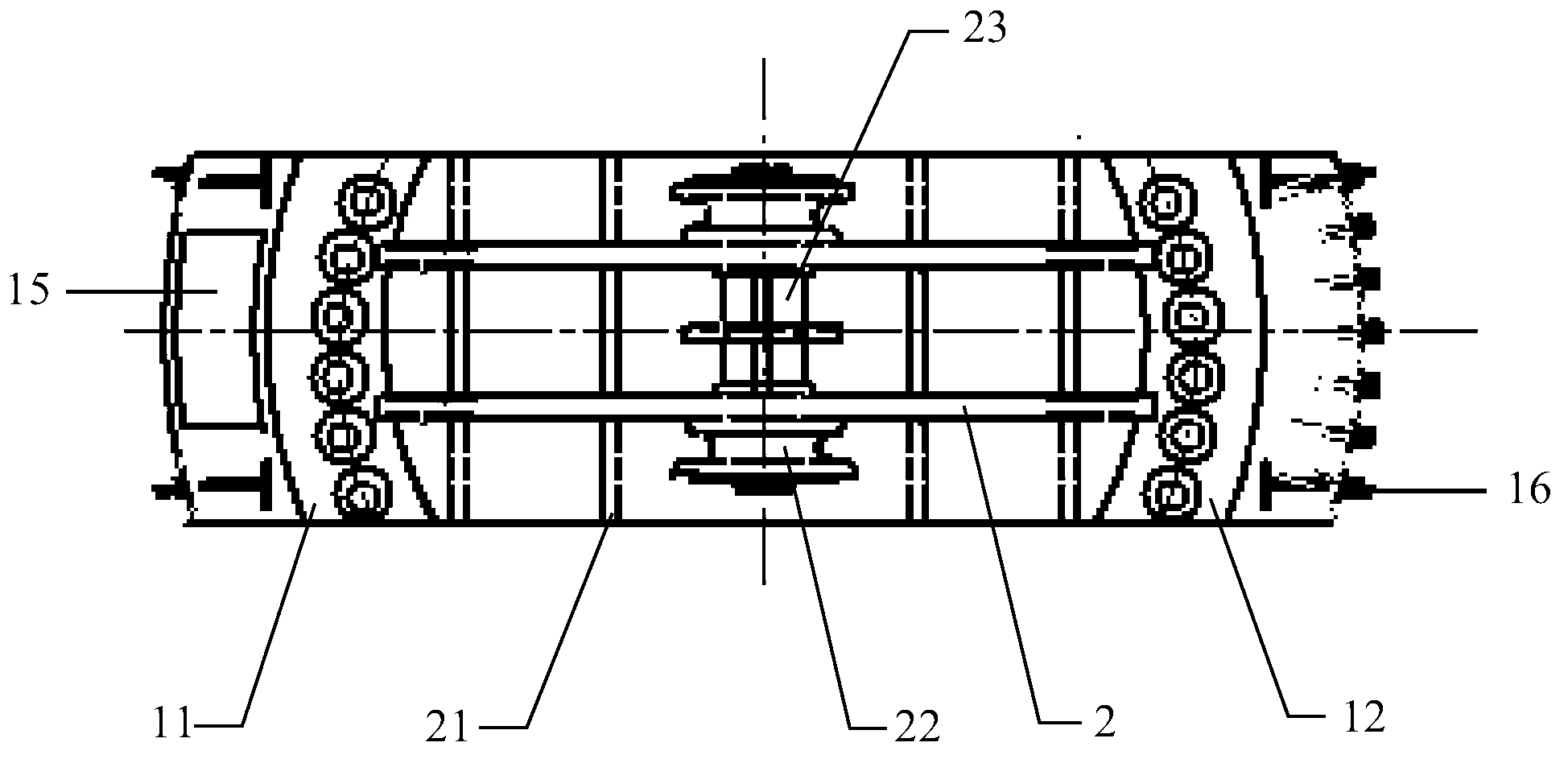

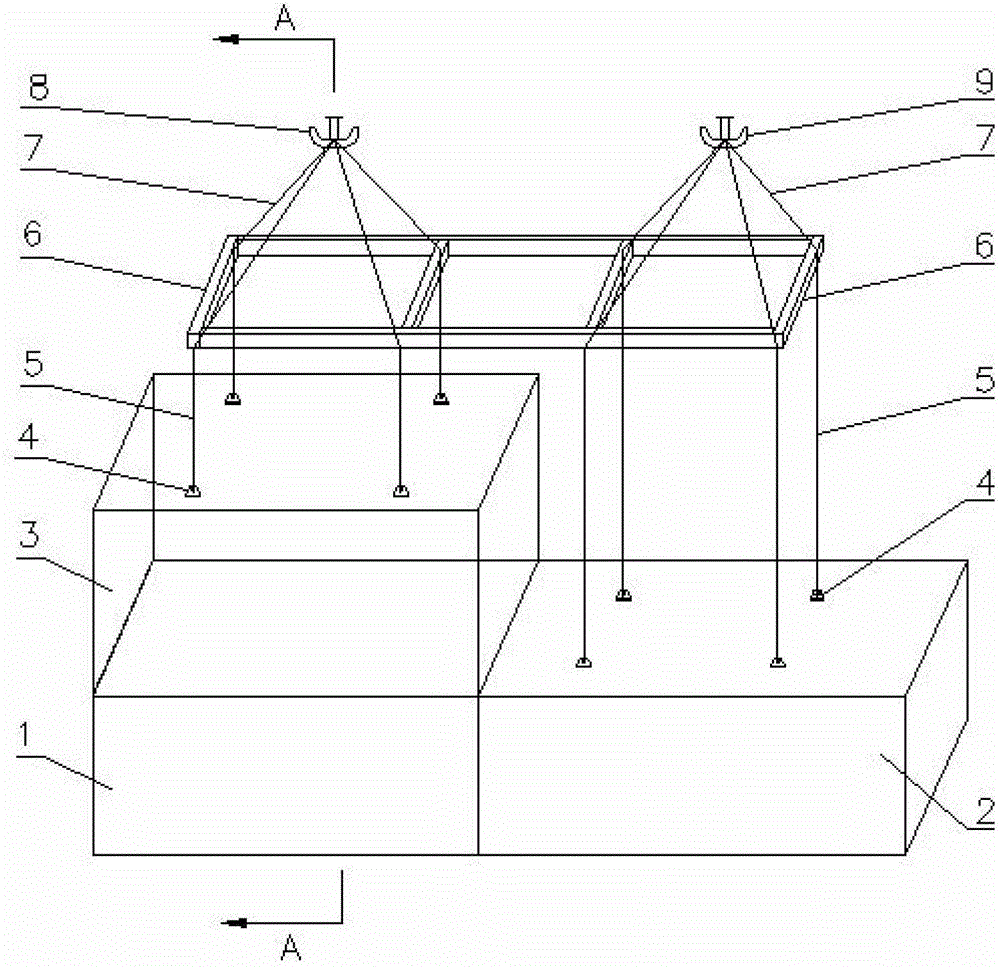

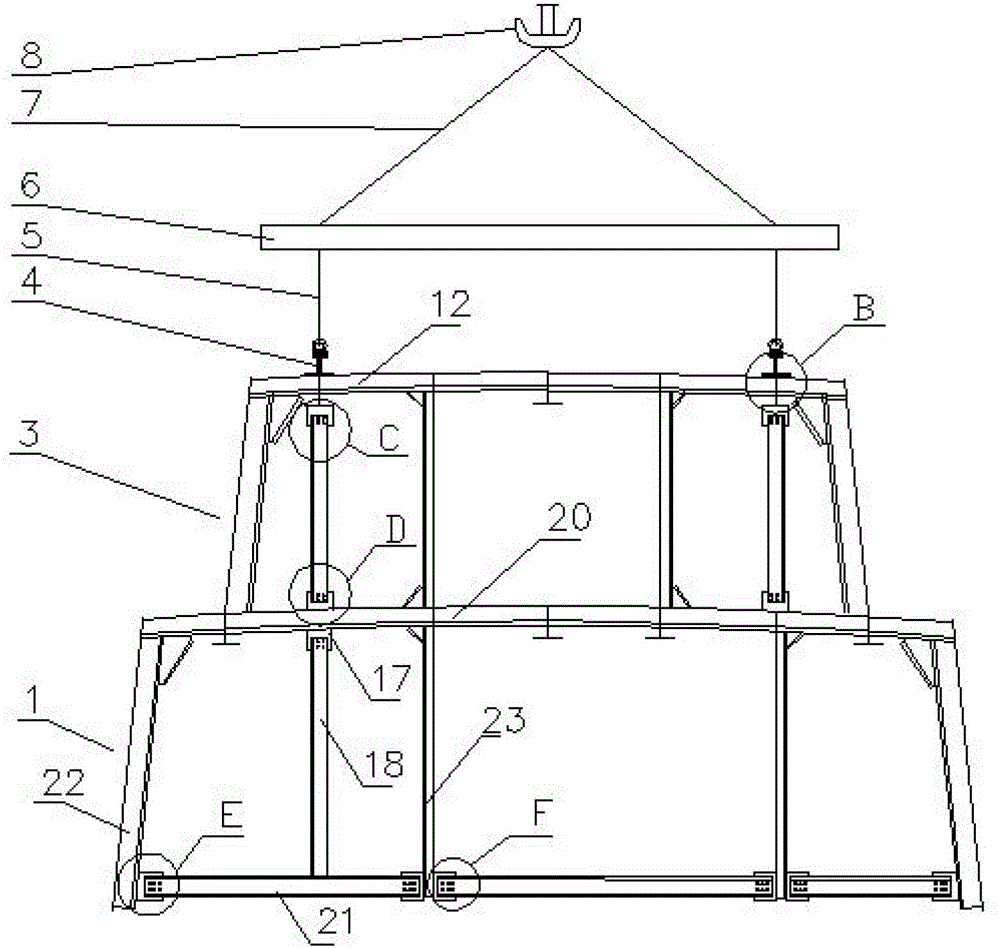

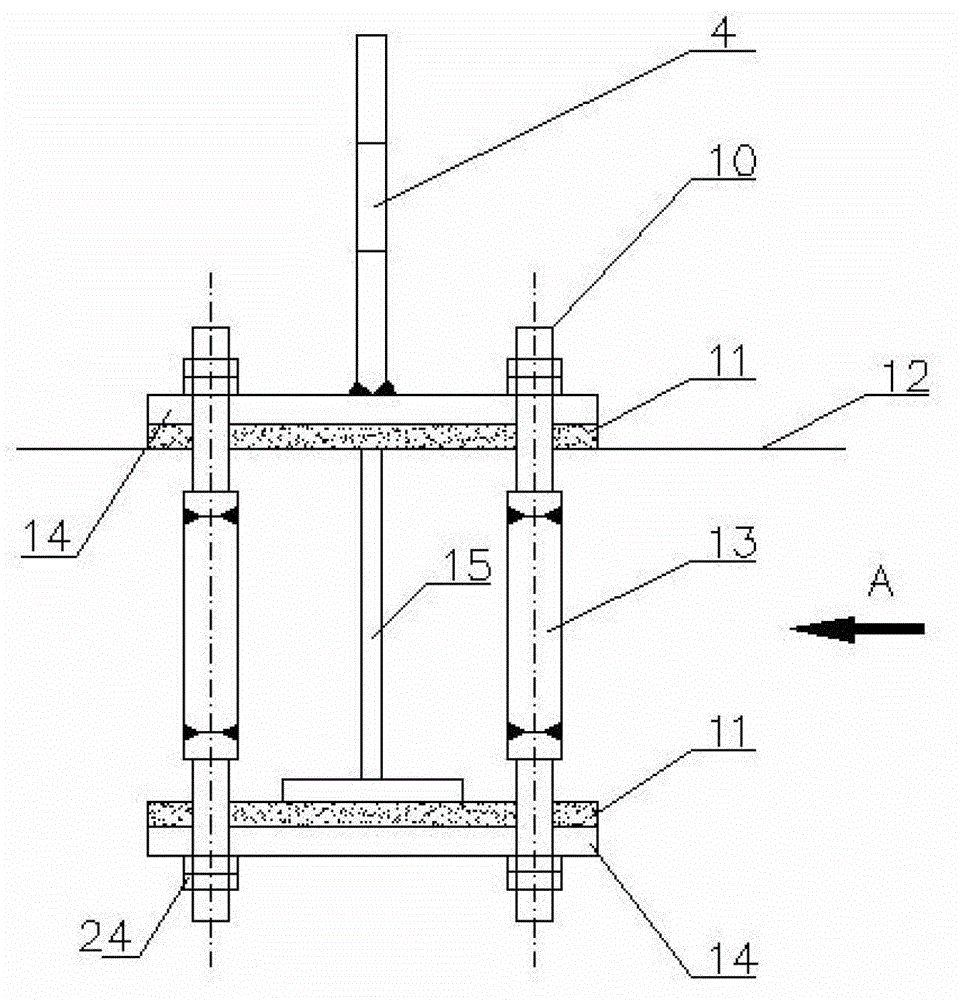

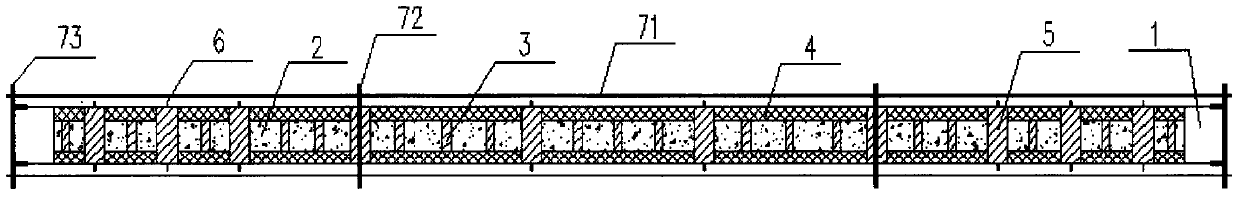

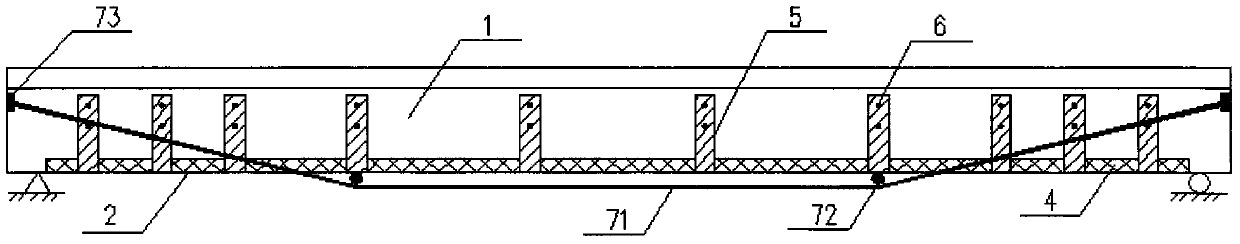

Aluminum alloy superstructure block hoisting method

The invention provides an aluminum alloy superstructure block hoisting method, which comprises the following steps of (1) determining the quantity of multiple hoisting points, positions of multiple hoisting points and an integral hoisting method of an aluminum alloy superstructure block according to the weight of the aluminum alloy superstructure block, a structural form and a gravity core; (2) producing a hoisting bracket for hoisting the aluminum alloy superstructure block; (3) designing and installing temporary reinforcement onto the aluminum superstructure block according to the integral hoisting method; (4) installing one hoisting hanger on each position of multiple hoisting points; and (5) vertically joining the hoisting hangers with the hoisting bracket through a wire cable, and utilizing the hoisting bracket to carry out the multipoint vertical hoisting. According to the hoisting method, not only can the deformation control problem for hoisting the aluminum superstructure block be solved and sectional construction of the aluminum alloy superstructure block be realized, but also the hoisting hangers and the temporary reinforcement for the hoisting are convenient to disassemble, and the block hoisting time can be shortened.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

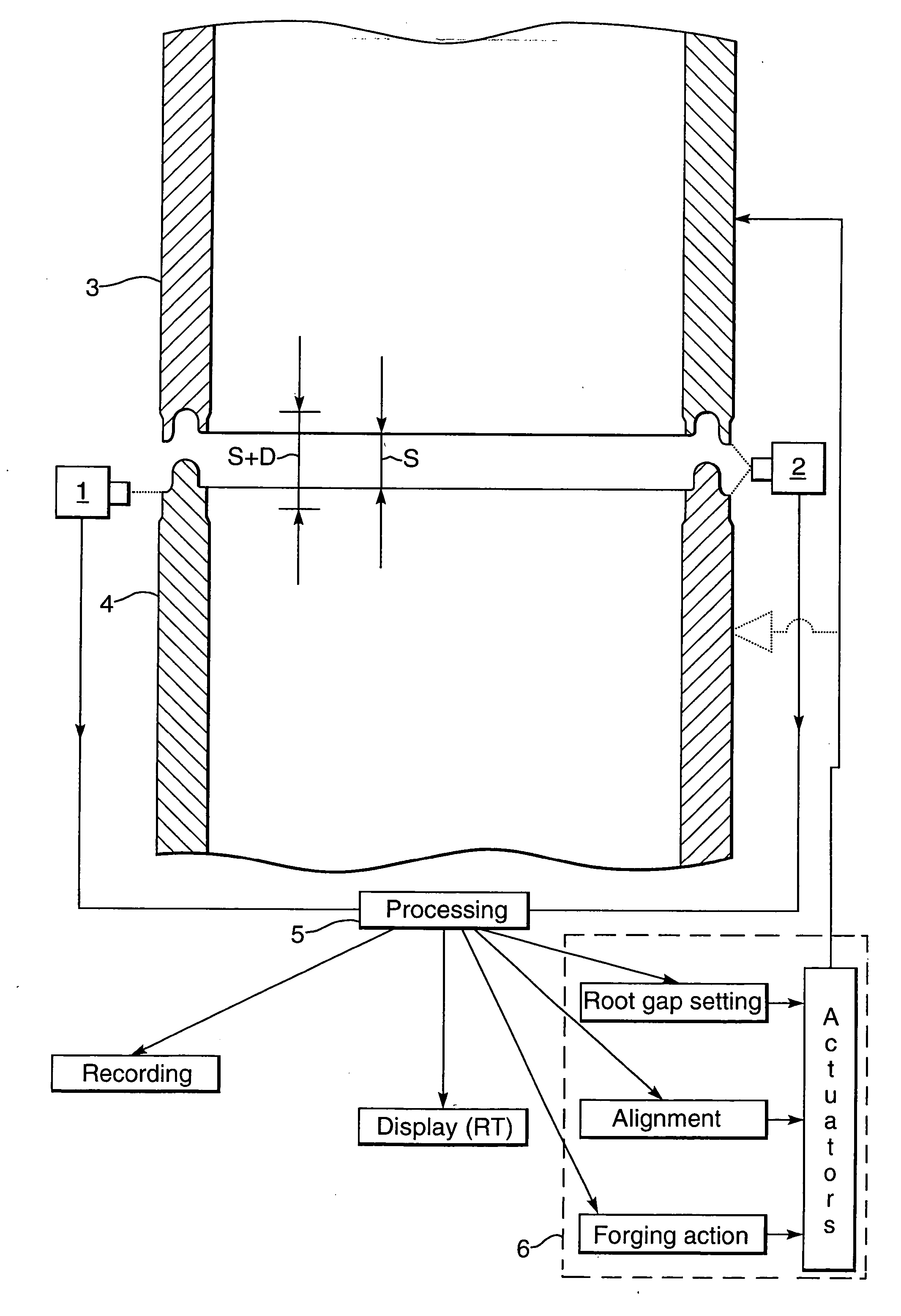

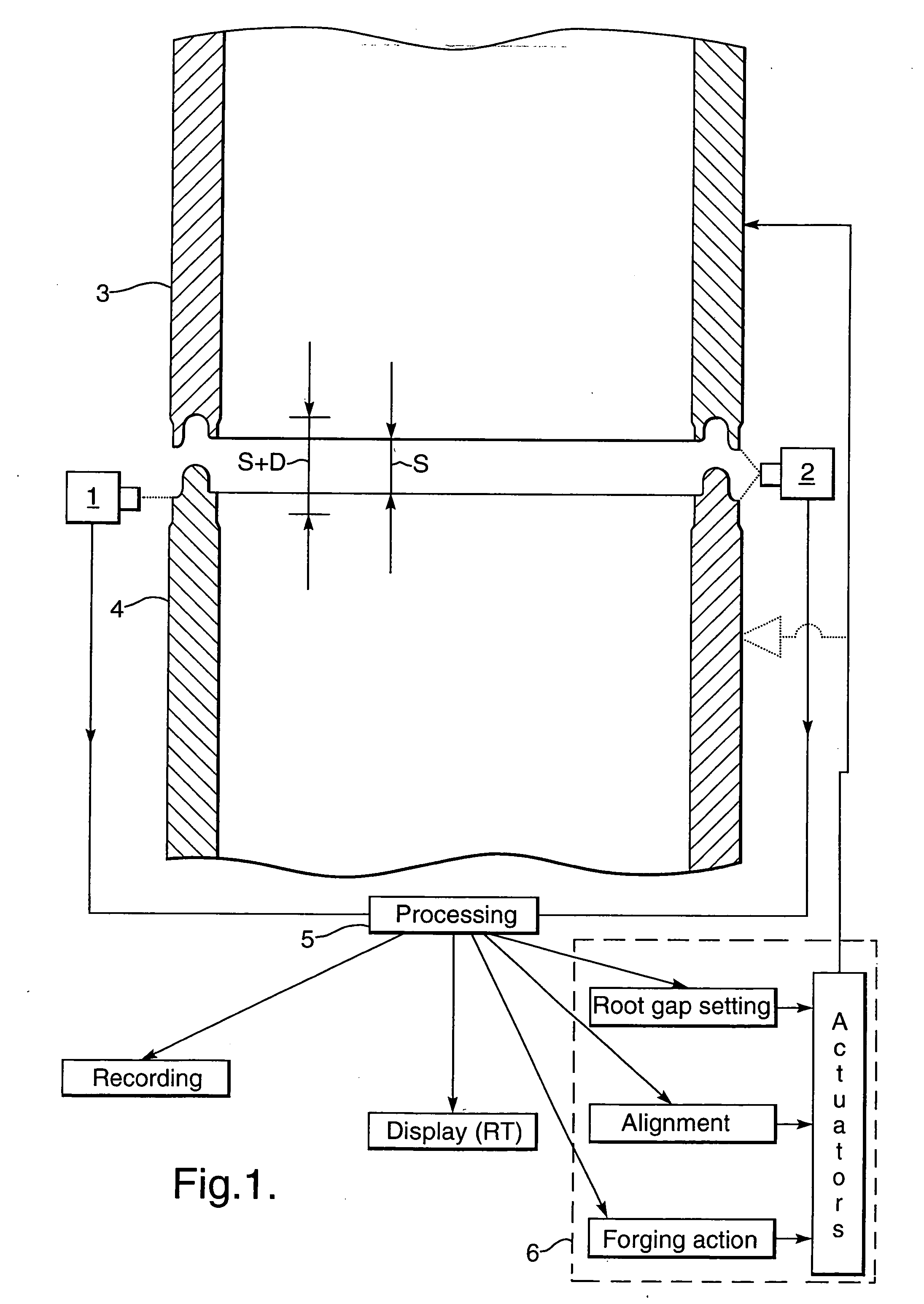

Forge welding of heavy duty tubulars

InactiveUS20060169752A1Avoid shear stressHigh frequency current welding apparatusWelding/cutting media/materialsPipe fittingEngineering

A method of joining heavy duty oilfield, well, or other tubulars includes the step of joining the tubulars by forge welding and flushing a reducing flushing gas around the heated tubular ends during at least part of the forge welding operation such that oxides are removed from the forge welded tubular ends and the amount of oxide inclusions and irregularities between the forge welded tubular ends is limited. The tubular ends may have a teethed sinusoidal or other non-planar shape to inhibit any abrupt variations of the wall strength in the welding area and / or to reduce shear forces to the forge weld when the tubulars are twisted and / or radially expanded.

Owner:SHELL OIL CO

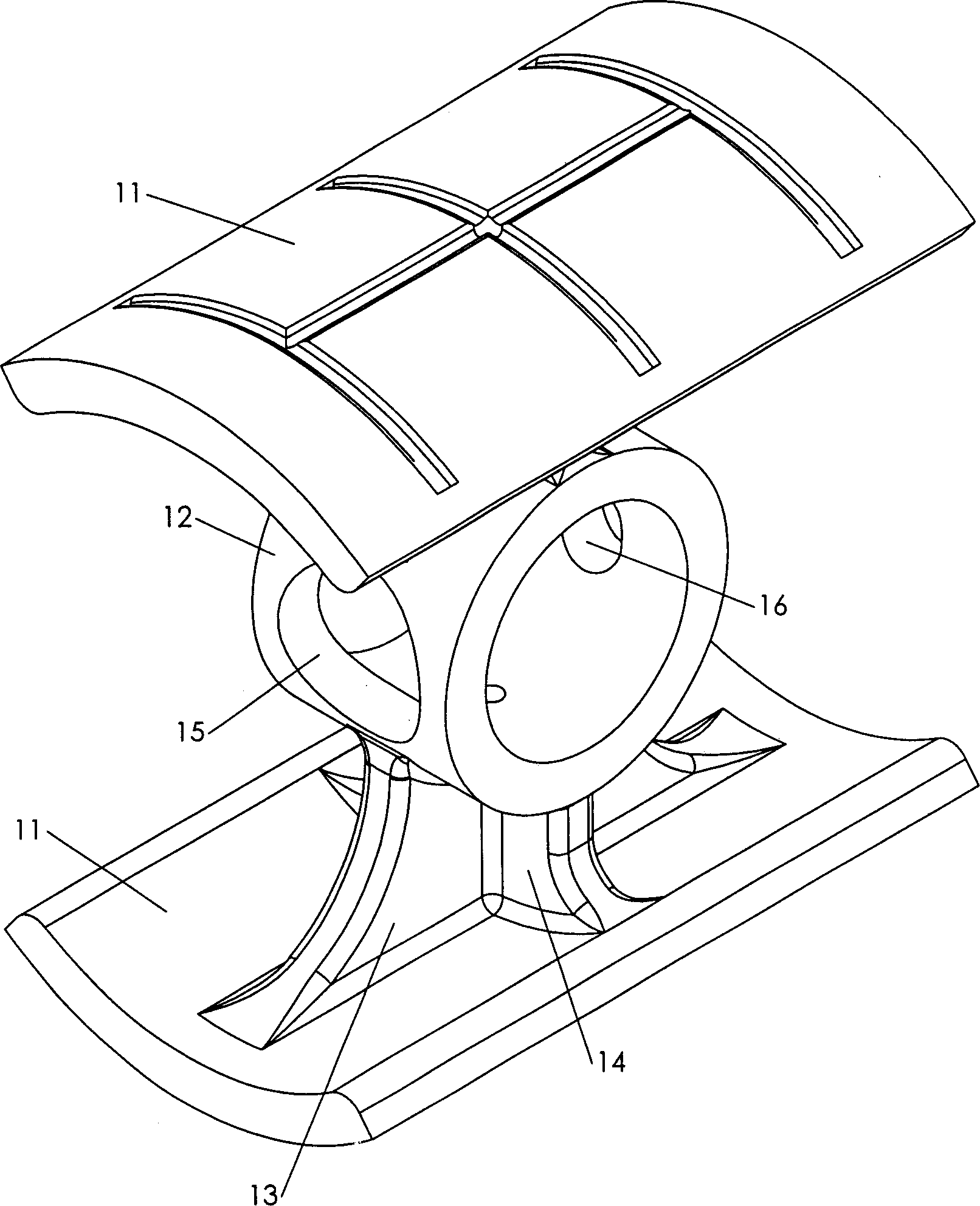

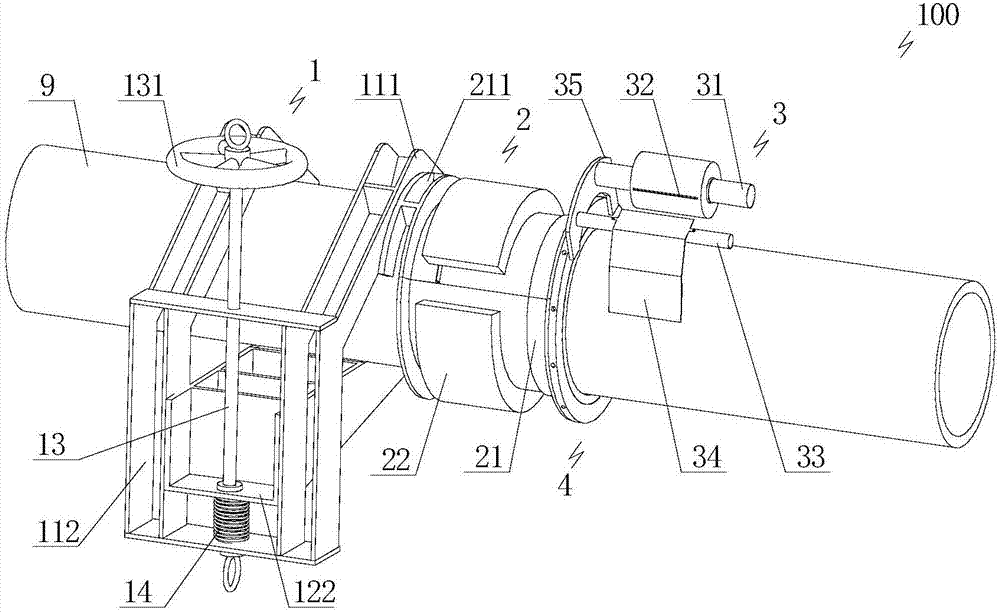

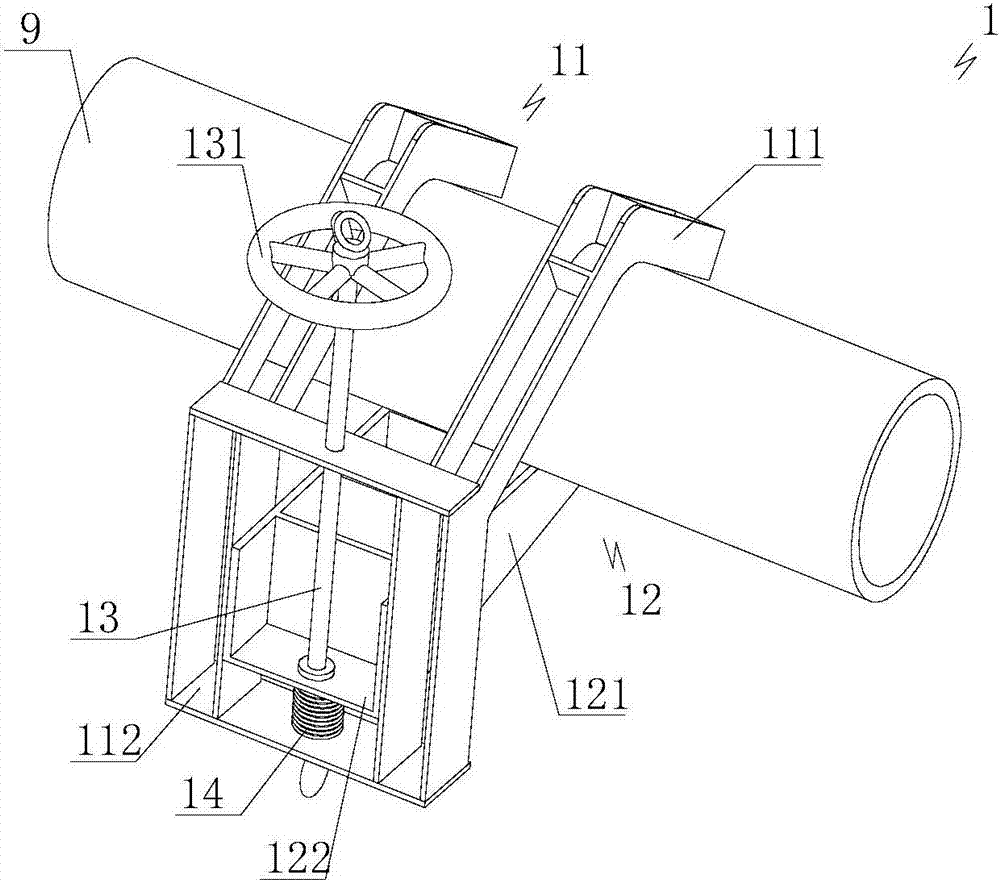

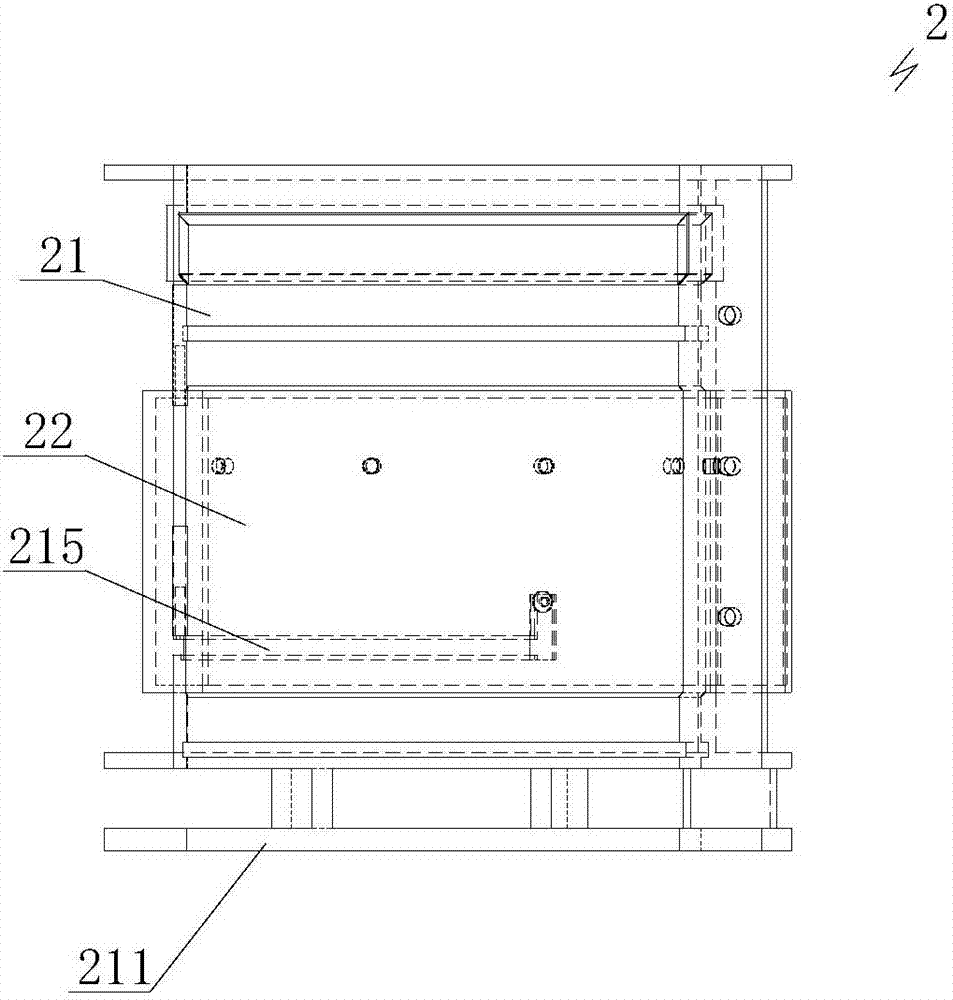

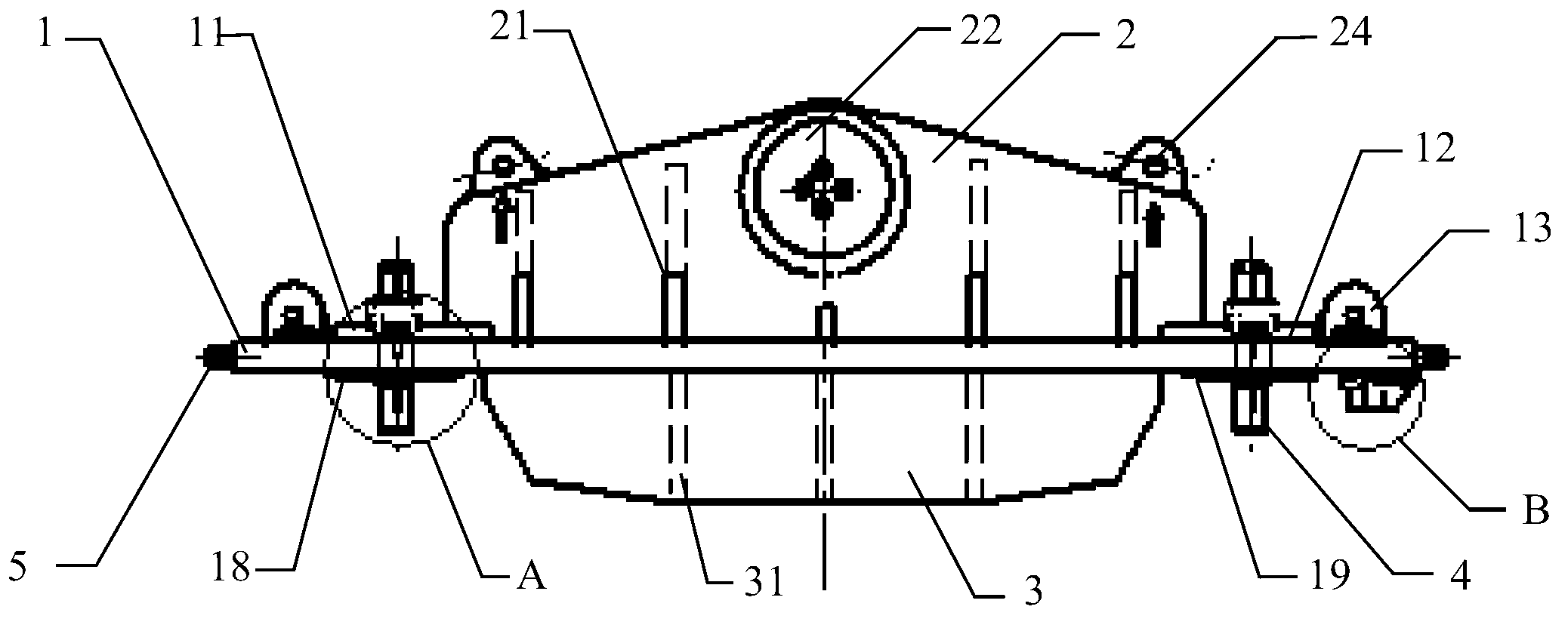

Defect repairing tool for submarine pipeline

ActiveCN106979383ASimple structureReduce radial loadPipe laying and repairOcean bottomMarine engineering

The invention provides a defect repairing tool for a submarine pipeline. The defect repairing tool for the submarine pipeline comprises a clamping module structure, a coating module structure and a coiling module structure, wherein the coating module structure capable of forming a coating layer on a defect area of the submarine pipeline to be repaired is connected to one side of the clamping module structure which is controlled through a remote operated vehicle (ROV) and capable of clamping the submarine pipeline to be repaired; the coating module structure sleeves the outer wall of the submarine pipeline to be repaired in a circumferential opening-closing manner and can axially move along the submarine pipeline to be repaired; the coiling module structure capable of forming a coiling layer on the coating layer is connected to one side, far away from the clamping module structure, of the coating module structure; the coiling module structure can axially move along the submarine pipeline to be repaired and can be rotated around the submarine pipeline to be repaired. The repairing tool is operated through the ROV, so that the maximum diving depth of workers can be overcome; the repairing process is continuous, complete and high in efficiency; and the problem of defect repairing of the submarine pipeline in a deep water environment can be solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

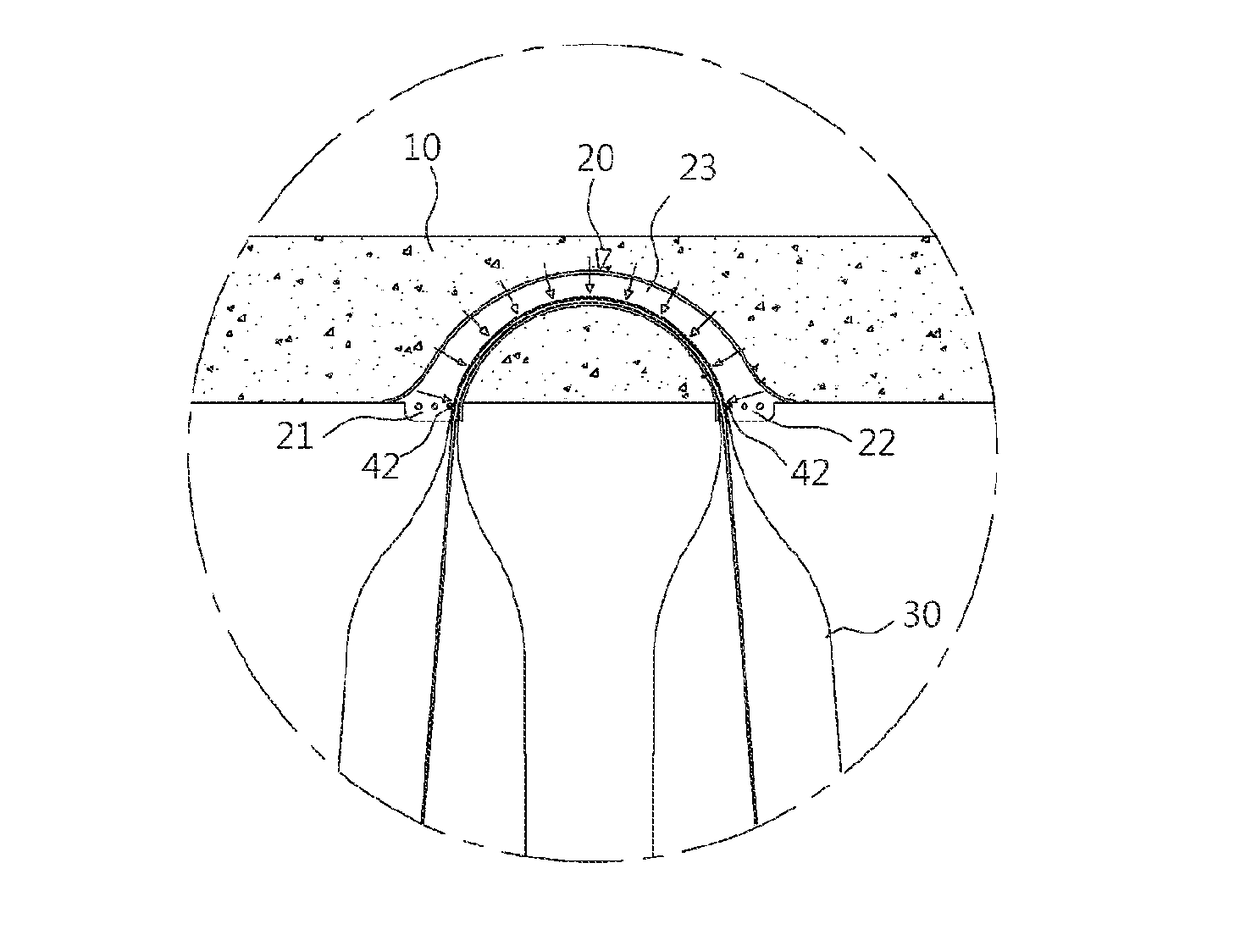

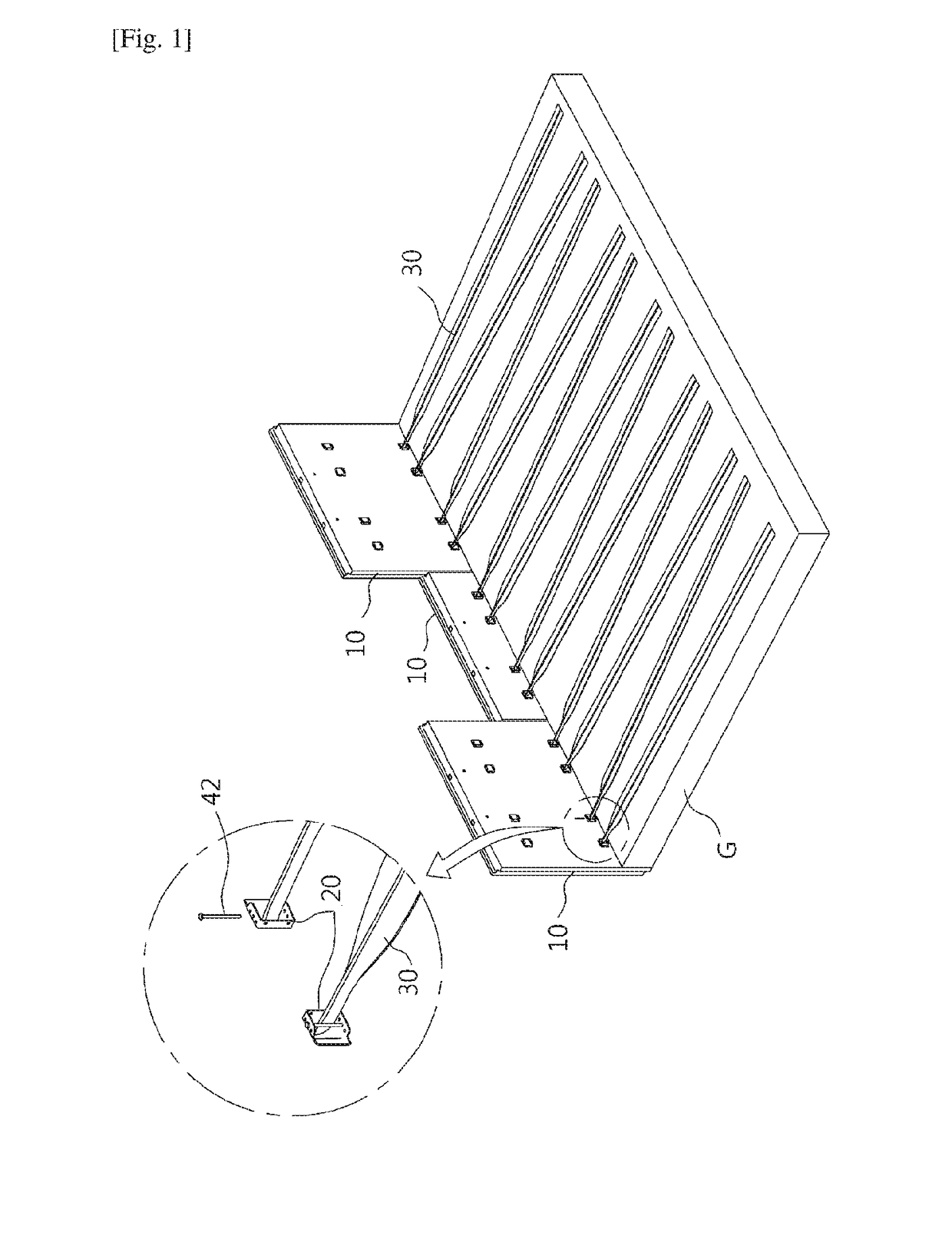

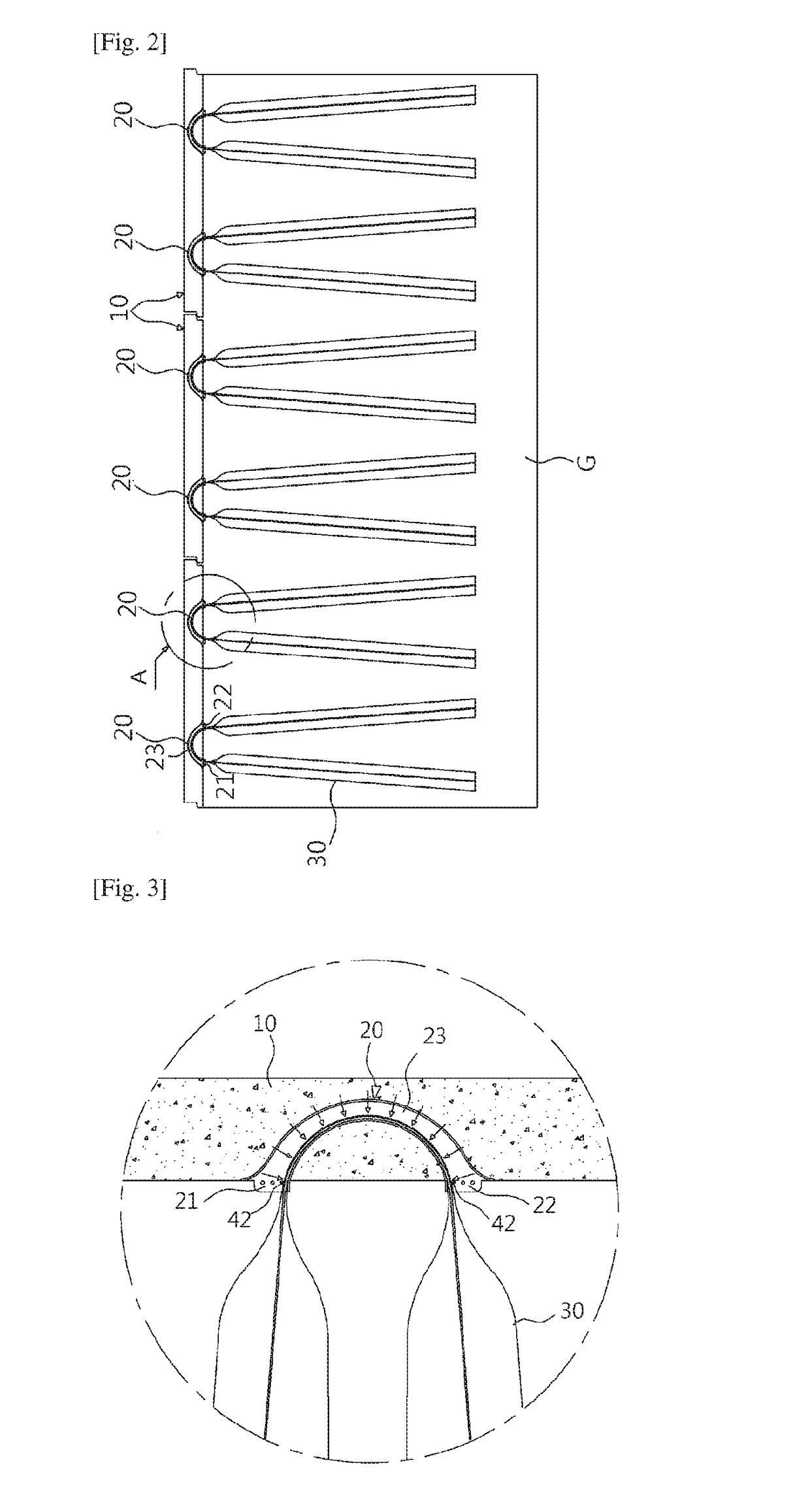

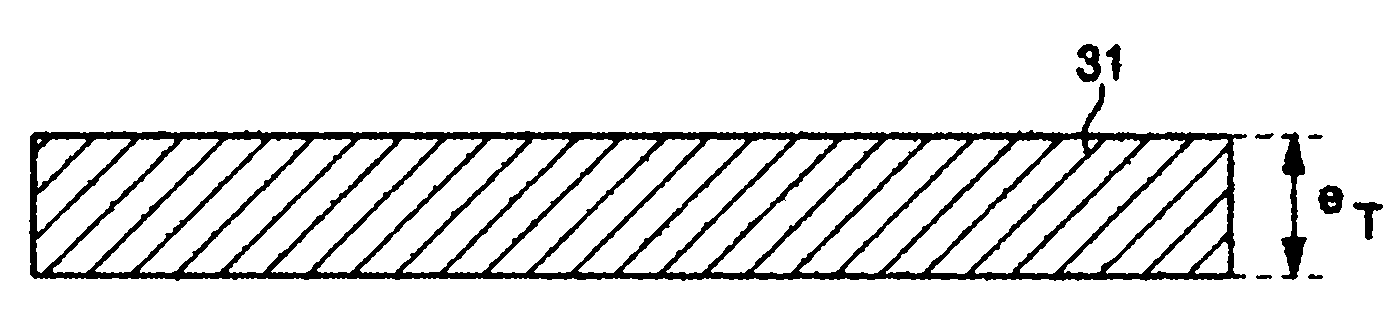

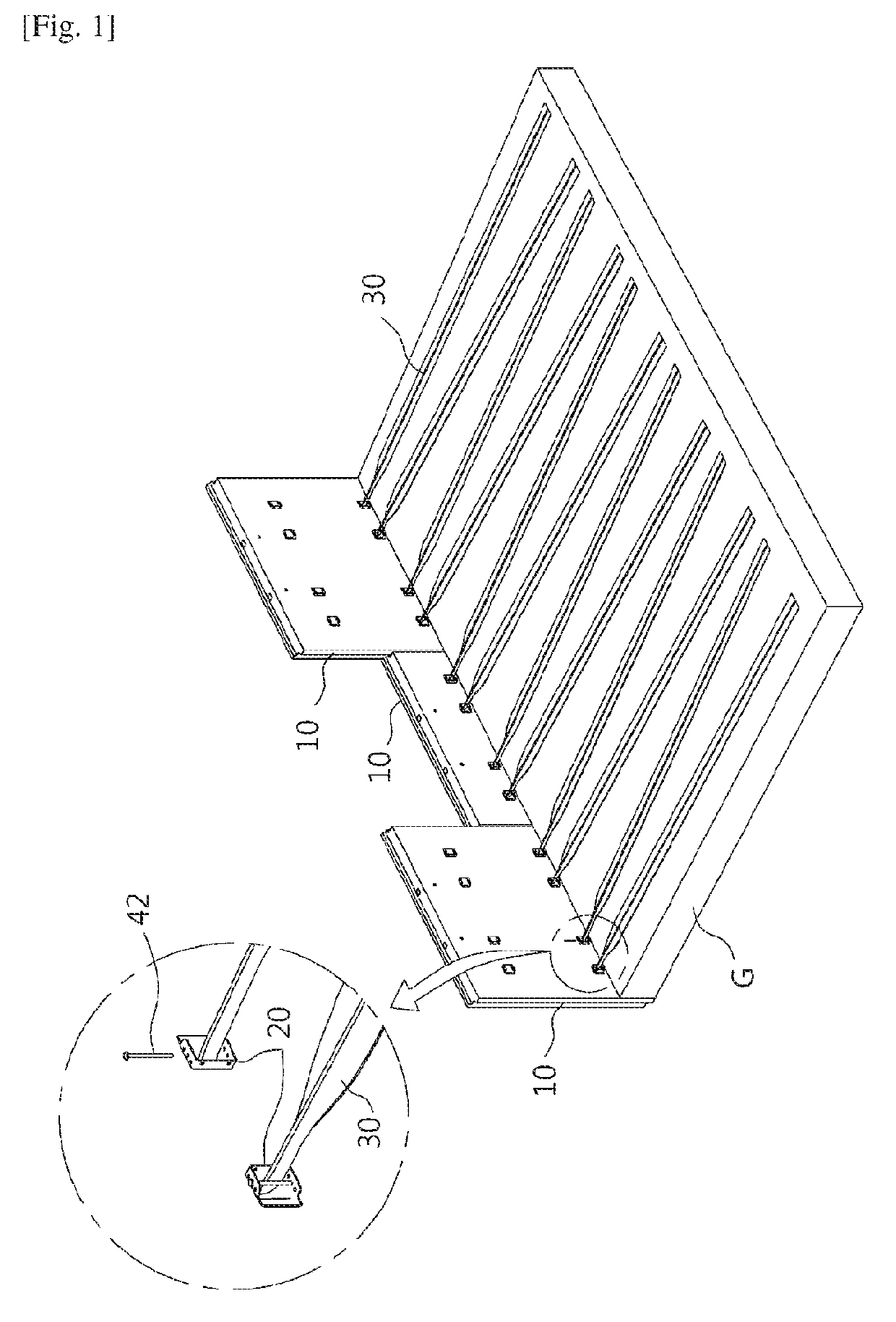

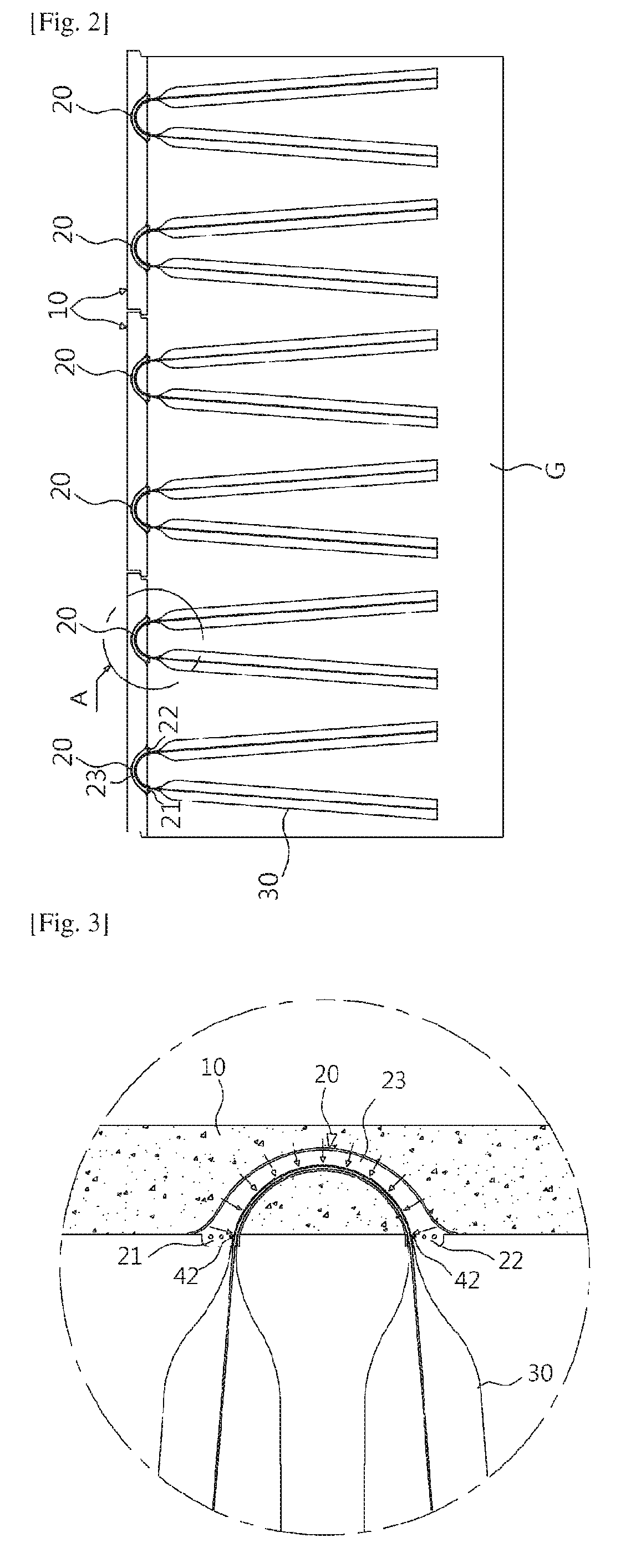

Construction method for band type fiber reinforcing material for reinforced-soil retaining-wall

ActiveUS20180044878A1Easy and rapid connectionImprove stabilityArtificial islandsExcavationsStress concentrationBand shape

The present invention relates to a method of constructing a band type fiber reinforcement material for a reinforced-soil retaining-wall structure which enables quick and easy connection of a band type fiber reinforcing material, provides various connection methods therefor, and prevents stress from being concentrated in a connection part with a facing member during the sinking of a reinforced soil body, including: inserting a band type fiber reinforcement material into reinforcement material insertion members provided in facing members standing at a front of a reinforced soil mass (G) such that the facing members are adjacent to each other in leftward and rightward directions; spreading the band type fiber reinforcement material on the reinforced soil mass and laying and hardening a backfill material on the band type fiber reinforcement material and the reinforced soil mass; and repeatedly carrying out the first step and the second step until a predetermined height is reached.

Owner:HANFORCE

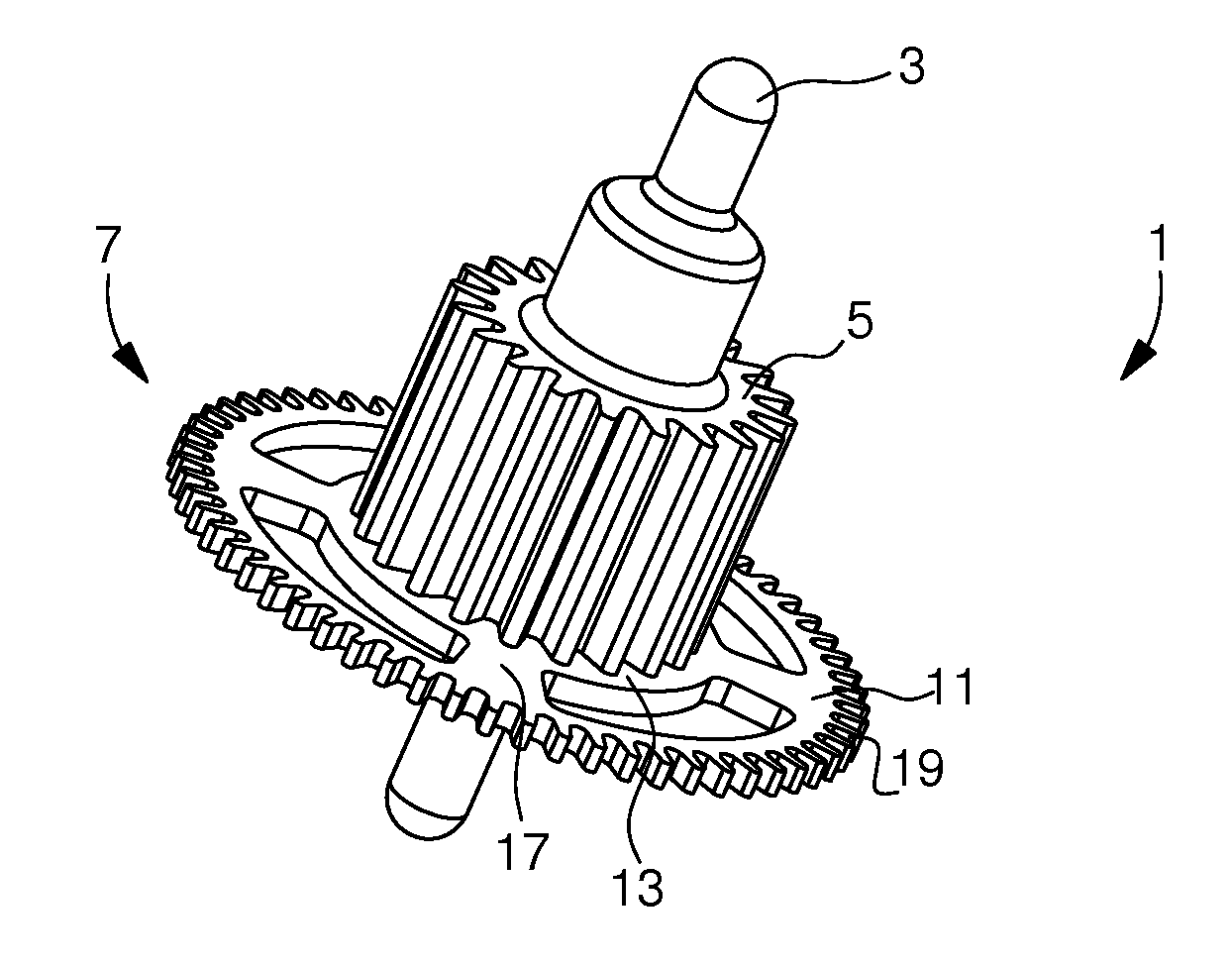

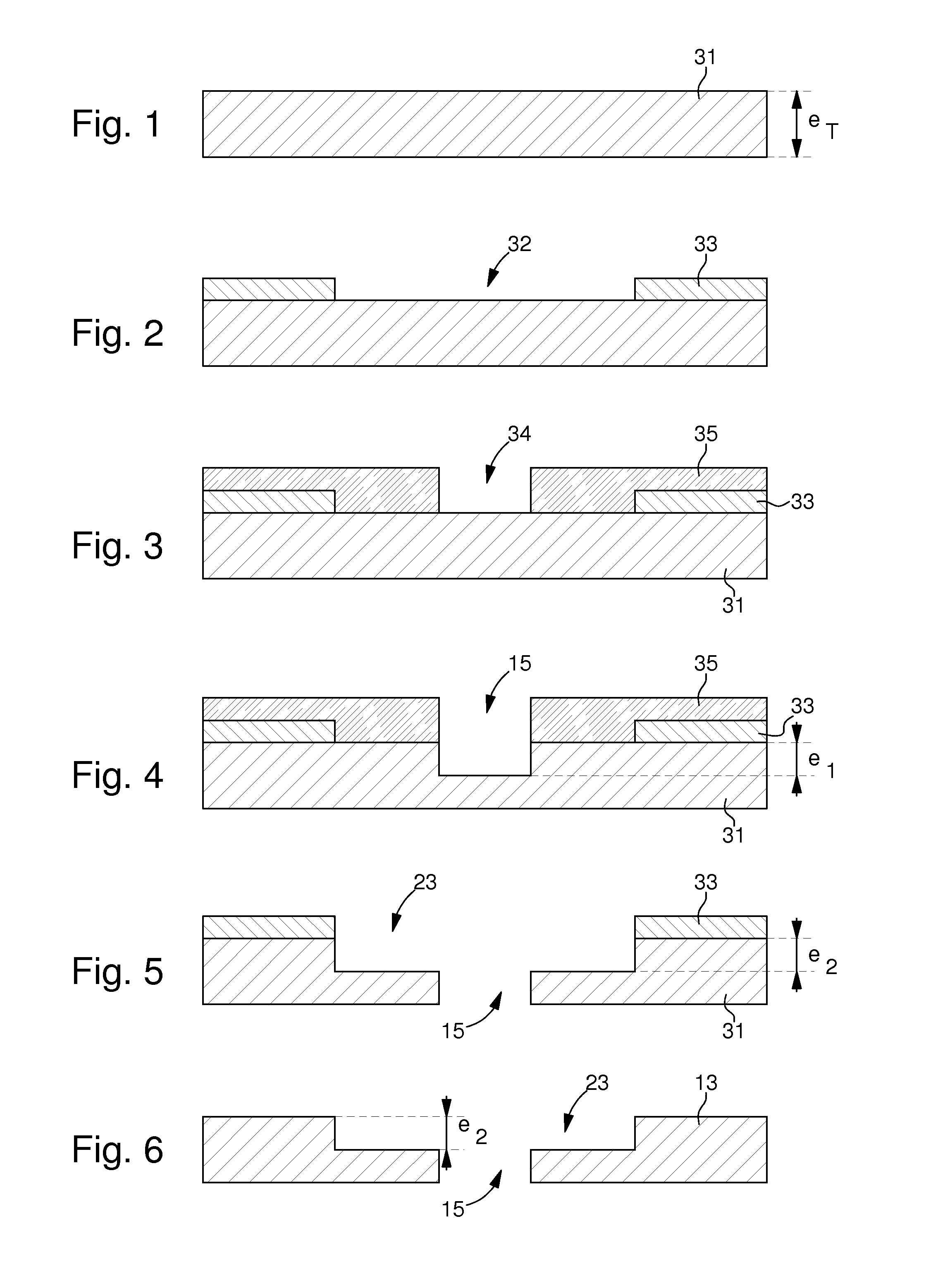

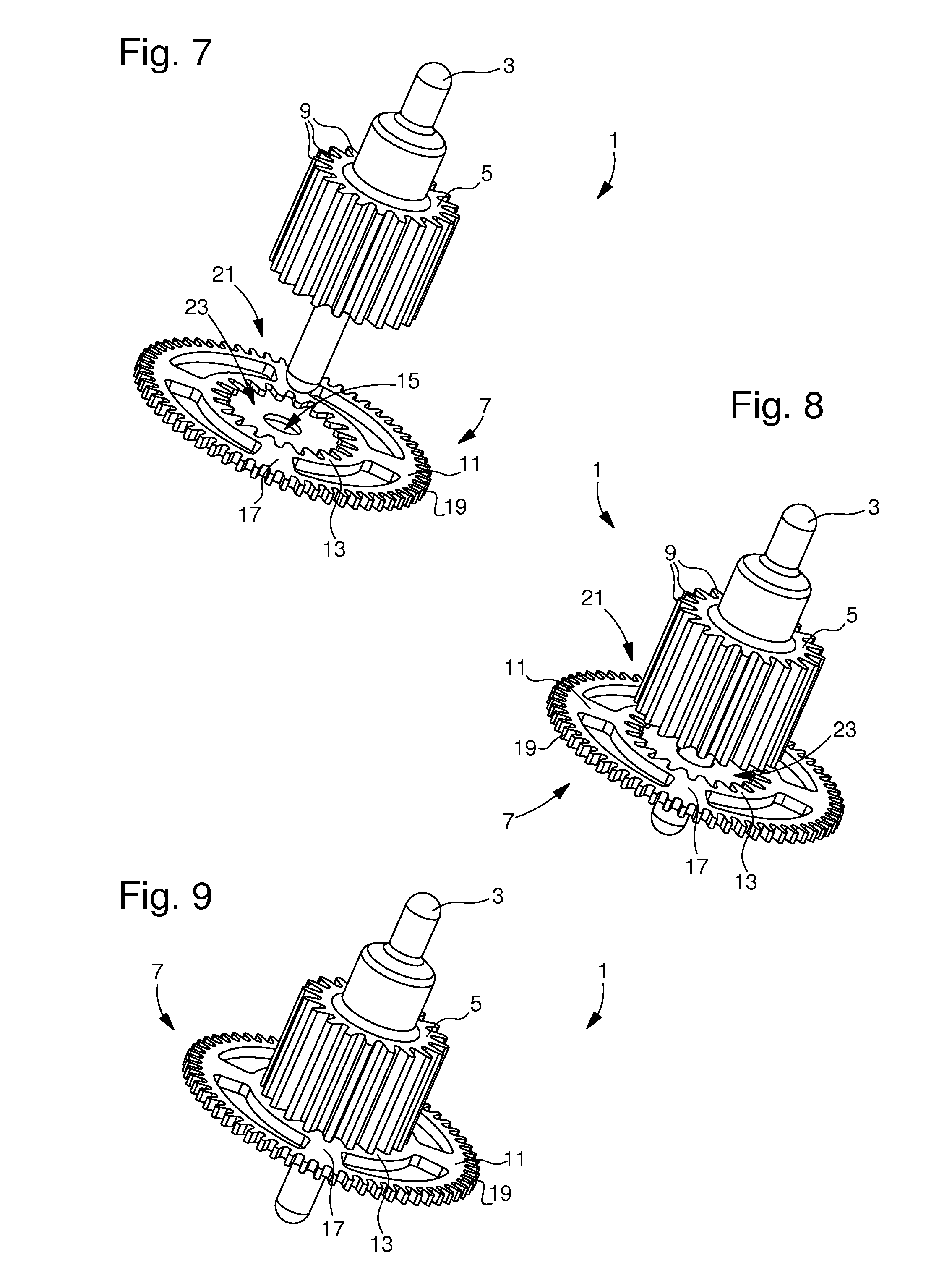

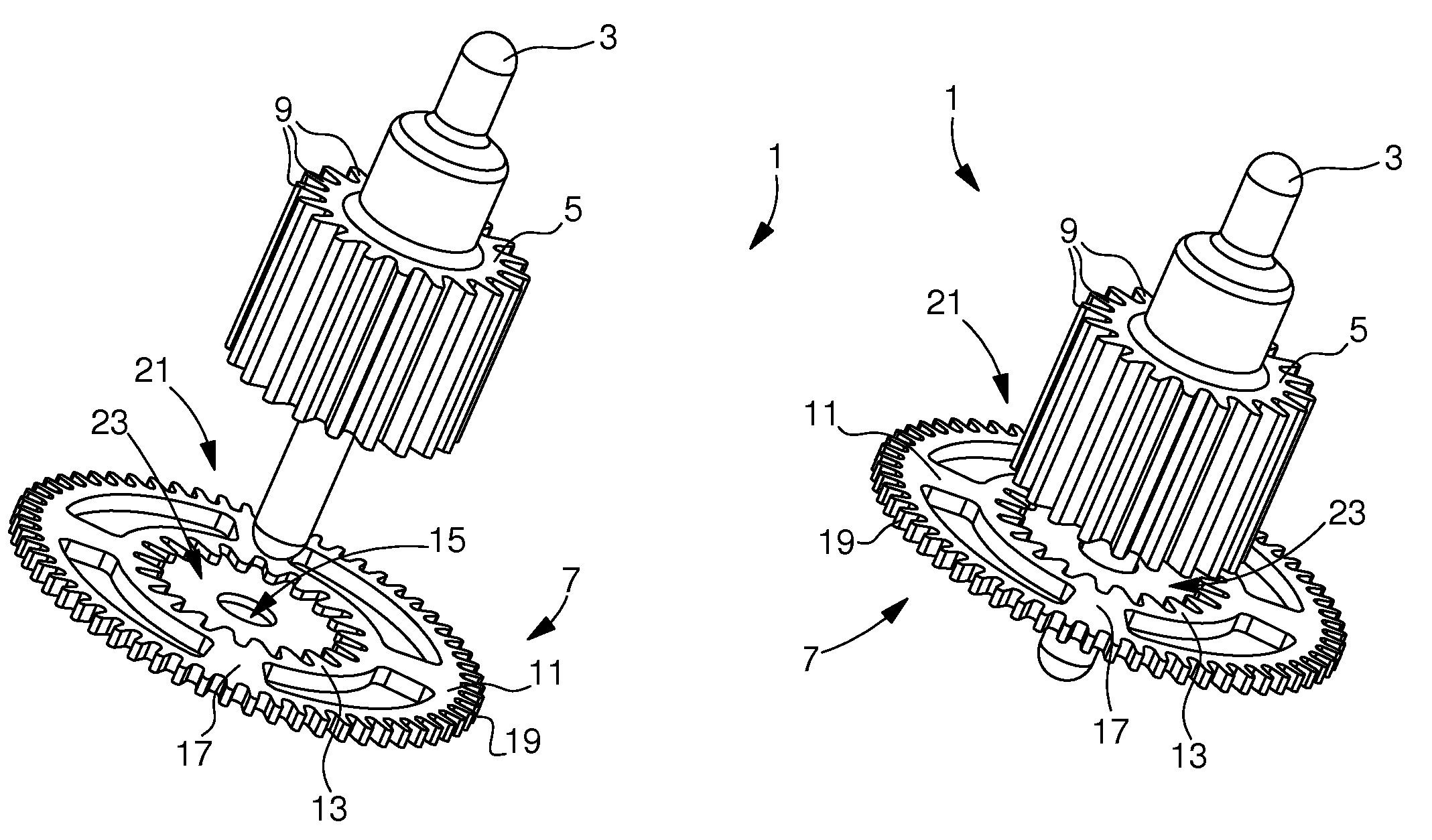

Gearing system for a timepiece

Owner:NIVAROX FAR

Turning process method for large container component

ActiveCN103303780ASolve the problem of flipping without lugsIncrease frictional resistanceLoad-engaging elementsEngineeringFatigue limit

The invention discloses a turning process method for a large container component. The method is characterized by comprising the steps of: turning the container component from the vertical direction to the horizontal direction, and turning the container component from the horizontal direction to the vertical direction. The problem that the large container component is turned without a lug is solved in a process from sling mounting to turning, a flange sealing surface is protected through an additionally arranged sealing base plate for protection, a method for applying a pre-tightening force on the bolt is adopted, the frictional resistance of the contact surface between a sling and the container component is increased, a double-end main bolt is prevented from bearing the shear force, and the fatigue limit of the bolt is reduced. In addition, a uniaxial double-wheel sling is hung on two wheels by utilizing two annular steel wire ropes, so that the container component is stable during turning and lifting, and the turning and lifting difficulty and risk are reduced.

Owner:CFHI DALIAN HYDROGENANT REACTOR +1

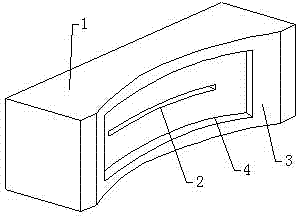

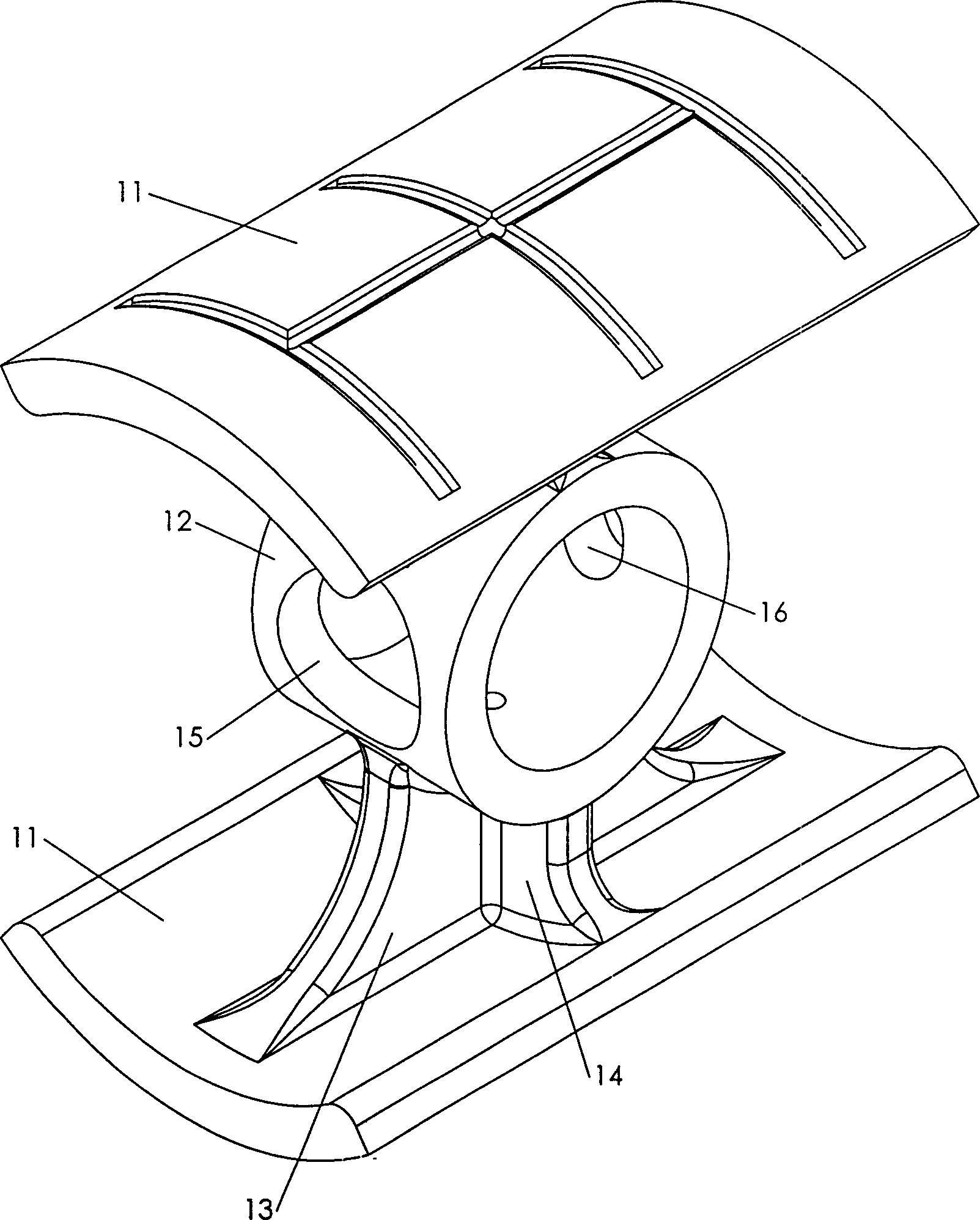

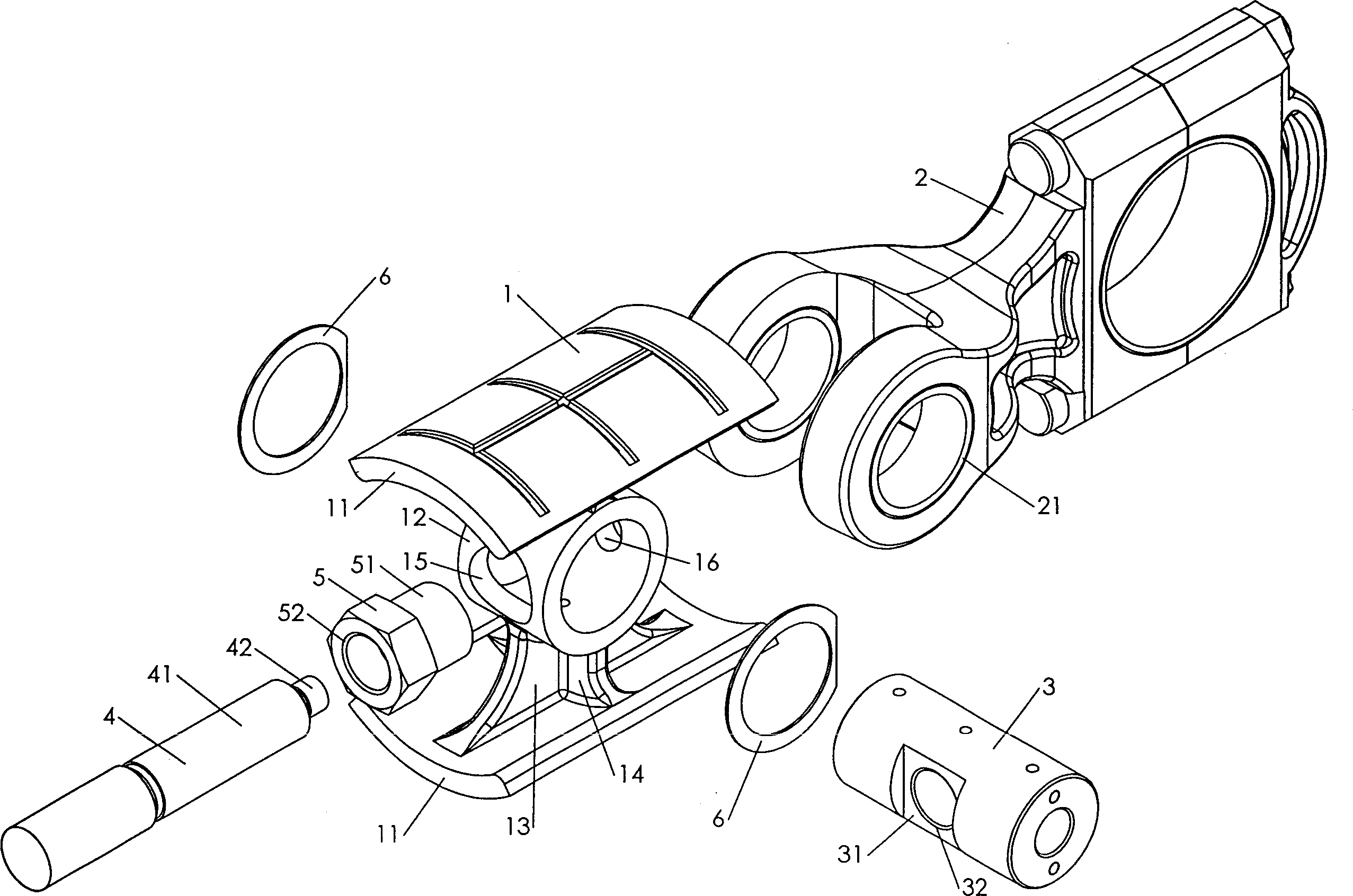

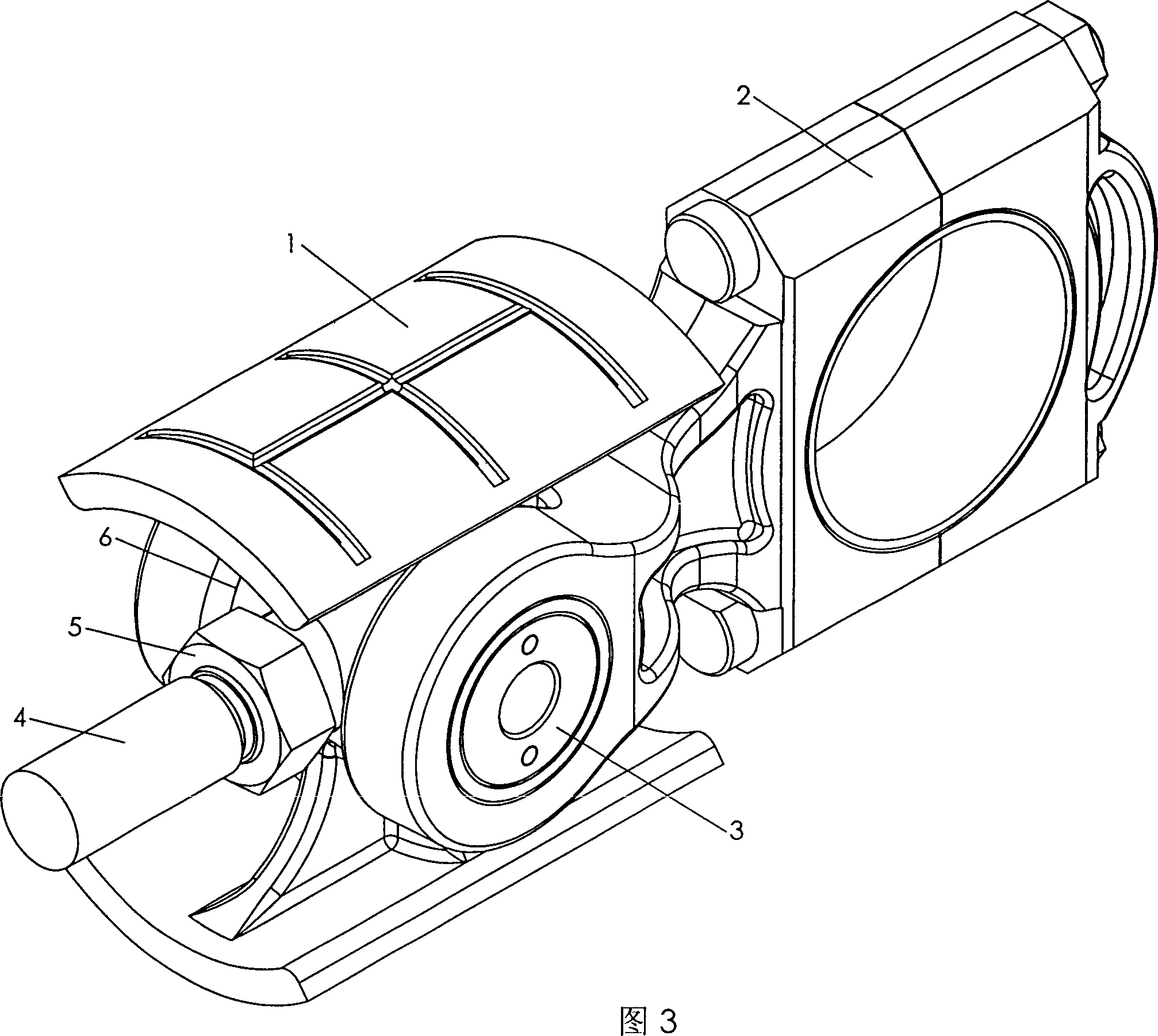

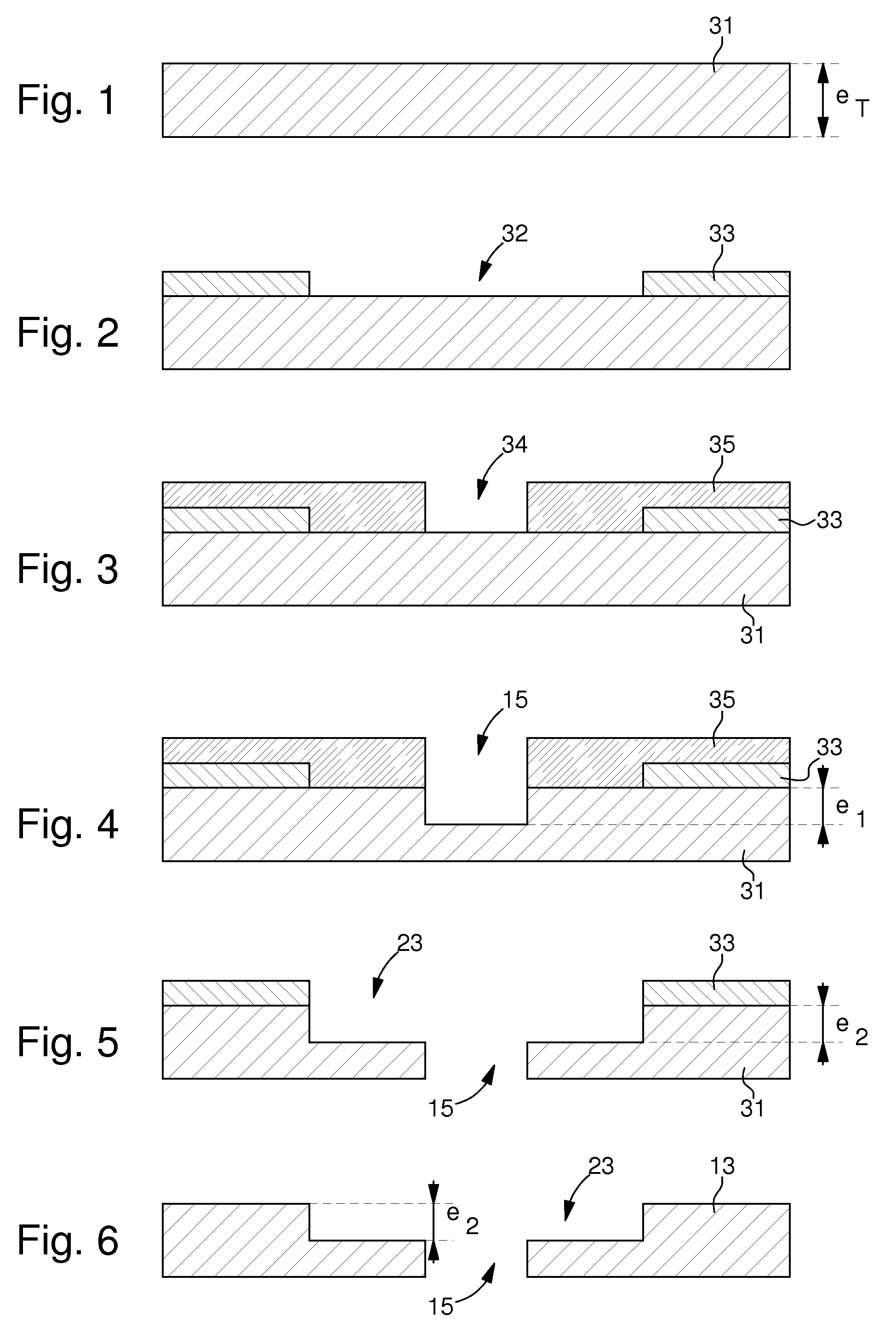

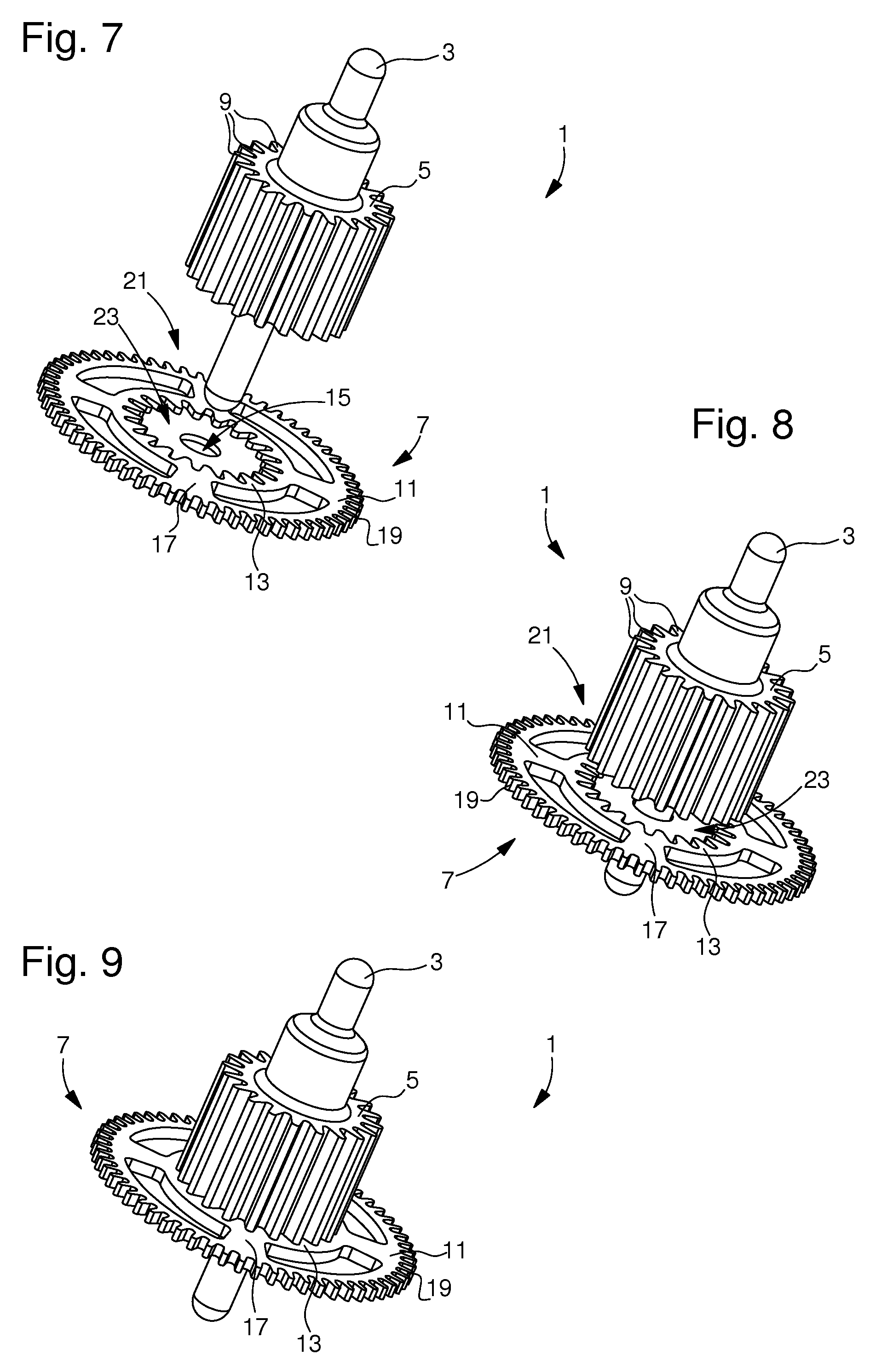

Gear system for a timepiece

ActiveUS20110141860A1Avoid shear stressEasy to fixGearworksDecorative surface effectsGear wheelGear system

The invention relates to a system including a pinion (5) and a toothed wheel (7) coaxially mounted relative to a pivoting arbour (3). According to the invention, the gear system (1) includes a securing device (21) between the pinion and the wheel so as to prevent any relative movement of one with respect to the other. The invention also relates to methods of manufacturing the toothed wheel (7) and the final assembly of the gear system (1). The invention concerns the field of timepieces.

Owner:NIVAROX FAR

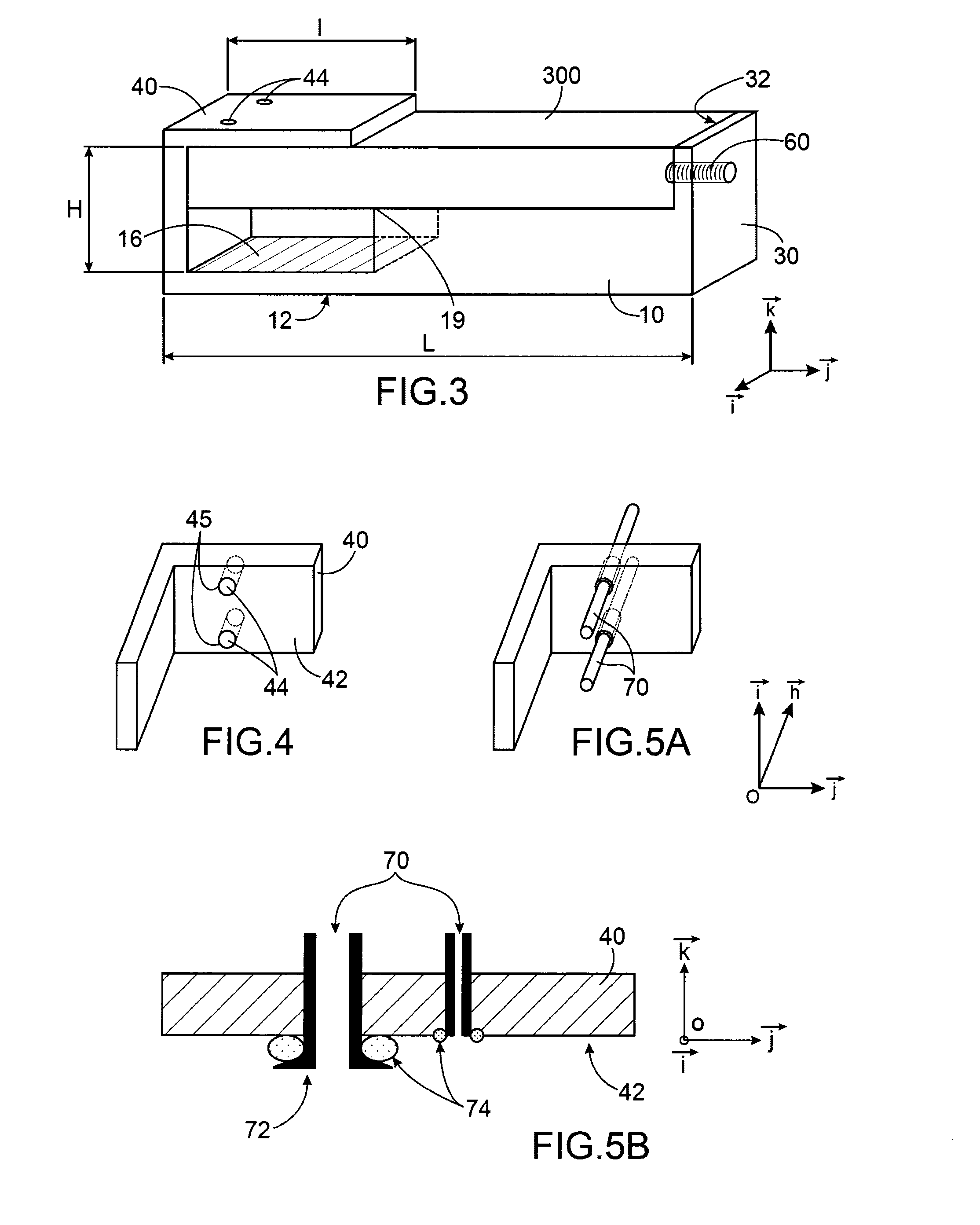

Knitting tool block and method for creating same

The bar (1) has a knitting tool receiver (4) attached at a body (2) and divided into multiple segments (7, 8) in a longitudinal direction (3), where each segment is fixed at the body in individual positions (9, 10) in the longitudinal direction by form closure. The knitting tool receiver comprises grooves (6) and a partition line (17) between the adjacent segments at edges of the grooves. The body comprises recesses (13, 14), where projections (11, 12) of the segments project into the recesses. The segments are made of metal, a ceramic material or a plastic i.e. fiber reinforced plastic. An independent claim is also included for a method for manufacturing a knitting tool bar.

Owner:KARL MAYER TEXTILMASCHFAB GMBH

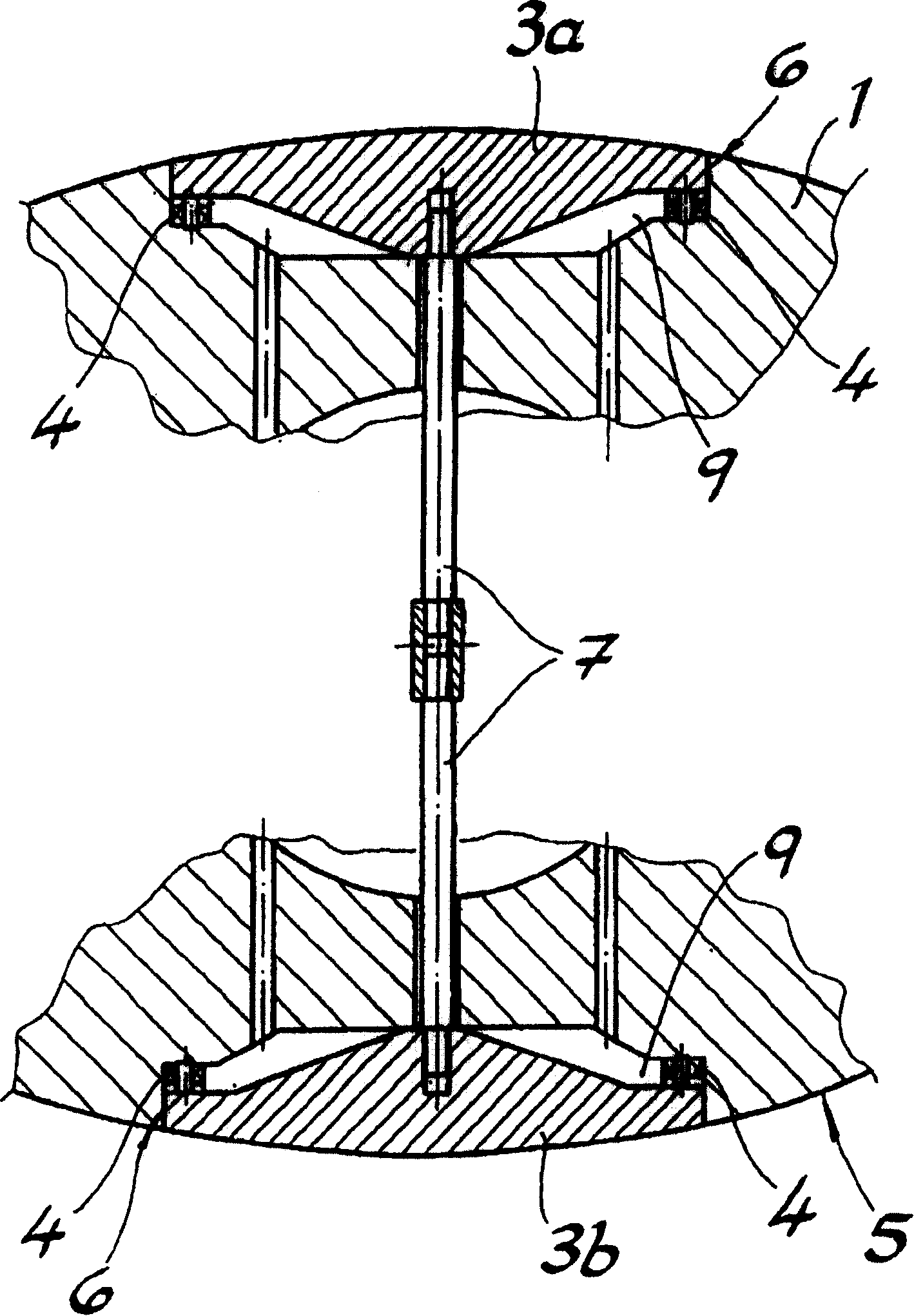

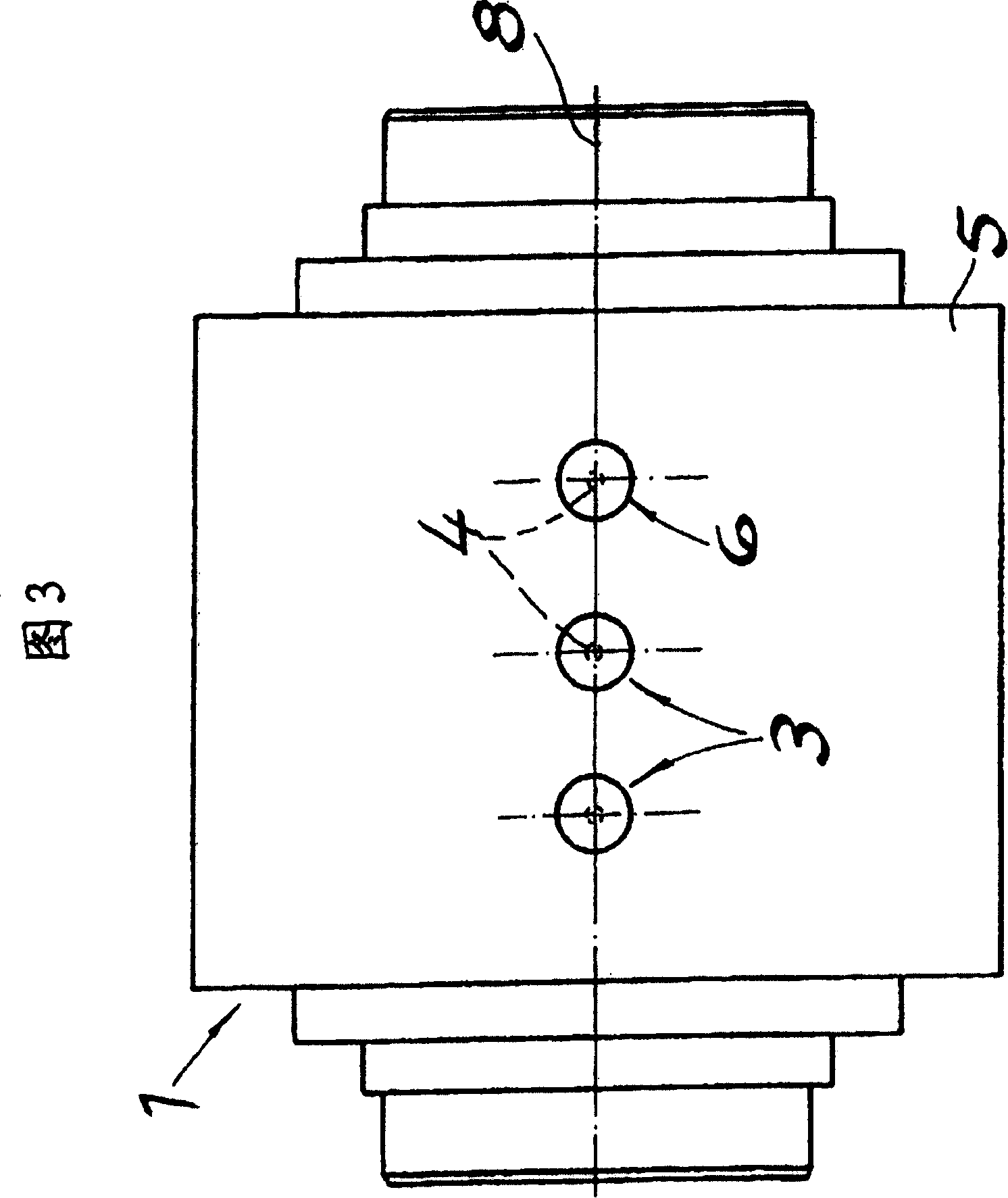

Stirring element and stirrer

ActiveCN109758942AEasy to cleanNo risk of damageTransportation and packagingRotary stirring mixersEngineeringBLENDER/MIXER

Owner:VISCO JET RUHRSYST

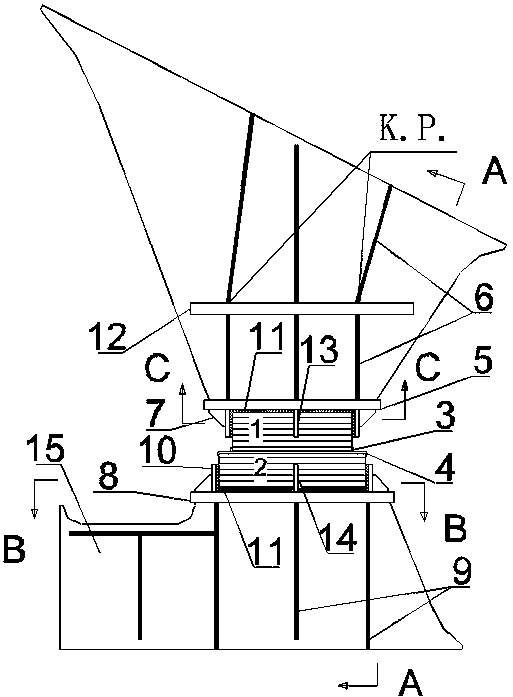

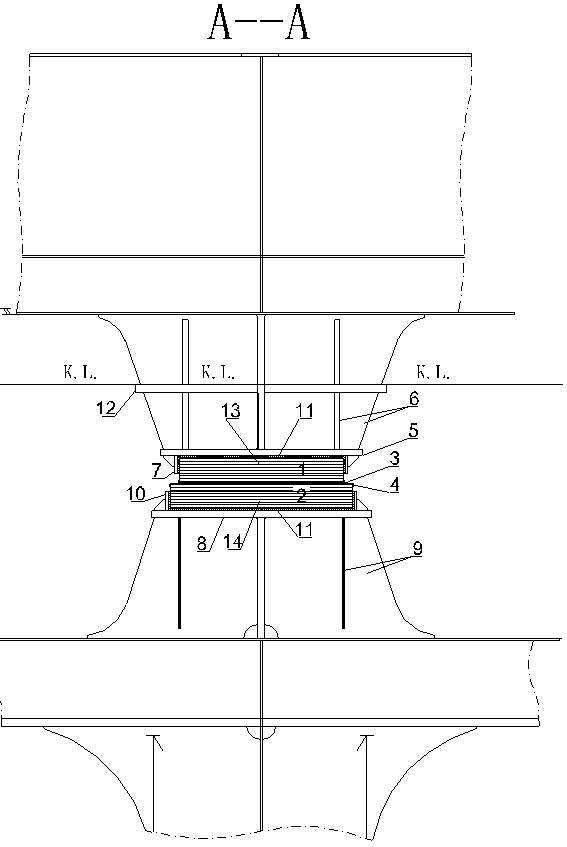

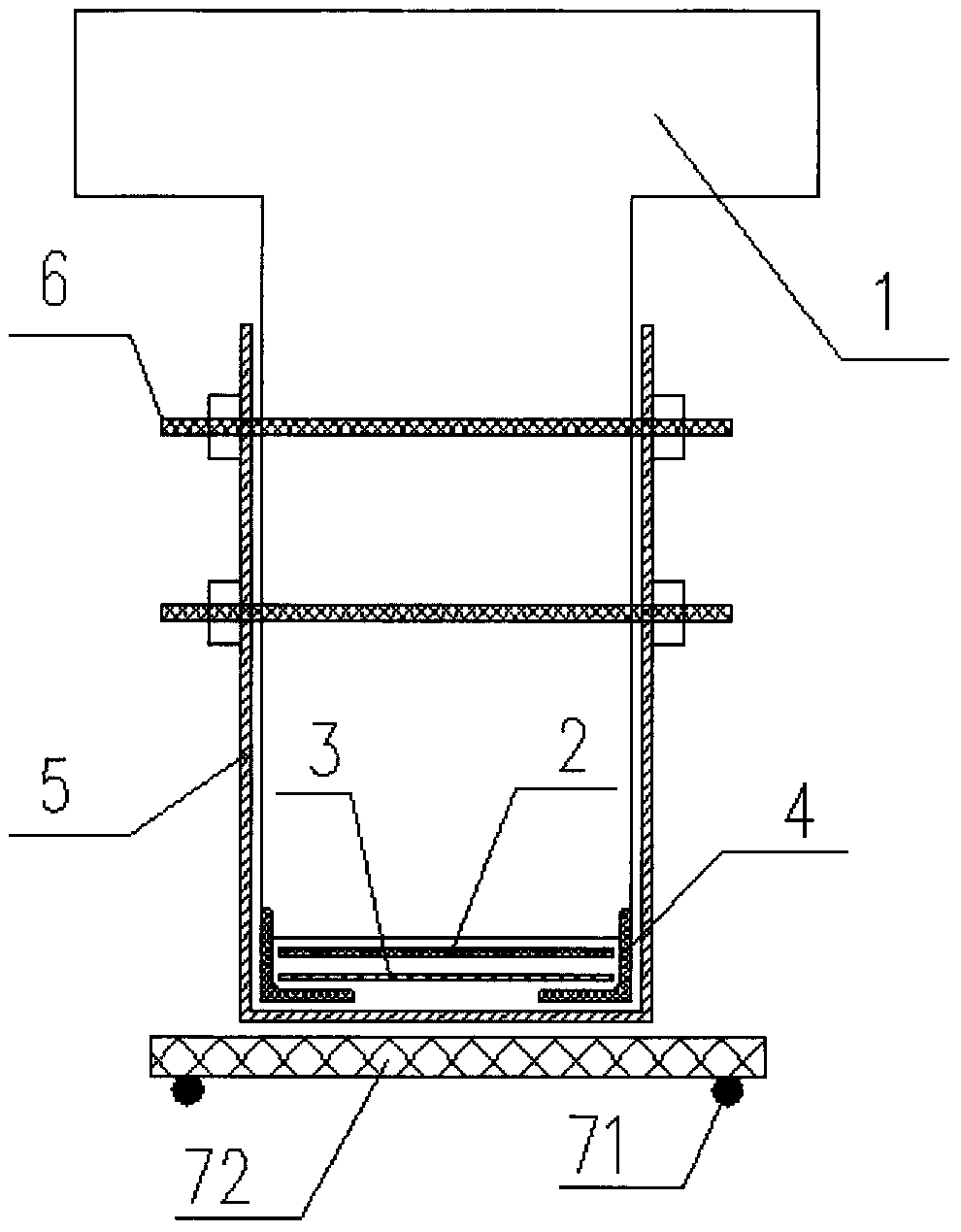

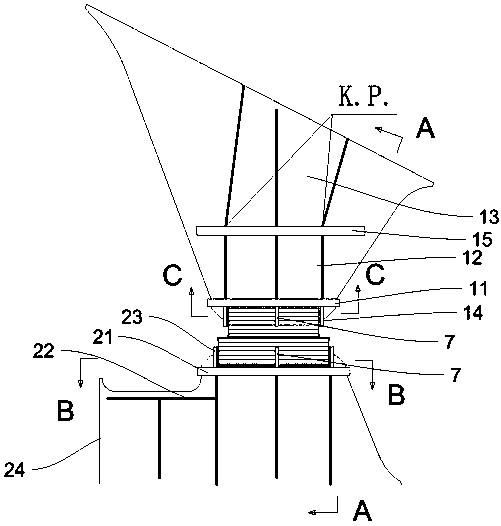

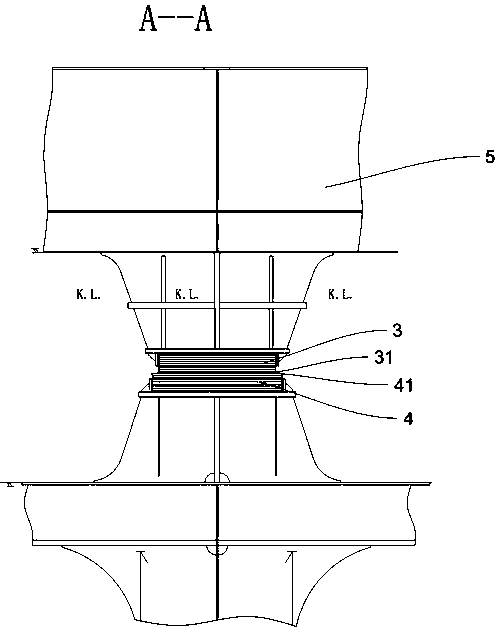

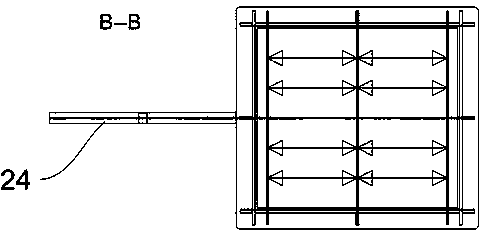

Vertical support method for B type fuel tank at container ship step

InactiveCN109606546AEffective insulationAvoid shear stressAccommodation for deck loadsVessel partsHull structureEpoxy

The invention relates to a vertical support method for a B type fuel tank at a container ship step. According to the method, a special-purpose vertical support device is used; the upper part of the vertical support device is supported at the inclined surface of the side wall of a B type fuel tank and the lower part is arranged a step inside a container. The vertical support device includes a fueltank support, a step base, a laminated batten part and a stainless steel plate. In addition, the method includes the following steps: assembling and welding the fuel tank support on a prefabricated steel frame platform; fixing the laminated batten part and the stainless steel plate at the bottom of the fuel tank support by epoxy; carrying out normality installation on the step base and a step connecting elbow plate and welding the step base at a ship structure by full-penetration welding; setting the lower laminated batten and the stainless steel plate at the top of the step base; and after overall completion and in-place hoisting of the B type fuel tank, placing the B type fuel tank at a corresponding accurate position directly. Therefore, the vertical load of the LNG fuel tank of the container ship is supported effectively.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

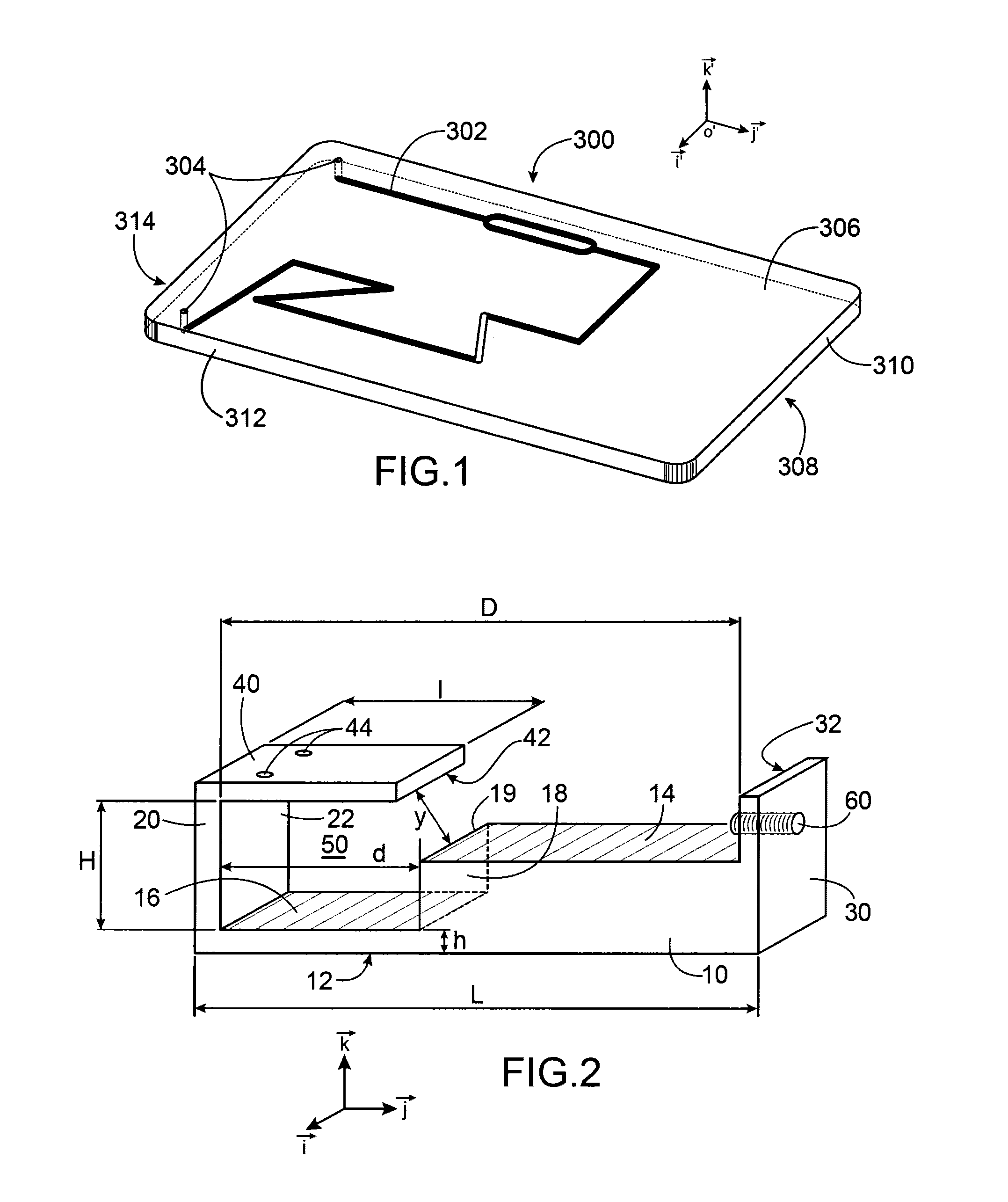

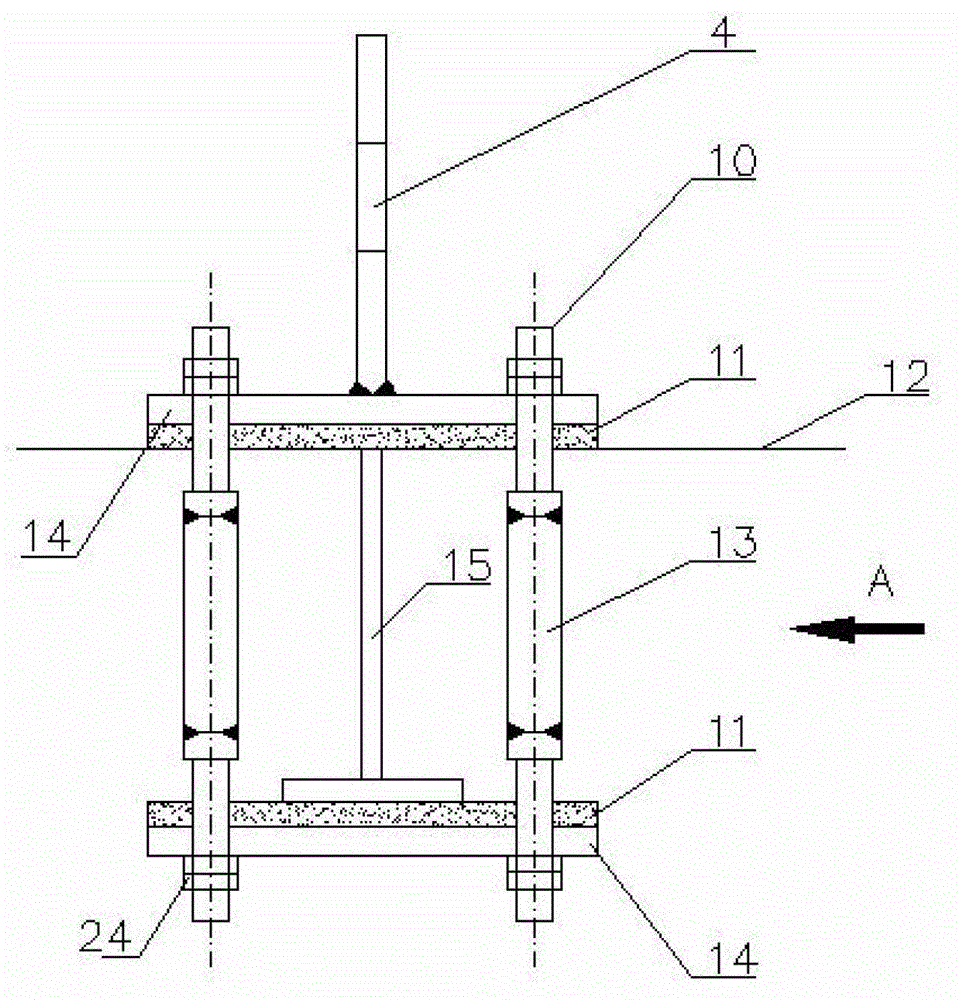

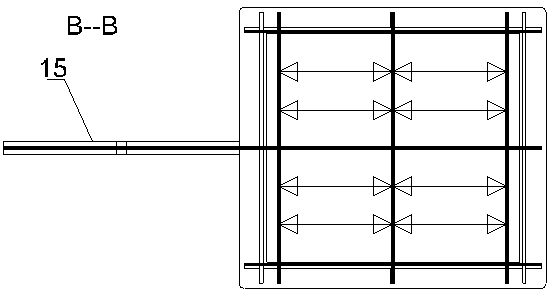

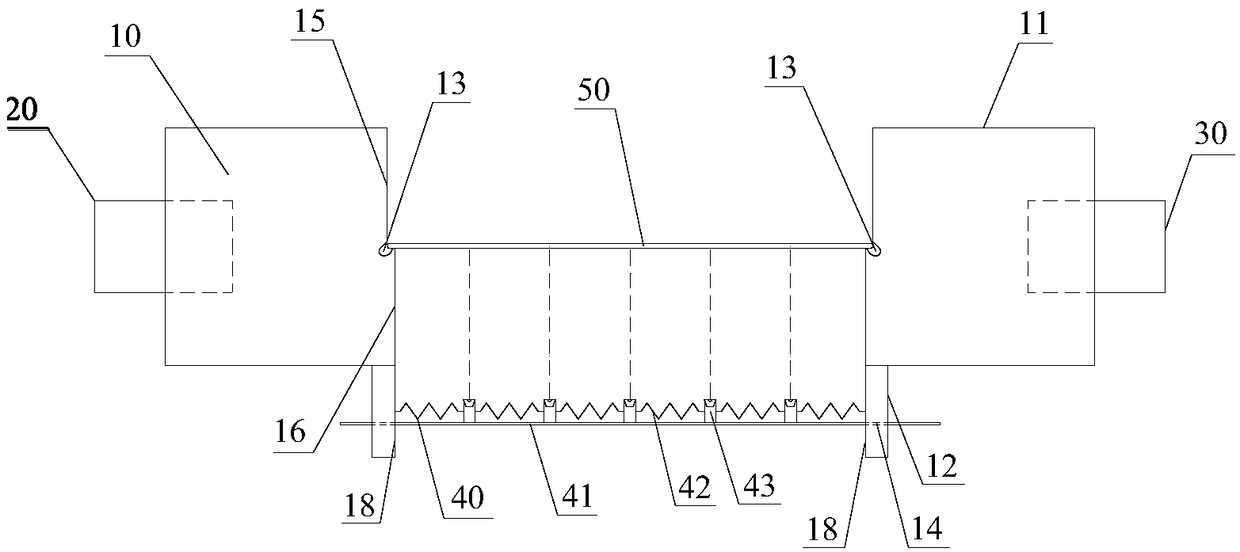

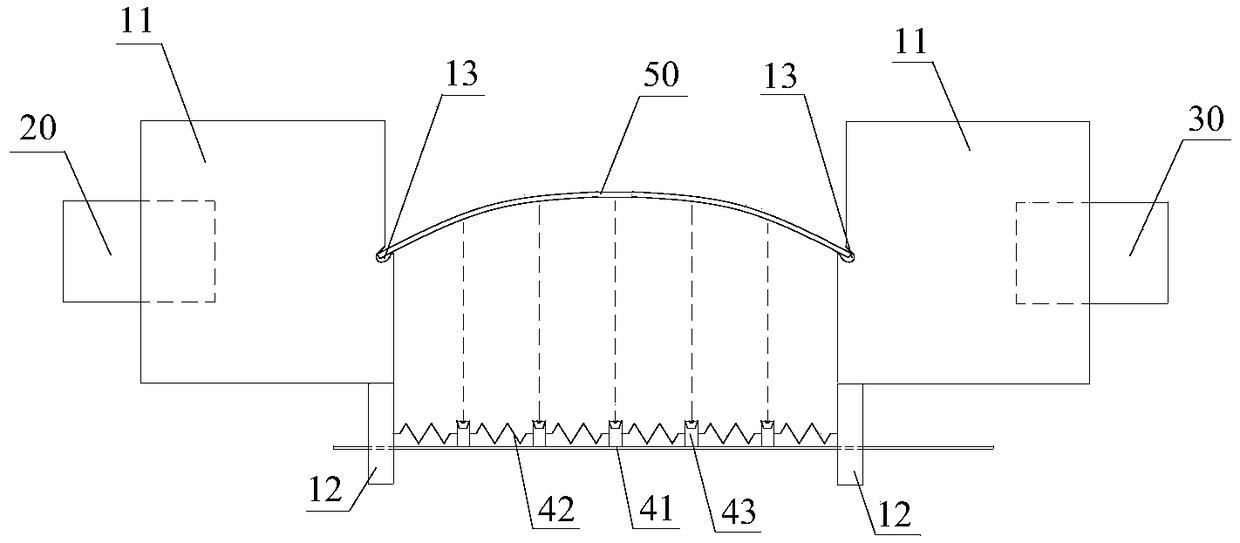

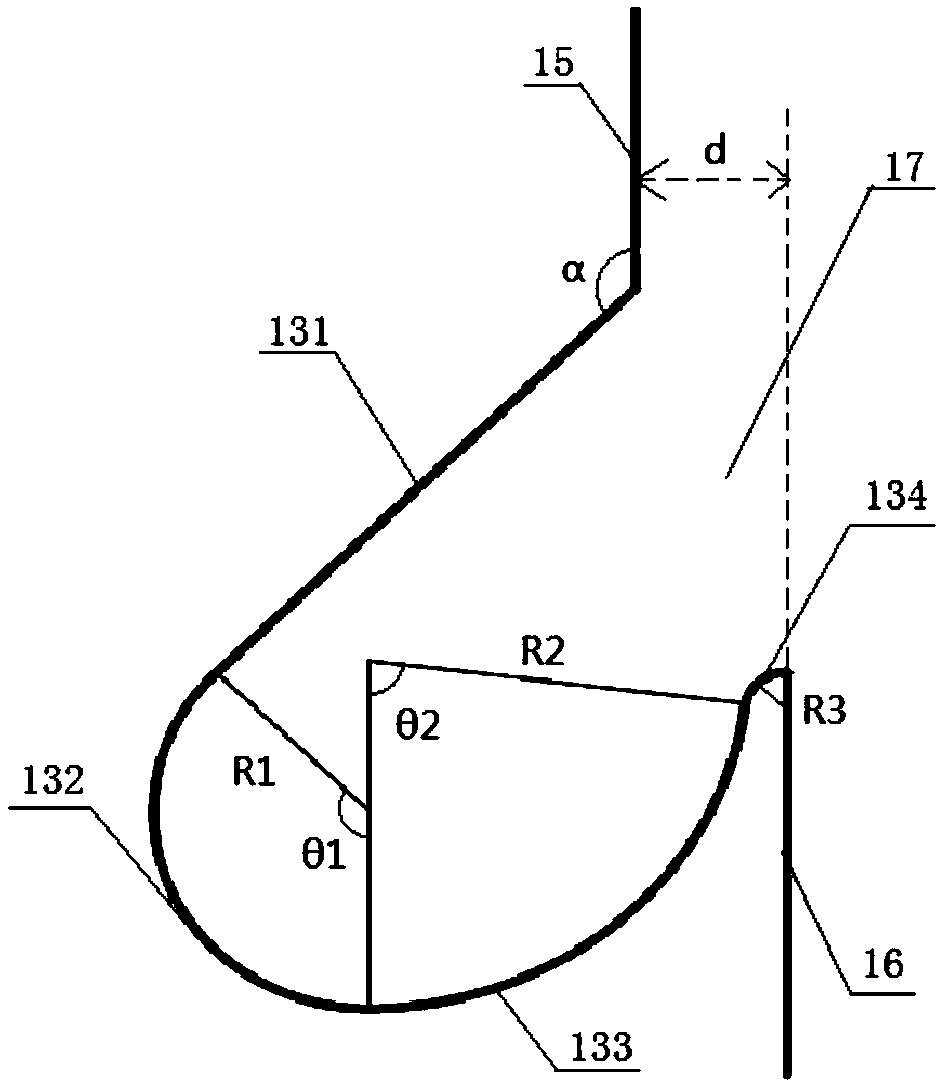

Pure bending test system for automobile steel having thin gauge and high strength and test method

ActiveCN109100236AReflect flexibilityAvoid shear stressMaterial strength using steady bending forcesShear stressEngineering

The invention discloses a pure bending test system for automobile steels having thin gauge and high strength and a test method. The system comprises two sets of clamps symmetrically arranged, a forcesensor, and a set of laser displacement test device; each set of clamps comprises a clamp body, a baffle fixed at the bottom of a working side of the clamp body, and a connection slot formed in the working side of the clamp body; the laser displacement test device comprises a chute, n laser displacement rangefinders arranged on the chute, and n + 1 springs arranged on the chute, wherein n is an odd number; n laser displacement rangefinders are equidistantly and symmetrically arranged on the chute between two inner sides of the baffle; and each adjacent two laser displacement rangefinders are connected through the spring, and the laser displacement rangefinder close to the baffle is connected with the inner side of the baffle through the spring. According to the pure bending test system forautomobile steels having thin gauge and high strength and the test method, only the axial force is generated in the whole process, a shear stress is completely avoided, the shear stress interferenceduring the conventional bending test is avoided, and the bending performance of the material is better reflected.

Owner:武汉钢铁有限公司

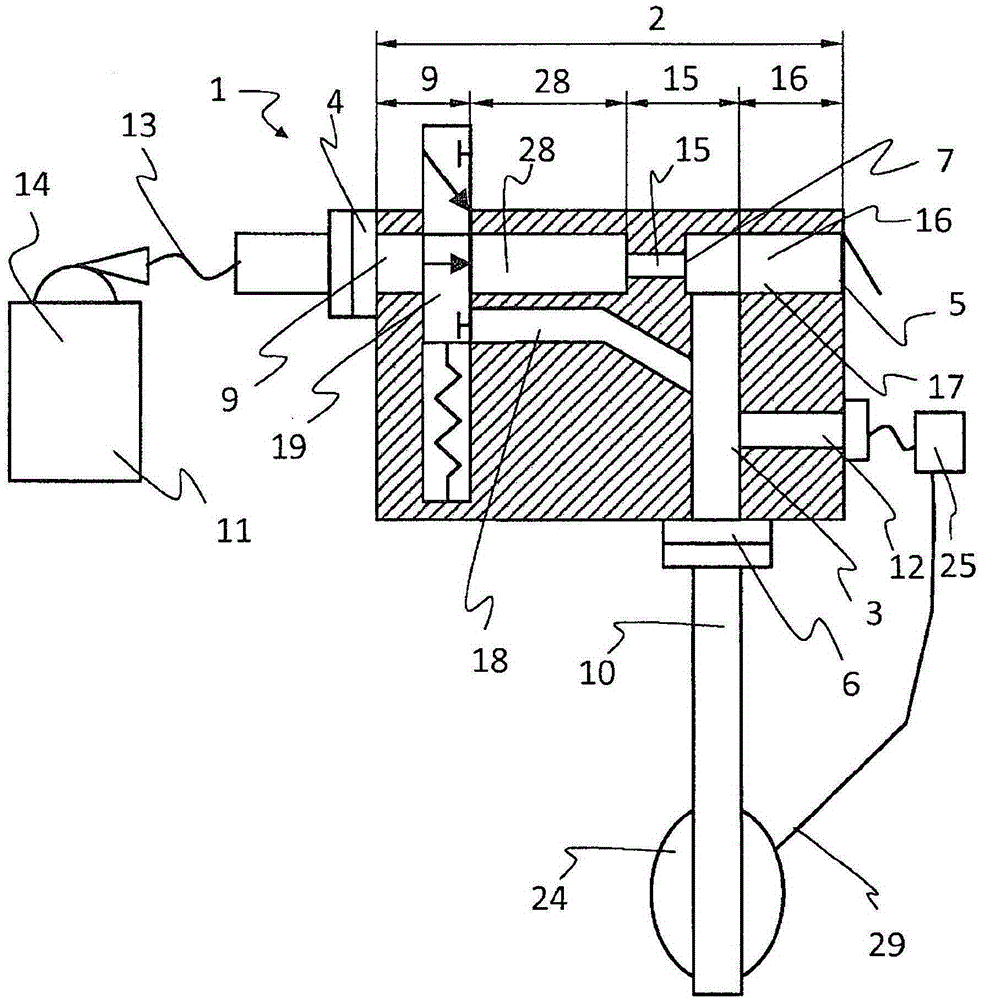

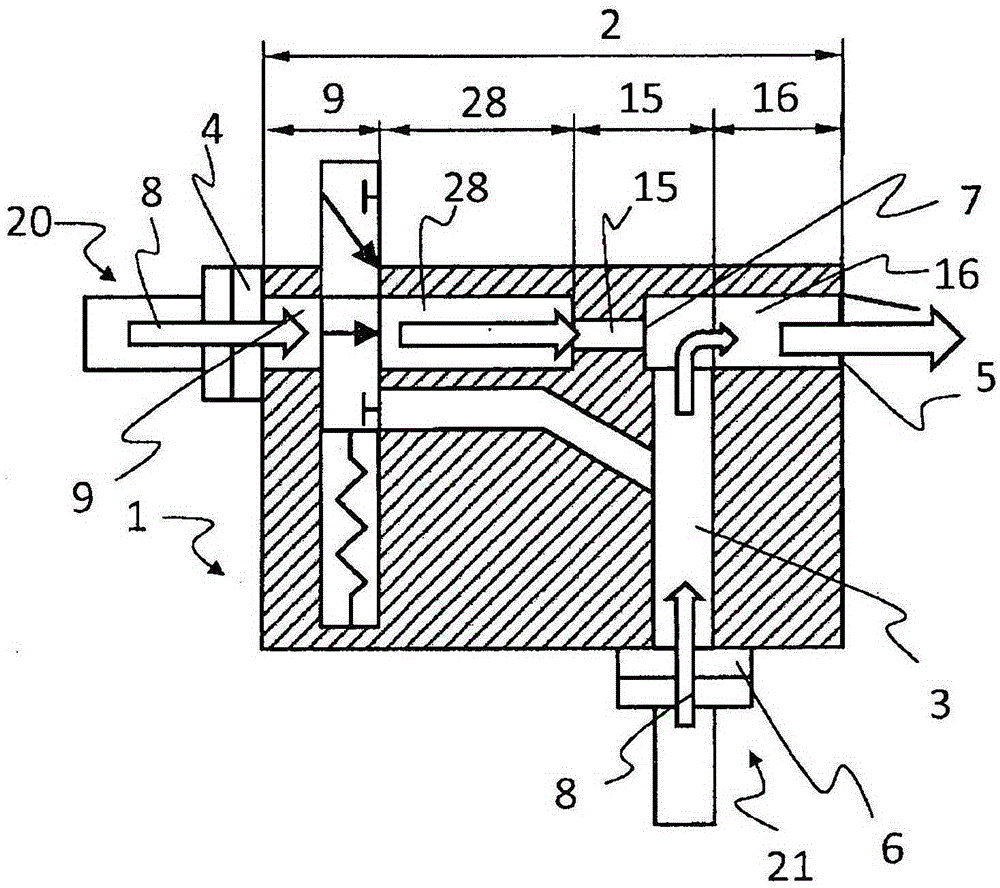

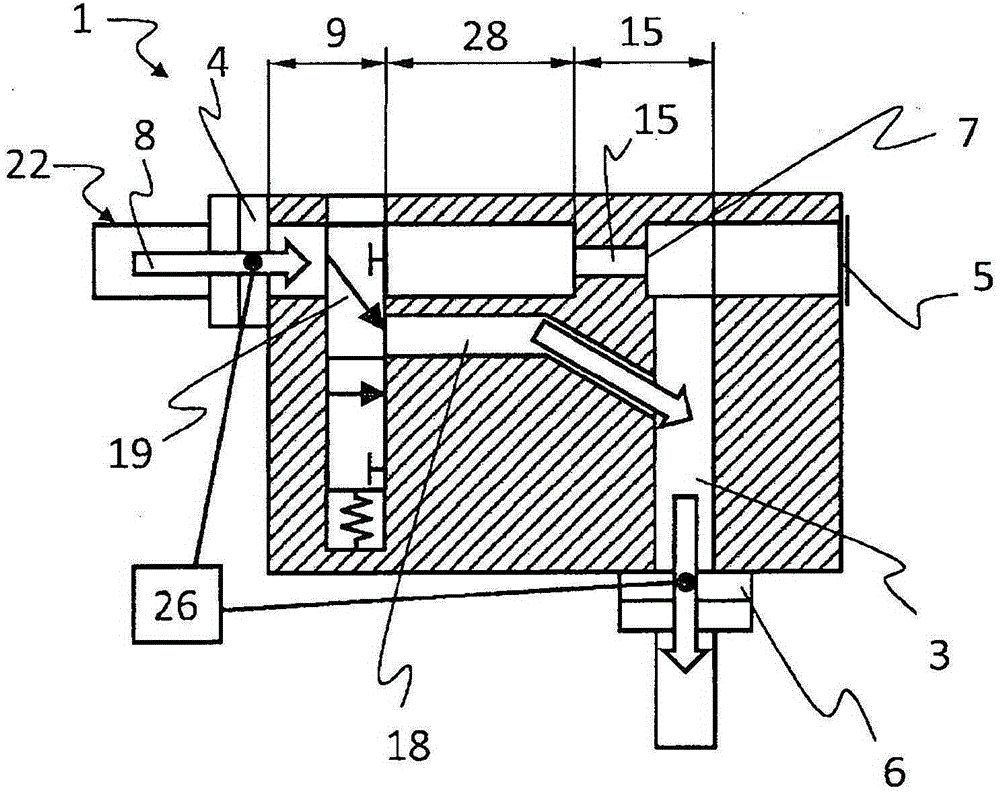

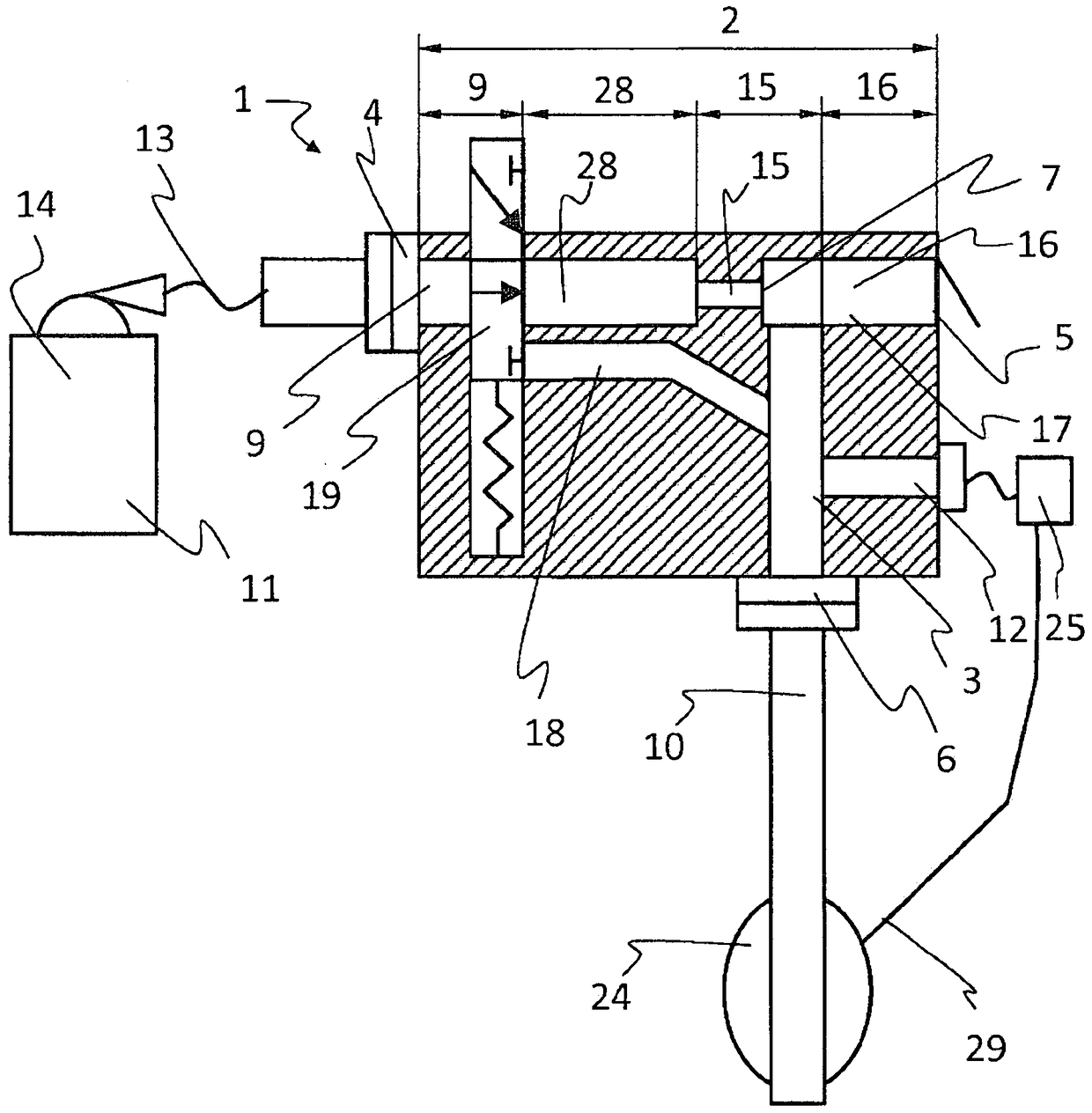

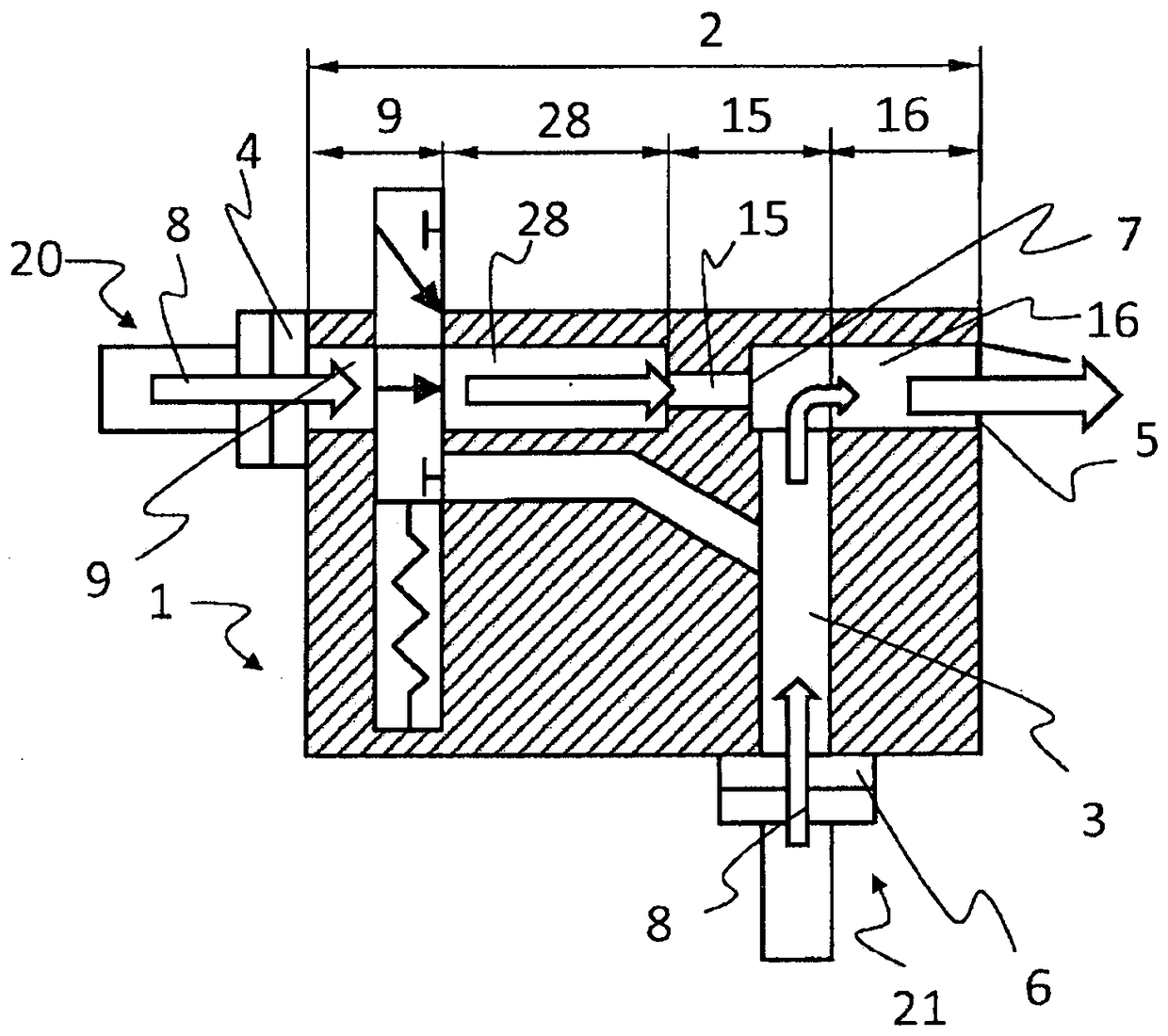

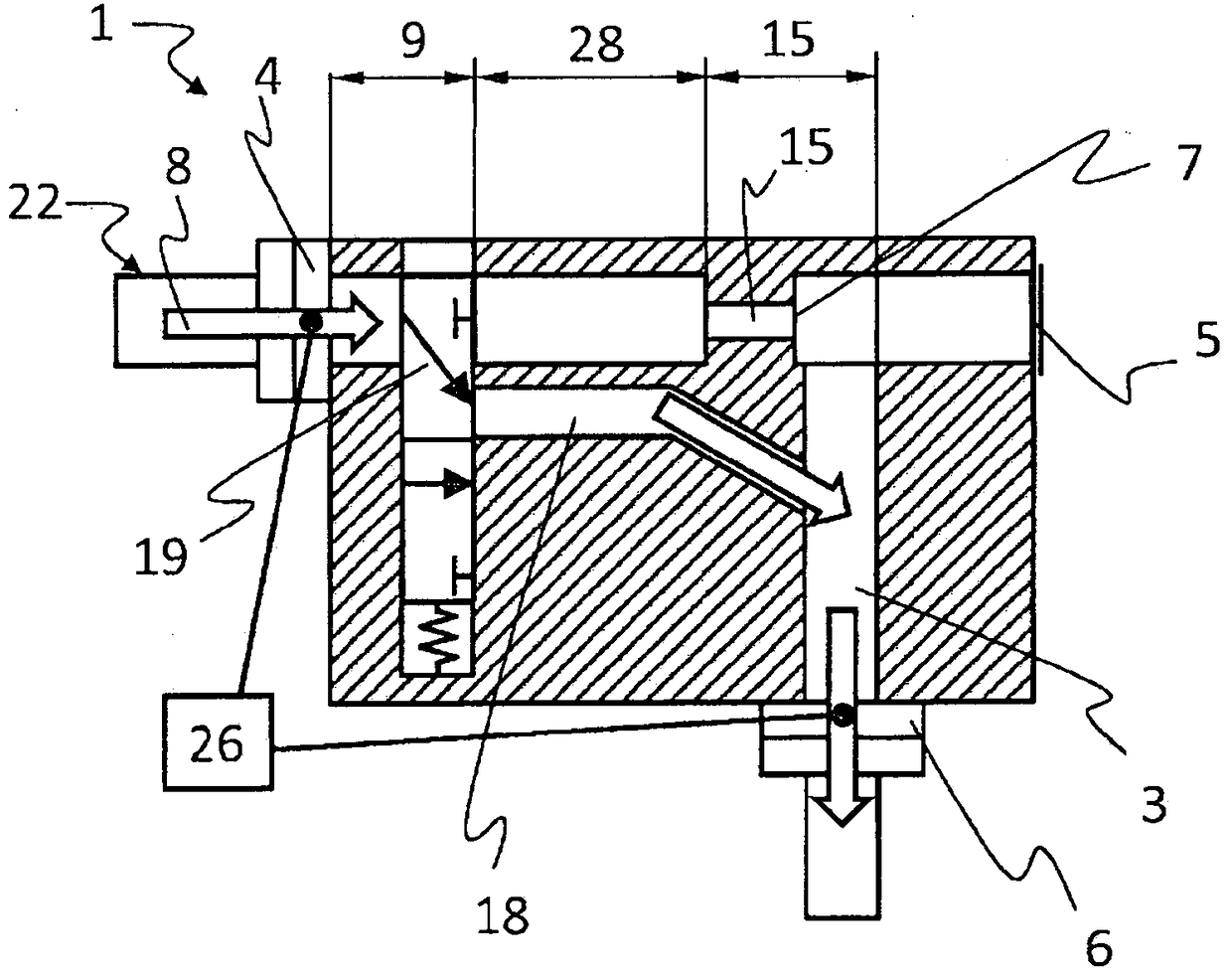

Gas flow reversing element with bypass and method for controlling expiration of a patient

Gas flow reversing element (1) for the use of a gas supply (14) under excess pressure, in particular inspiratory gases, for selectively generating a gas flow (8) from or to a line connector (6) which can in particular be connected to an airway of a patient, said gas flow reversing element (1) being designed as a main piece (2), the main piece (2) at least comprising an inflow region (9), a nozzle region (15) and a mixing region (16), and further a branching piece (3), the inflow region (9) connecting a pressure connector (4), for connection to the gas supply (14), to at least one closable outlet opening (5) arranged in the mixing region (16), and the branching piece (3) connecting the nozzle region (15) of the main piece (2) to the line connector (6), wherein a nozzle (7), particularly an injector nozzle, is configured and arranged in the nozzle region (15) in such a way that, a gas flow (8) flowing along a first flow path (20) through the main piece (2) from the pressure connector (4) subsequently through the inflow region (9), the flow region (28), the nozzle region (15) and through the nozzle (7) into the mixing region (16) to the outlet opening (5), with the outlet opening (5) opened, can generate a gas flow (8) in the branching piece (3) flowing along a second flow path (21) from the line connector (6) and subsequently through the branching piece (3), through the nozzle region (15) and through the mixing region (16) to the outlet opening (5), wherein the gas flow reversing element (1) further comprises a bypass (18) connecting the pressure connector (4) and the line connector (6) so that a gas flow (8) can flow along a third flow path (22) via the inflow region (9), the bypass (18) and the branching piece (3), wherein at least the bypass (18) and the flow region (28) are closable by at least one closing element (19), so that the gas flow (8) can bypass the nozzle (7) in the nozzle region (15) via the bypass (18) along the third flow path (22). The invention further relates to method for controlling expiration of a patient.

Owner:VENTINOVA TECH

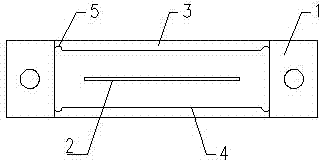

Carbon fiber plate anchorage device limiting tensioning block

InactiveCN104727561AAvoid shear stressReduce stress concentrationBuilding material handlingEngineeringFiber

The invention discloses a carbon fiber plate anchorage device limiting tensioning block which comprises a block body. A square through hole for a carbon fiber plate to penetrate through is formed in the block body, a curved surface concaved inwards is formed in the face, making contact with an anchorage device, of the block body, and a limiting groove communicated with the square through hole is formed in the center of the curved surface. According to the carbon fiber plate anchorage device limiting tensioning block of the structure, in the process that a carbon fiber plate is stretched, shear stress in the thickness direction of the carbon fiber plate can be avoided, stress concentration of the tensioning block can be reduced, and therefore the service life of the tensioning block is prolonged.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

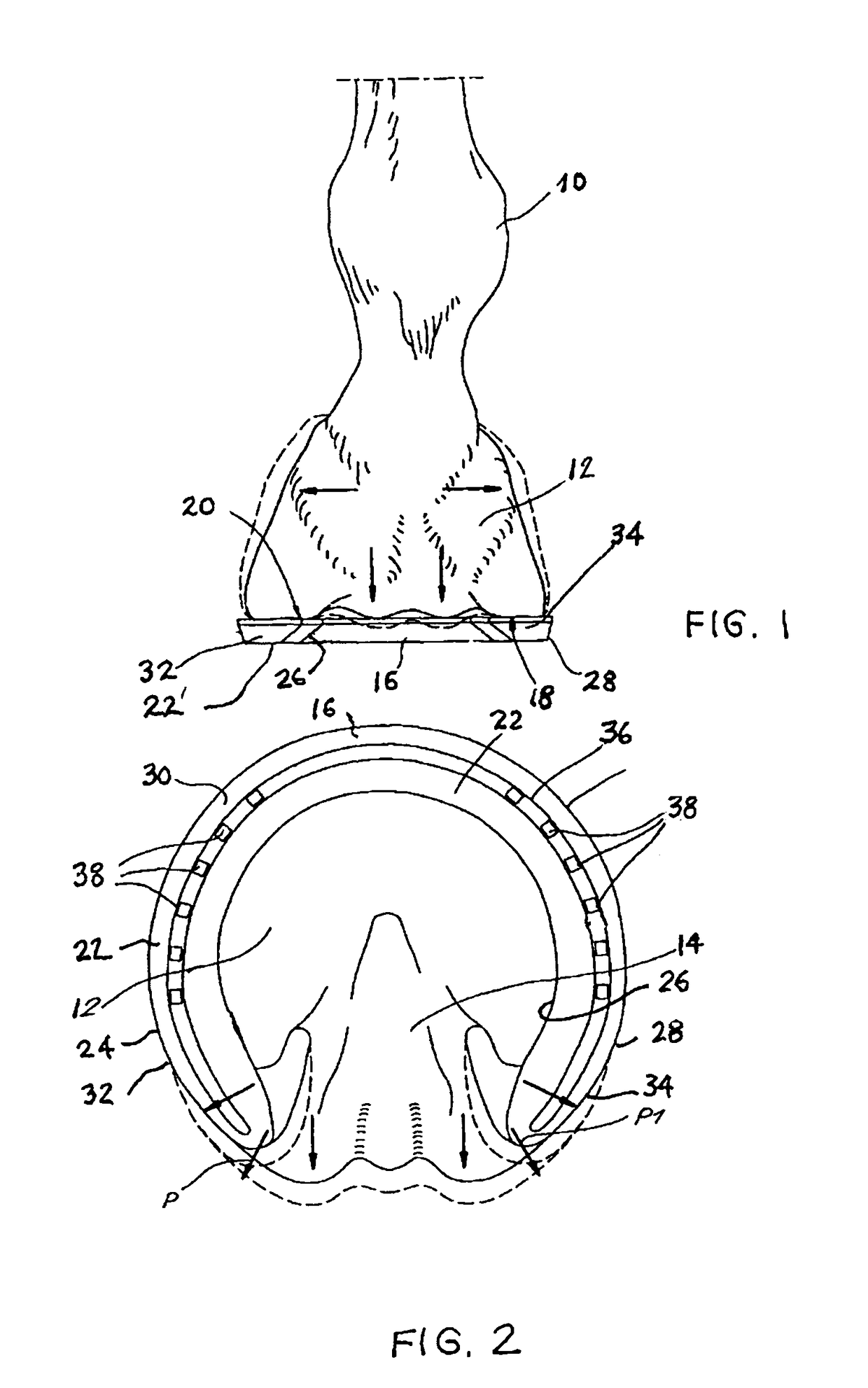

Horseshoe

The present invention provides an improved horseshoe, which comprises a hoof engagement surface that is provided with an unevenness and makes contact with the hoof in such a manner that the shoe will fit more closely to and immovably against the bottom of the hoof. The unevenness provides an anti-slip interference with fibrous material of the hoof to lessen relative movement between the horseshoe and the hoof, both during assembly thereto by a farrier and during galloping of the horse, desirably inhibiting shearing stresses being placed on the securement nails. The anti-slip interference is provided by an array of bumps or hemispherical shaped domes that project upwardly from the hoof-engaging surface to displace fibrous hoof material and complete an interlocking engagement therewith in an amount sufficient to inhibit relative movement but not create discomfort to the horse.

Owner:MUSTAD HOOFCARE

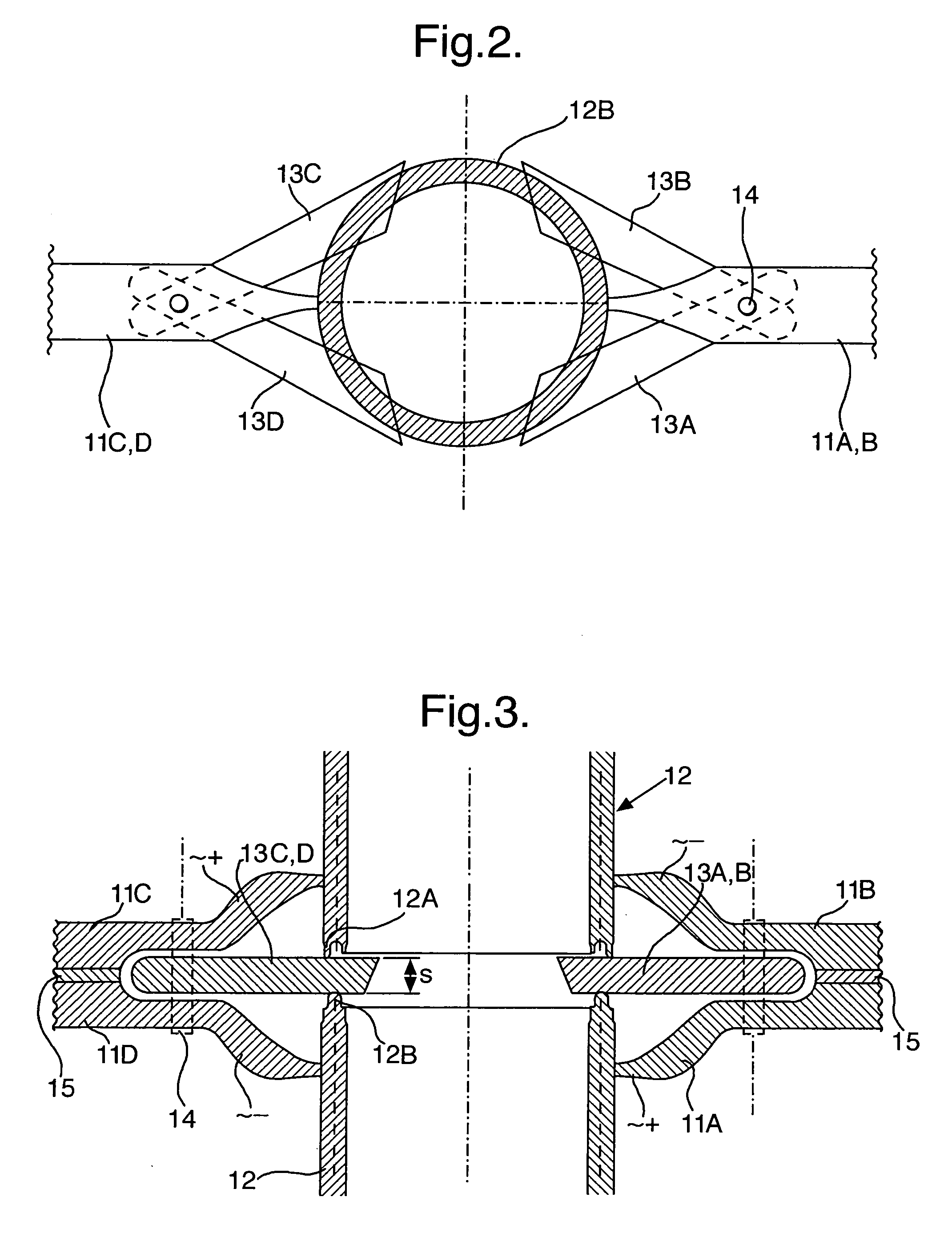

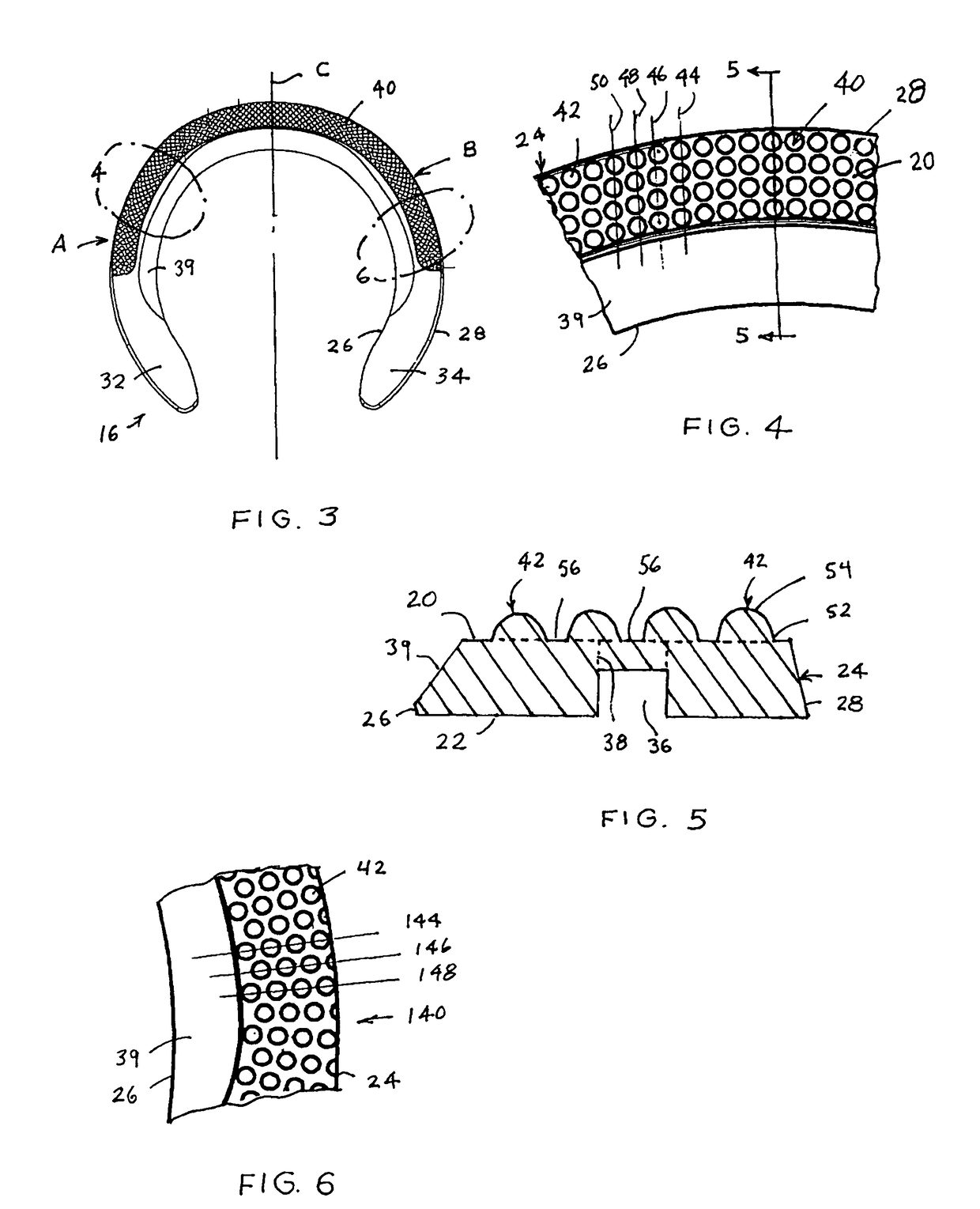

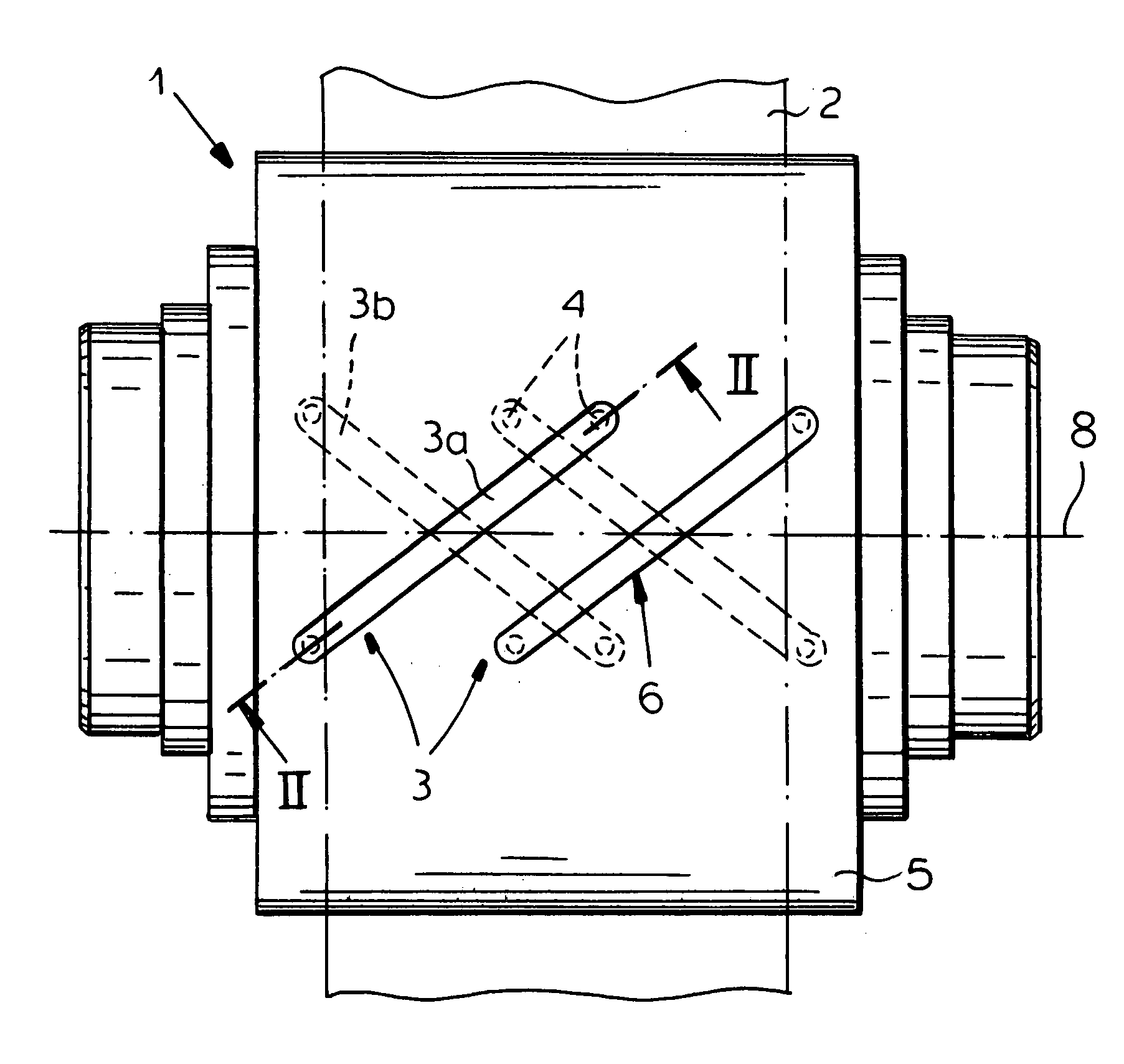

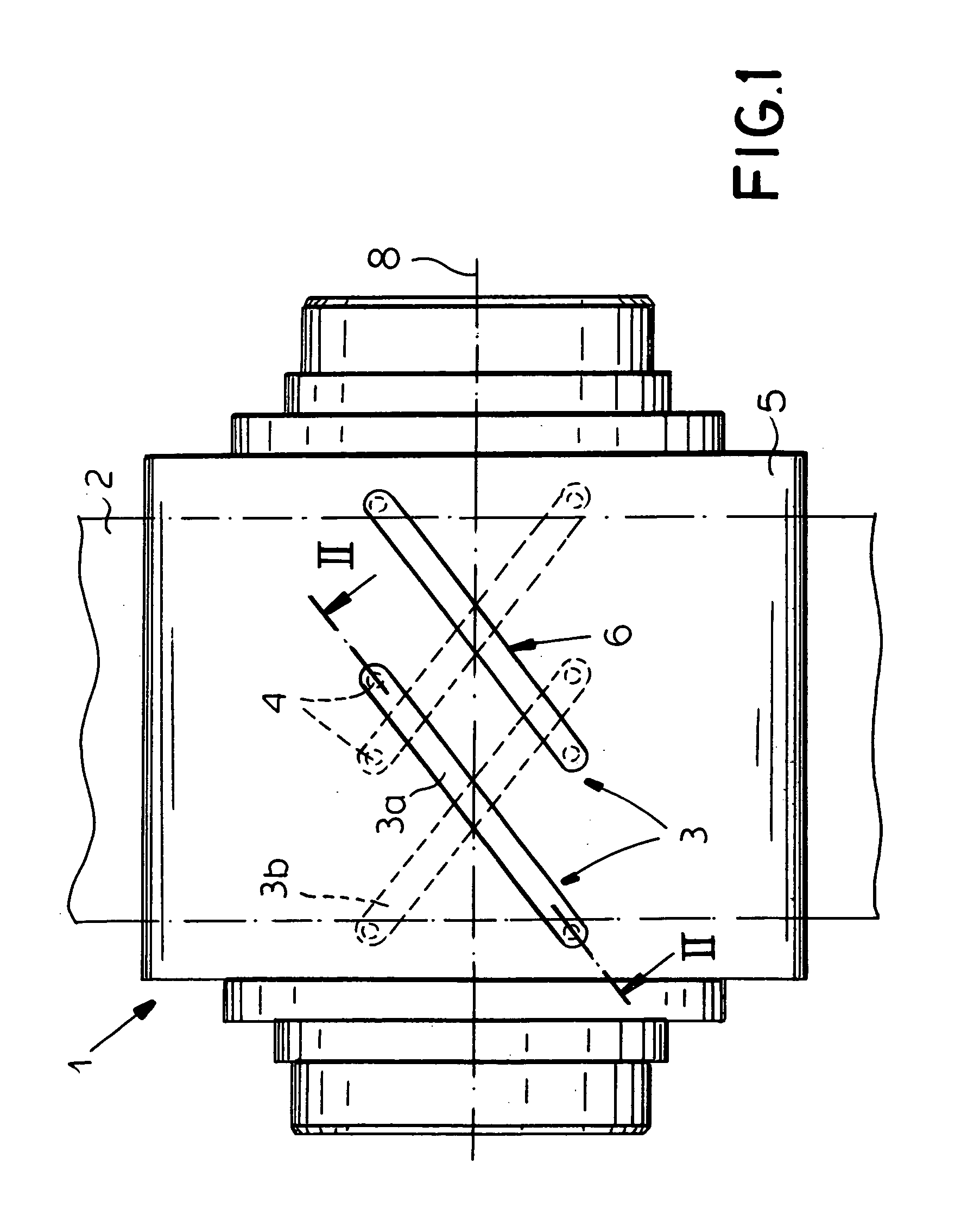

Process for the purpose of determining surface evenness errors in band and particularly steel and metal band and further a surface evenness measuring roller

InactiveCN100396393CImprove dynamic response characteristicsHigh measurement accuracyGas treatmentPhysical/chemical process catalystsObservational errorStress distribution

A method and a surface evenness measuring roller for determining surface evenness measurement errors in steel and metal band comprising at least one measuring head having part measuring heads which part measuring heads are integrated respectively offset by 180 DEG into the roller mantel and supported on two force transmitters and are further separated from the roller mantle by means of a circumferential motion gap and are braced with respect to one another by means of at least one tie rod wherein in the course of a measurement of the band tensile stress distribution over the whole band width the band with band is subject to tension over its whole band width wraps around the surface evenness measuring roller with a predetermined arc of contact and thereby exerts pressing forces onto the surface evenness measuring roller from which pressing forces can be determined the band tension distribution.

Owner:BWG BERGWERK & WALZWERK MASCHINENBAU GMBH

Strip planarity measuring method and apparatus

InactiveUS20050183497A1Increase in numberAvoid shear stressDispersed particle filtrationSpecial data processing applicationsEngineeringWrap around

Owner:BWG BERGWERK & WALZWERK MASCHINENBAU GMBH

Cross head of crank rod type piston compressor

InactiveCN1166870CReduced strength requirementsEasy to manufactureCrossheadsMulti-stage pumpsCross-linkCoupling

A cross-linked coupling for crank-connecting rod piston compressor is disclosed. A short cylindrical cross pin with screwed through hole perpendiculart to its basic line is used to pivot a cross body having a single pin hole seat to the connecting rod with smaller fork end. Said pin hole seat has two through holes coaxial with the sliding cylindrical surface. The piston rod whose end has external screw passes through the bigger hole on pin hole seat and then is turned into the screwed through hole on cross pin. A short cylinder at the end is inserted in another hole to locate the cross-linked coupling. A cross nut has a cylindrical end, which is also inserted said bigger hole to lock the piston rod to the cross-linked coupling.

Owner:XI AN JIAOTONG UNIV

Microfluidic card connection device

ActiveUS9409169B2Avoid shear stressEasy to introduceMaterial analysis by optical meansLaboratory glasswaresEngineeringInterconnection

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

A kind of hoisting method of aluminum alloy superstructure general section

ActiveCN102975818BReduce stress concentrationImprove rigidityVessel partsDeformation controlSuperstructure

The invention provides an aluminum alloy superstructure block hoisting method, which comprises the following steps of (1) determining the quantity of multiple hoisting points, positions of multiple hoisting points and an integral hoisting method of an aluminum alloy superstructure block according to the weight of the aluminum alloy superstructure block, a structural form and a gravity core; (2) producing a hoisting bracket for hoisting the aluminum alloy superstructure block; (3) designing and installing temporary reinforcement onto the aluminum superstructure block according to the integral hoisting method; (4) installing one hoisting hanger on each position of multiple hoisting points; and (5) vertically joining the hoisting hangers with the hoisting bracket through a wire cable, and utilizing the hoisting bracket to carry out the multipoint vertical hoisting. According to the hoisting method, not only can the deformation control problem for hoisting the aluminum superstructure block be solved and sectional construction of the aluminum alloy superstructure block be realized, but also the hoisting hangers and the temporary reinforcement for the hoisting are convenient to disassemble, and the block hoisting time can be shortened.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Construction method for band type fiber reinforcing material for reinforced-soil retaining-wall

ActiveUS10392772B2Easy and rapid connectionImprove stabilityArtificial islandsExcavationsStress concentrationBand shape

Owner:HANFORCE

Anchoring technical measure for pasting carbon fiber plate to bottom of steel bar concrete beam

The invention provides an anchoring technical measure for pasting a carbon fiber plate to the bottom of a steel bar concrete beam. The carbon fiber plate is pasted at the bottom of an original steel bar concrete beam, the carbon fiber plate is wrapped in outer wrapped angle steel, a U-shaped steel hoop plate is installed, and the external prestress of a three folding line is constructed to form anexternal prestress-angle steel-carbon fiber plate combined strengthen beam. The bending deformation springback force of the angle steel and the external prestress lifting force are used, the normal force is provided to the carbon fiber plate, so that the friction force generates between the carbon fiber plate and the bottom of the steel bar concrete beam to overcome the shear stress between the carbon fiber plate and the bottom of the steel bar concrete beam, it is ensure that the reinforced steel bar concrete beam of the carbon fiber plate not generates bond slip failure, and the ultimate tensile strength of the pasted carbon fiber plate can be brought into full play; and the angle steel and the external prestress are both beam reinforcement materials and anchoring measure treatment materials for the carbon fiber plate, and killing two birds with one stone is achieved.

Owner:江苏交通工程咨询监理有限公司

Gear system for a timepiece

Owner:NIVAROX FAR

Air flow reversing element with bypass tube and method of controlling patient exhalation

A gas flow reversing element (1) using a gas source (14) under overpressure, in particular suction gas, for selectively generating a gas flow (8) from or to a pipe connection (6), in particular Can be connected to the patient's airway, the air flow reversing element (1) is designed as a main part (2) and an additional branch part (3), the main part (2) at least includes an inflow area (9), a nozzle area ( 15) and a mixing zone (16), the inflow zone (9) connects the pressure connection (4) for connection to the gas source (14) to at least one closable outlet hole ( 5), and the branch piece (3) connects the nozzle area (15) of the main part (2) to the pipe joint (6), wherein the nozzle (7), especially the injection nozzle, is configured and arranged in the nozzle area (15) , so that when the outlet hole (5) is opened, the air flow (8) flowing to the outlet hole (5) along the first flow path (20) through the main part (2) can be generated in the branch part (3) The gas flow (8) flowing to the outlet hole (5) along the second flow path (21), wherein the first flow path starts from the pressure joint (4), sequentially passes through the inflow zone (9), the flow zone (28) , the nozzle area (15), and enter the mixing area (16) through the nozzle (7), and the second flow path starts from the pipe joint (6), and passes through the branch piece (3), through the nozzle area (15) , and through the mixing zone (16), wherein the air flow reversing element (1) also includes a bypass pipe (18), which connects the pressure joint (4) and the pipe joint (6), so that the air flow (8) can Flow along a third flow path (22) via the inflow zone (9), the bypass tube (18) and the branch piece (3), wherein at least the bypass tube (18) and the flow zone (28) are closed by at least one The element (19) is closable so that the gas flow (8) can bypass the nozzles (7) in the nozzle zone (15) along the third flow path (22) via the bypass line (18). The invention also relates to a method of controlling a patient's exhalation.

Owner:VENTINOVA TECH

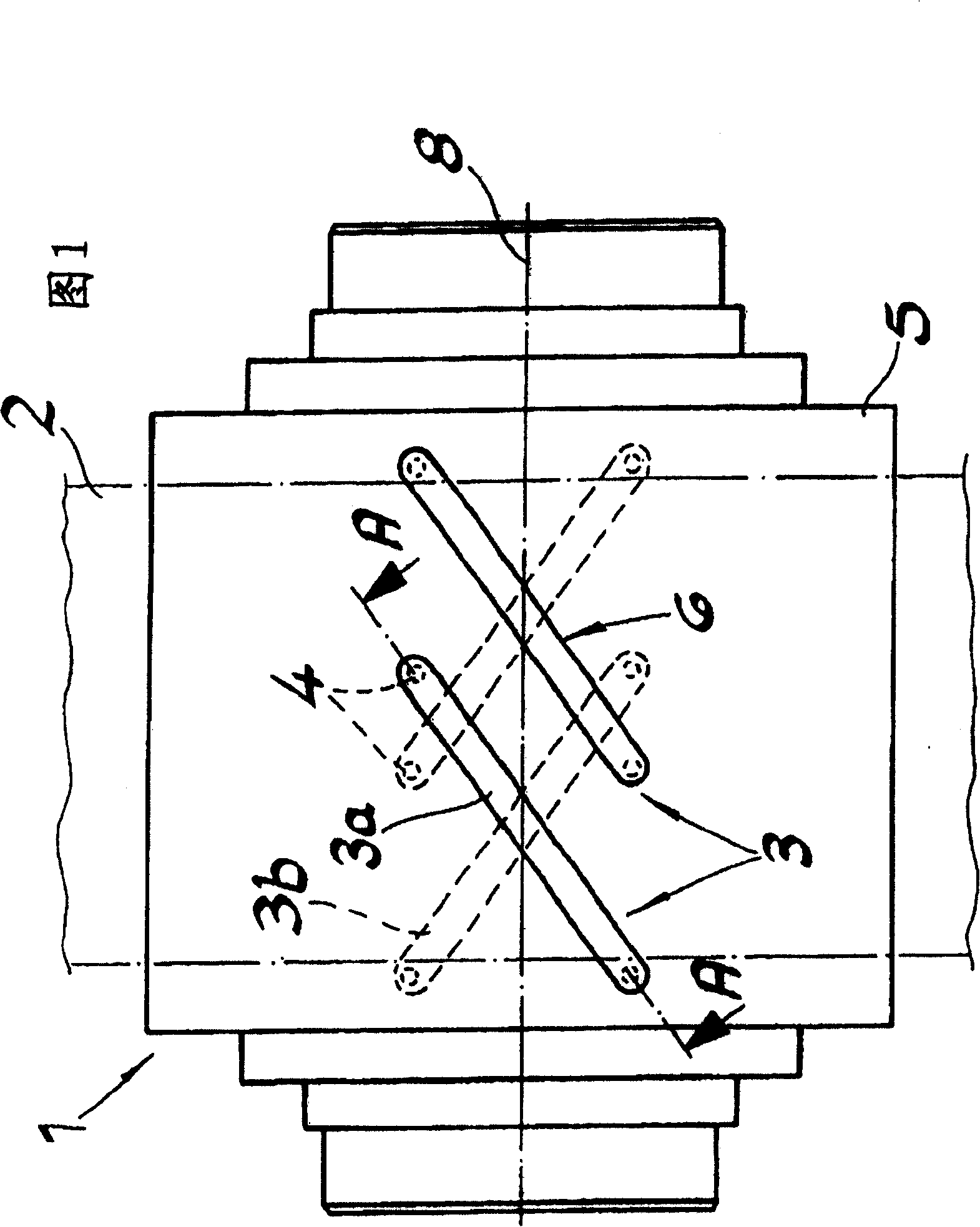

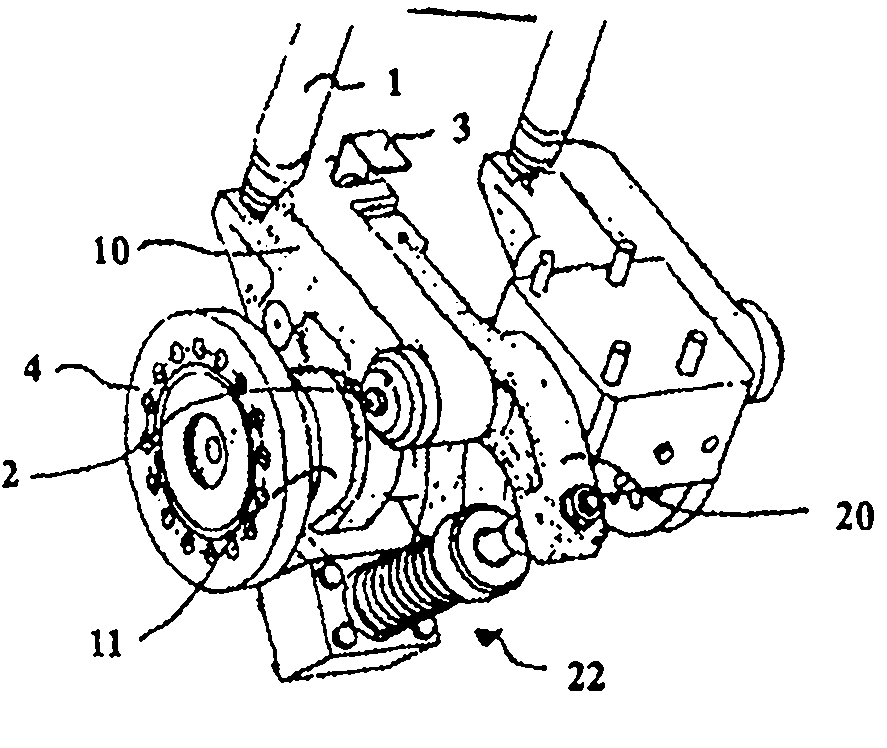

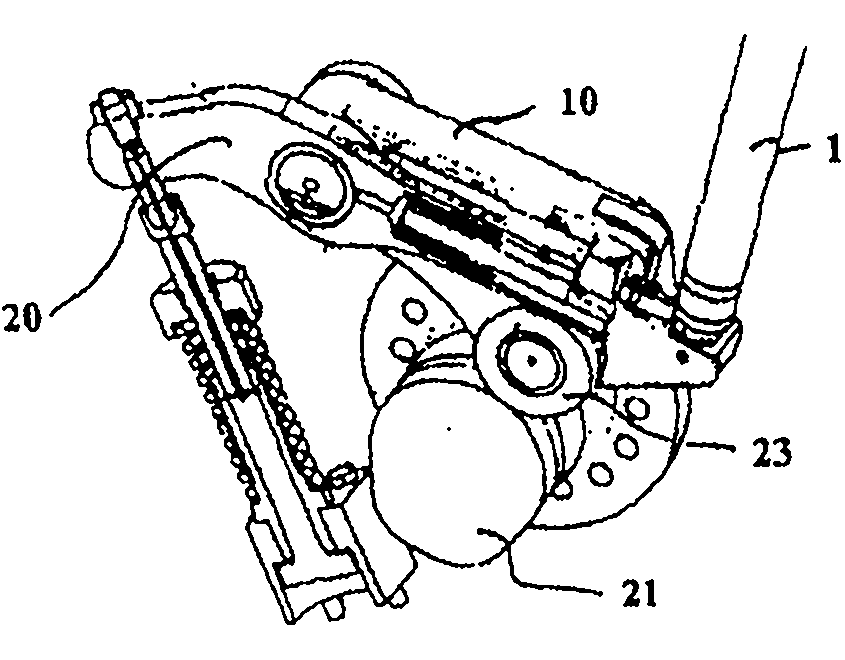

Valve train for internal combustion engine

InactiveCN101713305BTo rotate togetherPlay the role of rotationValve arrangementsMachines/enginesExternal combustion engineEngineering

PURPOSE: A valve train for an internal combustion engine is provided to prevent the displacement force of the switching element from acting in the axial direction of the valve lifter shaft, thereby reducing abnormal twist and deformation of the valve lifter. CONSTITUTION: A valve train for an internal combustion engine comprises a main valve lifter which rotates around a valve lifter shaft(2) in a rotational direction(D) by a first cam of a cam shaft, and a switching valve lifter(20) which rotates around the valve lifter shaft by a second cam(21) of the cam shaft. The switching valve lifter comprises a switching element with a switching pin(31) and a stopper(32). The stopper is arranged in the main valve lifter or the switching valve lifter. The switching pin is guided to slide in the progress direction from the main valve lifter or the switching valve lifter, where the progress direction is vertical to the valve lifter shaft.

Owner:MAN ENERGY SOLUTIONS SA

Vertical supporting device of fuel bunker on step of container ship and mounting method thereof

InactiveCN109398605AEffective insulationAvoid shear stressHull interior subdivisionVessel designingEngineering

The invention discloses a vertical supporting device of a fuel bunker on a step of a container ship. The vertical supporting device of the fuel bunker on the step of the container ship comprises a fuel bunker support, a step base, an upper laminating wood beam and a lower laminating wood beam; the step base is welded on the step; the lower laminating wood beam is connected to the step base; the fuel bunker support comprises a support bottom plate, a first reinforcing structure, a second reinforcing structure, an upper clamping groove plate and a buffering plate; the upper clamping groove plateis welded to the lower part of the support bottom plate; the upper clamping groove plate forms an upper accommodating cavity; the upper laminating wood beam is bonded in the upper accommodating cavity; the upper laminating wood beam is placed on the lower laminating wood beam; the first reinforcing structure is welded to the upper part of the support bottom plate; and the buffering plate is welded at he upper part of the first reinforcing structure. According to the vertical supporting device of the fuel bunker on the step of the container ship, heat transmission is effectively avoided, the design is reasonable, the manufacturing is convenient, the mechanical performance is good, the heat insulation performance is good, and very good practical value is realized.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

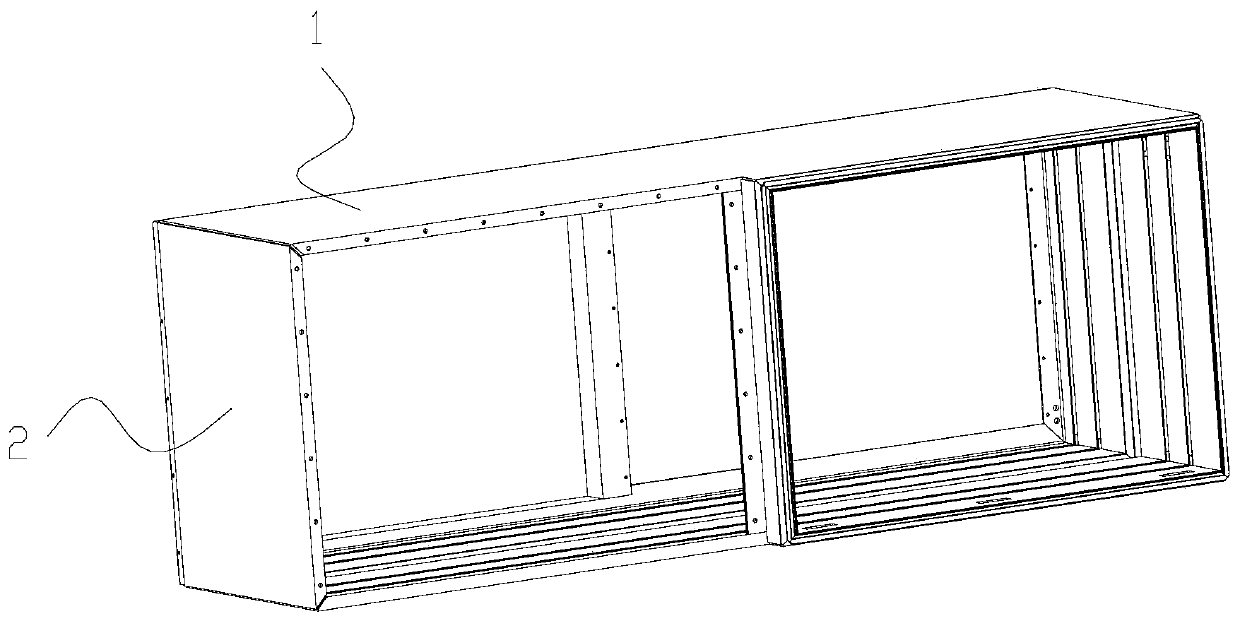

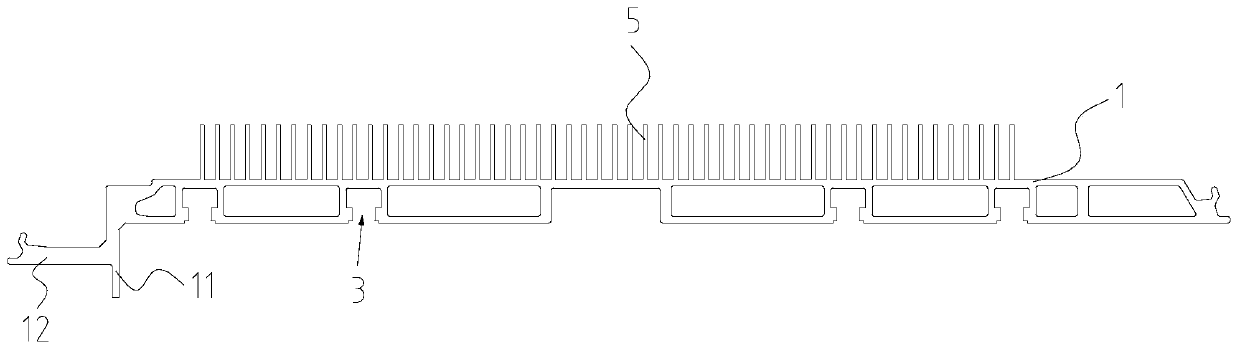

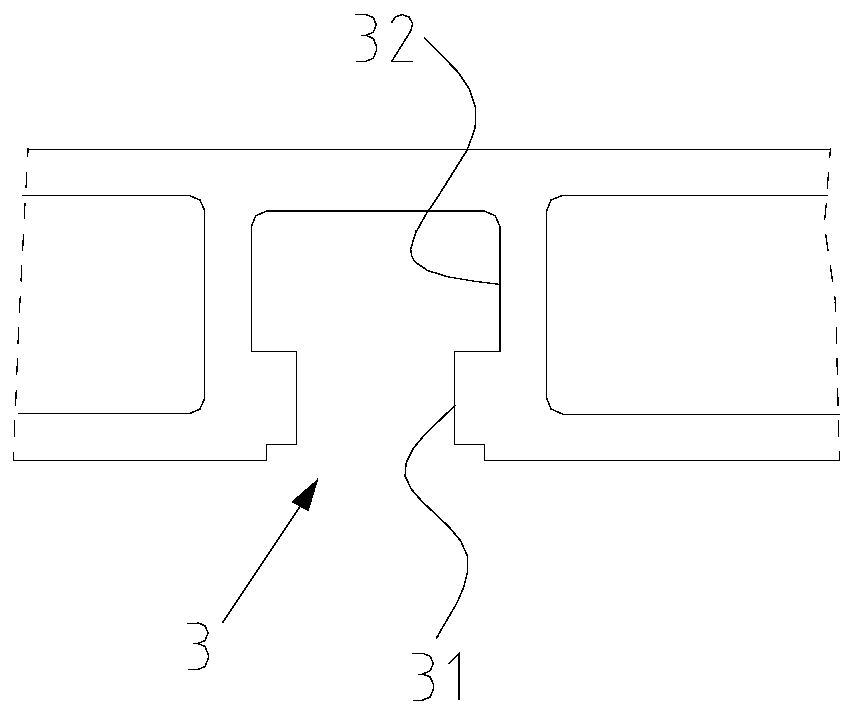

Electrical equipment box

ActiveCN109922628AEasy to installAvoid shear stressCasings/cabinets/drawers detailsSupport structure mountingElectrical devicesEngineering

The invention provides an electrical equipment box, comprising a box body plate and side plates, wherein the box body plate is connected with the side plates, T-shaped chutes for mounting bolts are formed in inner surfaces of the box body plate and the side plates, the T-shaped chutes comprise first rectangular grooves and second rectangular grooves, the first rectangular grooves and the second rectangular grooves are formed in a penetration manner, the first rectangular grooves and the second rectangular grooves are formed in the surfaces of the box body plate and the side plates, and the widths of the first rectangular grooves are less than the widths of the second rectangular grooves. According to the electrical equipment box provided by the invention, by forming the T-shaped chutes formounting bolts in the inner surfaces of the box body plate and the side plates, the opposite edges of the bolts can be firmly clamped, the traditional double-faced mounting operation form of bolts and nuts is changed into single-faced operation, so that the installation is convenient and fast.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

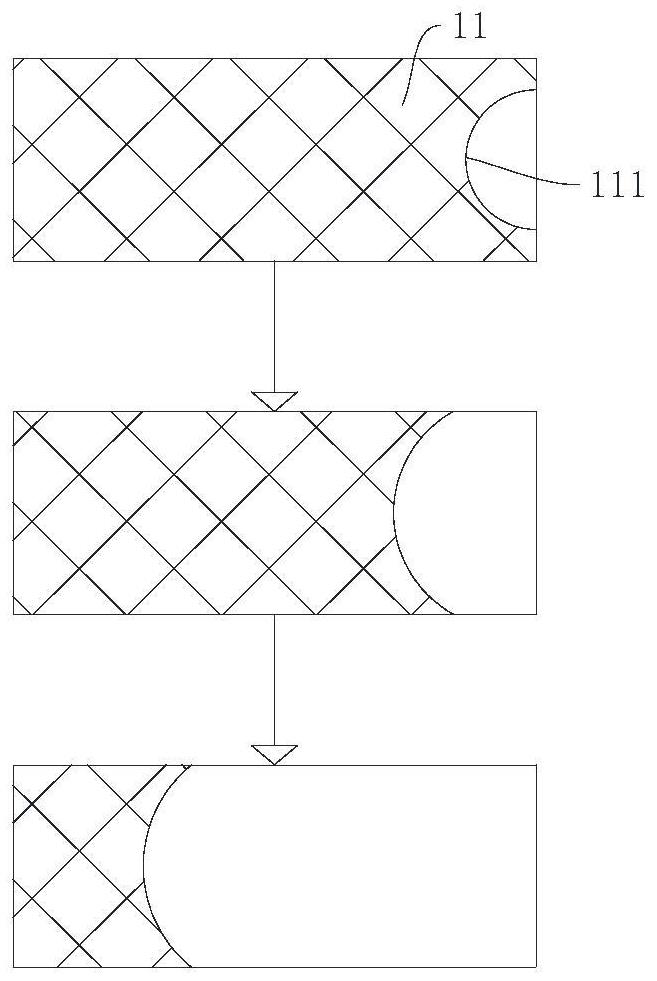

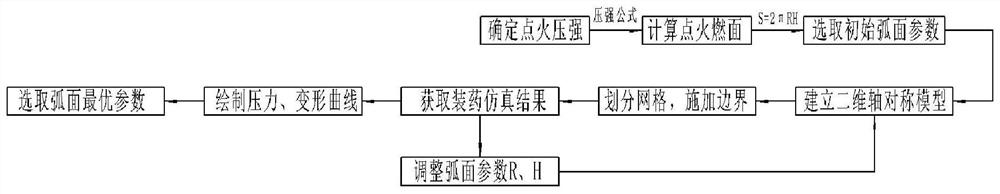

High-overload solid rocket engine and explosive type design method thereof

PendingCN114233517AImprove stressAvoid shear stressGeometric CADDesign optimisation/simulationCombustion chamberMechanical engineering

The invention provides a high-overload solid rocket engine and a charge design method thereof.The high-overload solid rocket engine comprises a combustion chamber shell, an end socket arranged at one end of the combustion chamber shell and a spray pipe assembly arranged at the other end of the combustion chamber shell, the combustion chamber shell is filled with grains and a buffer pad, the buffer pad is provided with a through hole for ignition, and the through hole is communicated with the end socket. The hole diameter of the through hole is larger than that of a hole, communicated with the grain, of the spray pipe assembly, and the side, close to the spray pipe assembly, of the grain is concaved inwards to form a curved surface. The method has the effects that the probability of ignition failure in the prior art can be relatively reduced, and the problem that the structural integrity of the grain is damaged under the overload working condition can be relatively solved.

Owner:西安零壹空间科技有限公司 +4

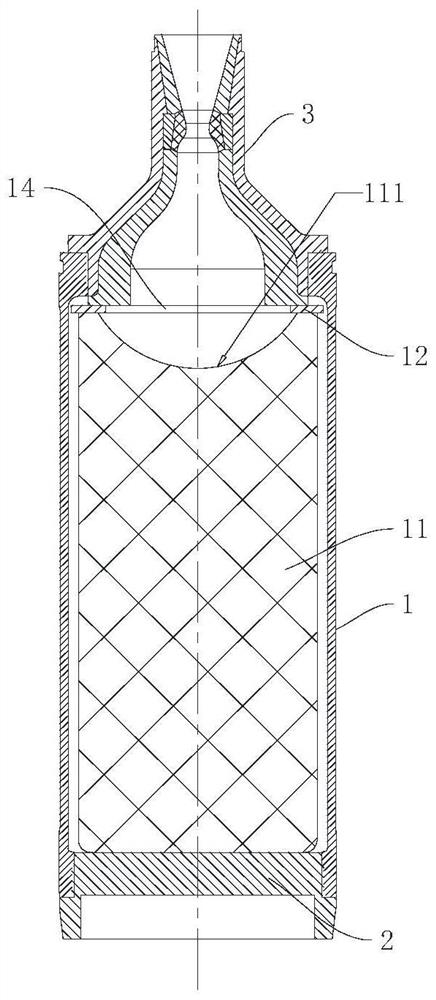

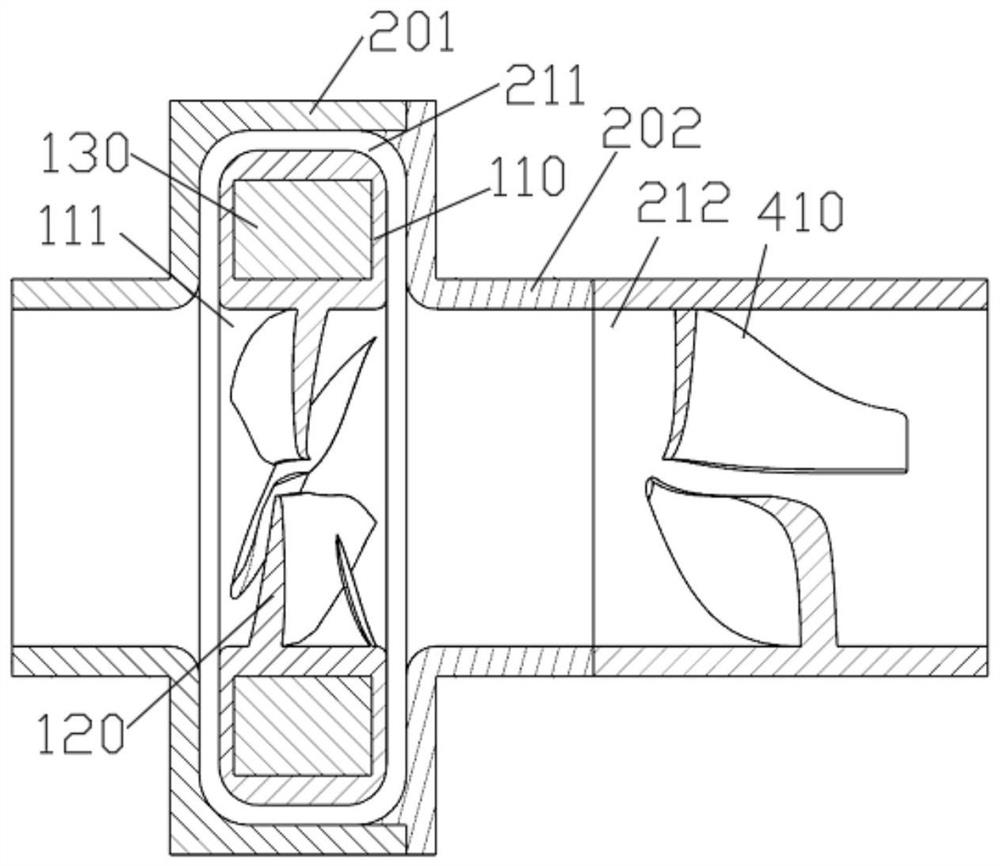

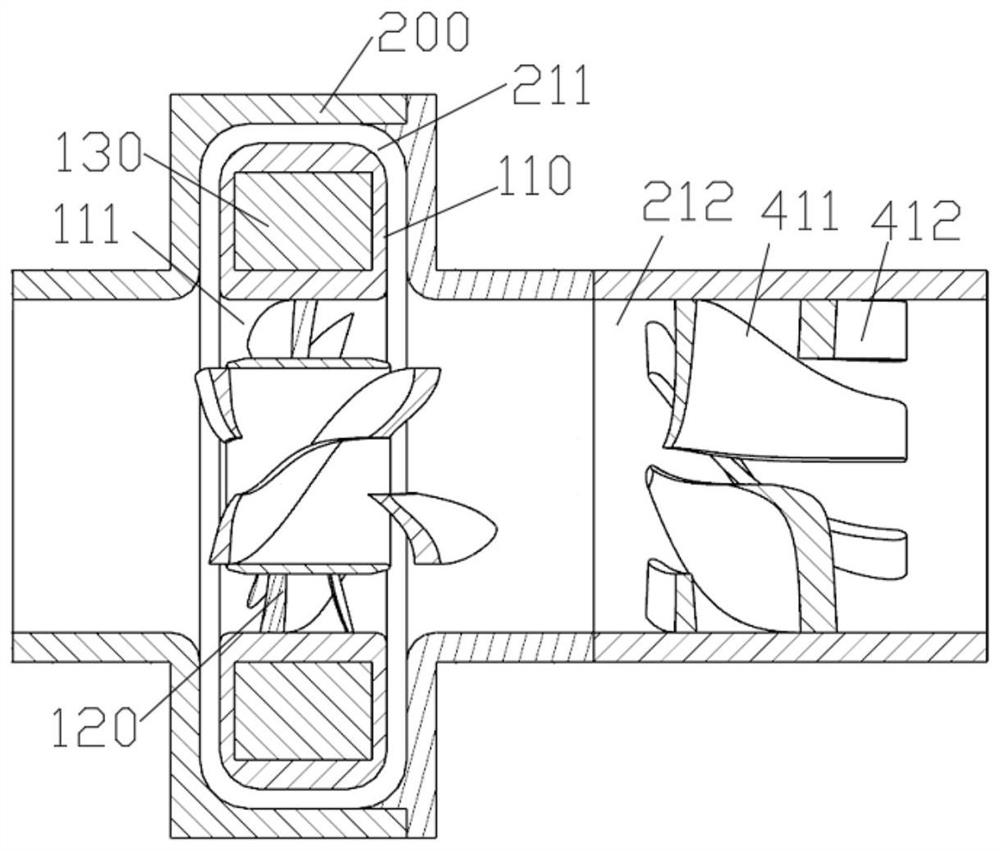

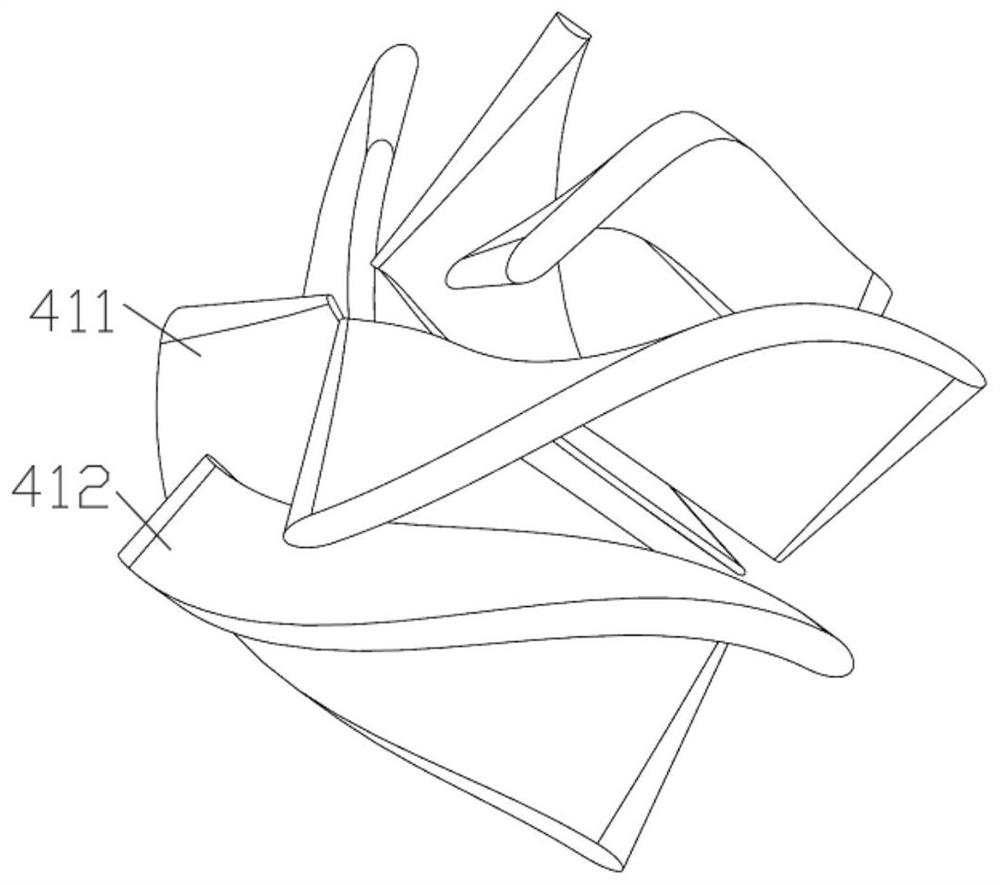

Rotation device and blood pump

PendingCN114534089AAvoid shear stressAvoid destructionIntravenous devicesBlood pumpHemocytoblastBlood pump

The embodiment of the invention discloses a rotating device and a blood pump, and the rotating device comprises a first housing which is provided with a first accommodating cavity; the rotating assembly is arranged in the first containing cavity and can rotate in the first containing cavity; the rotating assembly comprises a first body and a first blade; a first through groove is formed in the first body; the first blade is fixed on the inner wall of the first through groove; the guide assembly is arranged in the first accommodating cavity; under the condition that the rotating assembly rotates, the first blade is used for pushing blood to flow in the first direction and rotate in the second direction; the guide assembly is used for rotating the blood in a third direction. According to the blood pump, due to the fact that the first blade is directly fixed to the inner wall of the through groove, shear stress is prevented from being generated between the first blade and the inner wall of the through groove, blood cell damage caused by gaps between the blades and the inner wall of the through groove can be prevented, and hemolytic reaction is prevented; the tendency that the first blade enables the blood to rotate in the second direction can be reduced through the guide assembly.

Owner:浙江宏海医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com