Gas flow reversing element with bypass and method for controlling expiration of a patient

A technology of reversing components and bypass tubes, which is applied in the direction of respirators, medical devices, and other medical devices, and can solve problems such as blockage of air flow reversing components and failure to guarantee patients to provide predetermined volumes and concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

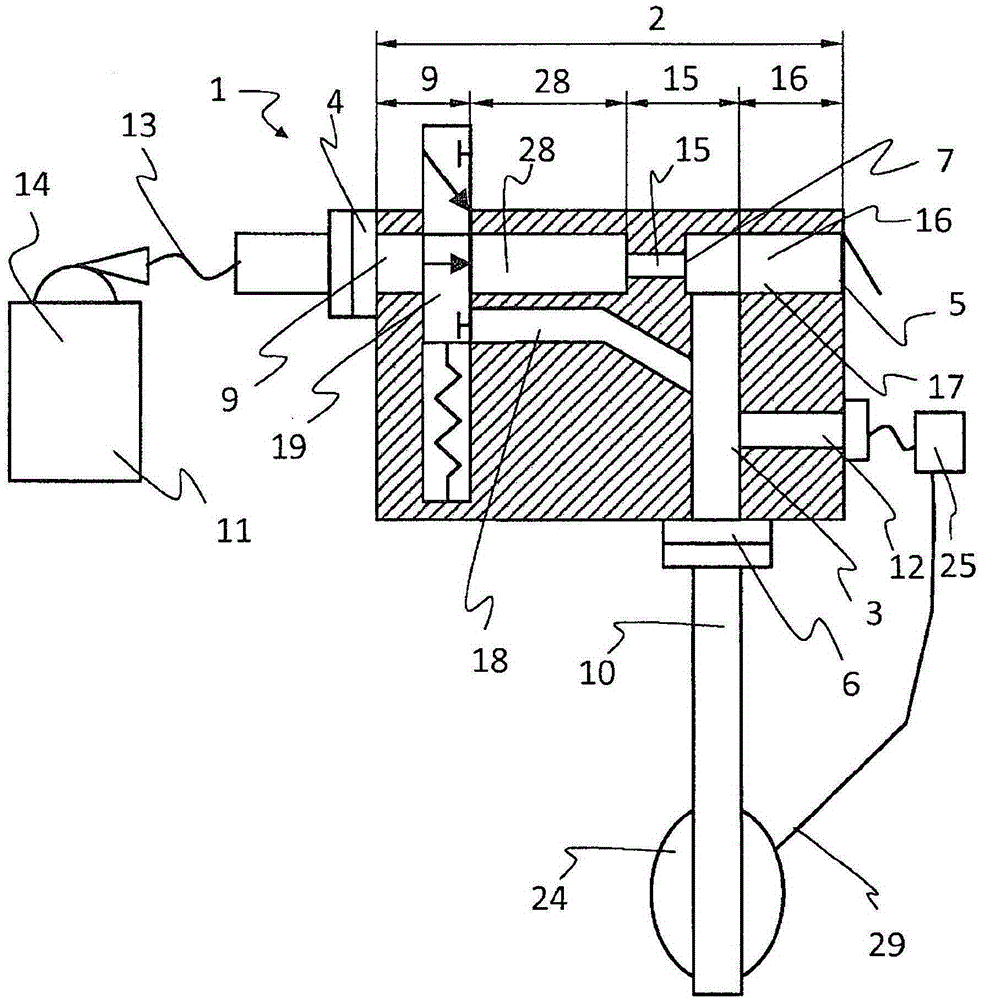

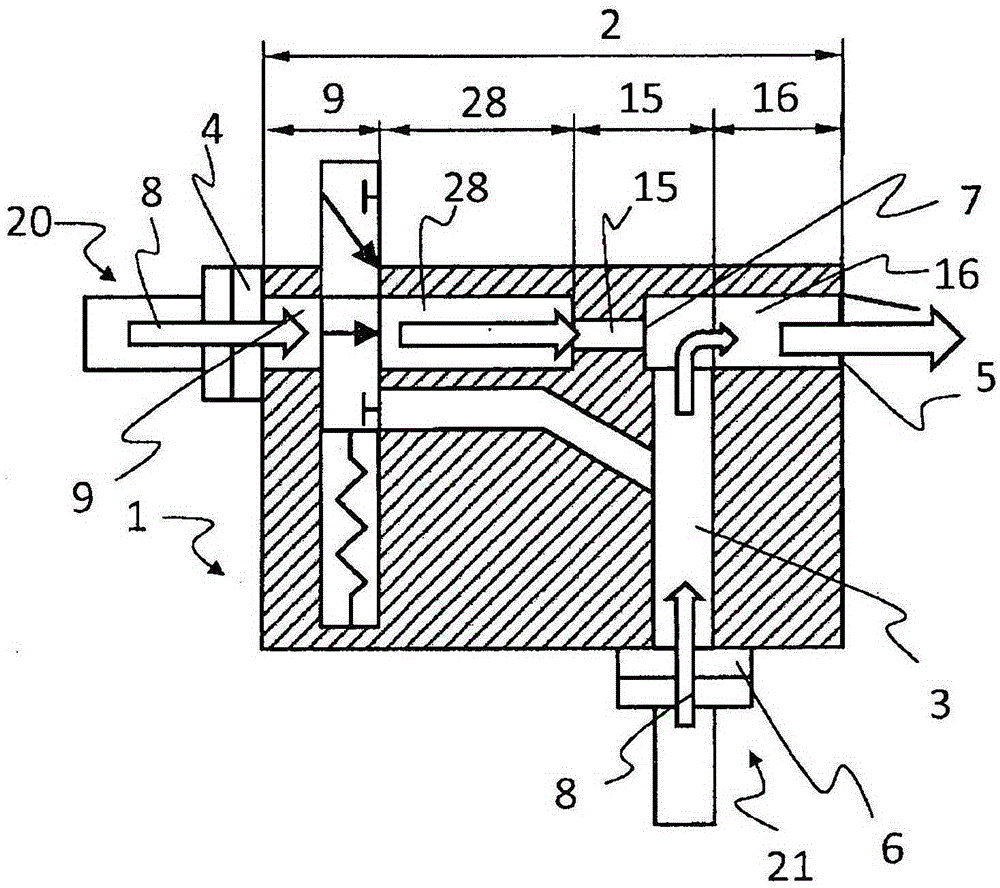

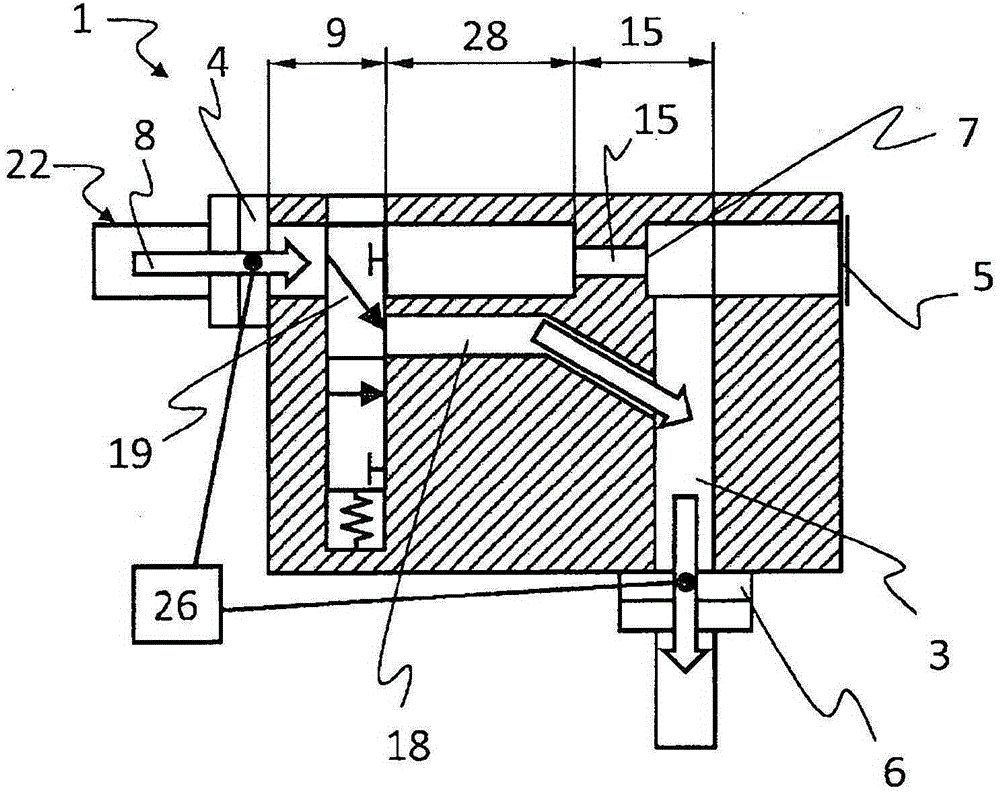

[0086] figure 1 A longitudinal section through the air flow reversing element 1 with the main part 2 connecting the pressure connection 4 to the outlet opening 5 is shown. The pressure connection 4 can be connected via a connecting pipe 13 to a gas source 14 in a compressed gas source 11 , which is under excess pressure. Compressed oxygen tanks are generally manufactured for use in emergency patient care. Additionally, complex gas mixtures may be provided as gas source 14 . The part extending from the main part 2 is a branch part 3 which leads to a pipe connection 6 . In the main part 2 , an inflow area 9 , a flow area 28 , a nozzle area 15 with nozzles 7 and a mixing area 16 with mixing channels 17 are realized. Inside the nozzle zone 15 there are nozzles 7 through which gas can flow from the pressure connection 4 to the outlet opening 5 . This nozzle 7 is located near the branch 3 so that the gas flowing through the nozzle 7 to the outlet hole 5 creates an underpressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com