High-overload solid rocket engine and explosive type design method thereof

A technology of solid rockets and design methods, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of increasing the risk of ignition failure, damage to the structural integrity of the charge, large shear force, etc. The effect of medicine space, ignition failure probability reduction, and stress improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

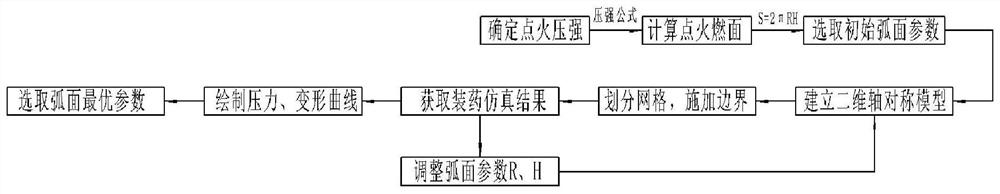

[0045] Attached below Figure 1-15 The present invention is further described.

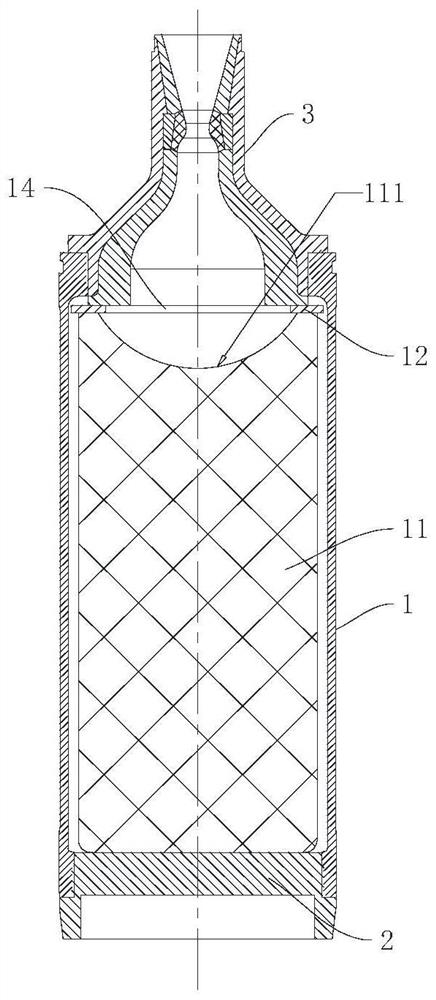

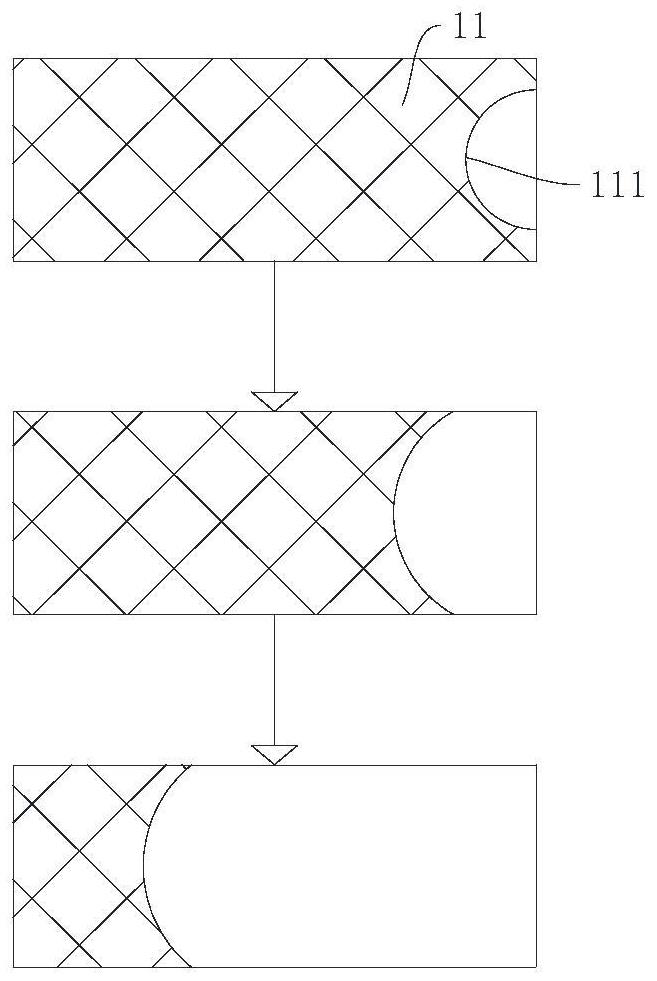

[0046] refer to figure 1 and figure 2On the one hand, the embodiment of the present invention proposes a high-overload solid rocket motor, including a combustion chamber casing 1, a head 2 and a nozzle assembly 3, the combustion chamber casing 1 penetrates the opening along its axial direction, and the sealing The head 2 and the nozzle assembly 3 are respectively arranged at both ends of the combustion chamber housing 1; the inside of the combustion chamber housing 1 is filled with a charge column 11 and a buffer pad 12, and the two sides of the buffer pad 12 respectively abut against the charge column 11 And the nozzle assembly 3, and the cushion pad 12 is penetrated with a through hole 14 along the thickness direction, so that the charge 11 can be ignited through the through hole 14, so that the engine can be accelerated again.

[0047] The aperture of the through hole 14 is larger than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com