Carbon fiber plate anchorage device limiting tensioning block

A carbon fiber plate and anchorage technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of stress concentration of tension blocks, shorten the service life of tension blocks, and shear fracture of carbon fiber plates. Effect of small stress concentration, improved service life, and avoidance of shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

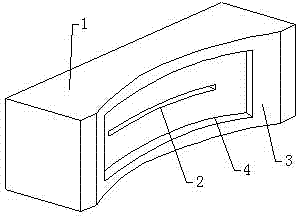

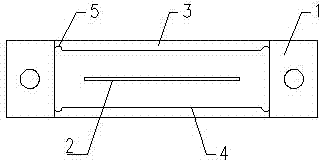

[0013] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-2 As shown: the carbon fiber plate anchorage limiting tension block of this embodiment includes a block 1, and the block is provided with a square through hole 2 for the carbon fiber plate to pass through, and the size of the square through hole is smaller than that of the carbon fiber plate The cross-section of the block body is provided with an inwardly concave curved surface 3 on the side in contact with the anchorage, and a limiting groove 4 communicating with a square through hole is provided in the center of the curved surface. The carbon fiber plate anchor limit tension block of this structure, on the one hand, is provided with a curved surface on the side in contact with the anchor, so that the tension block can be evenly stressed during the stretching process of the carbon fiber plate, which can effectively reduce the The stress concentration of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com