Anchoring technical measure for pasting carbon fiber plate to bottom of steel bar concrete beam

A carbon fiber board, reinforced concrete technology, applied in building maintenance, construction, building construction, etc., can solve the problem of time-consuming and laborious construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

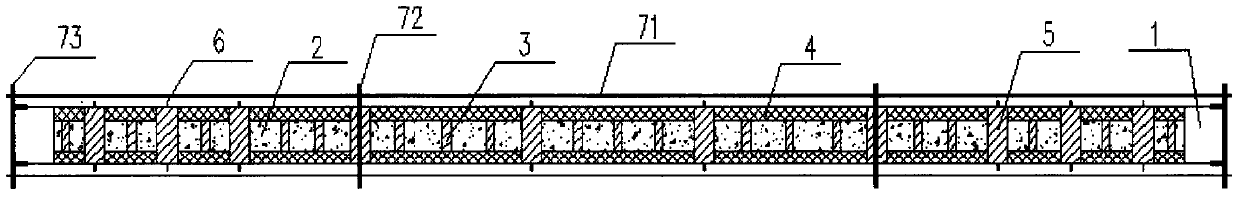

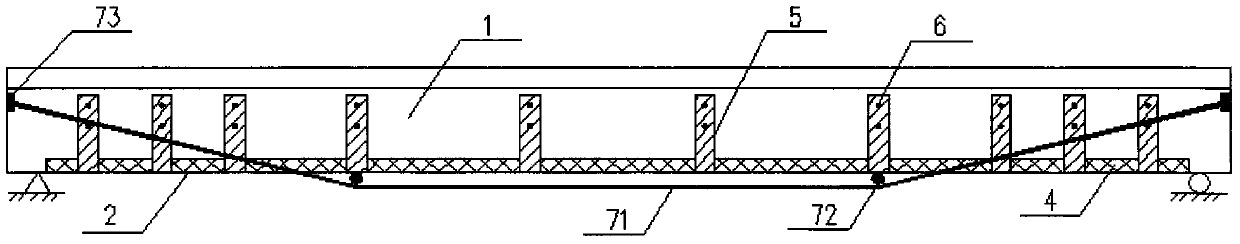

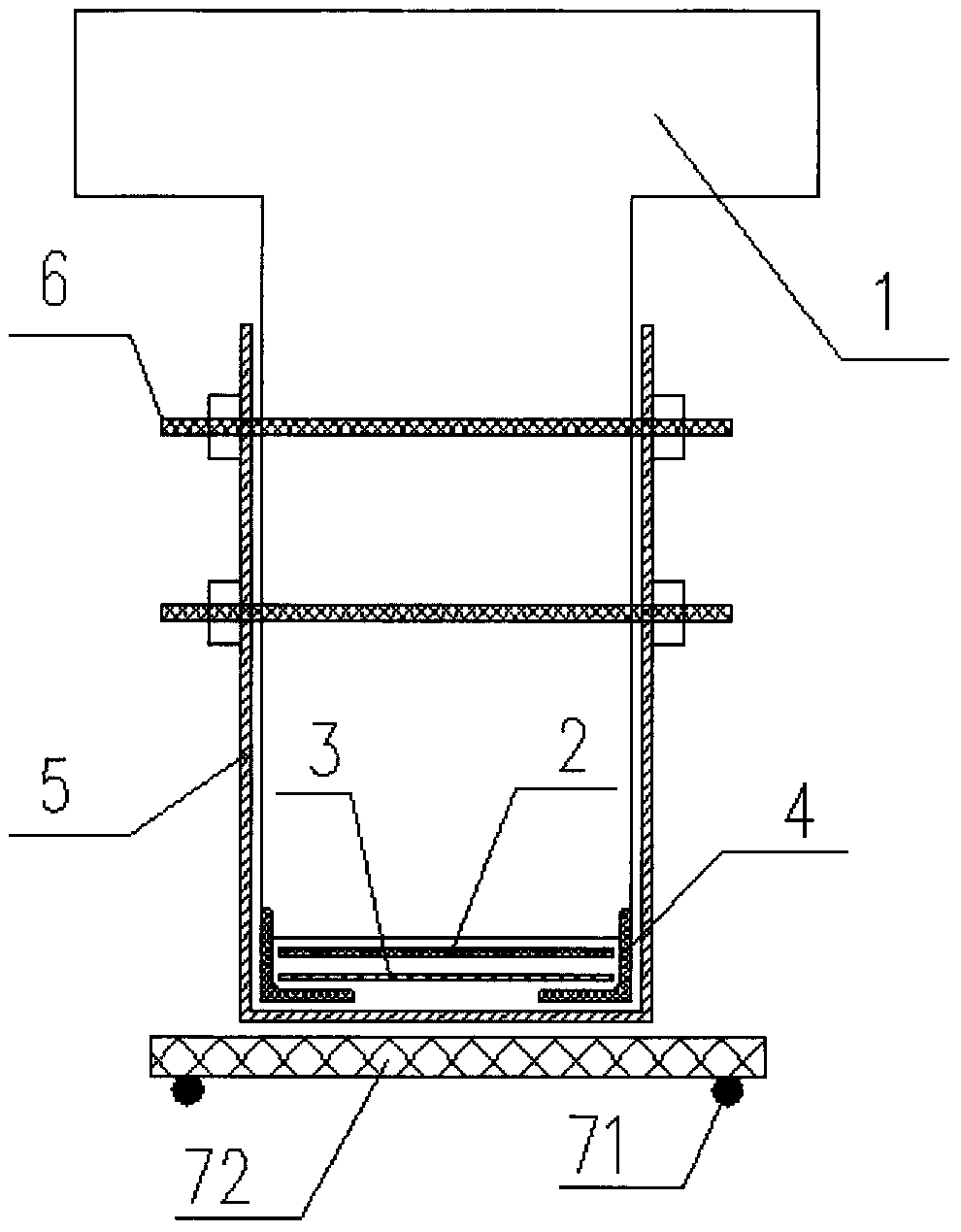

[0032] An anchoring technical measure for sticking carbon fiber plates to the bottom of a reinforced concrete beam of the present invention, comprising carbon fiber plates 2, angle steel profiles 4 and a three-fold line external prestressing system 7, the carbon fiber plates 2 are pasted on the beam bottom of the original reinforced concrete beam 1 A plurality of rows of steel laths 3 are arranged at intervals on the lower part of the carbon fiber plate 2, angle steel profiles 4 are arranged on both sides of the bottom of the reinforced concrete original beam 1, the angle steel profiles 4 enclose the carbon fiber plates 2 and the steel laths 3, and several U-shaped steel hoops 5 Embrace the angle steel profile 4, tighten the tension bolt 6, firmly fix the U-shaped steel hoop plate 5 and the original reinforced concrete beam 1, and install a three-fold line external prestressing system 7 on both sides of the original reinforced concrete beam 1.

[0033] The three-fold line exter...

Embodiment 2

[0035] A construction method of an anchoring technical measure pasted with a carbon fiber plate at the bottom of a reinforced concrete beam, comprising the following steps:

[0036]The first step: the beam bottom of the reinforced concrete original beam 1 is polished, and the laitance layer is removed. The carbon fiber plate 2 is pasted on the beam bottom of the reinforced concrete original beam 1. The lower part of the carbon fiber plate 2 is provided with multiple rows of steel laths 3 at intervals. The reinforced concrete original Angle steel profiles 4 are installed on both sides of the bottom of the beam 1, and the angle steel profiles 4 wrap around the carbon fiber plates 2 and steel laths 3. Several U-shaped steel hoop plates 5 are used to wrap around the angle steel profiles 4, and the left and right two angle steel profiles 4 are clamped using special fixtures. Temporarily fixed at the bottom of the original reinforced concrete beam 1, tighten the pull bolts 6, firmly ...

Embodiment 3

[0040] The original beam is a reinforced concrete simply supported T beam, the total length of the beam is 6000mm, the calculated span is 5700mm, the beam height is 500mm, the beam bottom width is 200mm, the flange width is 400mm, and the flange width and height are 100mm. HRB400 steel bars are equipped with 2φ16 steel bars, and the cross-sectional reinforcement ratio of tension steel bars is 0.335%. The strength grade is designed as C25.

[0041] The bottom of the original reinforced concrete beam is pasted with a carbon fiber plate with a thickness of 1.4mm, a width of 200mm and a length of 6m. The ultimate tensile strength of the carbon fiber plate is 3000MPa. is 300mm.

[0042] The angle steel section steel wraps the carbon fiber plate and the steel lath. The reinforced angle steel section steel is two L50×50×4 angle steel with a length of 6m. Three U-shaped steel hoops with a width of 100mm are installed at both ends of the reinforced beam, and four U-shaped steel hoops ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com