Patents

Literature

49 results about "Bond slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

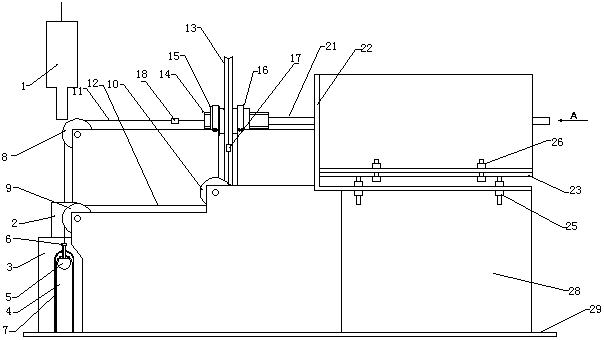

Experimental device and experimental method of impact drawing-twisting load

InactiveCN104181102ARealize dynamic impact tension and torsion experimentEasy to operateUsing mechanical meansMaterial analysisCircular discEngineering

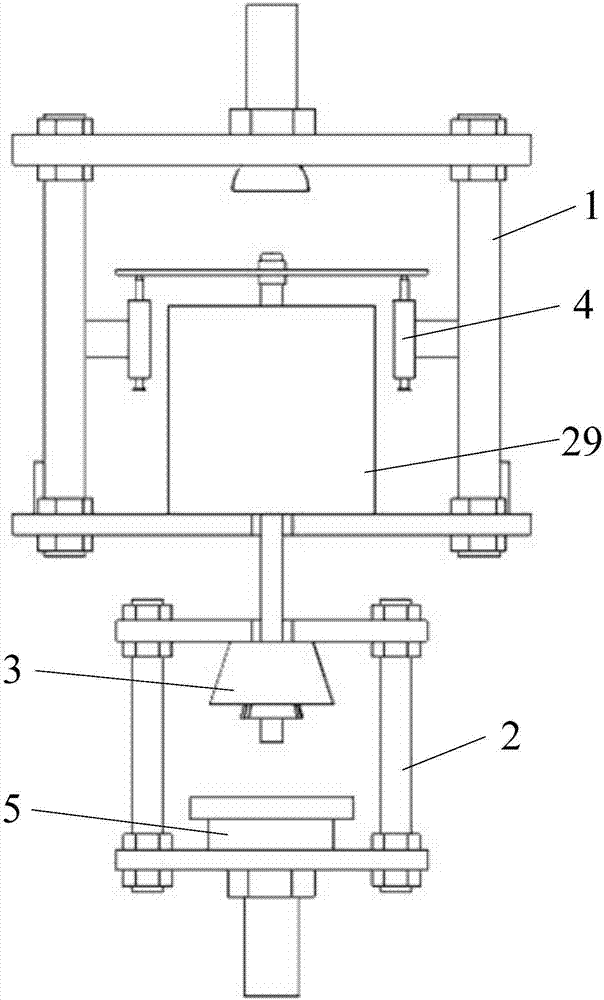

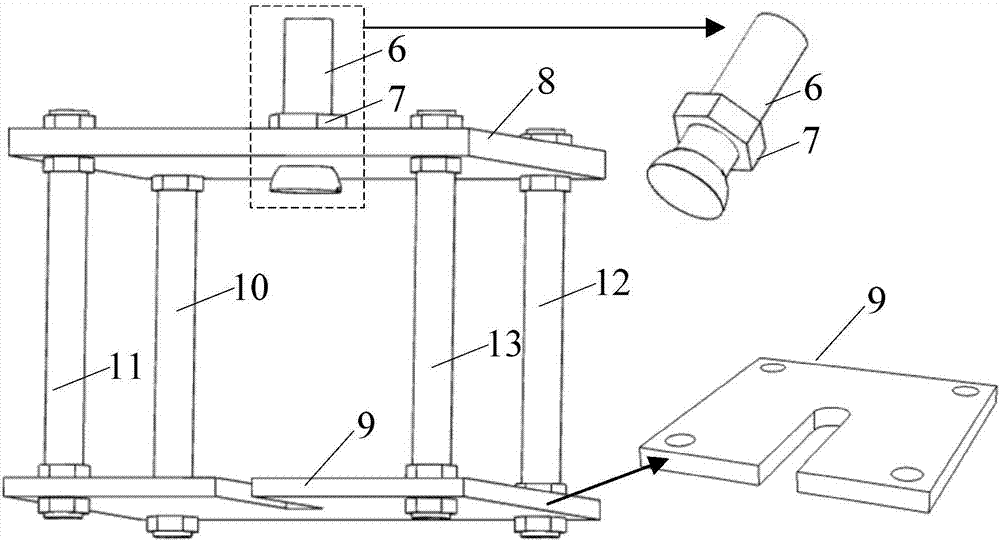

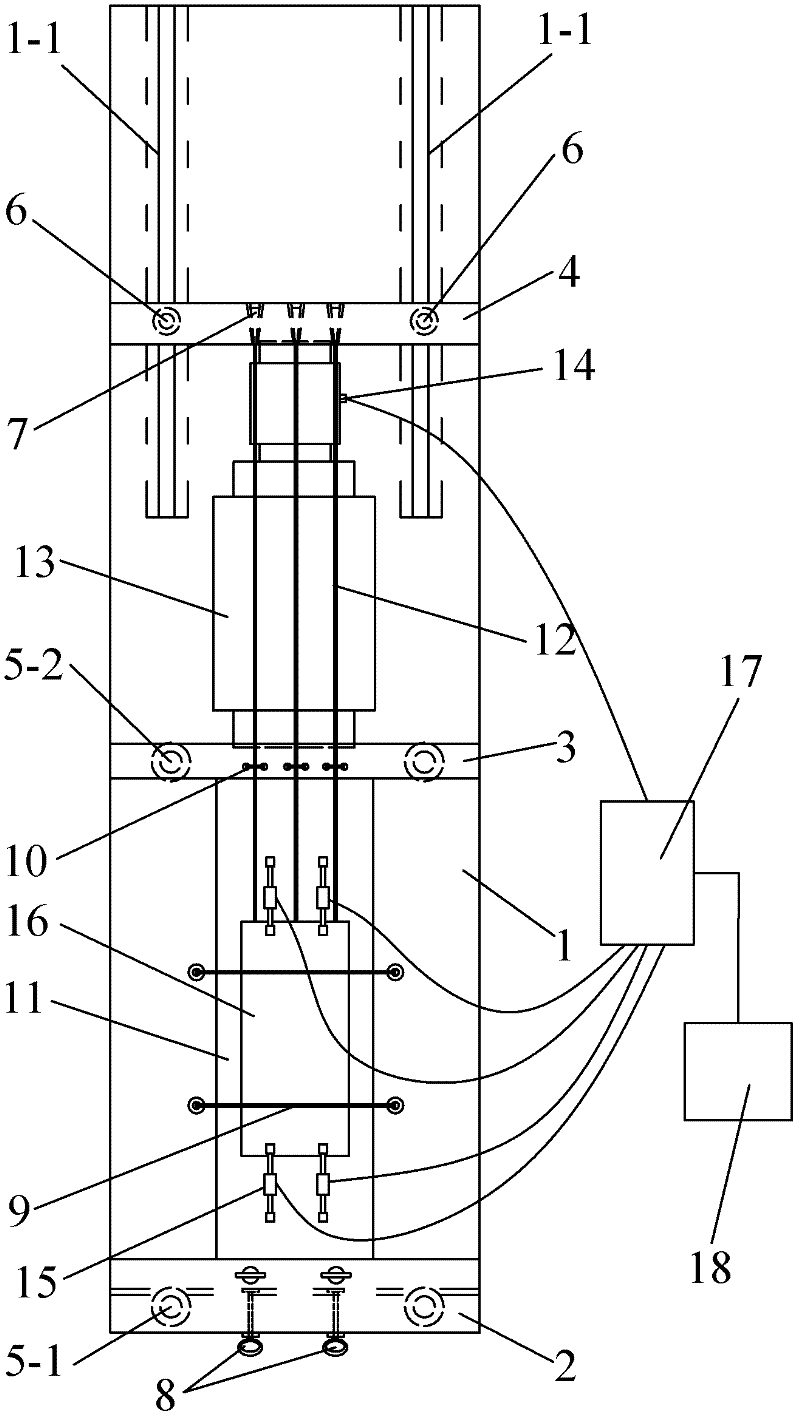

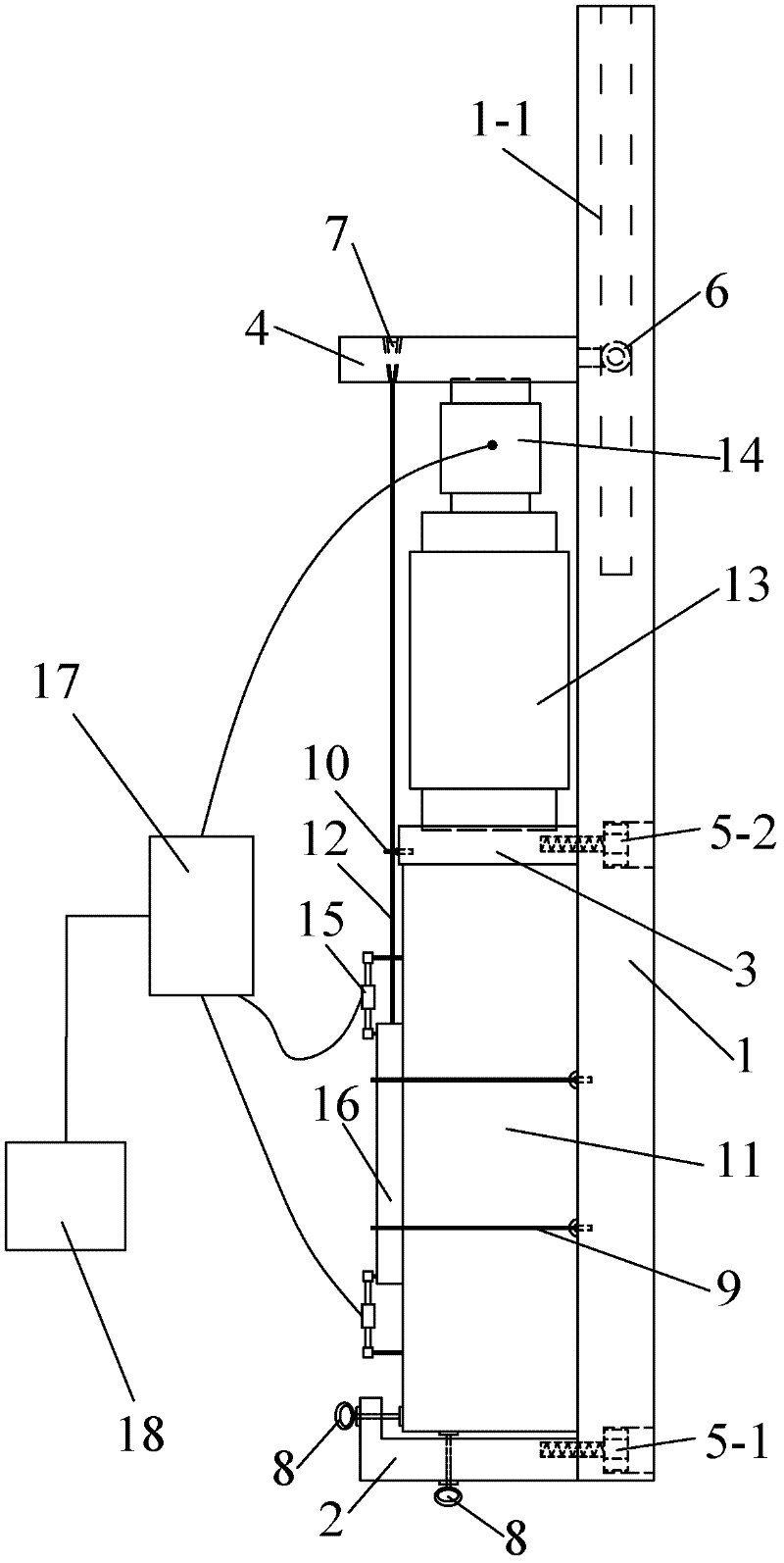

The invention discloses an experimental device and an experimental method of impact drawing-twisting load, belonging to the field of impact dynamics experiments. The experimental device comprises a drop hammer, a test piece, an impact force transfer device, a loading disc, a measuring device and a test piece fixing device; the drop hammer drops down to impact a transmission target, the transmission target moves on a track after being impacted, a base is provided with a prestress loading device, the prestress is applied to an impact target through an adjusting threaded rod, two sides of the impact target are respectively connected to the loading disc through steel wire ropes, each steel wire rope is provided with a force sensor, the disc transfers the drawing force and twisting force to a reinforcing steel bar of the test piece, and a metal strain gauge is attached inside the reinforcing steel bar of the test piece and used for measuring the stress distribution along the anchoring length of the reinforcing steel bar. According to the experimental device and the experimental method, the bond stress distribution of a reinforcing steel bar concrete anchoring reinforcing steel bar under the drawing and twisting load effects of the impact is researched, and a powerful foundation is set for researching a constitutive relation of anchoring bond slip under the effect of complicated stress.

Owner:TAIYUAN UNIV OF TECH

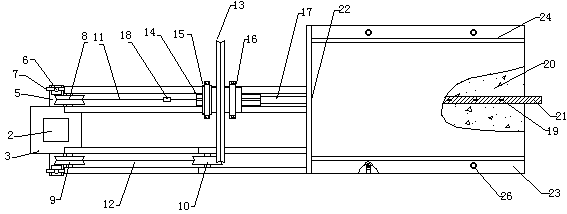

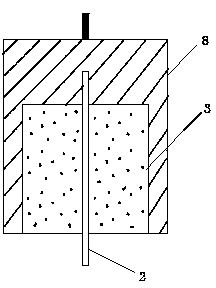

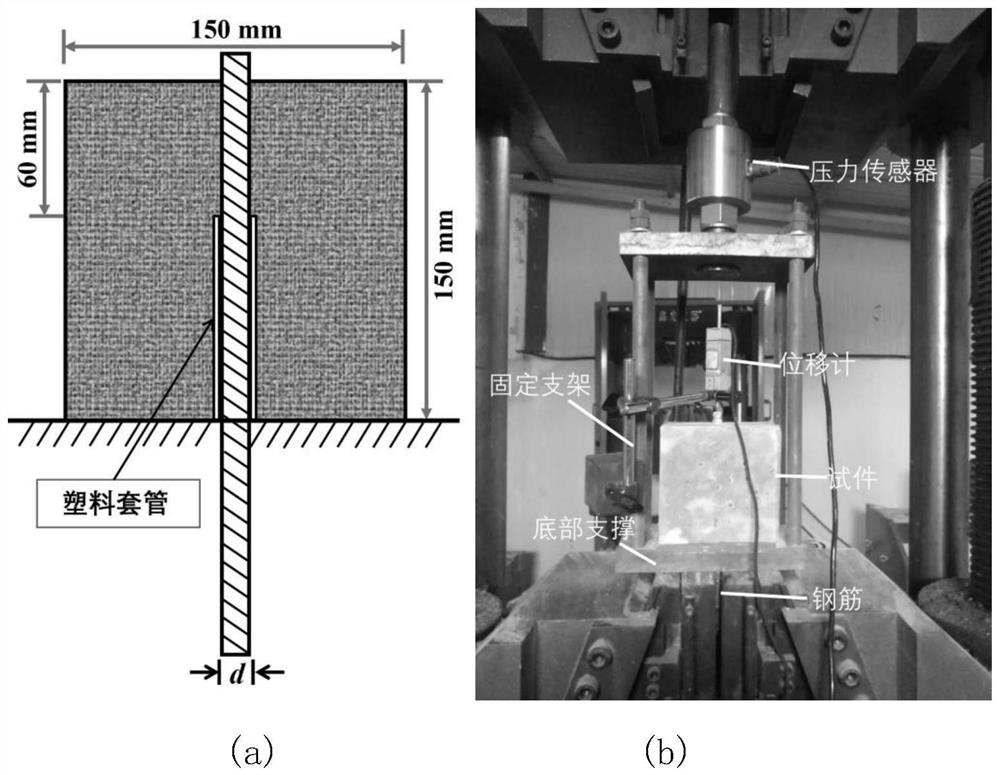

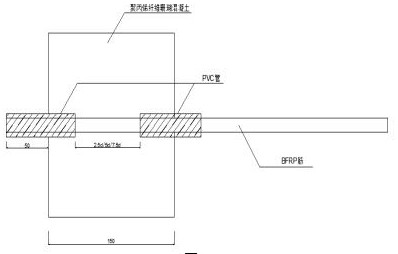

Method of FRP reinforced concrete bond slip test

InactiveCN103954200AConsistent bond lengthBond stress decayMechanical measuring arrangementsMaterial analysisRelative displacementDisplacement control

The invention discloses a method of an FRP reinforced concrete bond slip test. The method comprises the steps of determining a test piece for the test, manufacturing a connection structure of an FRP reinforced concrete test piece, selecting a universal testing machine, and determining a loading scheme as one-end loading and determining a loading mode as a displacement control mode. According to the step of manufacturing the connection structure of the FRP reinforced concrete test piece, a test piece component is arranged in the middle of poured concrete, and the test piece component is formed by inserting two FRP ribs into the two ends of a sleeve pipe respectively; the other ends of the two FRP ribs extend out of the sleeve pipe, and a bonding layer is arranged in the middle of the sleeve pipe; the two ends of the sleeve pipe are respectively provided with at least two wedged key blocks which are arranged in the sleeve pipe in the direction of the FRP ribs, and the two FRP ribs extend out of the two ends of the concrete; sleeves are arranged at the matched positions of the extending ends of the two FRP ribs respectively. The sleeves at the upper end and the lower end of the connection structure are fixed on an upper anchor and a lower anchor of the universal testing machine respectively. A data collecting system of the universal testing machine is used for collecting the total displacement of the whole connection structure, and a dial indicator is used for collecting relative displacement of the two FRP ribs and the test piece component, namely the sliding amount of the FRP ribs in the test piece component is obtained.

Owner:SHENYANG JIANZHU UNIVERSITY

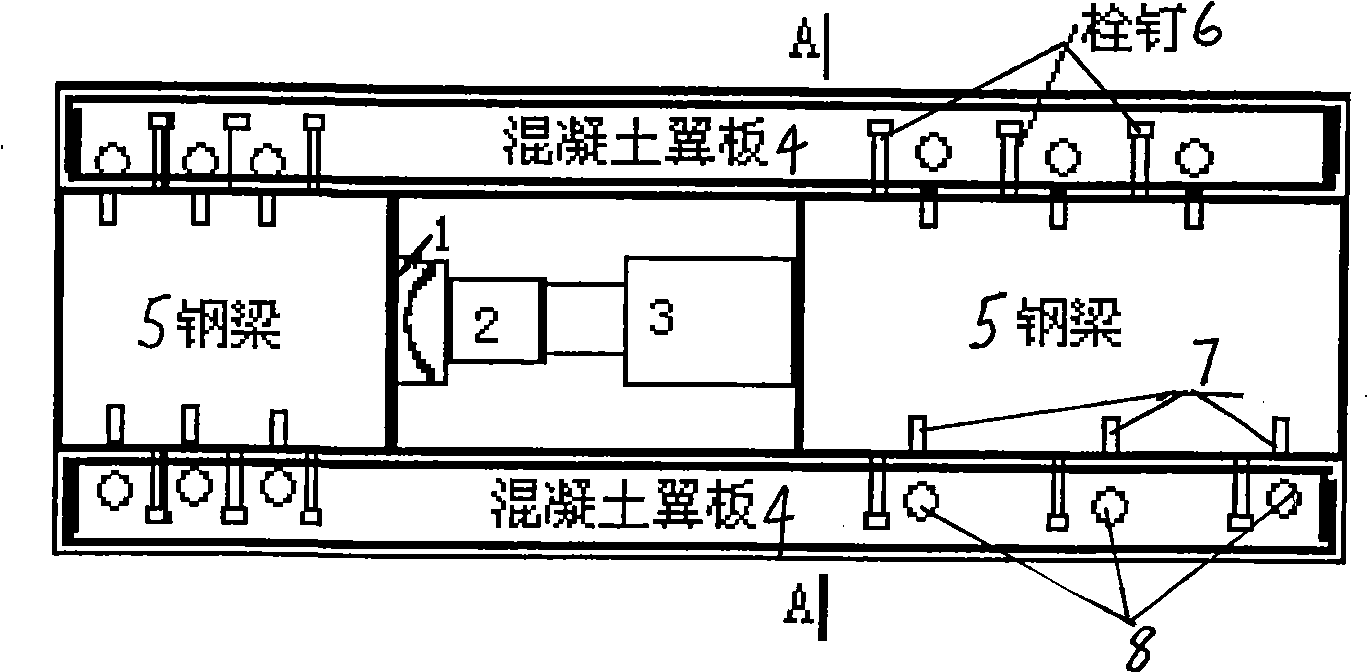

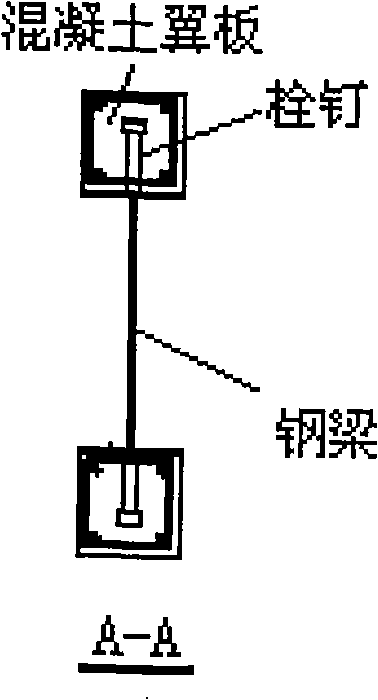

Test method for accurately simulating bond-slip property of male pin in tensile area

InactiveCN101315321AAccurately simulate stud performanceAccurately simulate mechanical propertiesStructural/machines measurementUsing mechanical meansBond slipEngineering

The invention discloses a test method which can accurately simulate the bond-slip properties of a stud connector in a tensile area in a combined structure. The method comprises the steps of combining two push-out samples; reserving a space for a jack between the two samples; loading through a spherical hinge; conveniently arranging a displacement sensor on a shearing surface; measuring relative slippage between a steel beam and a concrete slab, thus accurately simulating the constructive relations and the bearing capacity of the bond-slip properties of the stud connector in the tensile area of a combination beam. The method can accurately simulate the mechanical properties of the stud in the tensile area of a beam-type component in a combined structure of steel beam and concrete. Furthermore, the method is convenient to operate.

Owner:XUZHOU UNIV OF TECH

Testing method for testing steel bar-concrete bonding and slipping performance

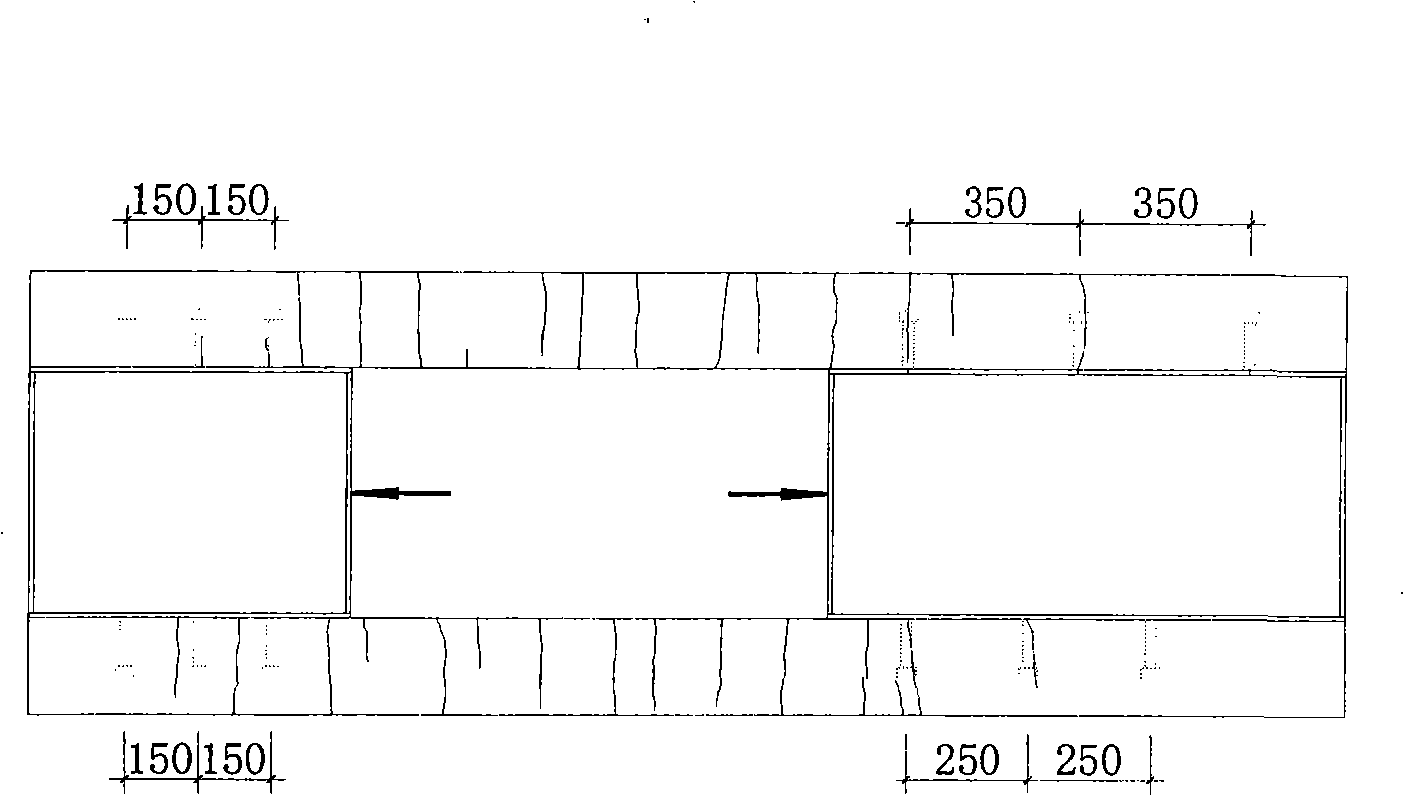

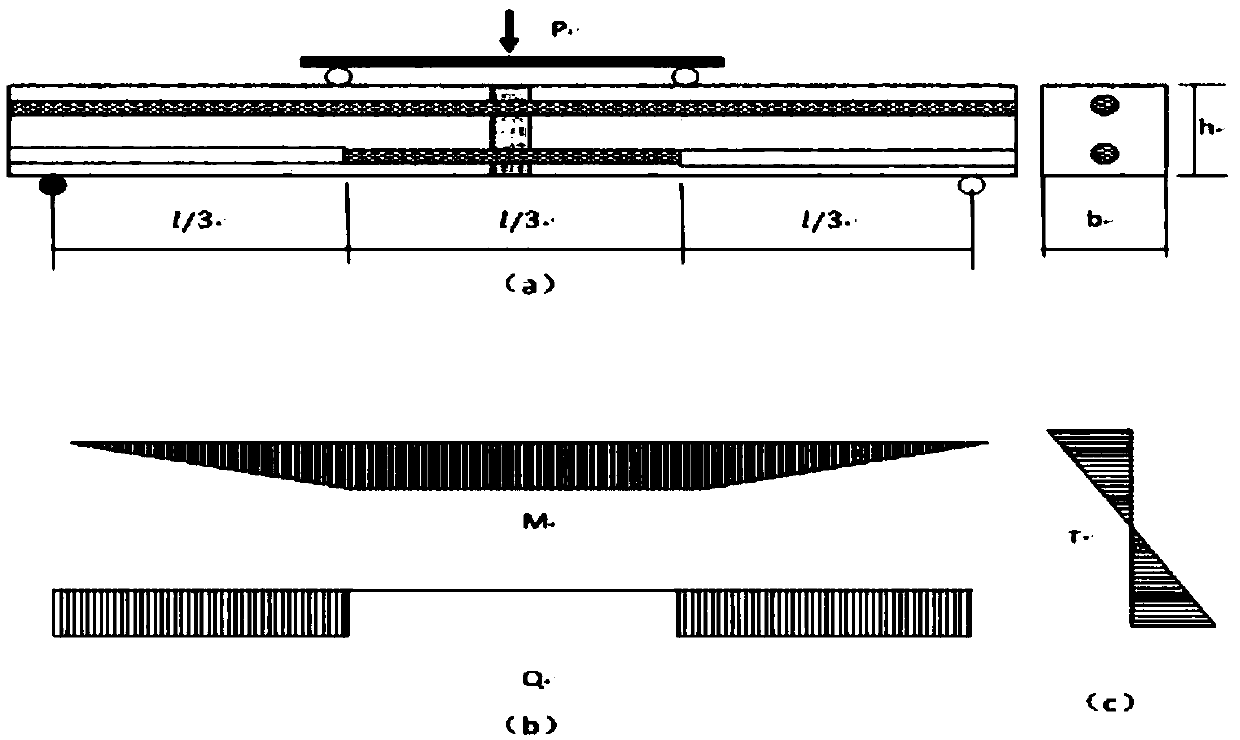

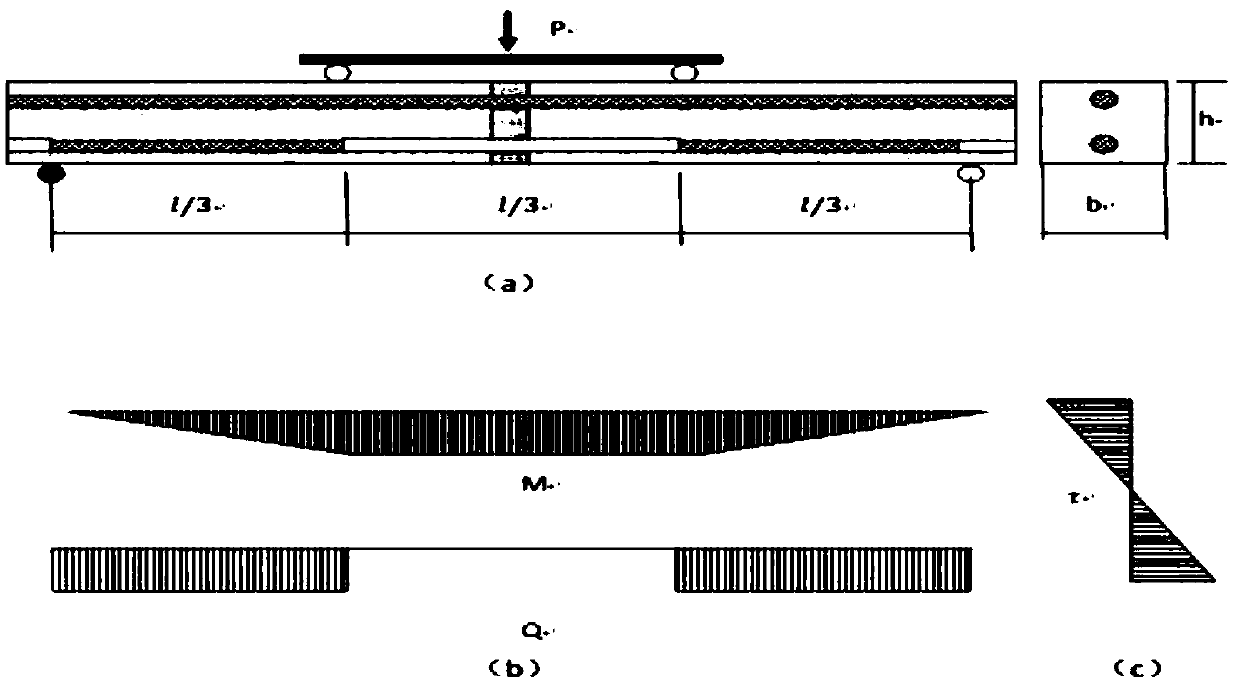

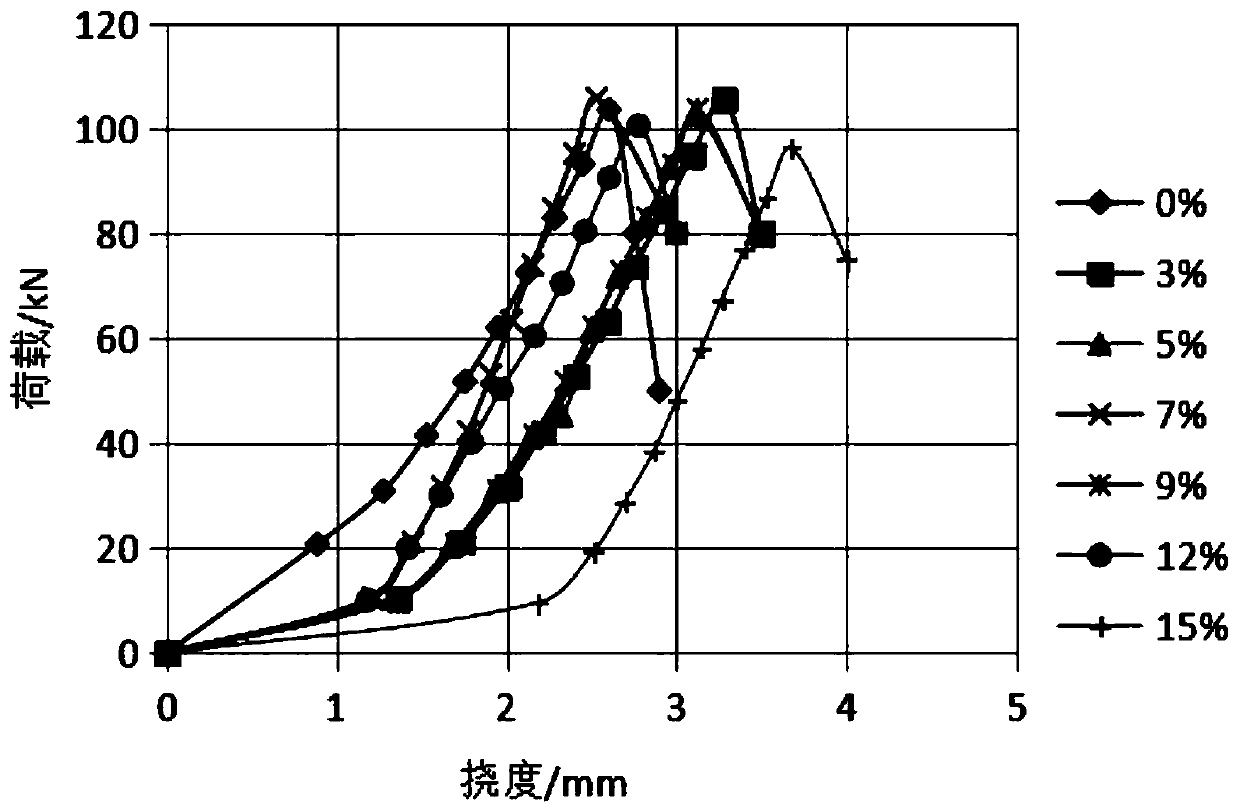

The invention discloses a testing method for testing steel bar-concrete bonding and slipping performance. The testing method comprises the following steps: carrying out a testing design according to astress moment theory; determining a loading method, a section size of a test piece and a production method of the test piece; determining a load-deflection curve and calculating steel bar slipping strain, bonding stress, maximum slipping amount and bonding strength; then identifying a damage mode and processing a testing result. According to the testing method, measured bonding-slipping characteristic parameters eliminate influences, caused by various factors of the testing method, on the testing result; the bonding strength is close to the tensile strength of concrete; the testing method hasgood repeatability and stability. The testing method can be used for researching the bonding and slipping performance of concrete with different types and different strengths, and steel bar-concretewith different types; the testing cost is low and the testing precision is high; abundant results are obtained, and the testing method has a remarkable effect on structure analysis, design and new finding of steel reinforced concrete.

Owner:GUANGXI UNIV

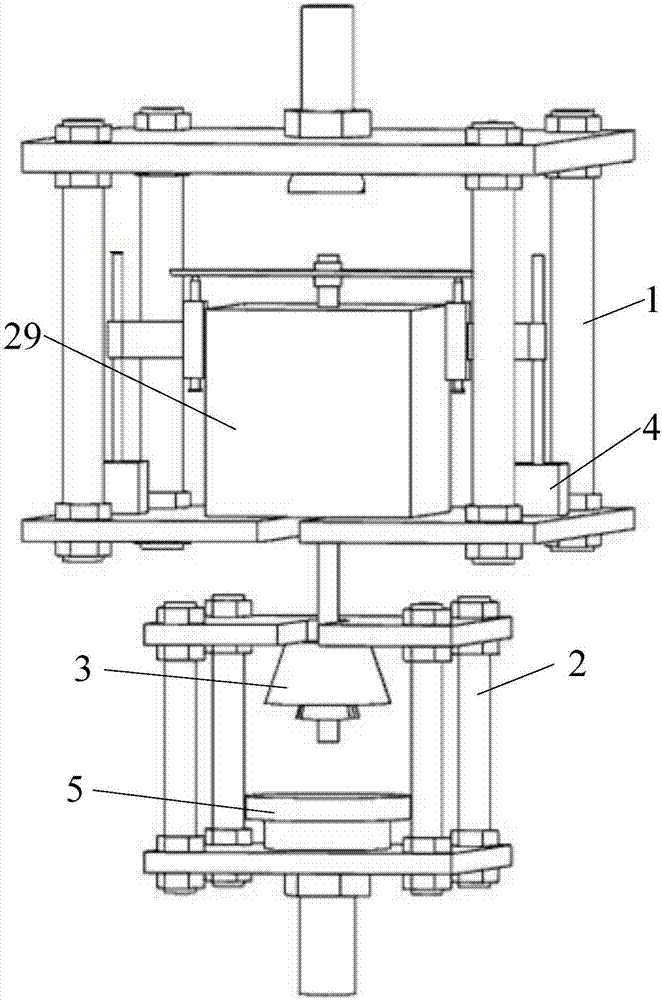

Pull-out test device for bond-slip hysteretic behavior testing of stiffening rib

ActiveCN106018270AConsistent stress stateWill not affect test resultsUsing mechanical meansMaterial strength using repeated/pulsating forcesRelative displacementBond slip

The invention belongs to the field of civil and structural engineering, and relates to a pull-out test device for bond-slip hysteretic behavior testing of a stiffening rib. The pull-out test device comprises a counter-force frame, a fastening steel plate, an upper clamping device and a pull-out test piece, wherein the counter-force frame is formed through fixed connection of a top plate, side plates and a bottom plate through bolts, and the counter-force frame is fixedly connected with a tester base through a connecting part; the fastening steel plate and the pull-out test piece are pressed through a bolt; the upper portion of a deformed steel bar shaft in the upper clamping device is in spiral connection with a load sensor of a tester, the lower portion of the deformed steel bar shaft is in spiral connection with the inner side of the upper portion of a steel sleeve and rotates in the thread direction to enable the steel sleeve to rise and fall, and the lower portion of the steel sleeve is connected with the end of the stiffening rib. The pull-out test device is simple in structure. During cycling load application, static balancing is maintained between the test piece and the counter-force frame, and relative displacement is avoided; the stiffening rib and concrete have the same stress state.

Owner:DALIAN UNIV OF TECH

Reinforcing steel bar and concrete pull-out testing device capable of eliminating high-temperature influences

PendingCN107247020AEliminate the effects of acquisitionAvoid damageMaterial strength using tensile/compressive forcesUsing mechanical meansTester deviceEngineering

The invention discloses a reinforcing steel bar and concrete pull-out testing device capable of eliminating high-temperature influences, and belongs to the technical field of testing devices. The reinforcing steel bar and concrete pull-out testing device comprises an upper pull-out frame, a lower pull-out frame, an anchorage device, a slip measuring assembly and a force measuring assembly. By the combination effect of the upper pull-out frame and the slip measuring assembly, the force measuring assembly and a high-temperature test piece are separated and achieve testing, and therefore the phenomena that a test instrument is damaged by the temperature and reinforcing steel bar bonding power and slip value measurement is disturbed are avoided. The testing device is simple and controllable in machining and manufacturing, assembling and installing are convenient, a force transfer mechanism is clear, the testing device is applicable to reinforcing steel bar-concrete center pull-out tests, the bonding strength and relative slippage between reinforcing steel bars and concrete are measured, and the reinforcing steel bar-concrete bonding slippage performance can be effectively tested under high temperature.

Owner:HUNAN UNIV

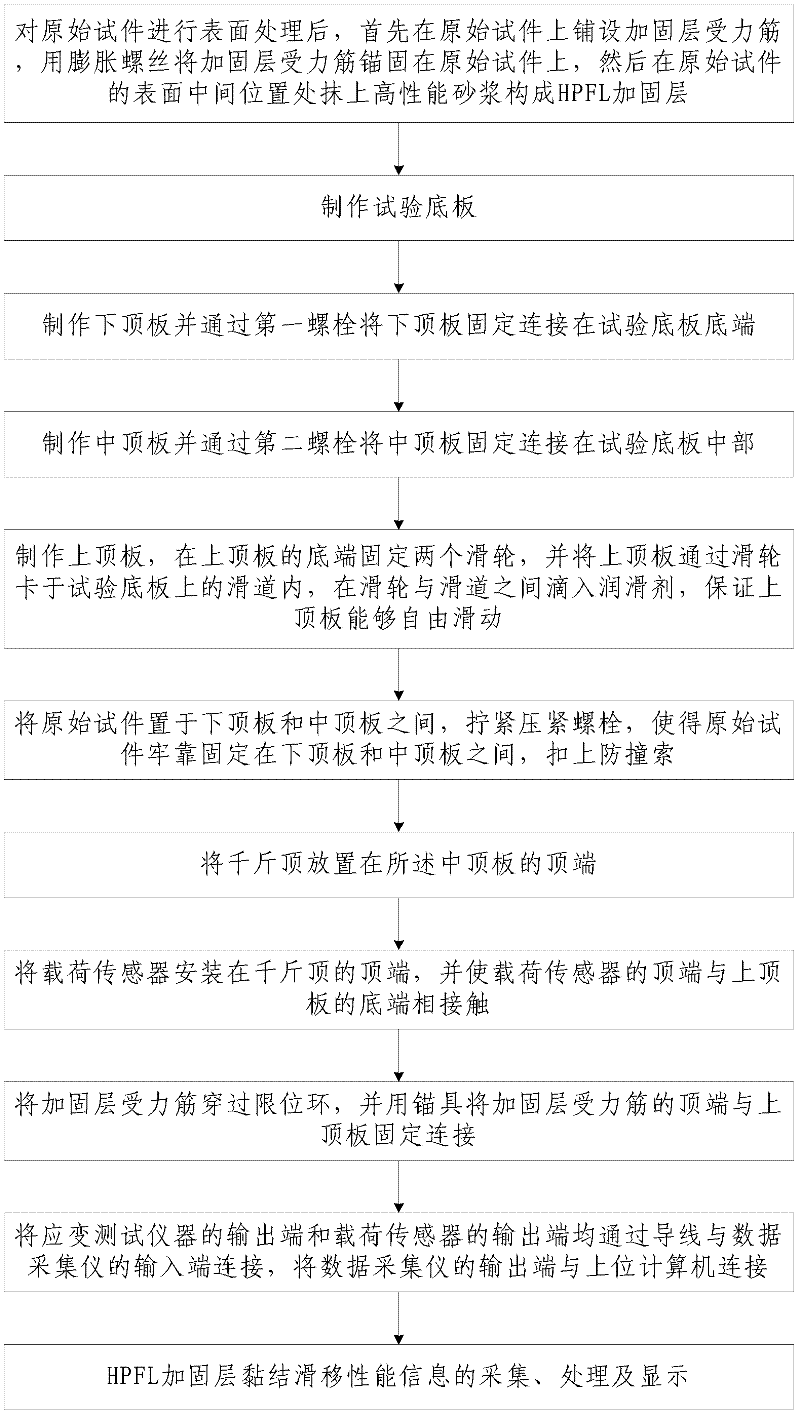

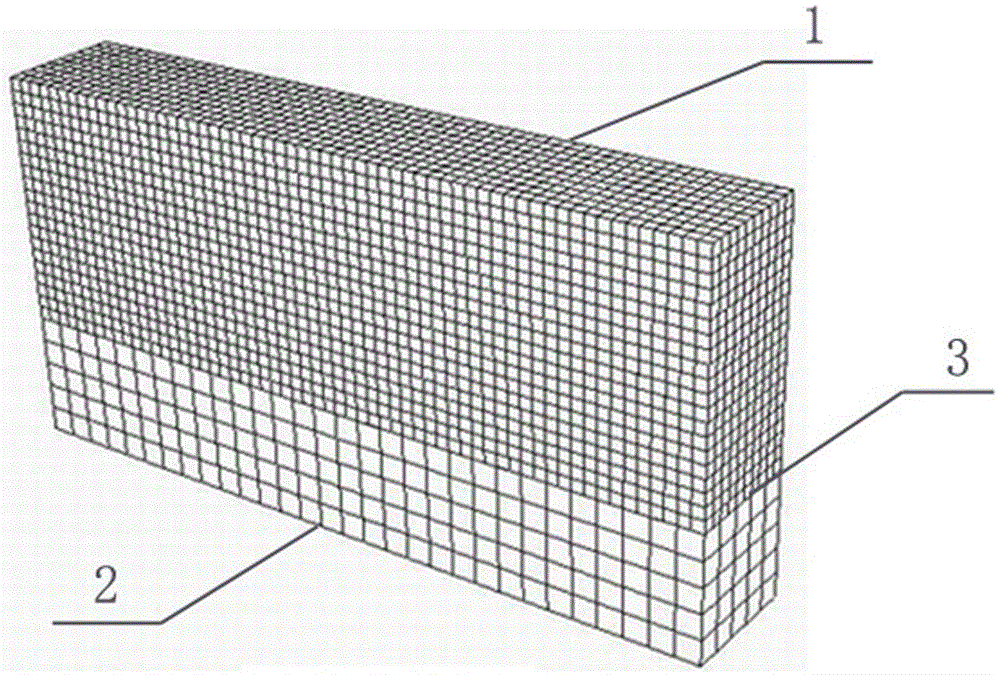

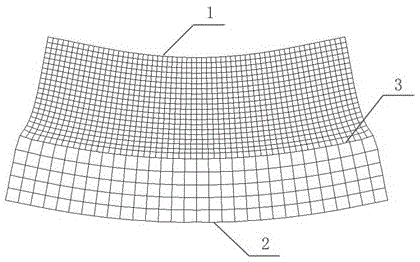

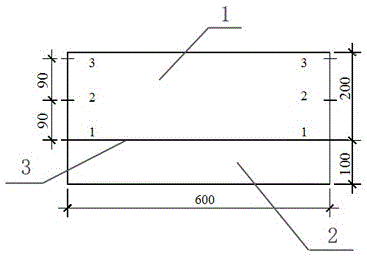

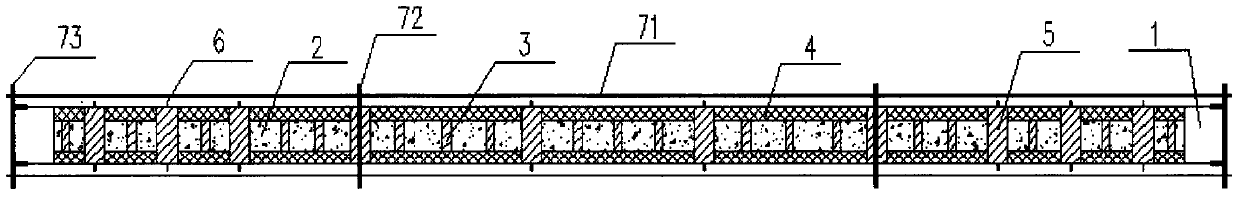

High-performance ferrocement laminate (HPFL) reinforcement layer bond slip test device and method

InactiveCN102590081ASolving Loading Issues for Peel TestsImplement slippage testUsing mechanical meansMaterial analysisData acquisitionBond slip

The invention discloses a high-performance ferrocement laminate (HPFL) reinforcement layer bond slip test device and method. The HPFL reinforcement layer bond slip test device comprises a test bottom plate, a lower top plate, a middle top plate, an upper top plate, a strain test instrument, a load sensor, a data acquisition instrument and a host computer. The method comprises the following steps of: laying bearing bars of the reinforcement layer on an original test piece to form an HPFL reinforcement layer; making the test bottom plate; making and fixing the lower top plate; making and fixing the middle top plate; making the upper top plate and clamping the upper top plate in a slideway; arranging the original test piece between the lower top plate and the middle top plate; placing a jack on the top of the middle top plate; mounting the load sensor on the top of the jack; fixing the bearing bars of the reinforcement layer and the upper top plate; connecting the strain test instrument, the load sensor, the data acquisition instrument and the host computer; and acquiring, processing and displaying the bond slip performance of the HPFL reinforcement layer. The HPFL reinforcement layer bond slip test device and method have the advantages of reasonable design, high intelligent degree, convenience in operation, safe and reliable test process and high practical value.

Owner:CHANGAN UNIV

Method of constructing new and old concrete bond constraint shrinkage finite element model

The invention relates to a method of constructing a new and old concrete bond constraint shrinkage finite element model. The method includes the following steps that a new and old concrete model is built through a linear shrinkage integral unit in ABAQUS finite element software; new concrete is associated with old concrete through definition contact in the new and old concrete model, bond slip between the new concrete and the old concrete is not considered, and bond is simulated through binding constraint; the creep coefficient of the concrete is determined; the change of elasticity modulus along with the age of the concrete is calculated; the bond face of the new concrete is defined to be an auxiliary face in the model, the bond face of the old concrete is defined to be a main face, the shrinkage value is converted into equivalent temperature difference, and calculation is conducted on the new concrete through action of the form of a temperature field. The model constructed by the method can provide a practical analysis model for researches on stress and deformation generated in the new and old concrete bond shrinkage process in reinforcing engineering.

Owner:FUJIAN JIANGXIA UNIV

Testing device and method for bidirectional tensile bonding of weak-rigidity reinforcement

ActiveCN108760495AAccurate measurementOvercome the effects of slippageMaterial strength using tensile/compressive forcesBond slipActuator

The invention discloses a testing device and method for bidirectional tensile bonding of weak-rigidity reinforcement. The testing device comprises a bidirectional actuator, a test piece, a counterforce frame and a loading frame, wherein the test piece comprises a concrete test block and a reinforcement, the reinforcement penetrates the concrete test block and is bonded with the concrete test block, the bidirectional actuator can drive the loading frame to apply bidirectional force to the concrete test block in the length direction of the reinforcement through a converter; when the loading frame applies force to the concrete test block in the length direction of the reinforcement, the counterforce frame applies counterforce to the reinforcement. Relative slip between the weak-rigidity reinforcement and the concrete test block can be measured, so that the bond-slip constitutive relationship of the weak-rigidity reinforcement under the action of bidirectional stress load can be established, and reliable and real theoretical support can be provided for practical engineering.

Owner:ZHENGZHOU UNIV

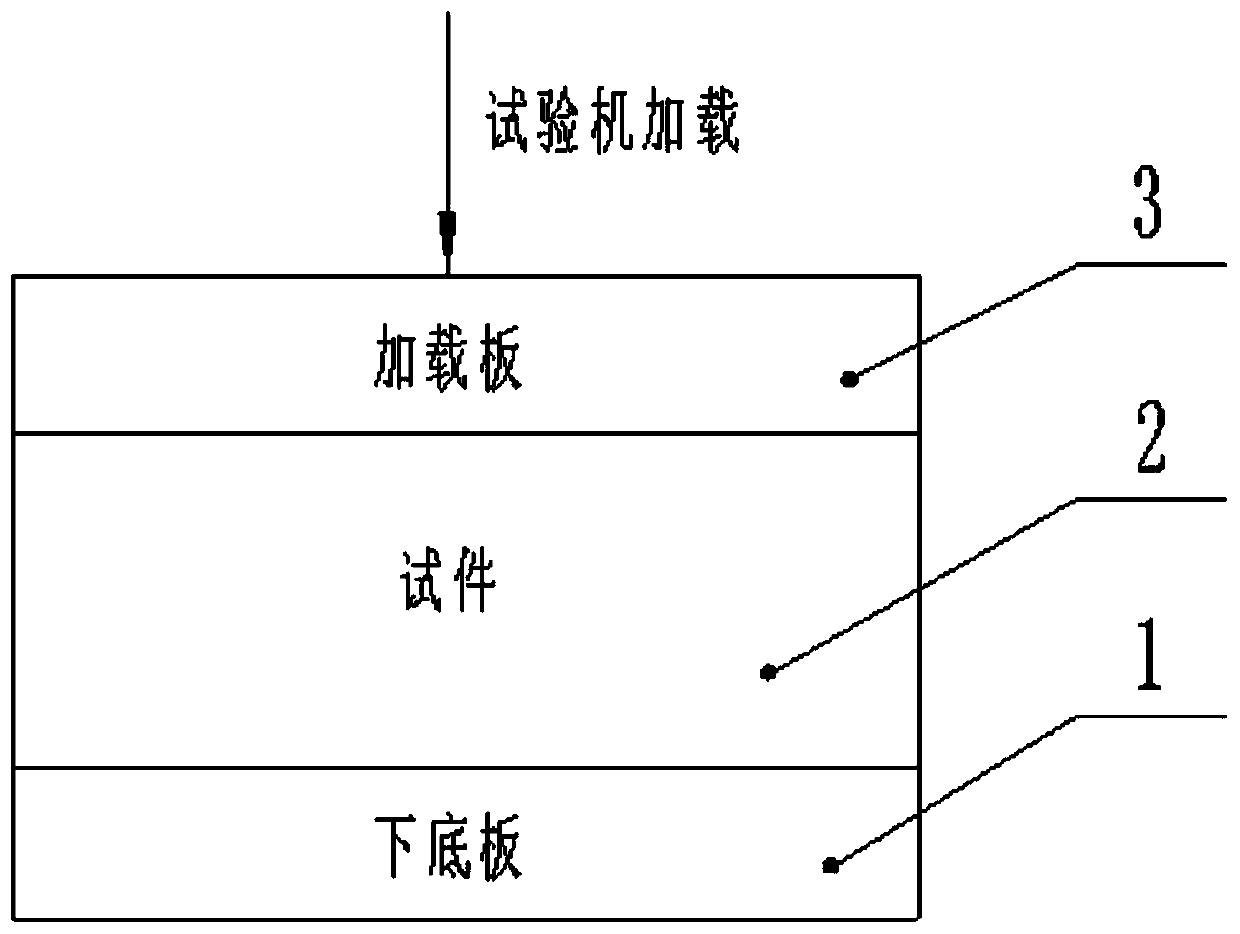

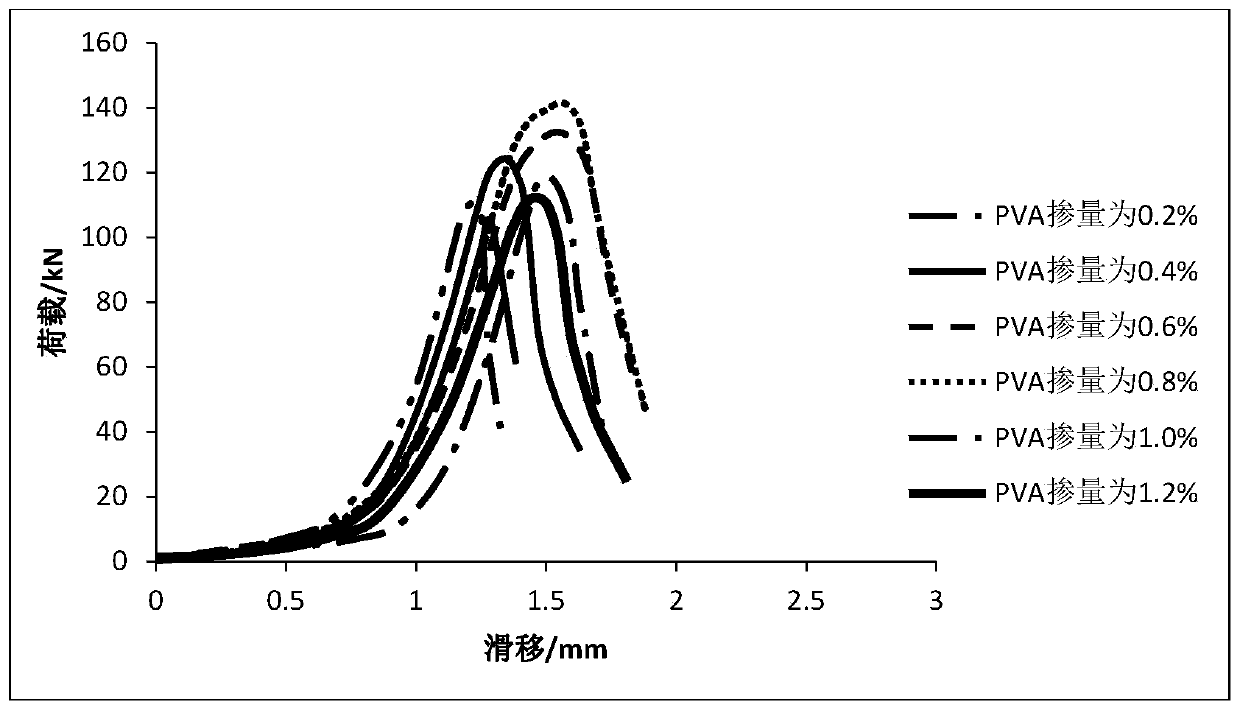

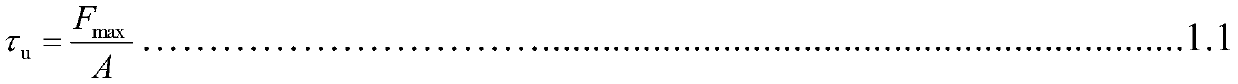

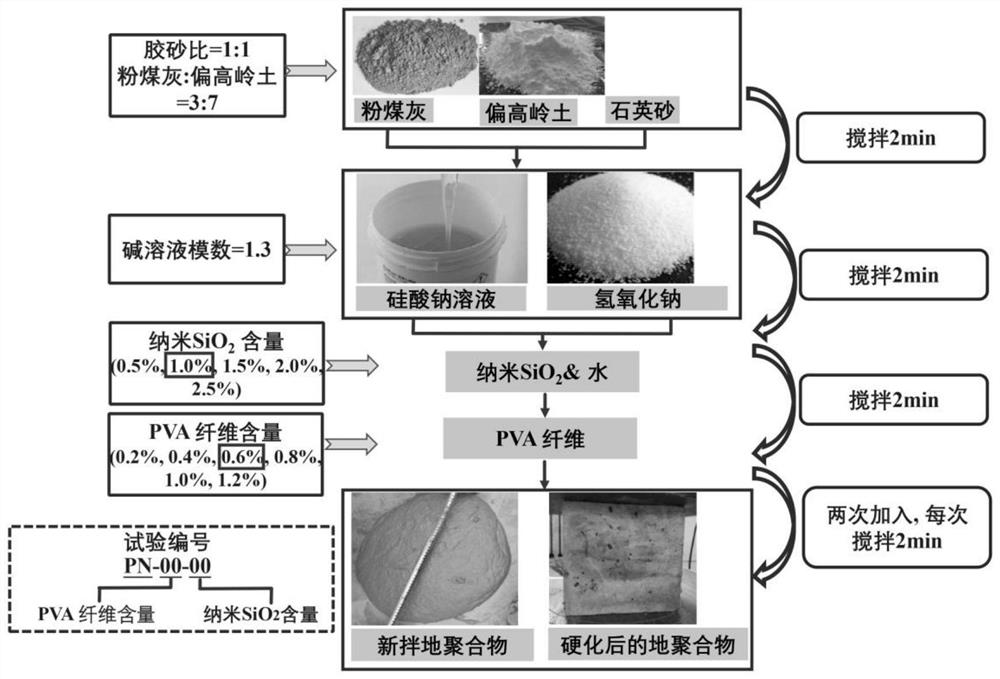

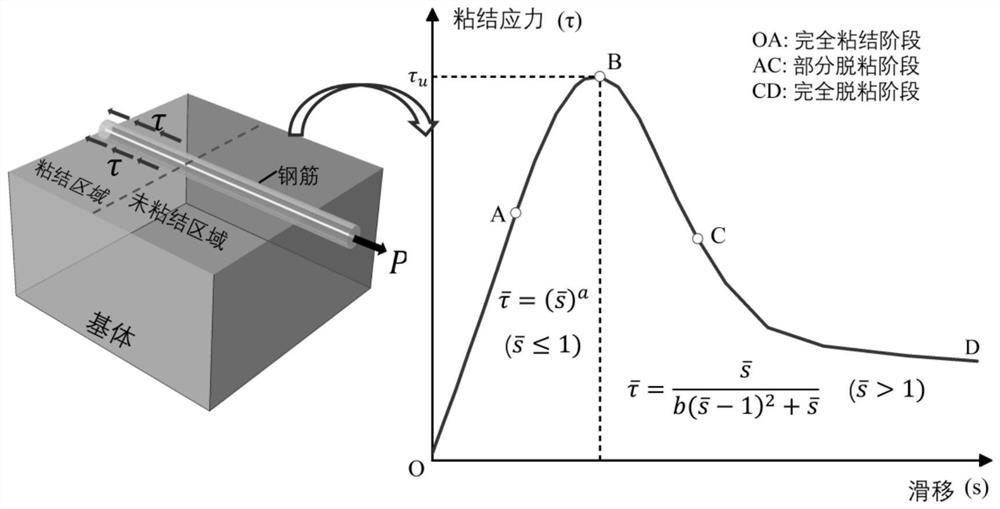

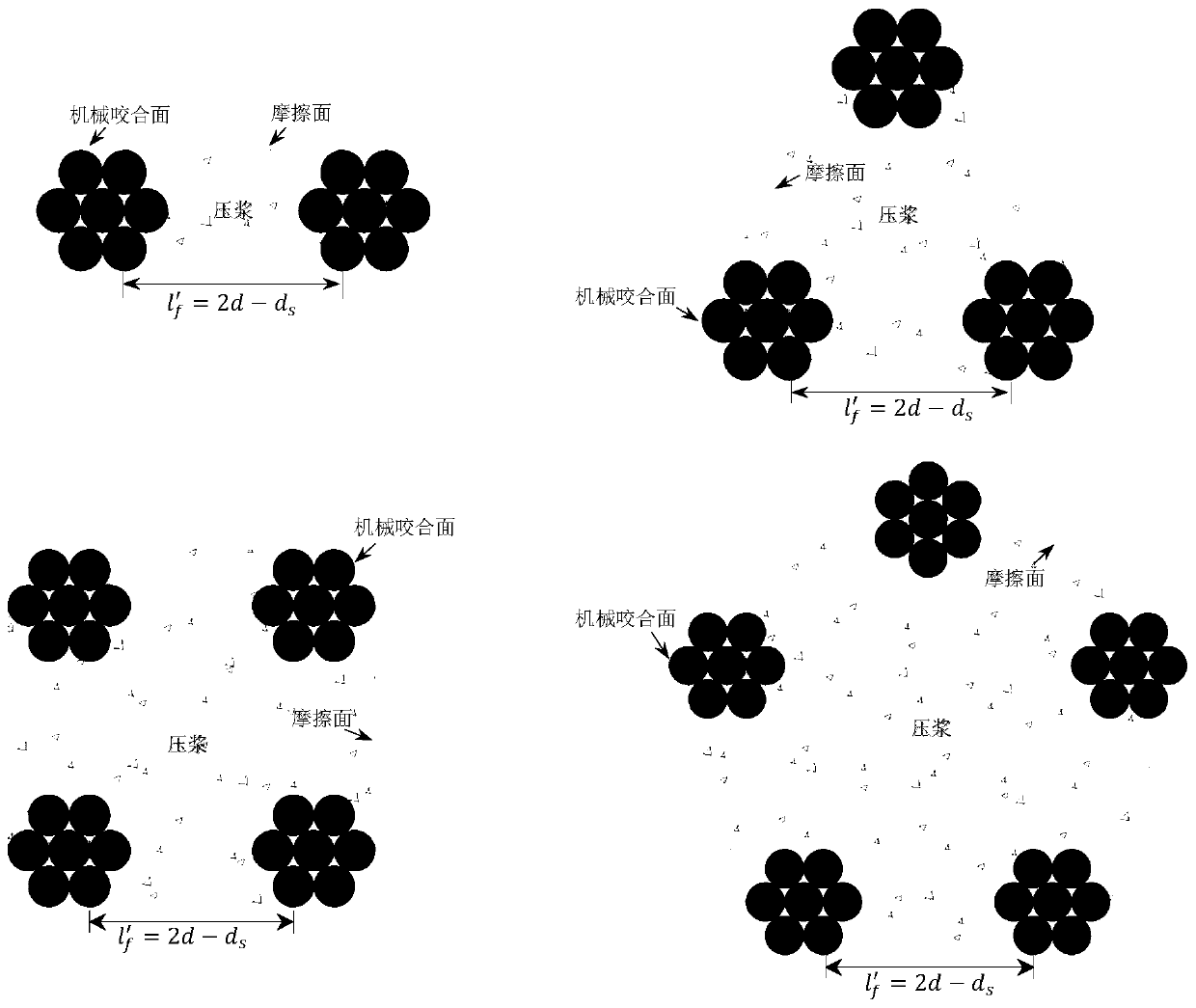

Bond-slip model between steel bars and nano-SiO2 and PVA fiber reinforced geopolymer mortar

ActiveCN109801686AImprove hydrophilicityImprove brittlenessCement productionUsing mechanical meansFiberNano sio2

The invention discloses a bond-slip model between steel bars and nano-SiO2 and PVA fiber reinforced geopolymer mortar. The bond-slip model between steel bars and nano-SiO2 and PVA fiber reinforced geopolymer mortar is characterized by wiping out a plurality of test pieces with the same SiO2 content and different dosage of PVA fibers, measuring the size, and calculating the shearing area of the test pieces; placing the test pieces in the middle position of a lower bottom plate, so as to cut the lower end of each test piece to enable the lower end of the test piece to contact the lower bottom plate and enable the upper end of the test piece to contact a loading plate to form a shear of the test piece, aligning the center of the test piece with the center of a lower platen of an electro-hydraulic three-axis servo test machine, starting the electro-hydraulic three-axis servo test machine, and uniformly, continuously and slowly loading; and loading in a mode of mixed control of load gradingand deformation grading, when the test piece is damaged by shearing, resetting the instrument, recording the damaged load and the damaged position, and calculating the shearing strength while the bonding strength is the shearing strength. The bond-slip model between steel bars and nano-SiO2 and PVA fiber reinforced geopolymer mortar reduces maintenance costs, realizes environmental optimization and prolongs the service life of the structure in engineering construction.

Owner:ZHENGZHOU UNIV

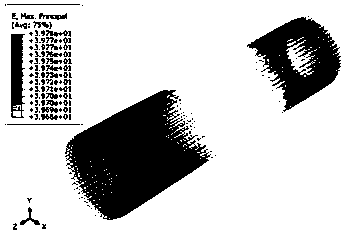

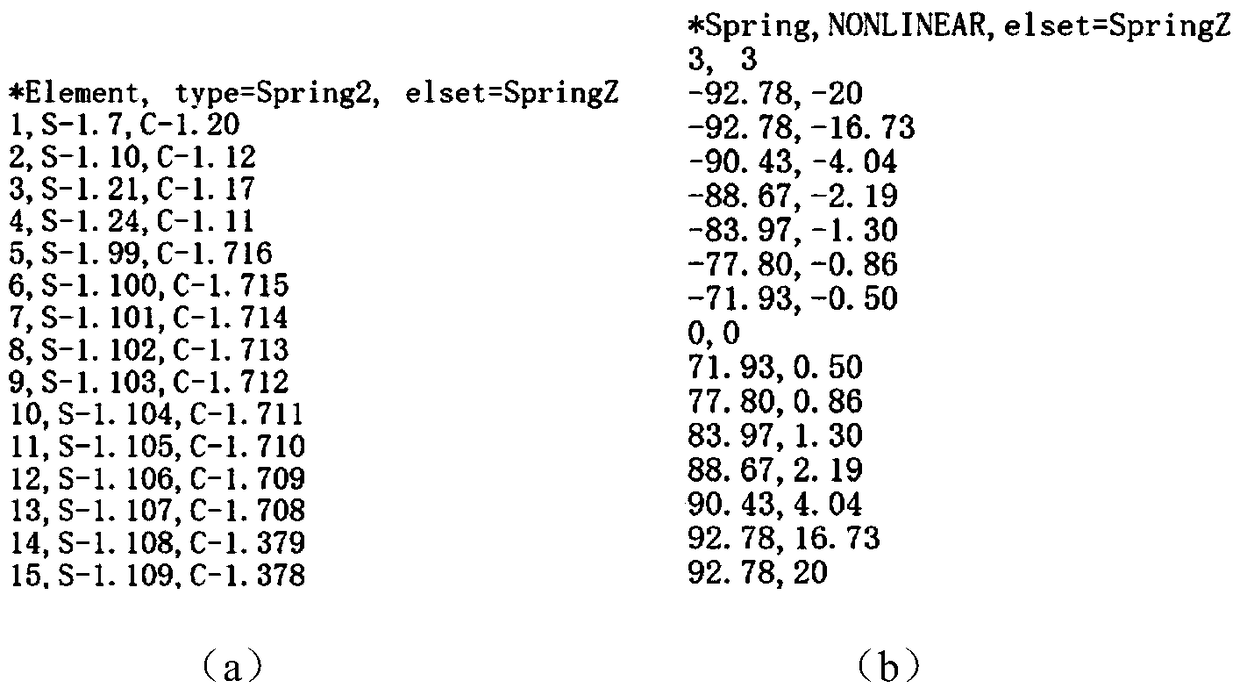

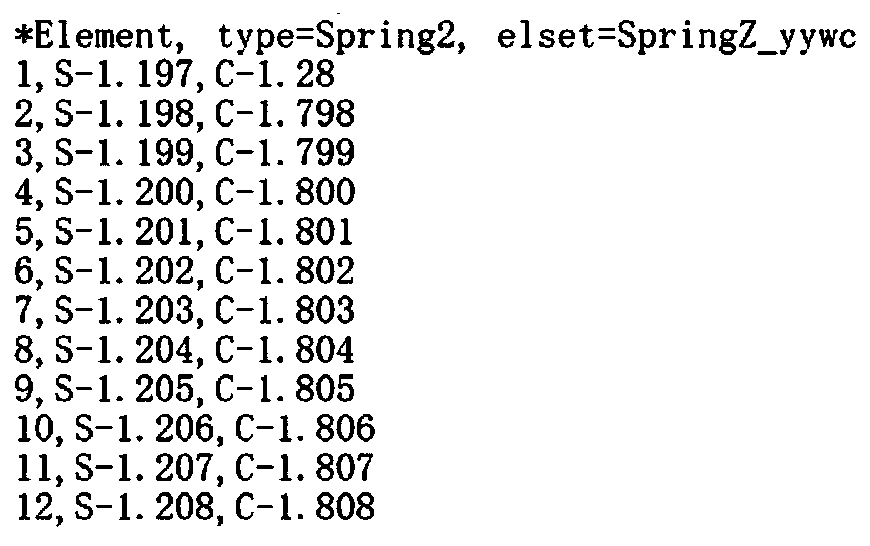

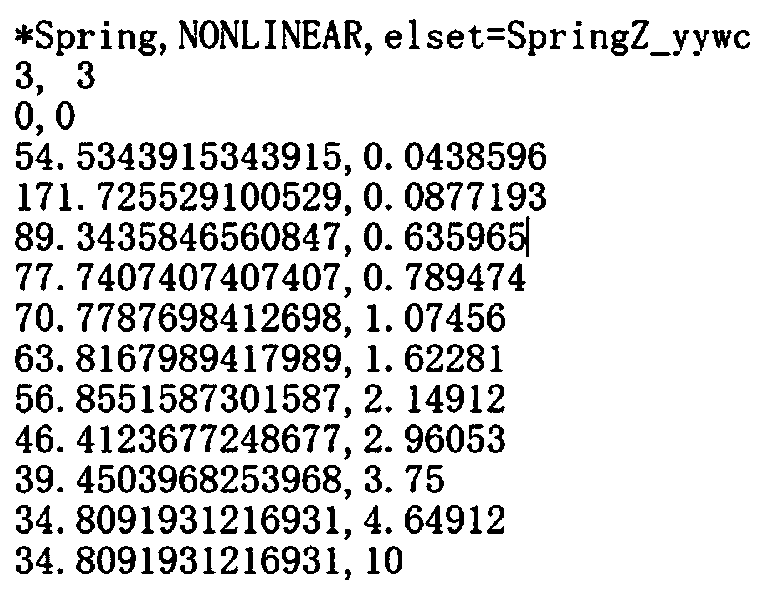

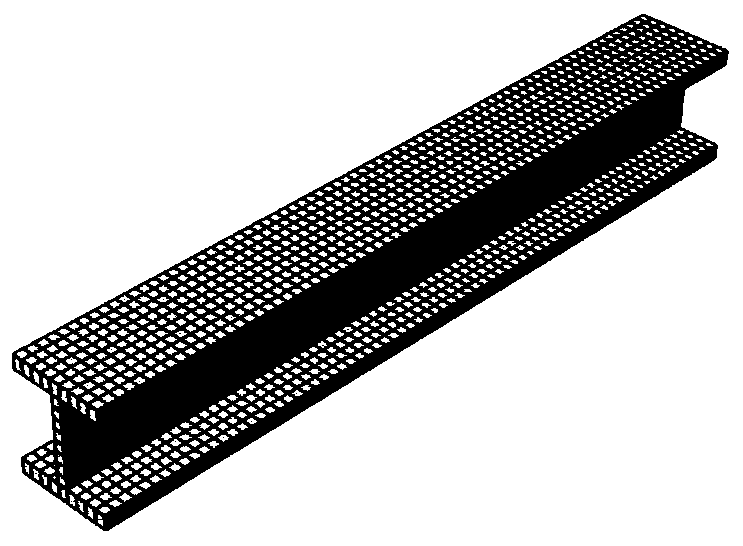

A method for adding a spring unit to a concrete filled steel tube finite element model

ActiveCN109446734AEfficient additionAdd accurateGeometric CADDesign optimisation/simulationElement modelBond slip

The invention discloses a method for adding a spring unit to a concrete-filled steel tube finite element model. The method comprises the following steps of step 1 establishing the concrete-filled steel tube finite element model; step 2 performing grid division on the steel pipes and the concrete; step 3 storing a. Inp file of the finite element model; step 4 extracting node numbers and coordinateinformation of the steel pipe component and the concrete component; step 5 storing the extracted information into a txt format file 1; step 6 reading the txt format file 1 and storing the txt format file 1 into the csv format file 1, then creating a list, storing four numbers in each line of the csv format file 1 into a sub-list, and storing all the sub-lists into the list; step 7 creating an Excel table to obtain spring unit contents meeting ABAQUS format requirements; step 8 obtaining an inp file added with a spring unit; and step 9 submitting the inp file added with the spring unit. According to the invention, the addition of the spring unit can be automatically, efficiently and accurately completed, thereby providing a finite element simulation analysis service for the test related tothe bonding slip performance of the concrete filled steel tube.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

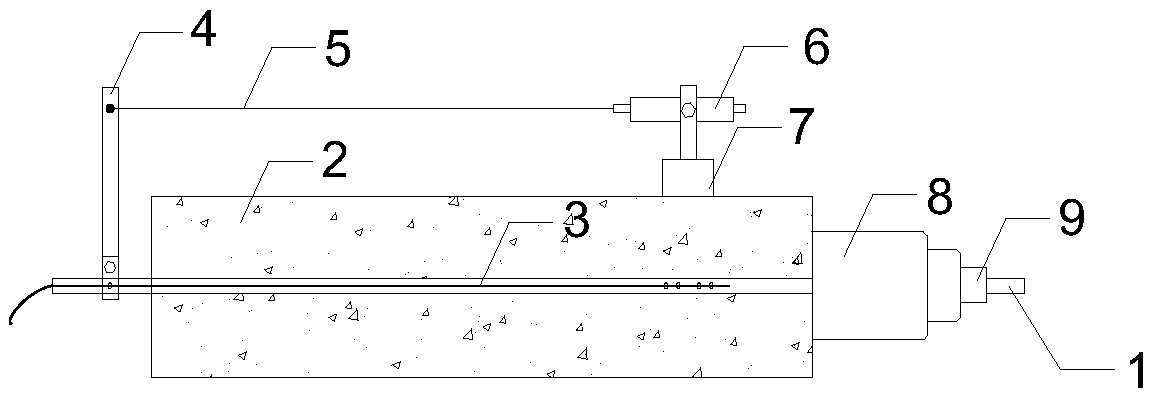

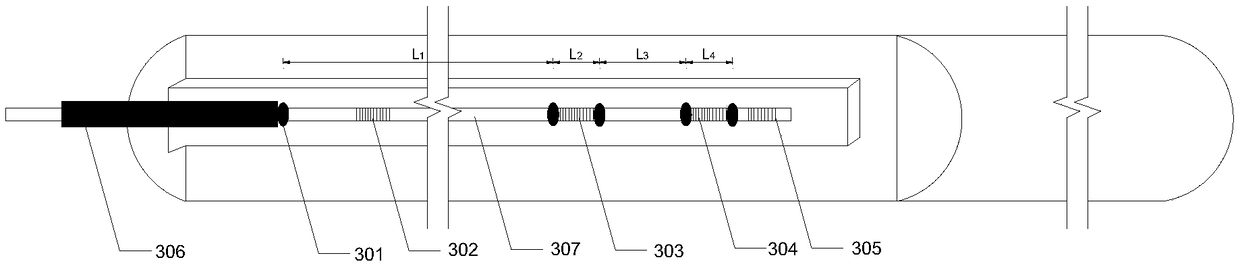

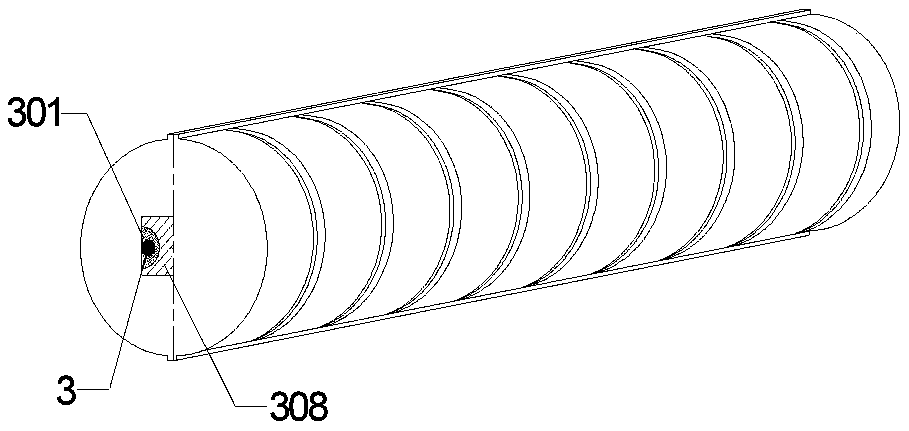

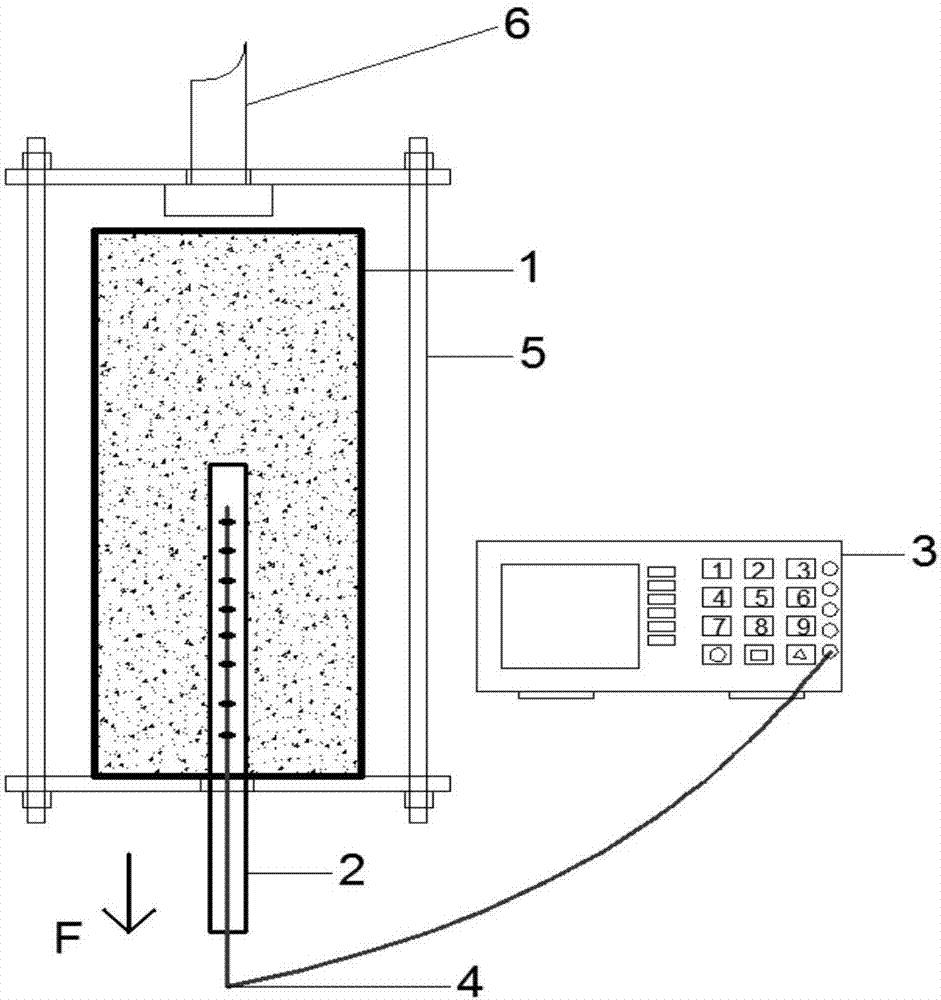

Fiber sensor-based reinforced concrete bonding and slipping constitutive test method and device

InactiveCN109060538AEasy to testAccurate measurementMaterial strength using tensile/compressive forcesFiberEngineering

The invention discloses a fiber sensor-based reinforced concrete bonding and slipping constitutive test method and device. The device comprises a reinforcement steel bar, concrete, a fiber grating, adisplacement transferring device, a thin wire, a displacement meter, a displacement meter support, a drawing device and an anchoring tool, wherein a stress monitoring grating, a slipping monitoring grating and a temperature compensation grating are arranged on a fiber and are fixed in reinforcement steel bar groove holes by welding glass, two ends of the reinforcement steel bar extend out of the concrete, the displacement transferring device and the drawing device are respectively arranged at the two ends of the reinforcement steel bar, the displacement transferring device is connected with the displacement meter by the thin wire, local slipping quantity is measured by combining the slipping monitoring grating, the stress monitoring grating is used for measuring local bonding stress of thereinforcement steel bar, and the drawing device is used for drawing and loading. With the monitoring device and method provided by the invention, accurate test on a local bonding and slipping constitutive model between a long drawing test piece reinforcement steel bar and the concrete can be achieved, an error of a short drawing test piece caused by average stress and a slipping value is reduced,and particularly, accurate measurement of a curve a bonding and slipping reduction segment under large slipping can be achieved.

Owner:XIANGTAN UNIV

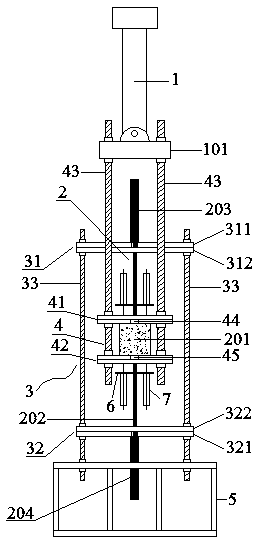

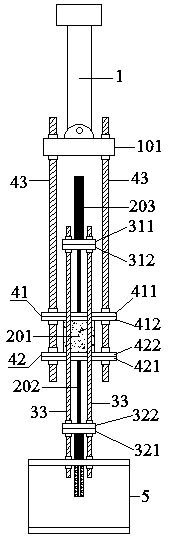

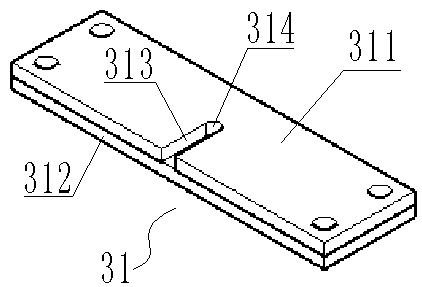

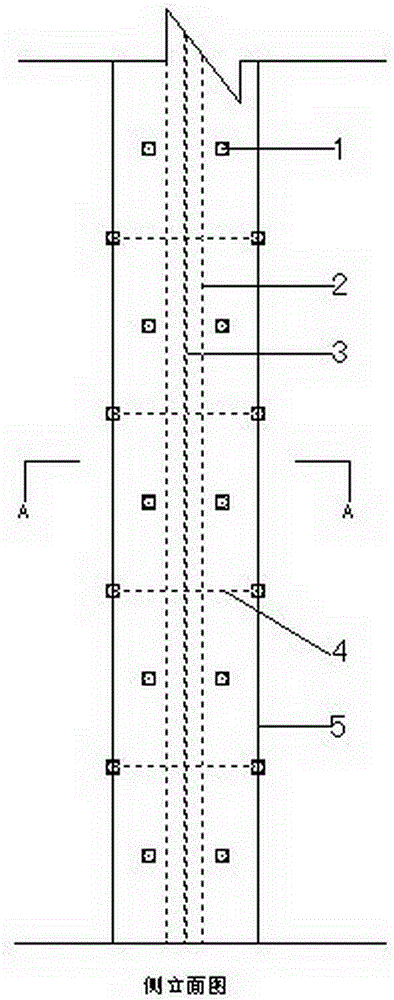

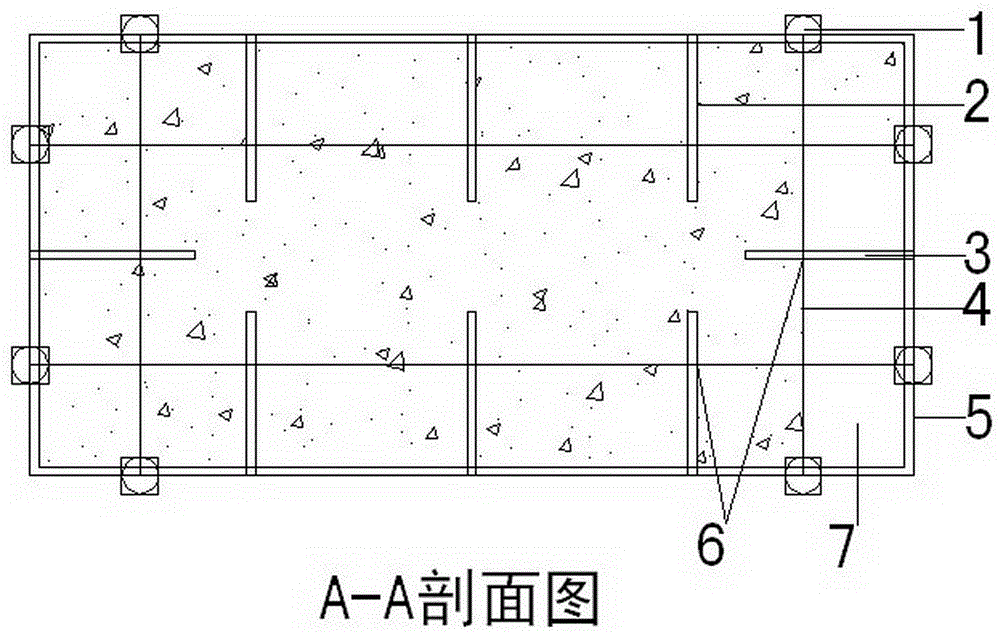

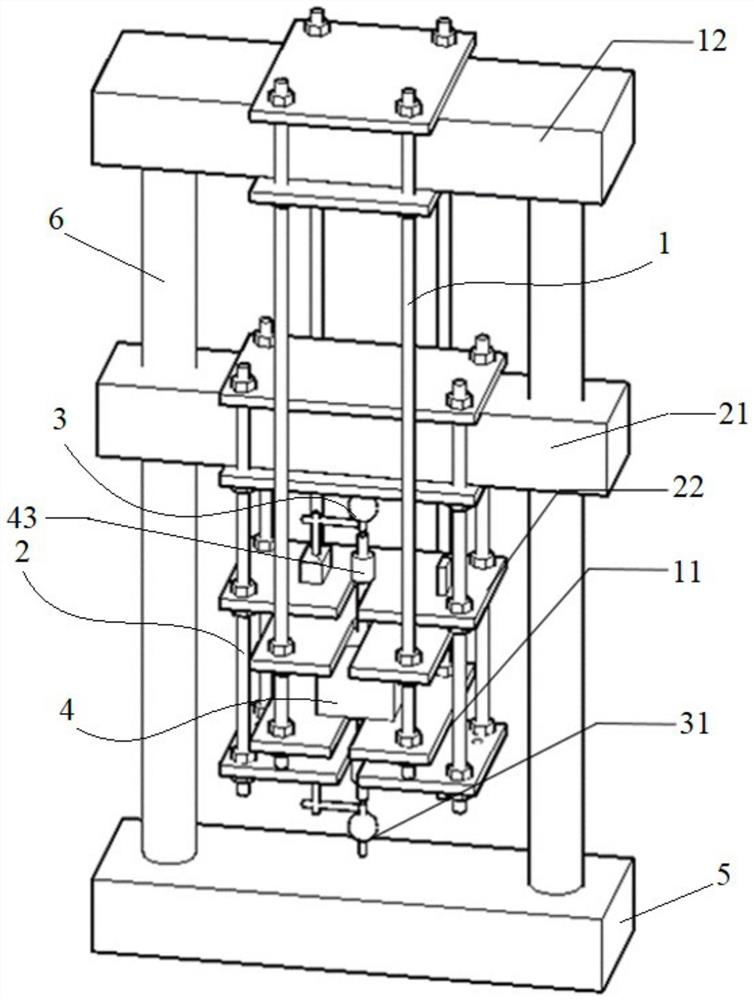

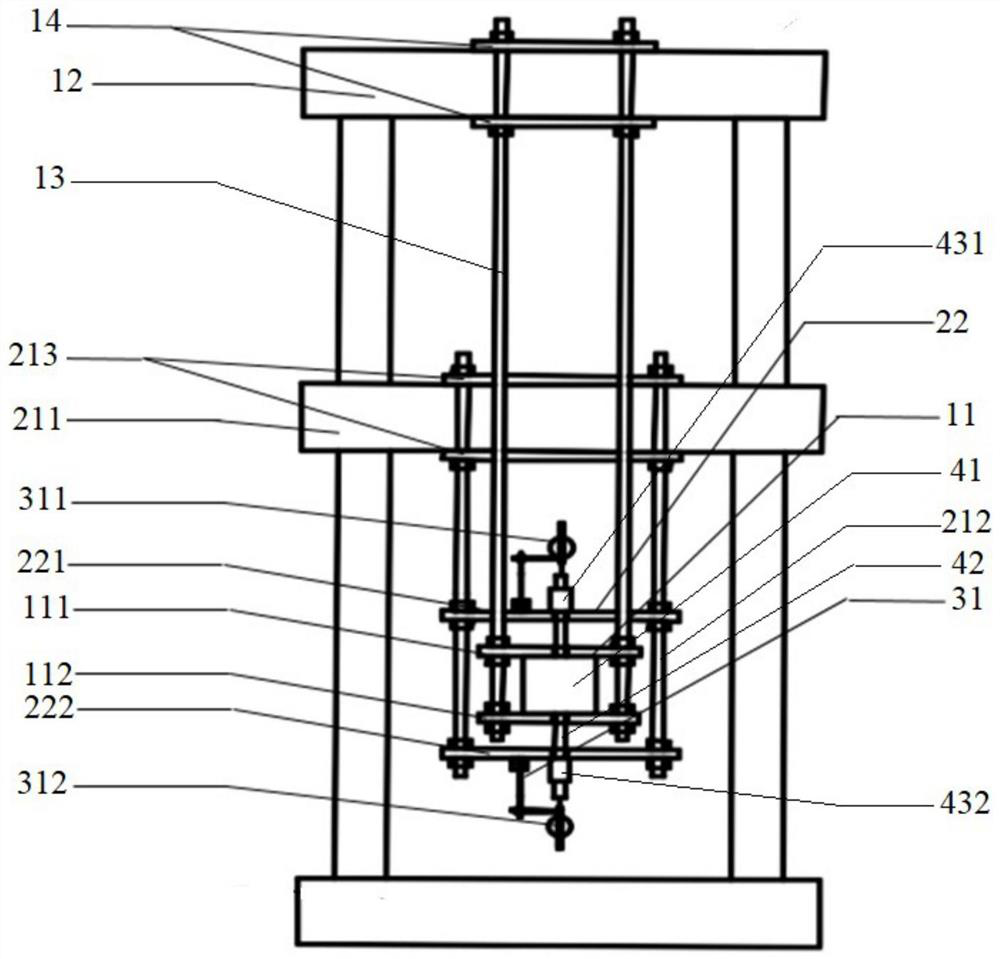

Loading device and method for bond slip performance test

PendingCN108801906AReduce lossDirect forceUsing mechanical meansMaterial analysisSoftware engineeringBond slip

The invention discloses a loading device and method for bond slip performance test. The loading device comprises a loading frame comprising support legs, a first support plate, a second support plateand a third support plate, wherein the first support plate, the second support plate and the third support plate are fixedly arranged on the support legs in sequence and are provided with coaxial mounting through holes; a penetrating ball hinge is fixedly arranged on the first support plate, and a center hole of the penetrating ball hinge is coaxial with the mounting through hole in the first support plate; a ball-hinge connecting rod with a ball hinge is installed in the mounting through hole in the third support plate, and the third support plate can be connected with a chuck of a testing machine through the ball-hinge connecting rod. The loading device can enhance the accuracy of bond slip performance test by bending moment release during self alignment.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

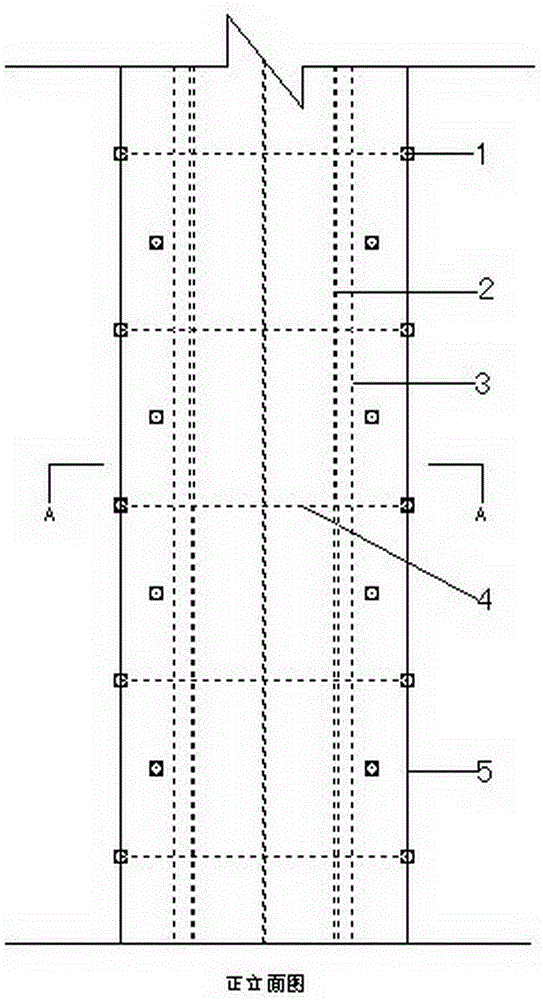

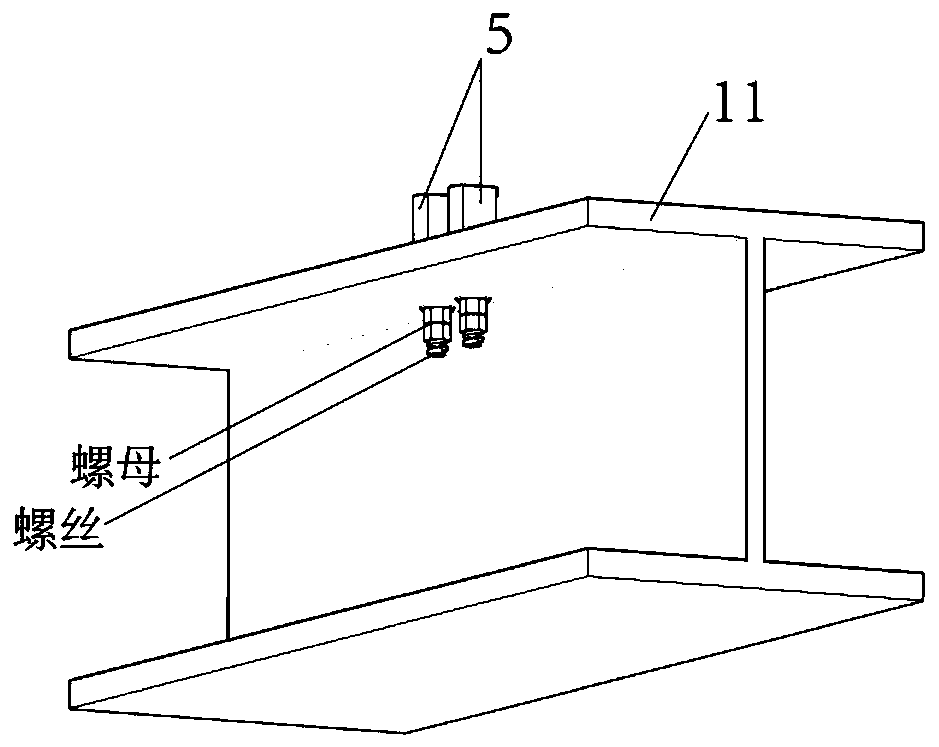

Rectangular concrete-filled steel tube column restrained by rib-perforating pull bars

The invention discloses a rectangular concrete-filled steel tube column restrained by rib-perforating pull bars. The rectangular concrete-filled steel tube column comprises stiffening ribs, pull bars, a rectangular steel tube and concrete. The stiffening ribs are strip-shaped steel plates with thickness identical to the thickness of the steel tube. The stiffening ribs are provided with holes at positions where the pull bars pass through, and the holes are of the exact size that allows the pull bars to pass through. The stiffening ribs are uniformly arranged at the internal circumference of the wall of the steel tube, perpendicular to the steel tube wall and connected with the steel tube wall in a welding manner. The pull bars are common pull bars or steel bars, vertically penetrate the tube wall of the rectangular steel tube and are staggerly arranged at proper intervals along the long side and short side of the column. The end parts of the pull bars are connected with the steel tube wall through welding or by bolts. According to the invention, the stiffening ribs are cooperated with the restraining pull bars, so bonding slip between the steel tube wall and concrete can be delayed, local outer surface deformation of the steel tube wall can be alleviated, the lateral rigidity of the steel tube wall can be improved, and the steel tube wall has improved capacity in resisting local bending and restraining effect on core concrete; and thus, the rectangular concrete-filled steel tube column has improved bearing capacity and ductility.

Owner:HENAN POLYTECHNIC UNIV

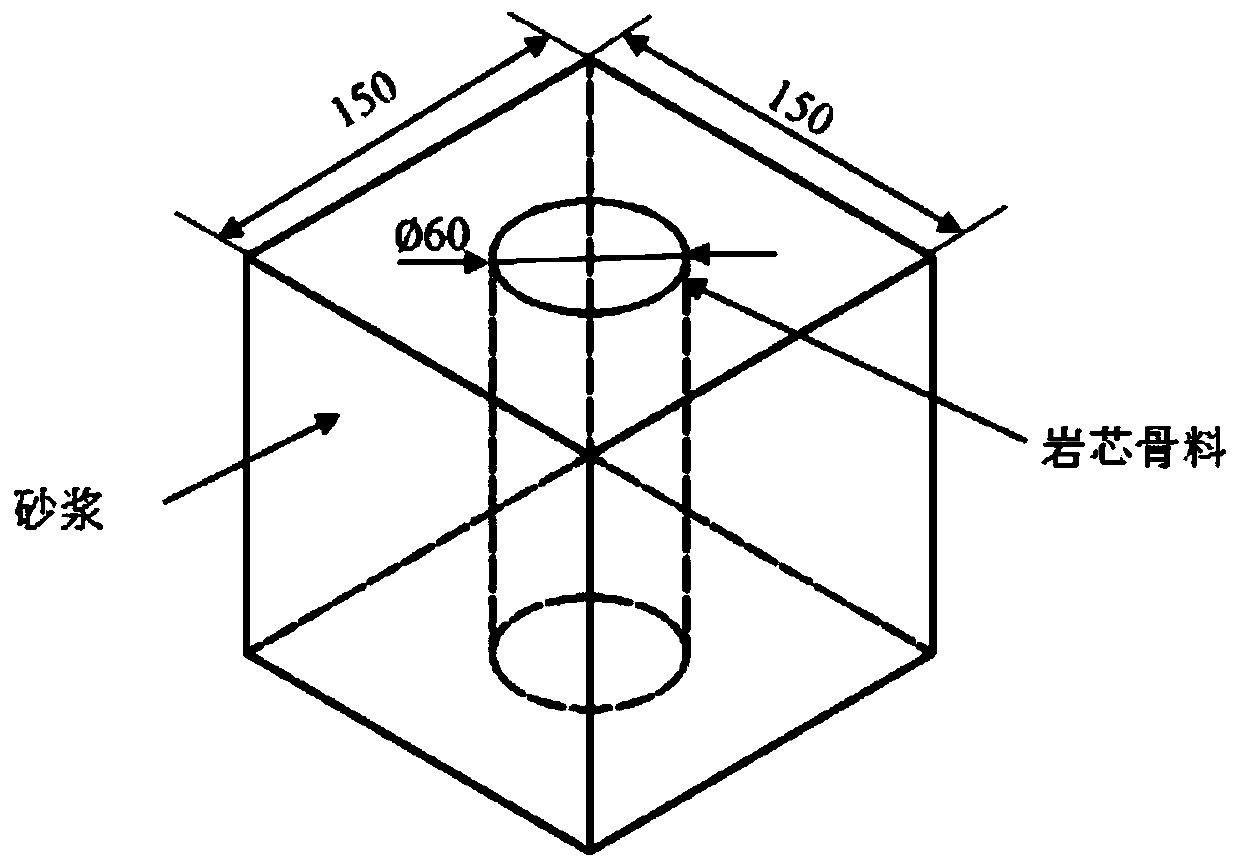

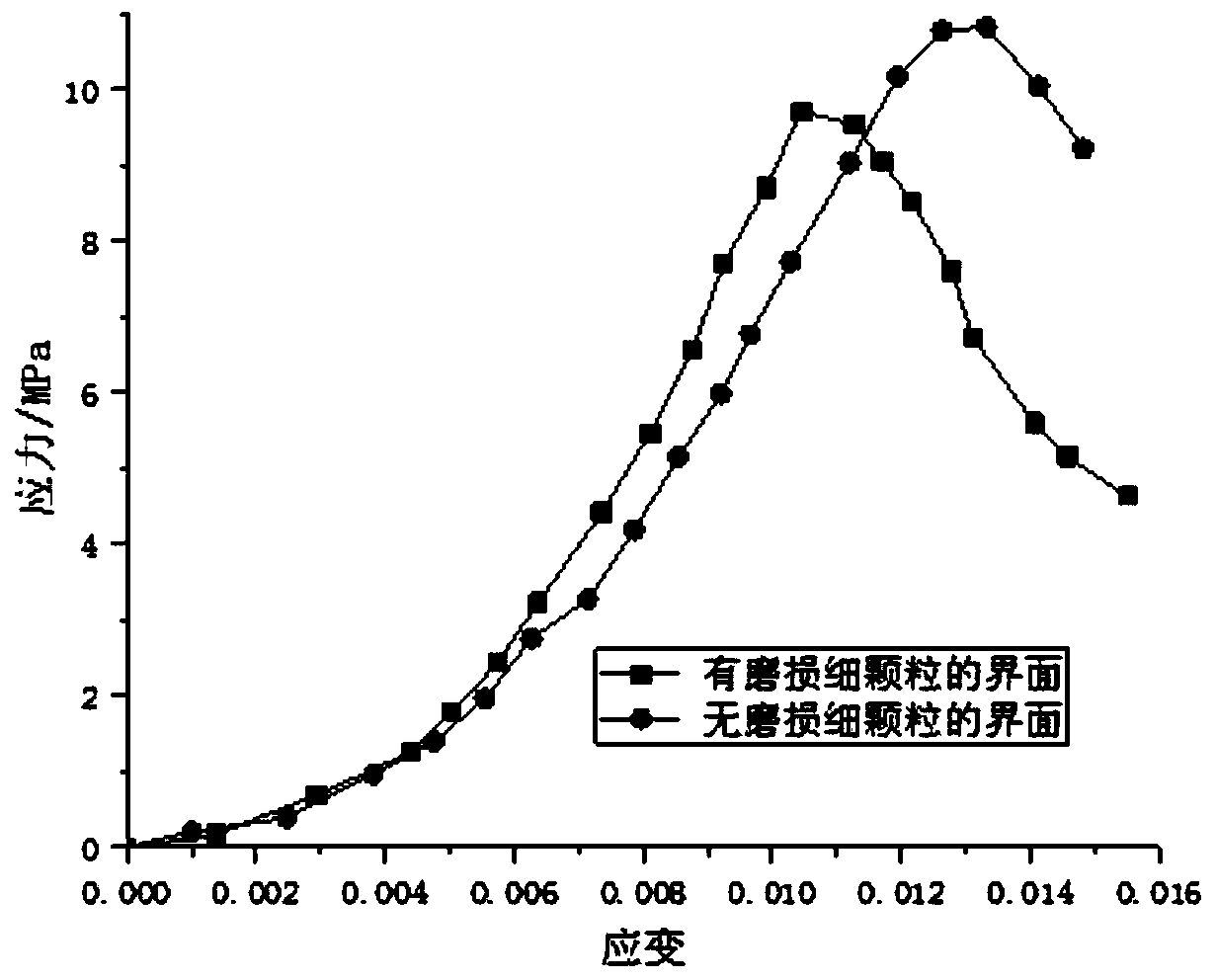

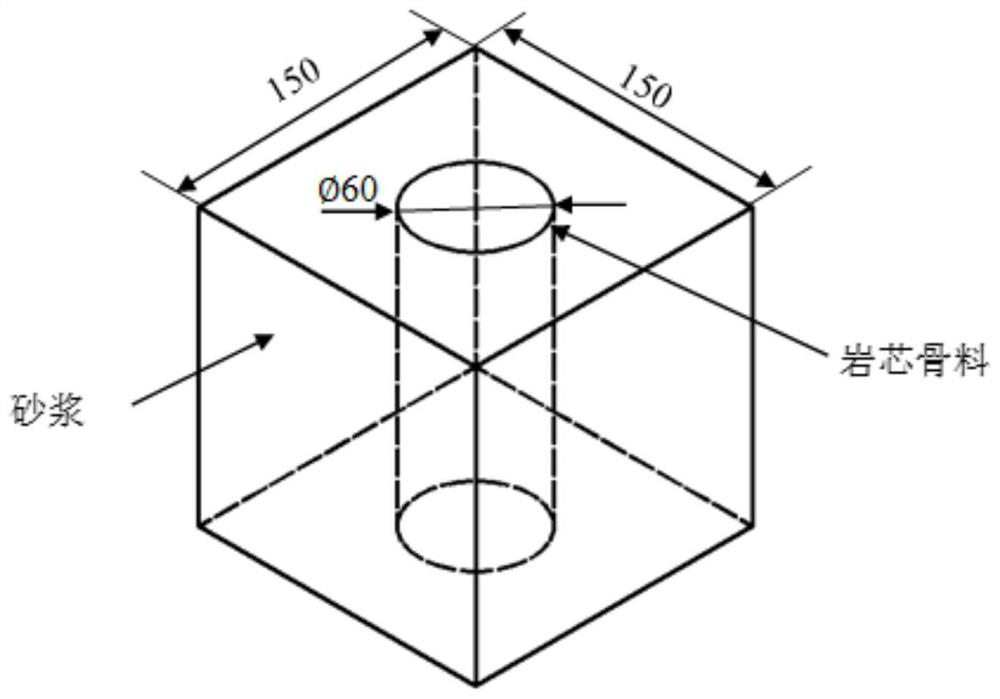

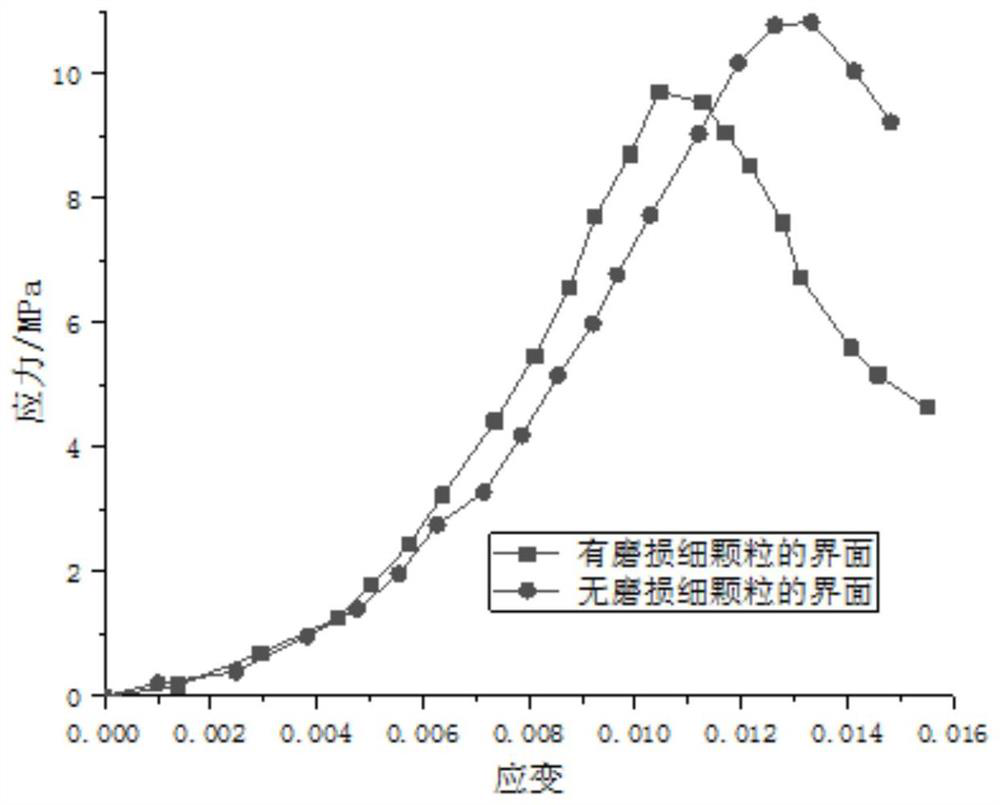

Test method for simulating coarse aggregate-mortar weakened interface

ActiveCN110376031ALarge experimental errorAccurate determination of interface deformationPreparing sample for investigationUsing mechanical meansPrillBond slip

The invention, which belongs to the technical field of construction engineering, discloses a test method for simulating a coarse aggregate-mortar weakened interface. The method mainly comprises: making a cylindrical core aggregate, placing the core aggregate in water, carrying out standing processing till pouring, and taking out the processed core aggregate for standby; attaching ground rubber particles to the surface of the core aggregate; pouring mortar around the core aggregate to obtain a composite test piece; and carrying out loading testing on the composite test piece on a testing machine, applying a pressure load on the surface of the core aggregate till extrusion of the composite test piece from the core aggregate to obtain anti-shear strength and bond-slip characteristics of the simulated coarse aggregate-mortar weakened interface. According to the invention, the rubber fine particles with sufficiently small particle diameters have the strong adhesiveness and are attached to the surface of the core aggregate based on the own adsorption forces; when the core aggregate with the worn rubber fine particles attached is combined with the mortar, the contact area between the mortar and the coarse aggregate is reduced based on the worn fine particles; and the friction and bonding performances between the mortar and the coarse aggregate are weakened, so that the effect of simulating the weakened interface is realized.

Owner:TIANJIN UNIV

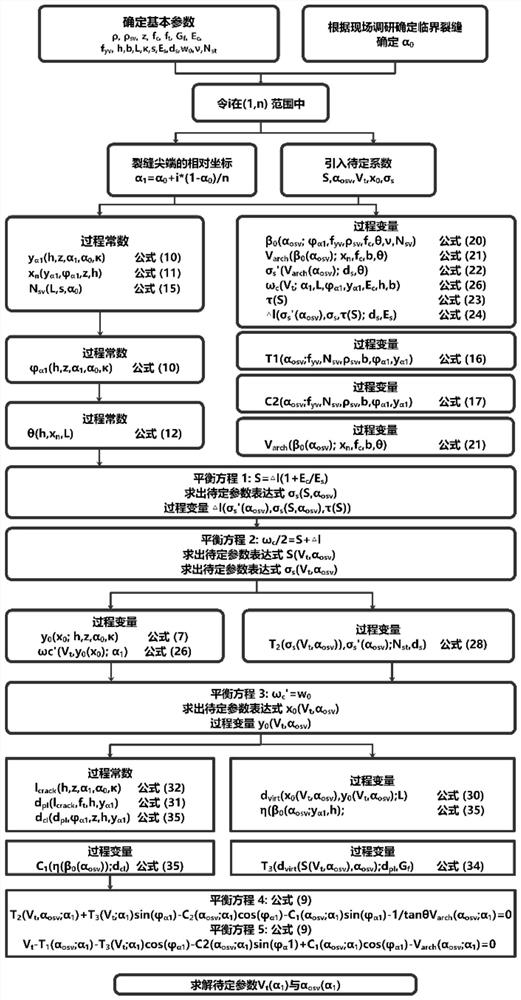

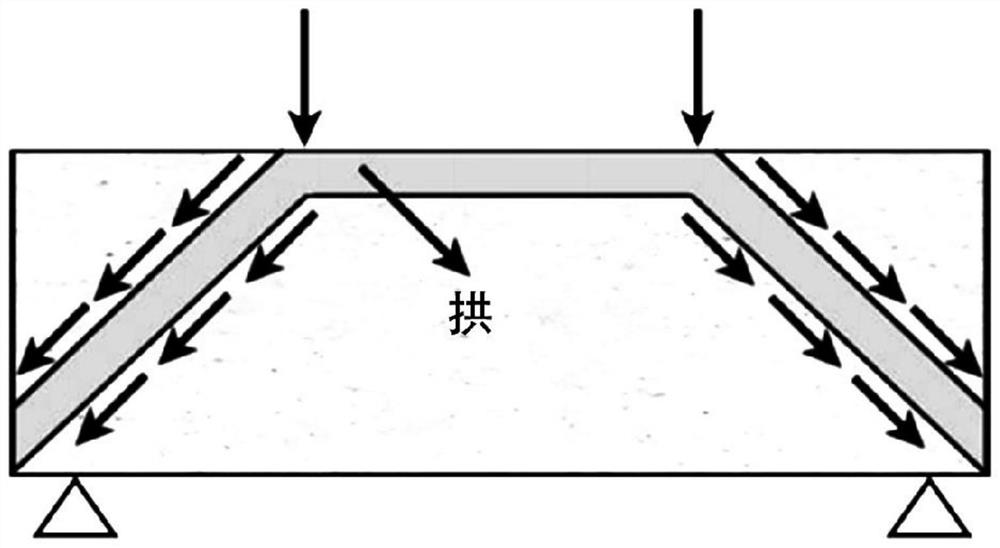

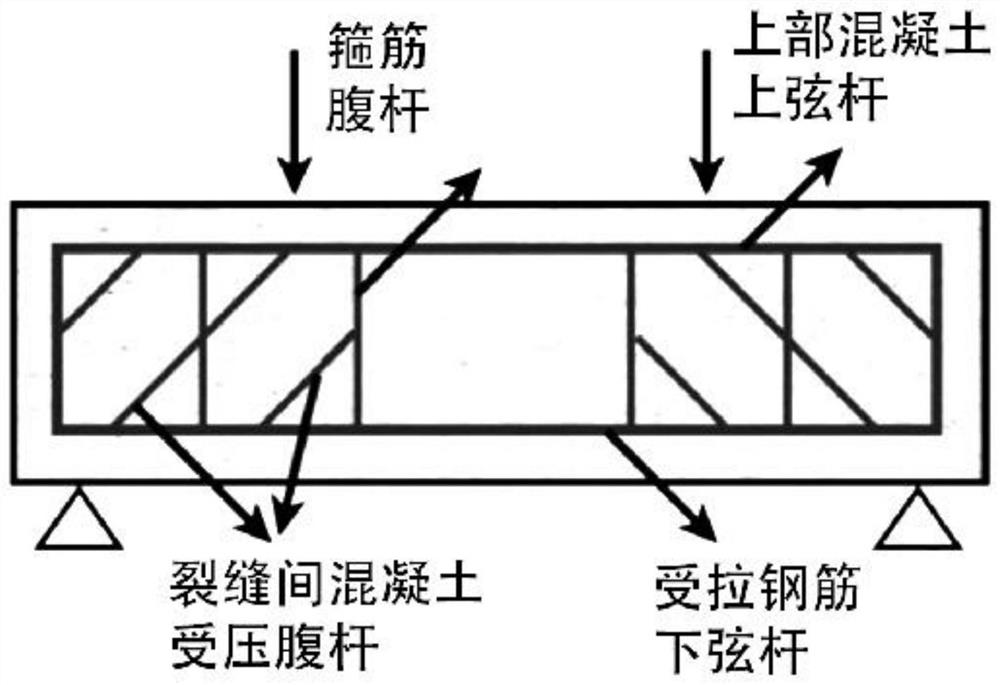

Method for predicting shear performance of square-section reinforced concrete beam

ActiveCN113642087AImprove calculation accuracyGeometric CADForecastingArchitectural engineeringBond slip

The invention discloses a method for predicting the shear performance of a square-section reinforced concrete beam. The calculation method comprises the steps of S1, determining a beam shear balance expression through an improved internal force arch truss model; S2, solving a fracture angle; S3, solving an arch inclination angle; S4, solving the tension of a stirrup; S5, solving the pressure of a concrete pressing rod; S6, solving the shearing force of an internal force arch; S7, solving the tension of a lower tensile steel bar; S8, solving the upper concrete pressure and the micro-crack cohesive force; and S9, performing comprehensive solution through each subitem to obtain the shear performance of the square-section reinforced concrete beam. According to the invention, bonding slippage between the concrete and the reinforcing steel bars and constitutive models of the reinforcing steel bars and the concrete are considered, meanwhile, the influences of the size effect and critical cracks are considered in a calculation formula, and then the calculation precision is high; and the shear performance of the square-section reinforced concrete beam can be evaluated, and a theoretical basis is provided for scientifically evaluating the stress performance of a square-section reinforced concrete structural member.

Owner:SOUTHEAST UNIV

Method for enhancing adhesive property of geopolymer composite material and reinforcing steel bar

PendingCN112816288AImprove adhesionAdhesion Enhancement MechanismPreparing sample for investigationUsing mechanical meansNano sio2Geopolymer

The invention discloses a method for enhancing the adhesive property of a geopolymer composite material and a reinforcing steel bar, which comprises the following steps that an improved mathematical model is established based on a Harajli bond slip model, a finite element numerical model is proposed by adopting a Mori-Tanaka homogenization method and a Tsai-Hill failure criterion, the prediction results of the finite element numerical model and the improved mathematical model are compared and analyzed with the existing Harajli model and the corresponding test result, so that the bond slip behavior of the nano SiO2 and PVA fiber reinforced geopolymer composite material can be effectively predicted.

Owner:ZHENGZHOU UNIV

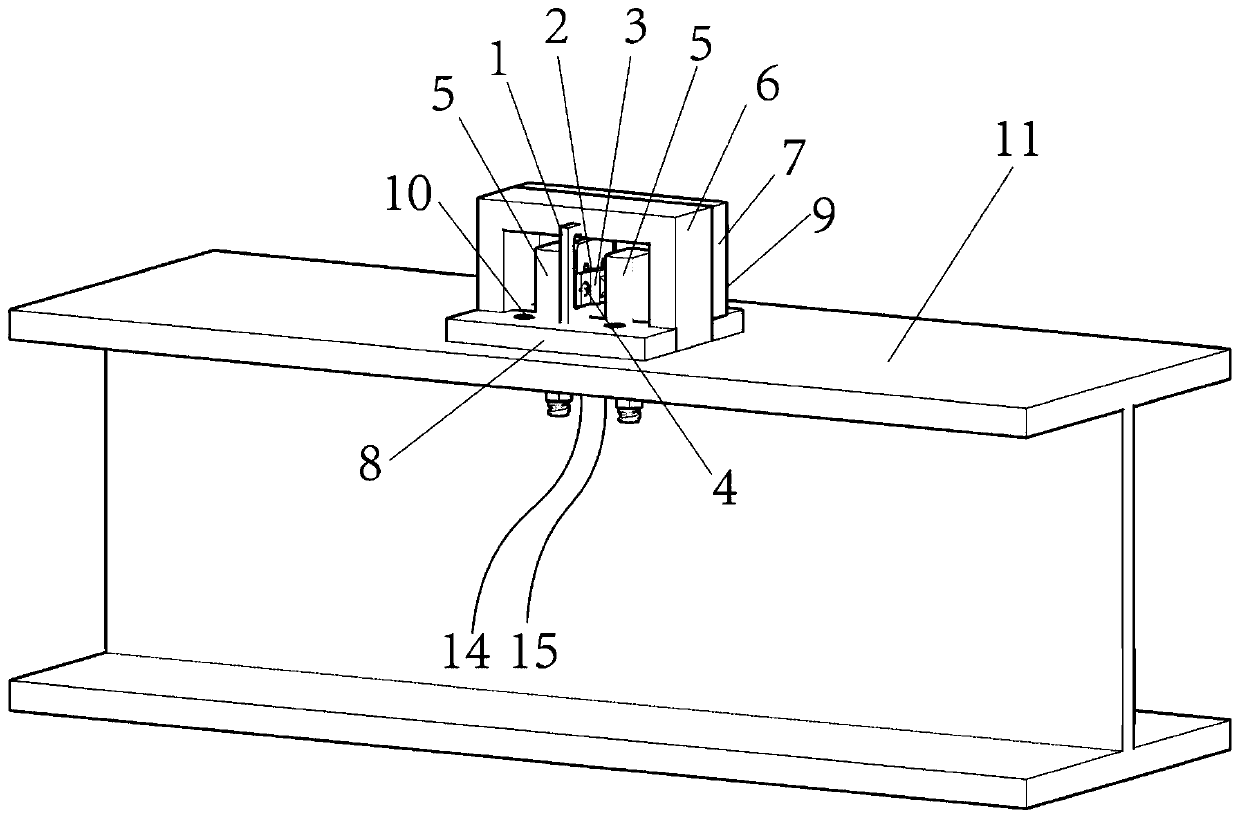

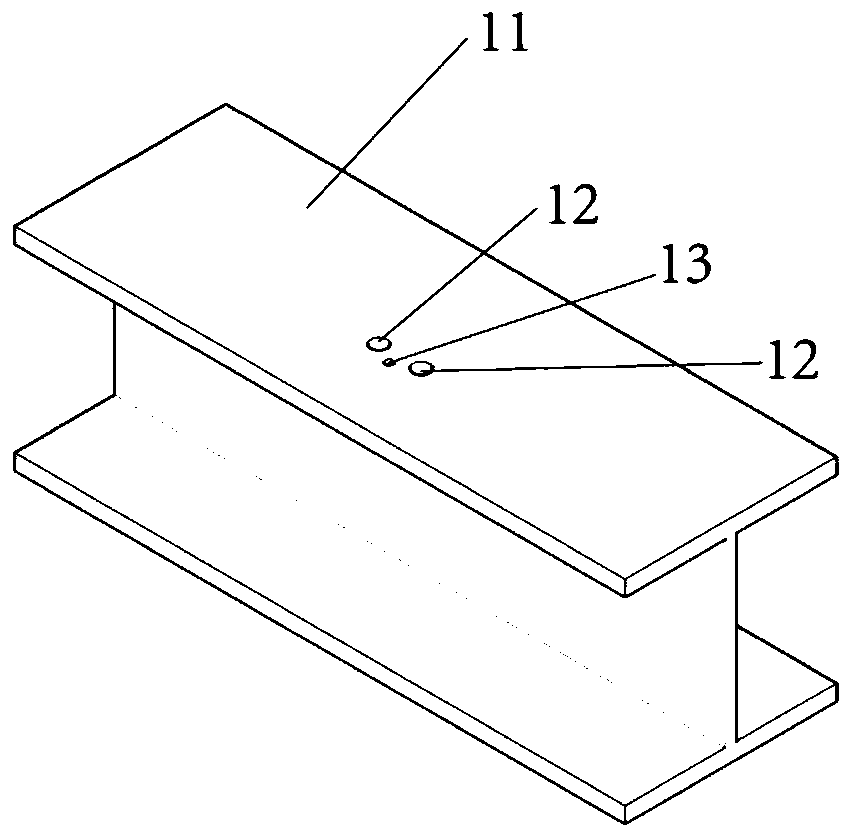

Measuring sensor for measuring bond slip at interface between structural steel and concrete and measuring method thereof

PendingCN110208182AAccurate measurementSolving Difficult Measurements of Bond-Slip PropertiesUsing mechanical meansMaterial analysisElectrical resistance and conductanceChinese characters

The invention, which belongs to the field of civil engineering, relates to a measuring sensor for measuring the bond slip at an interface between a structural steel and concrete and a measuring methodthereof. With the measuring sensor, the bond slip between the structural steel and the concrete can be measured conveniently and accurately and the bonding stress and bond slip at the interface can be obtained. The measuring sensor is mainly composed of a special spring steel disc, a strain gauge, force transmission fixtures, a flatheaded rounded limit rod, an inverted-U-shaped metal housing, a rectangular metal housing, a metal housing in a shape like a Chinese character "tu" and wires. Two resistance strain gauges are pasted to the front side and the rear side of the special spring steel disc respectively; and a thin wire is welded to each o resistance strain gauge. The two force transmission fixtures are fixed at the front side and the rear side of the special spring steel disc by rivets to form a core measuring element; the core measuring element is inserted into a measuring box formed by three metal housings; the metal housing in a shape like a Chinese character "tu" is fixed bya screw and is installed at a to-be-measured interface that has been drilled and is provided with the flatheaded rounded limit rod to form a measuring sensor. The measuring sensor and the measuring method have advantages of clear principle, high flexibility, linearity, reasonable and adjustable measuring range, simple processing and manufacturing, great convenience in mounting; and great easinessin operation; and a problem that the bond slip at the interface between the structural steel and the concrete is difficult to measure is solved.

Owner:DALIAN UNIV OF TECH

Spring unit modeling method of SRC component finite element model based on Excel

ActiveCN110147565AComplete efficientlyAccurately doneGeometric CADDesign optimisation/simulationElement modelBond slip

The invention discloses a spring unit modeling method of an SRC component finite element model based on Excel. The spring unit modeling method comprises the steps: establishing a finite element modelof an SRC component, and storing an inp file; copying profile steel node information in the inp file to the first column of Sheet1 and dividing the profile steel node information into four columns; copying the concrete node information to the fifth column and dividing the concrete node information into four columns; copying the first column of profile steel node numbers to the tenth column, searching concrete node numbers with the same coordinates as the profile steel nodes in the 2nd, 3rd and 4th columns of the first row from the concrete nodes, and obtaining profile steel and concrete node numbers with the same coordinates in the 10th and 11th column of each row; obtaining section steel and concrete joint numbers required by the spring units; obtaining a spring unit required by the inp file in the twelfth column; and copying the twelfth column of spring units to a required position in the inp file, and adding attributes of the spring units in front of the first spring unit. Accordingto the spring unit modeling method, the addition of the spring unit can be efficiently and accurately completed, so that the spring unit modeling method is used for finite element simulation analysisof the SRC component or structure considering the bonding slip performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

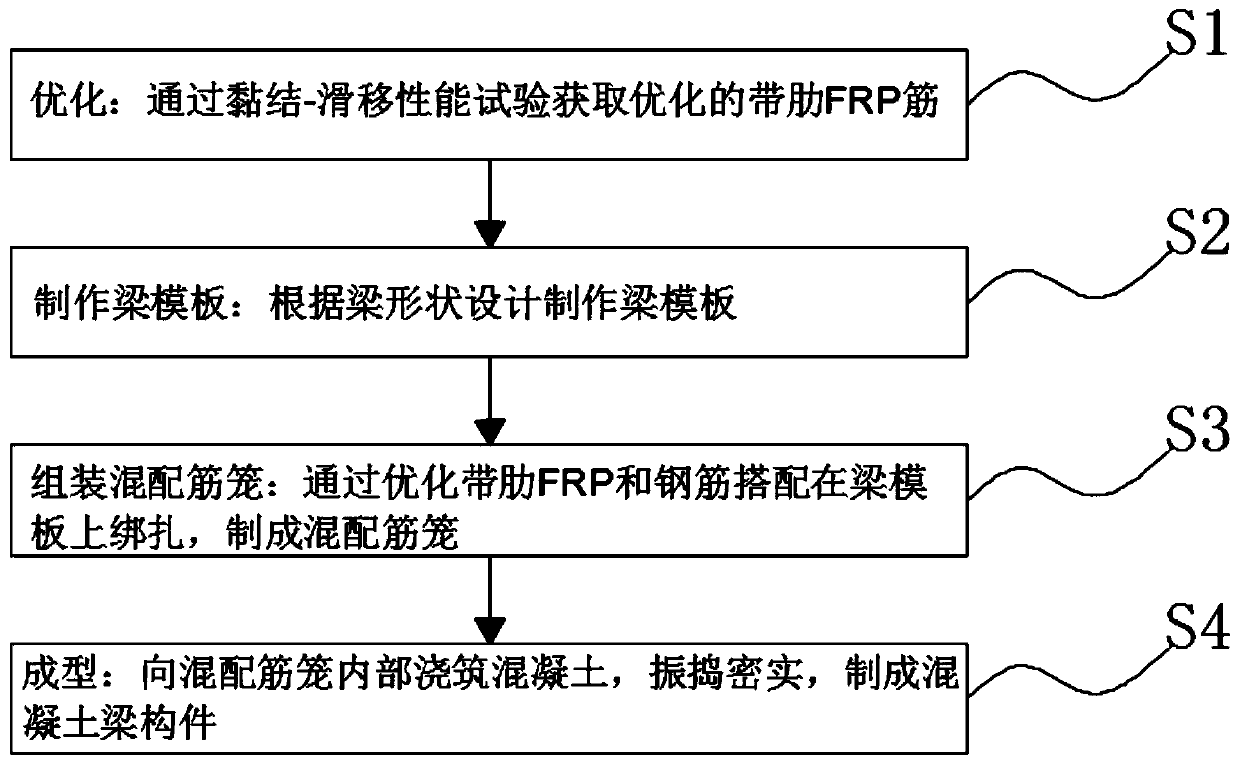

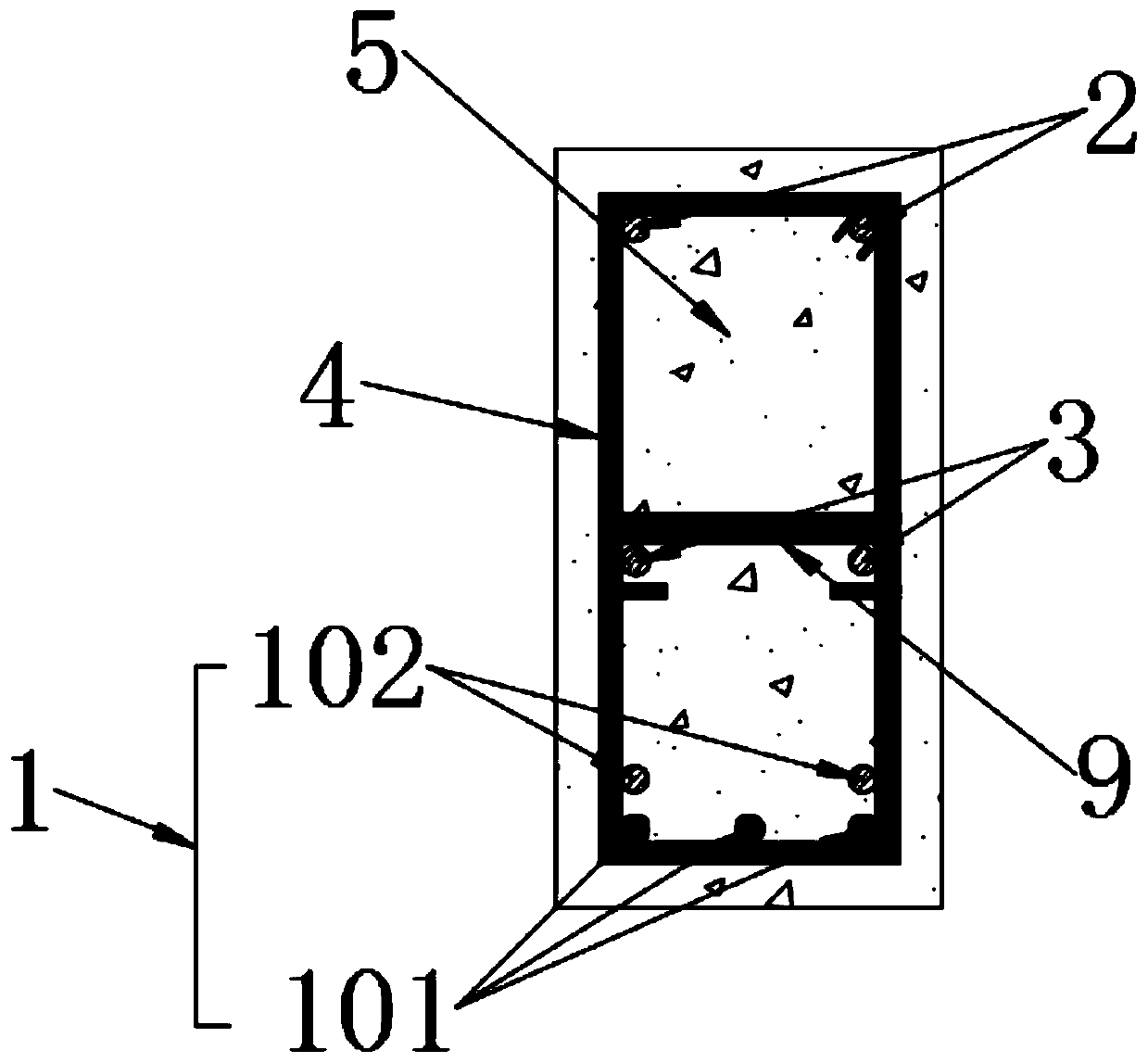

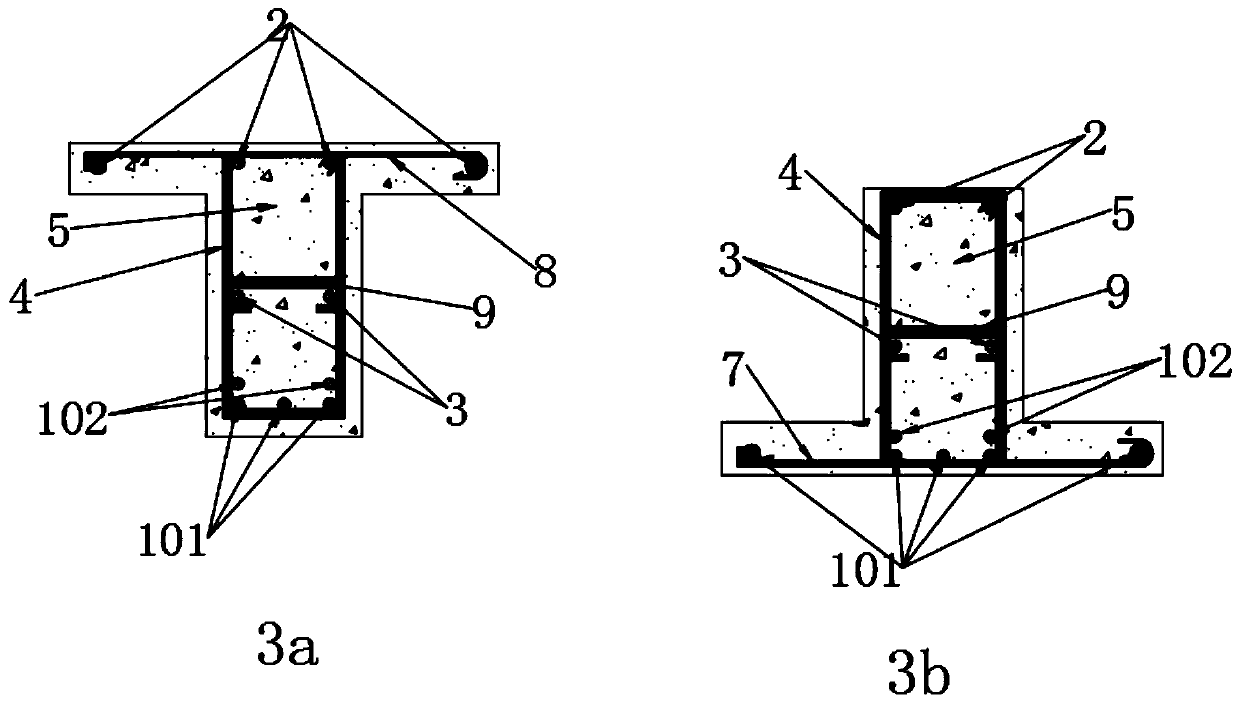

Method for realizing crack resistance of concrete beam member by optimizing ribbed FRP bars

InactiveCN111168809AScientific and reasonable structureSafe and convenient to useCeramic shaping apparatusBridge erection/assemblyRebar corrosionCrack resistance

The invention discloses a method for realizing crack resistance of a concrete beam member by optimizing ribbed FRP bars. The method comprises the steps of optimizing, manufacturing of a beam template,assembling of a mixed reinforcement cage and forming, the concrete beam member is reinforced by adopting the mixed reinforcement of the FRP bars and reinforcing bars, compared with single reinforcingbar reinforcement, the characteristics of high tensile strength and corrosion resistance of the FRP bars and good ductility of common reinforcing bars are sufficiently utilized, mutual complementation is realized, the defects of large deflection and crack width and insufficient ductility of the FRP reinforced concrete flexural member are overcome, the FRP bars are configured to the easy-to-corrode corner of the concrete beam member, the problem of steel bar corrosion of the reinforced concrete beam member and the defects of large deflection, wide cracks and brittle failure of the FRP reinforced concrete beam member are solved, the FRP bars are optimized, the problems that the bonding stress of the common ribbed FRP bars and concrete is small, bonding sliding performance is poor, the crackwidth cannot be effectively controlled are solved, and steel bars on the inner side are still likely to corrode are solved, the construction method is flexible, and both factory prefabrication and in-place casting can be realized.

Owner:江苏绿材谷新材料科技发展有限公司

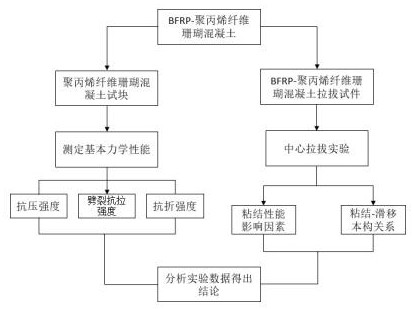

Method for verifying adhesive property of BFRP polypropylene fiber coral concrete

PendingCN113588547AAvoid generatingReduce stress concentrationUsing mechanical meansMaterial analysisStress concentrationBreaking strength

The invention discloses a method for verifying the adhesive property of BFRP polypropylene fiber coral concrete, which comprises the following operation steps of: 1, testing the compressive strength, the splitting tensile strength and the breaking strength of a polypropylene fiber coral concrete test block by measuring the basic mechanical property; 2, enabling a BFRP polypropylene fiber coral concrete drawing test piece to be subjected to bonding performance influence factor and bond slip constitutive relation testing through a center drawing experiment, and 3, obtaining a conclusion by analyzing experimental data. The polypropylene fiber is added, so that generation of cement matrix microcracks can be controlled, stress concentration in concrete is relieved, cracks are effectively prevented from being generated and expanded, the adhesive property between the BFRP and the coral concrete can be researched, the stress process and the failure mechanism of bonding slippage of the BFRP and the coral concrete are analyzed, and a reference basis is provided for engineering application and design calculation of a coral concrete structure.

Owner:WUHAN UNIV OF SCI & TECH

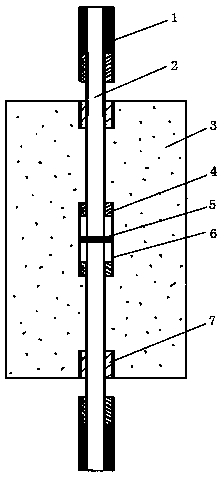

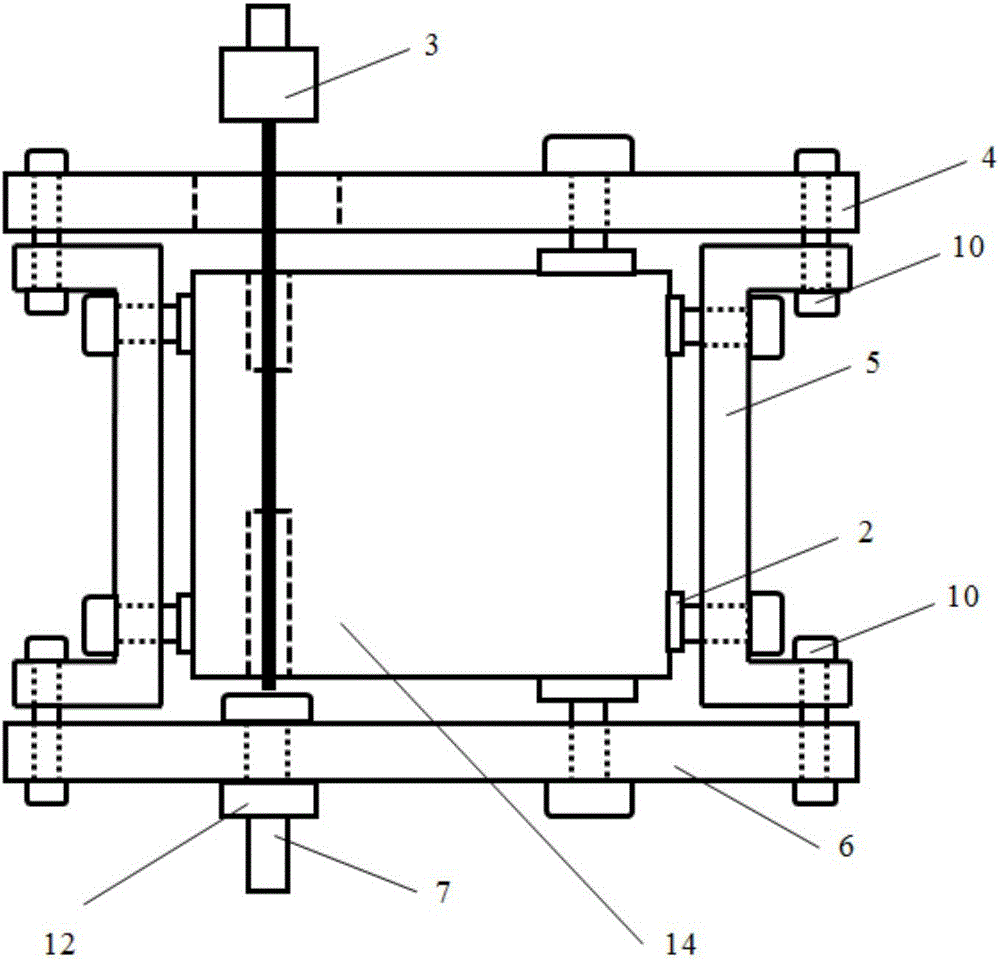

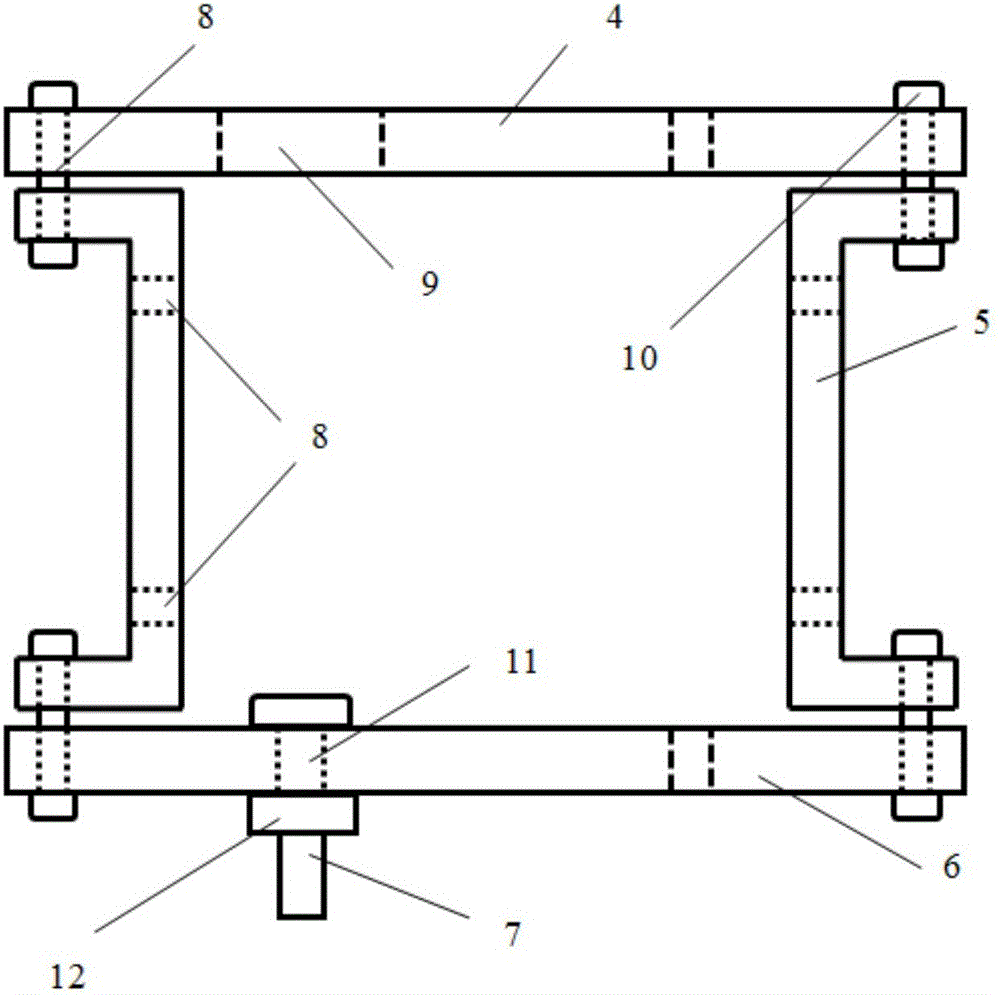

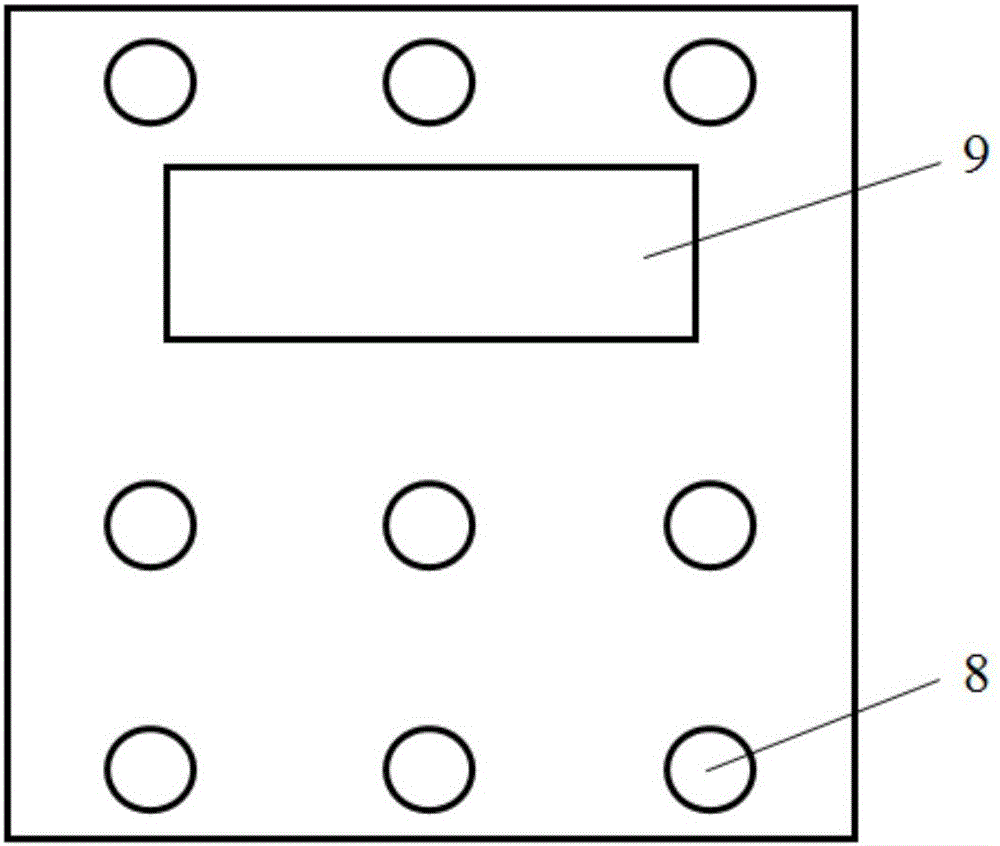

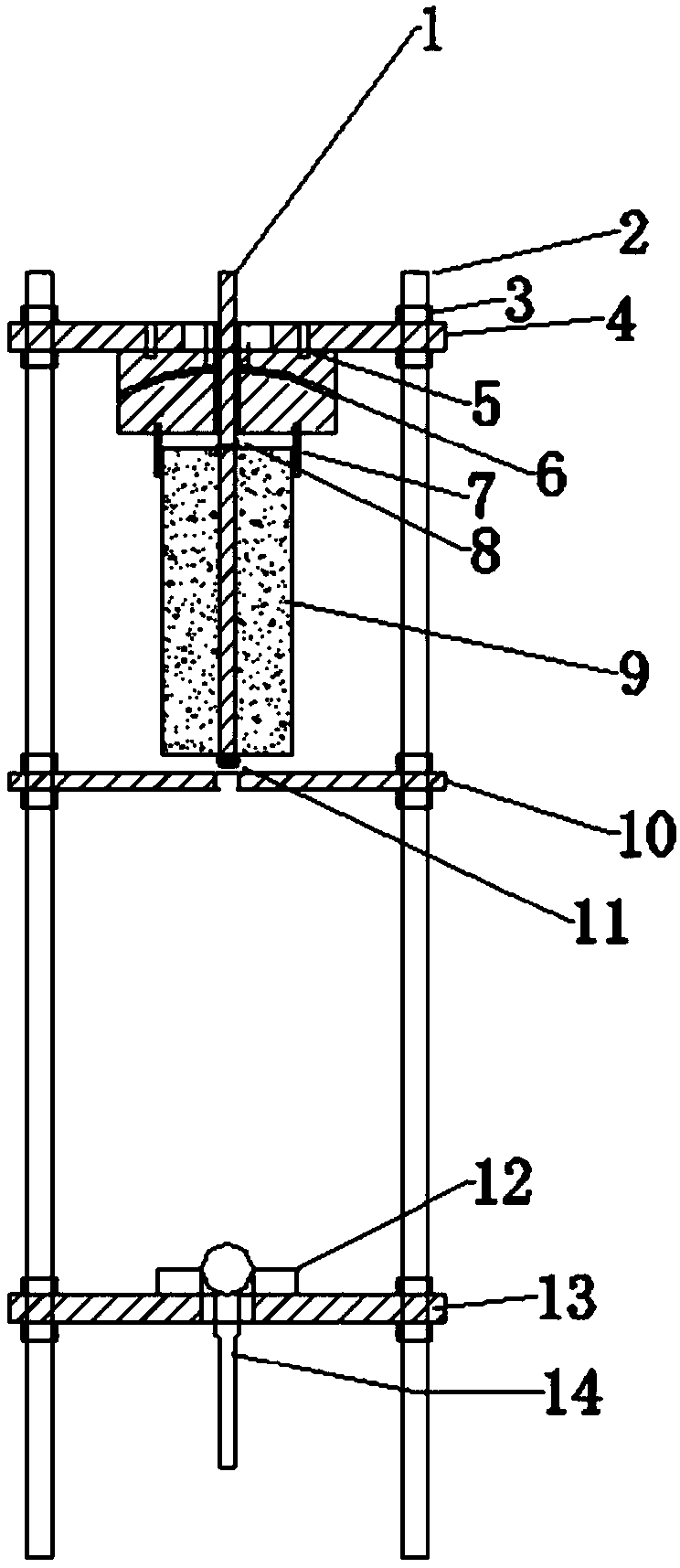

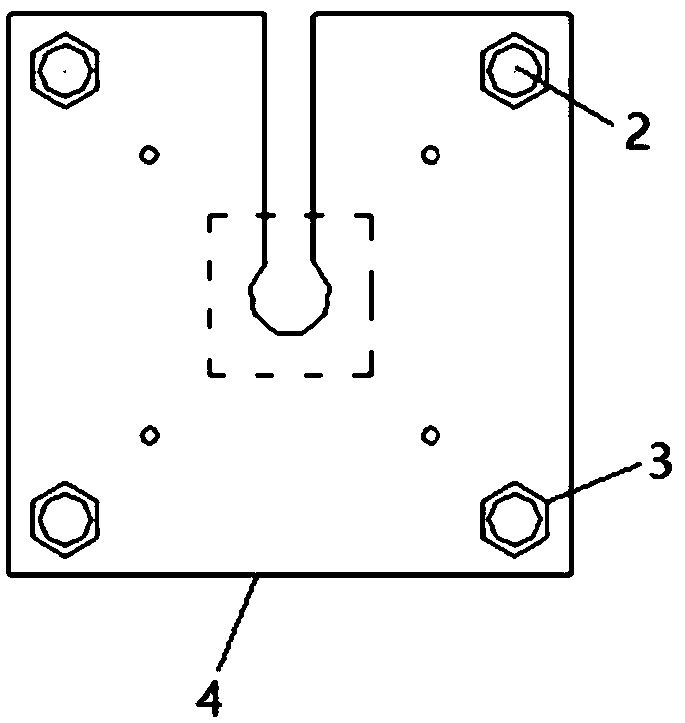

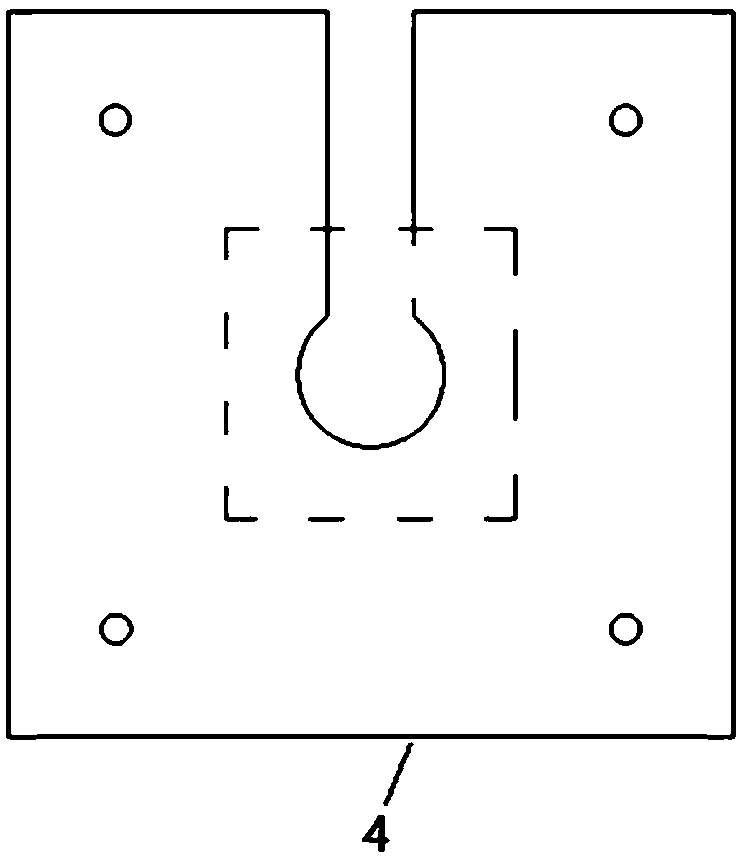

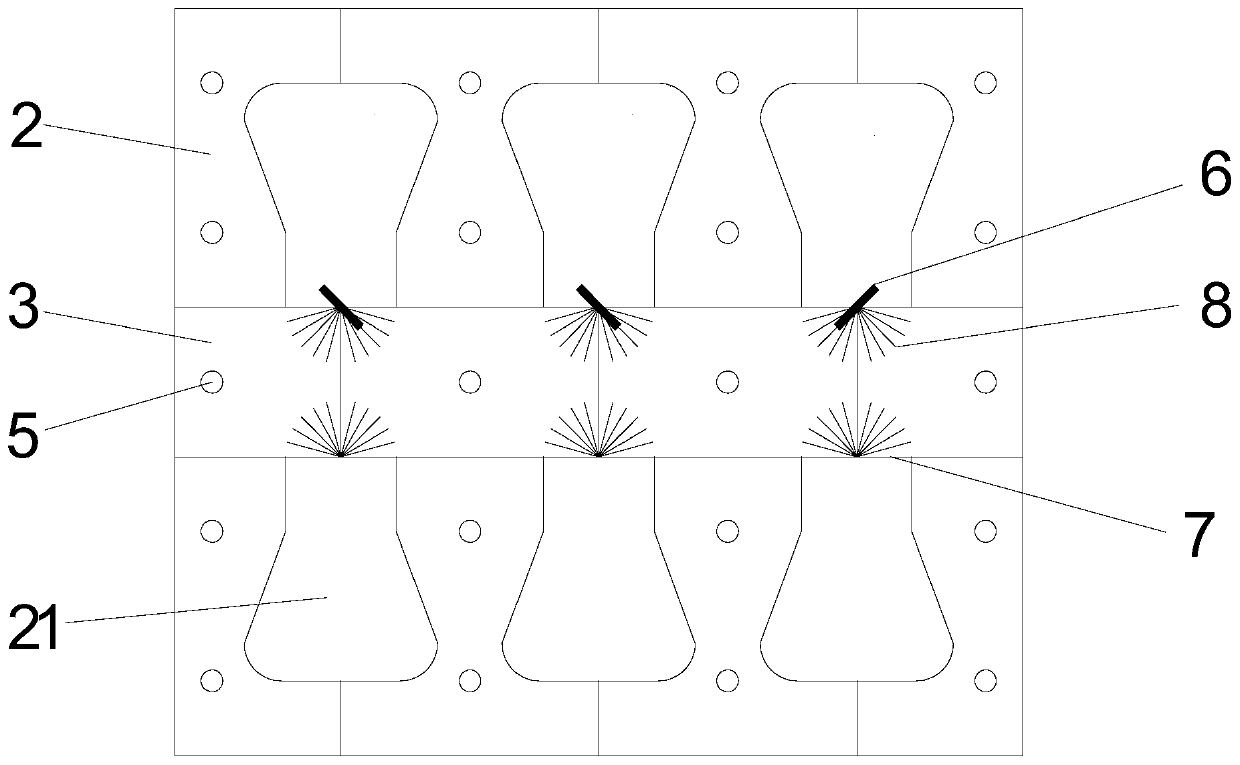

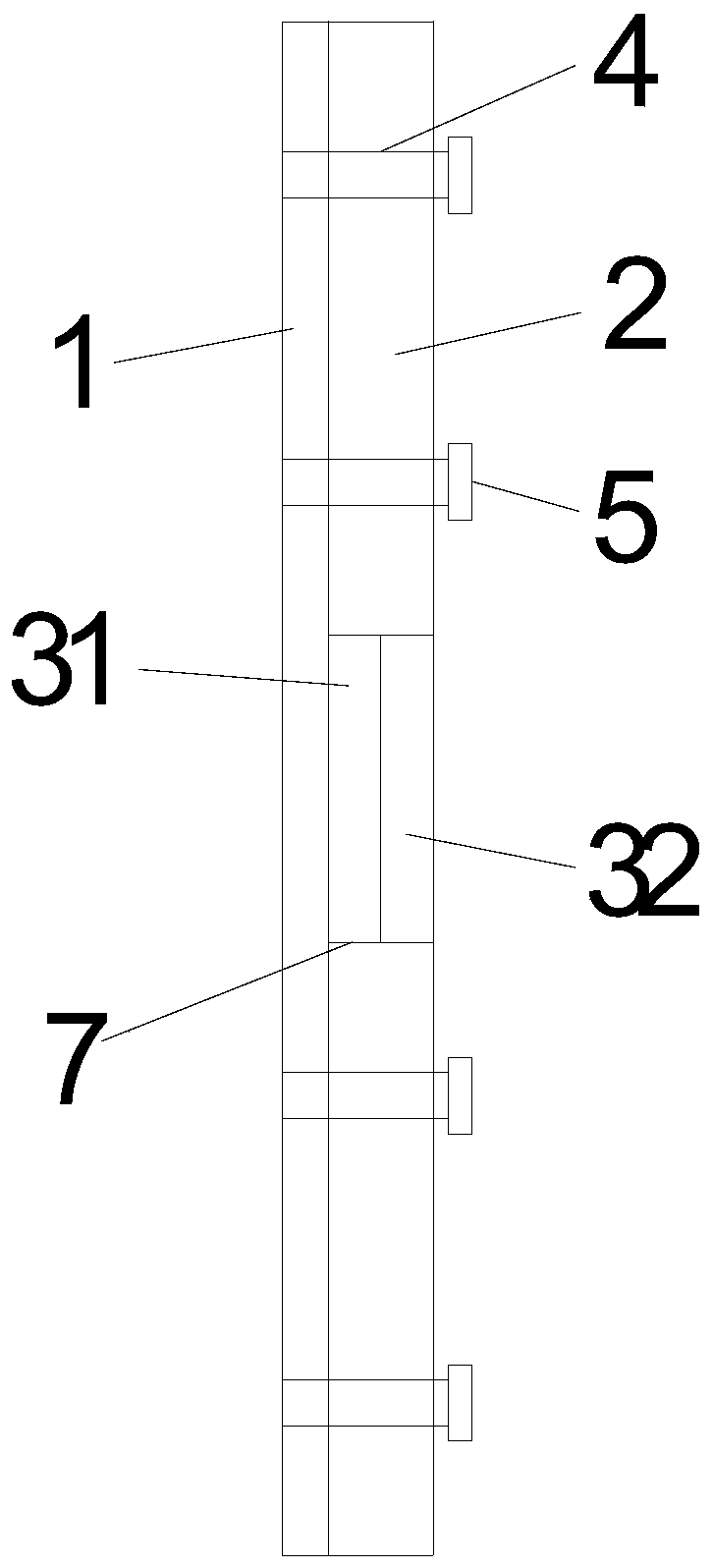

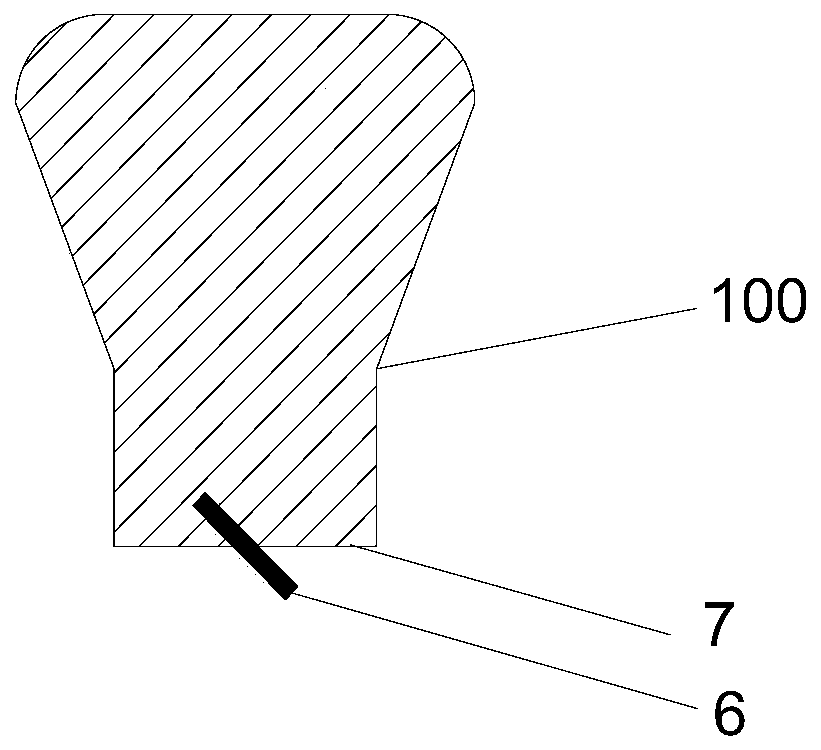

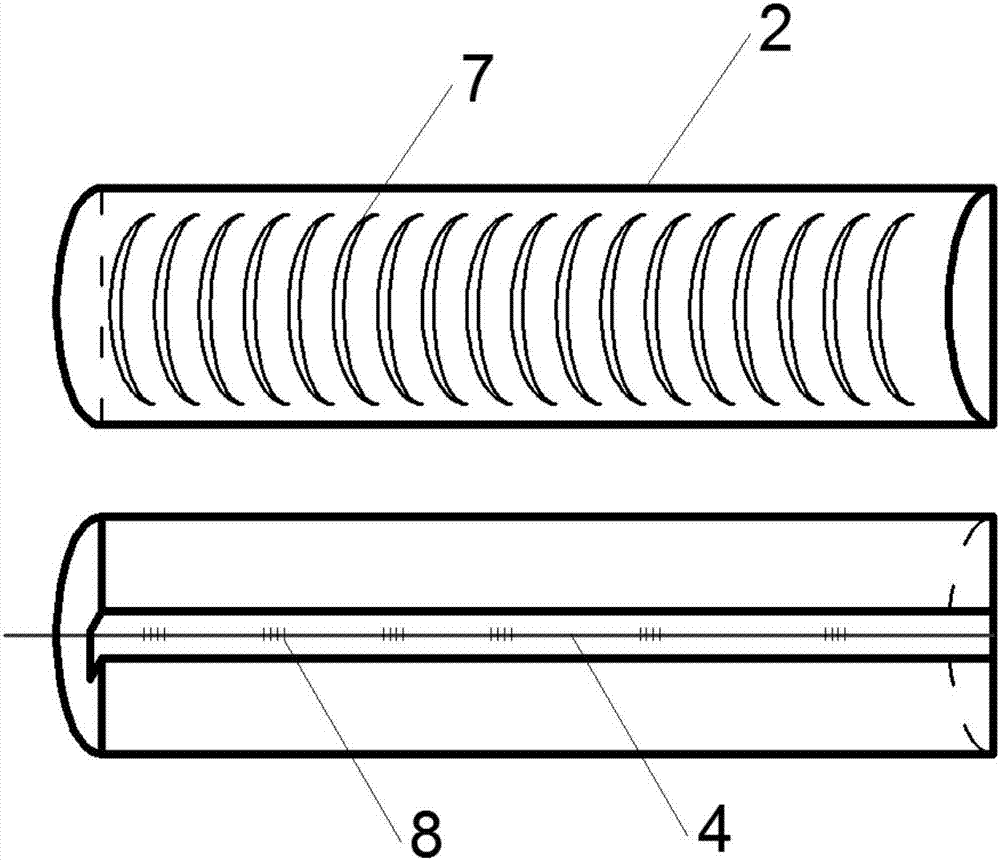

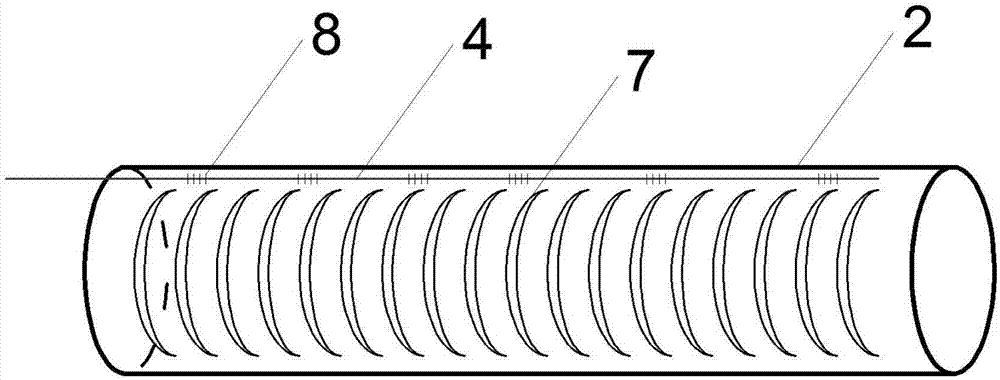

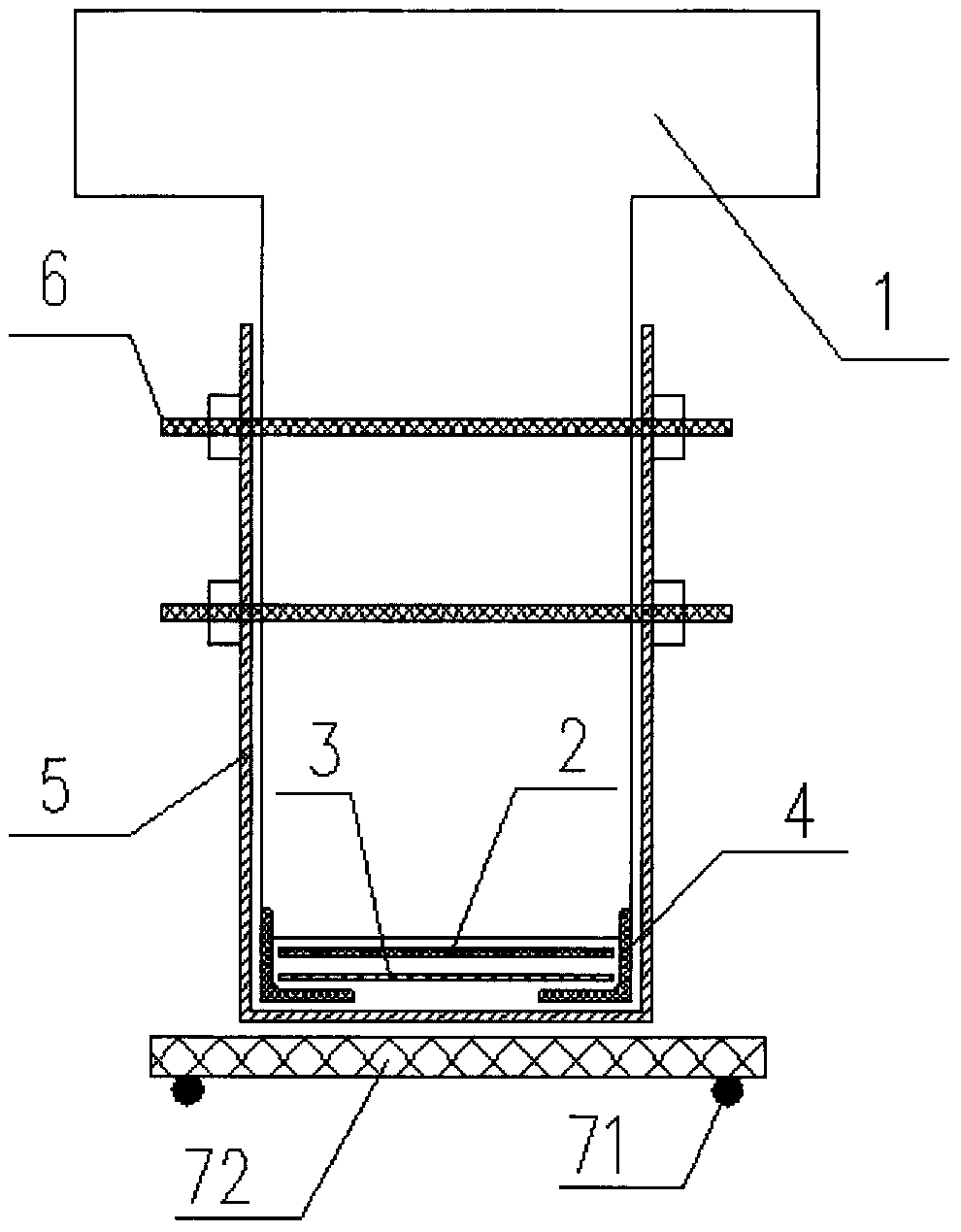

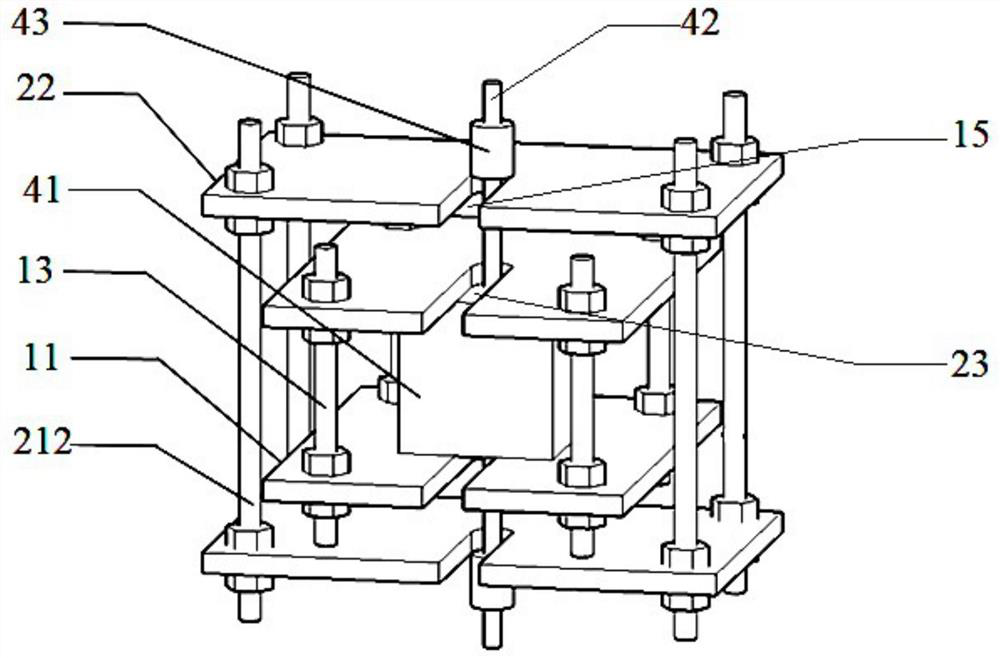

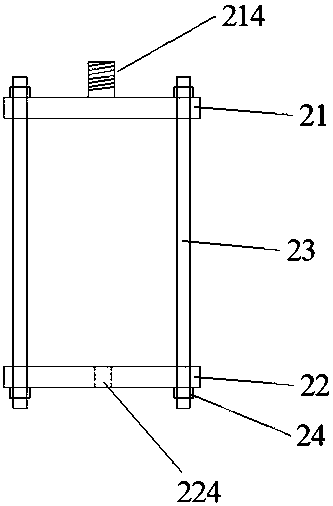

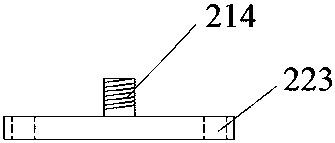

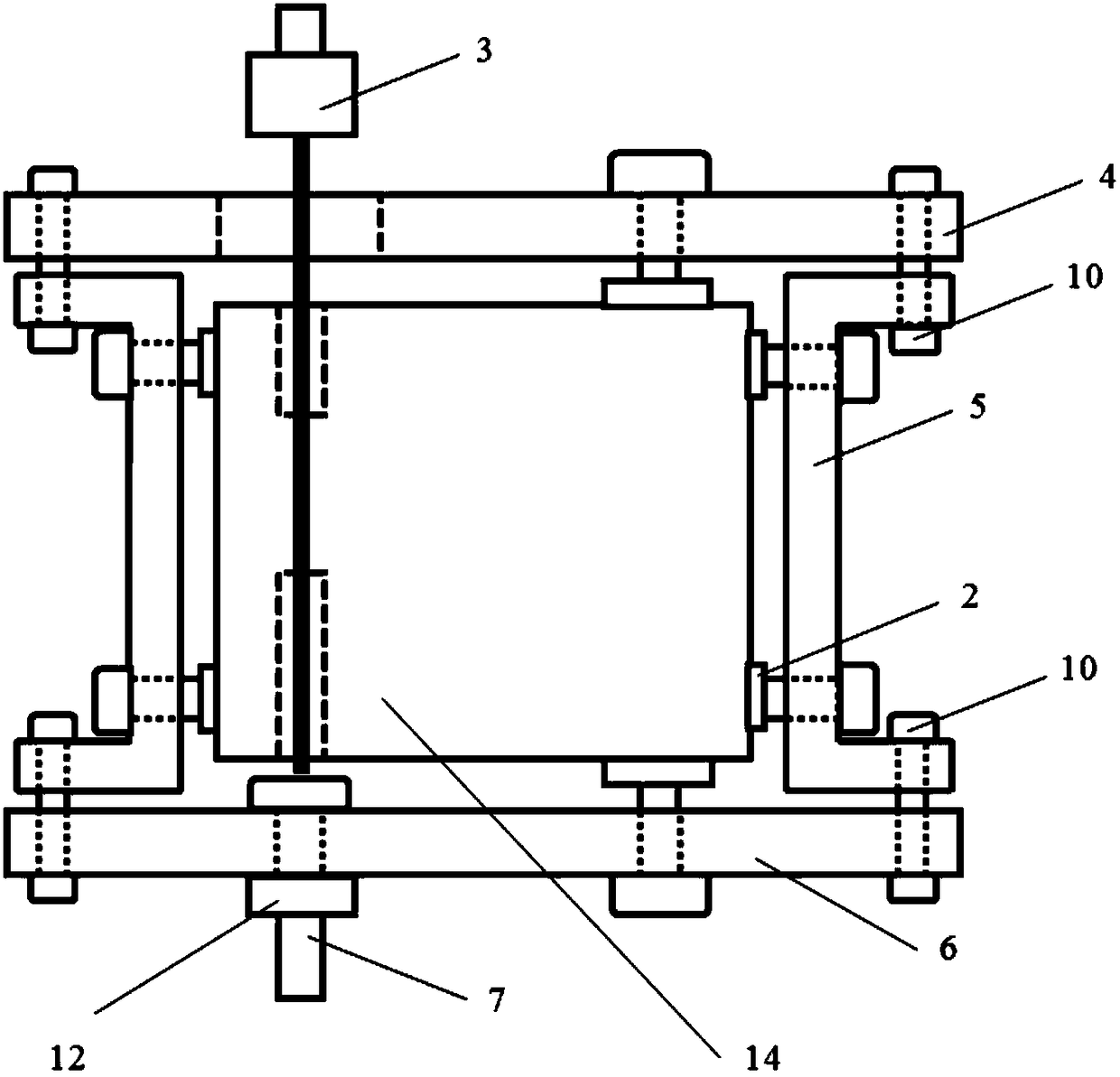

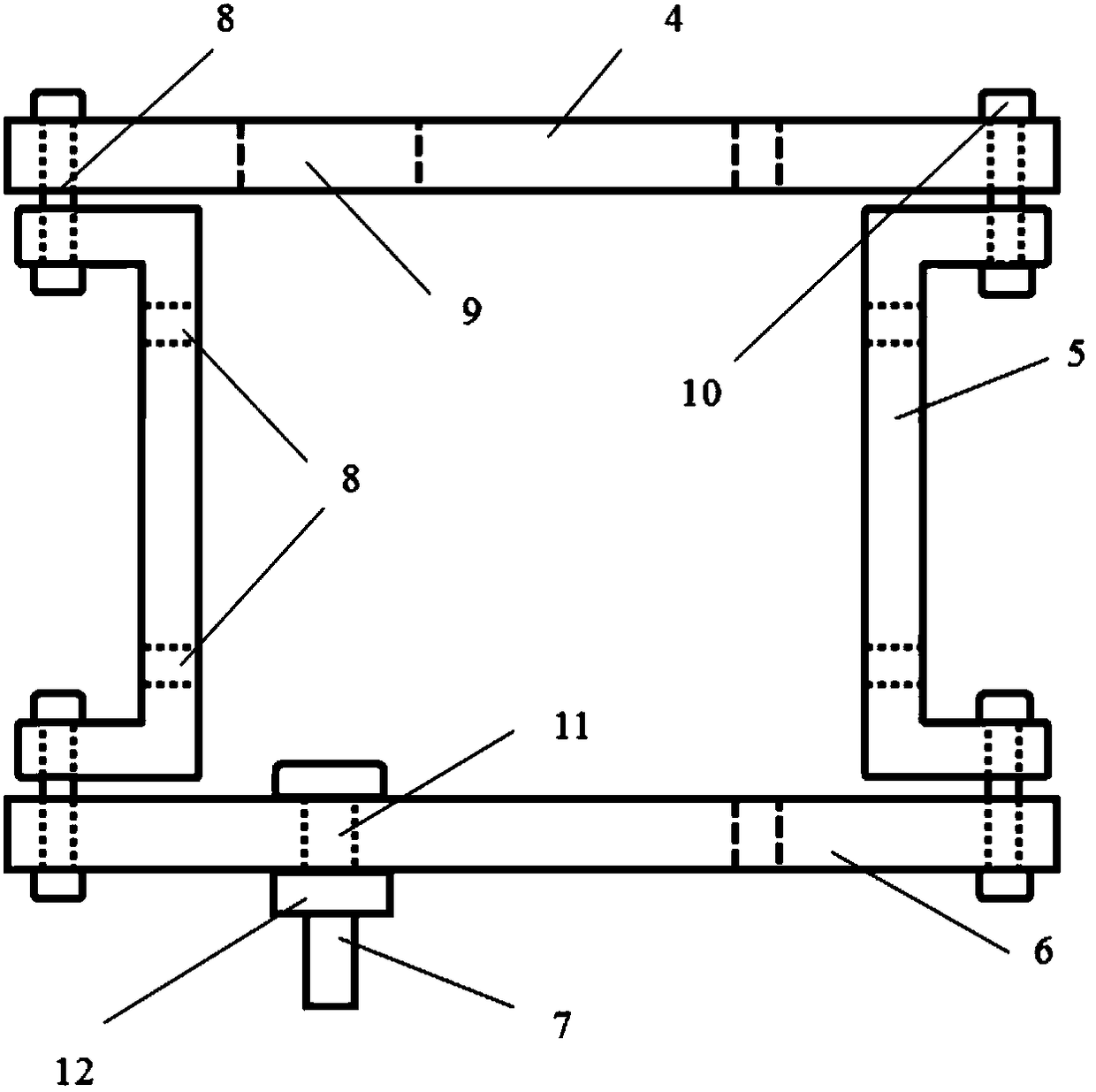

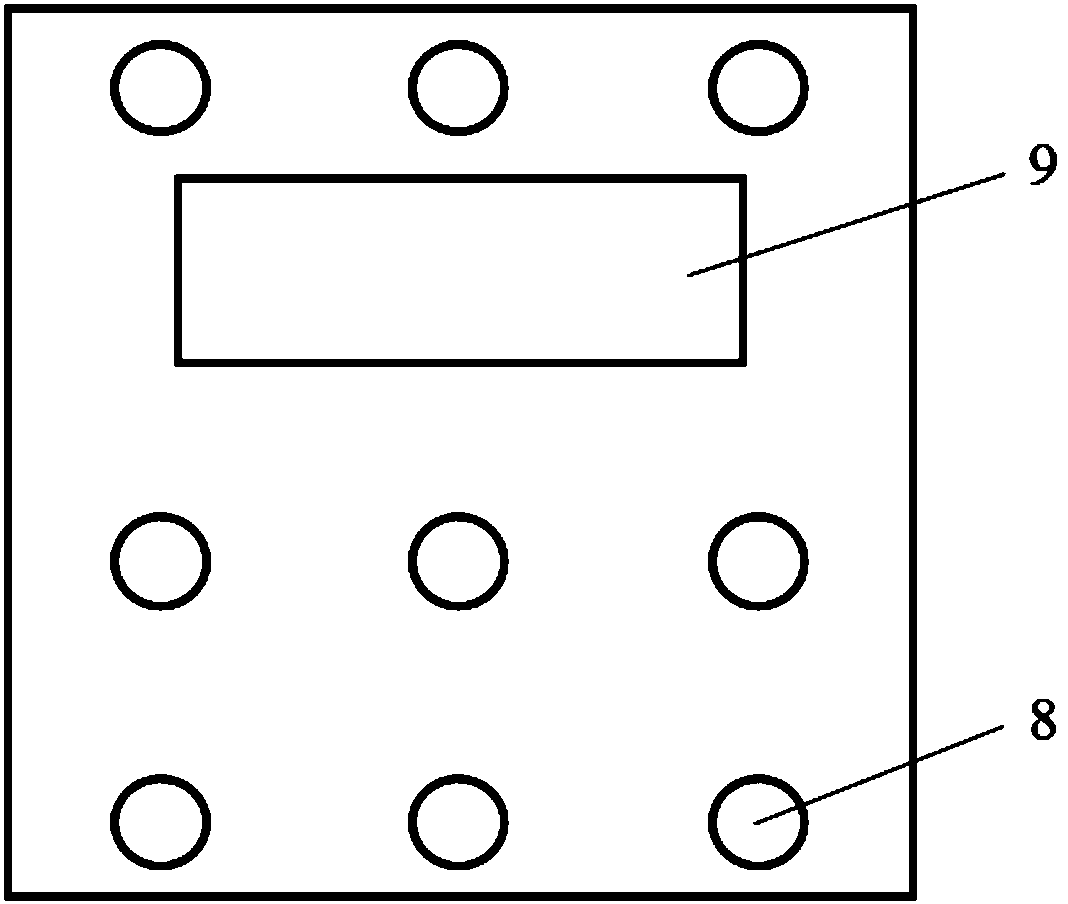

Steel fiber pull-out test piece pouring mold, pouring method and bond slip test method

PendingCN111024478ASimple structureEasy to assembleAngles/taper measurementsMechanical depth measurementsStructural engineeringFiber type

The invention discloses a steel fiber pull-out test piece pouring mold, a pouring method and a bonding slip test method. The mold comprises a bottom plate (1), a pair of top plates (2), a scale plate(3), bolts and nuts (4), bolt holes (5) and a slice (7), wherein the top plates and the scale plate are arranged on the bottom plate through bolts and nuts by passing through the bolt holes, the scaleplate is positioned between the pair of top plates, the top plates are provided with a test piece pouring hollowed-out part (21) used for pouring concrete, the test piece pouring hollowed-out part penetrates through the top plates, the scale plate is provided with scale marks (8), the slice covers an opening end of the test piece pouring hollowed-out part, one end of a steel fiber is inserted into the test piece pouring hollowed-out part along the scale marks, and the other end penetrates through the slice. The mold is advantaged in that a test piece type, a fiber type, an angle and burial depth are variable, test piece manufacturing efficiency and the pouring quality are improved, during testing, a test piece can be stably clamped, the more accurate fiber bonding slip relation can be measured, mounting, dismounting and cleaning are convenient, and test cost is effectively reduced.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD

Method for measuring adhesion between profile and substrate by using bare optical fiber gratings

InactiveCN106990039AHigh sensitivityHigh precisionUsing mechanical meansMaterial analysisGratingMeasurement point

The present invention provides a method for measuring the adhesion between a profile and a substrate by using bare optical fiber gratings. The method comprises: selecting measurement points inside a profile or on the surface of the profile; setting an optical fiber arrangement path according to all the measurement points, arranging optical fibers on the optical fiber arrangement path, and arranging bare optical fiber gratings on the optical fibers, wherein the bare optical fiber grating is corresponding to the measurement point; and adhering the profile and a substrate to be tested to form a connection body, performing a bond slip test on the connection body, and obtaining the temperature change and the strain change of the connection body during the bond slip test through the bare optical fiber gratings. According to the present invention, the used optical fiber grating sensor has advantages of high sensitivity, high precision and flexible arrangement compared t the traditional strain sheet, and can be widely used in the experimental study; and the method has little effect on the mechanical properties of steel bars, and has good applicability, the operation method is substantially simplified and has applicability, and the precision can be ensured.

Owner:BEIJING JIAOTONG UNIV

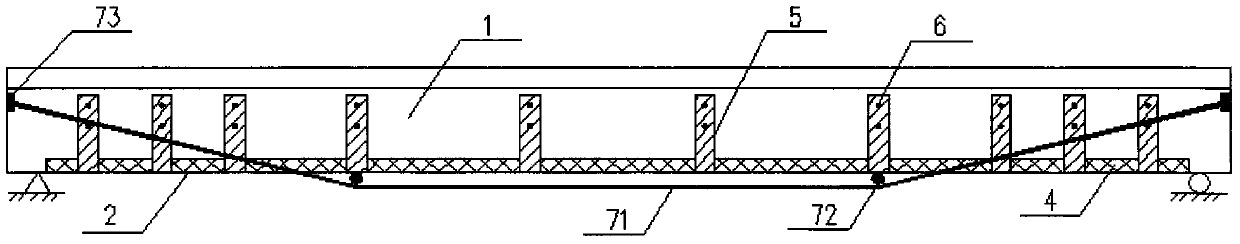

Anchoring technical measure for pasting carbon fiber plate to bottom of steel bar concrete beam

The invention provides an anchoring technical measure for pasting a carbon fiber plate to the bottom of a steel bar concrete beam. The carbon fiber plate is pasted at the bottom of an original steel bar concrete beam, the carbon fiber plate is wrapped in outer wrapped angle steel, a U-shaped steel hoop plate is installed, and the external prestress of a three folding line is constructed to form anexternal prestress-angle steel-carbon fiber plate combined strengthen beam. The bending deformation springback force of the angle steel and the external prestress lifting force are used, the normal force is provided to the carbon fiber plate, so that the friction force generates between the carbon fiber plate and the bottom of the steel bar concrete beam to overcome the shear stress between the carbon fiber plate and the bottom of the steel bar concrete beam, it is ensure that the reinforced steel bar concrete beam of the carbon fiber plate not generates bond slip failure, and the ultimate tensile strength of the pasted carbon fiber plate can be brought into full play; and the angle steel and the external prestress are both beam reinforcement materials and anchoring measure treatment materials for the carbon fiber plate, and killing two birds with one stone is achieved.

Owner:江苏交通工程咨询监理有限公司

A test method for simulating the weakened interface of coarse aggregate-mortar

ActiveCN110376031BWeakened interfaceInterfacial stress peak reductionPreparing sample for investigationUsing mechanical meansAggregate (composite)Structural engineering

The invention belongs to the technical field of construction engineering, and discloses a test method for simulating a coarse aggregate-mortar weakening interface, which mainly includes: making a cylindrical rock core aggregate, putting the rock core aggregate into water and standing until it is taken out before pouring Standby; attach the ground rubber fine particles to the surface of the core aggregate; pour mortar around the core aggregate to obtain a composite specimen; carry out a loading test on the composite specimen on the testing machine, and apply pressure on the surface of the core aggregate Load until the core aggregate is extruded out of the composite specimen, and the shear strength and bond-slip properties of the simulated coarse aggregate-mortar weakened interface are obtained. The present invention utilizes that the fine rubber particles with sufficiently small particle diameters have strong adhesiveness, and rely on their own adsorption force to adhere to the surface of the rock core aggregate. When the rock core aggregate with worn rubber fine particles is combined with the mortar, the worn Fine particles will reduce the contact area between mortar and coarse aggregate, weaken the friction and bonding performance between mortar and coarse aggregate, and achieve the effect of simulating a weakened interface.

Owner:TIANJIN UNIV

Reinforced concrete bond slip testing device

ActiveCN112504958ABi-directional loading process is stableStable manufacturingUsing mechanical meansMaterial analysisArchitectural engineeringBond slip

The invention relates to the technical field of experimental equipment, in particular to a reinforced concrete bond slip testing device which comprises a fixing assembly, a loading assembly and a measuring assembly, the fixing assembly is used for fixing a concrete block of a test piece, the loading assembly comprises a driving piece and two loading plates, and the driving piece is connected withthe two loading plates; the two loading plates are oppositely arranged in the loading direction, the two loading plates are located on the two sides, in the axial direction of the steel bar, of the concrete block of the test piece correspondingly and located between the two anchors of the test piece, and the measuring assemblies are arranged on the loading plates and used for measuring the relative sliding amount of the steel bar of the test piece and the concrete block. A bidirectional pull-out test can be carried out on a reinforced concrete test piece under the action of repeated loads, a bidirectional loading process is realized, and the stability of the test loading process is ensured. The method can effectively determine the bond slip performance of the reinforced concrete under theaction of repeated loads, and the obtained result can truly reflect the bond performance between the steel bar and the concrete in actual engineering.

Owner:BEIJING UNIV OF TECH

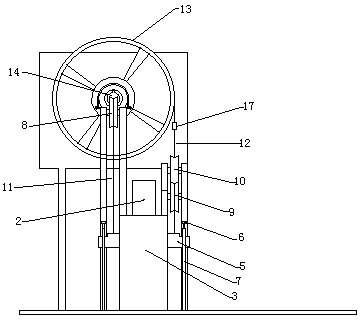

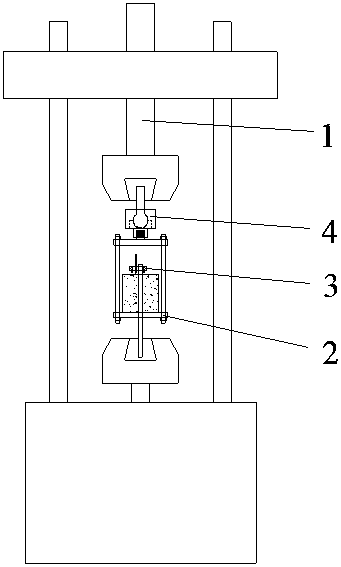

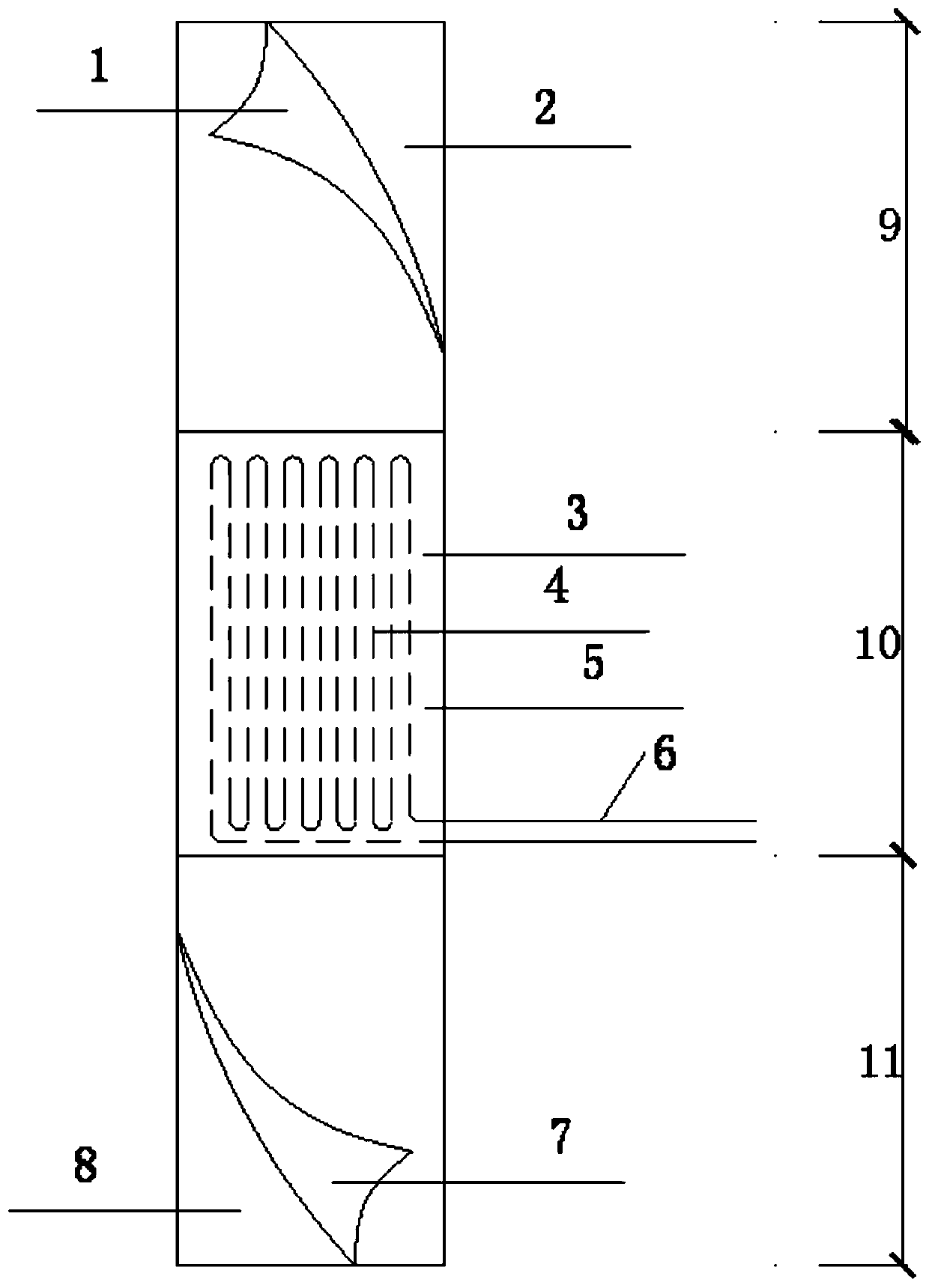

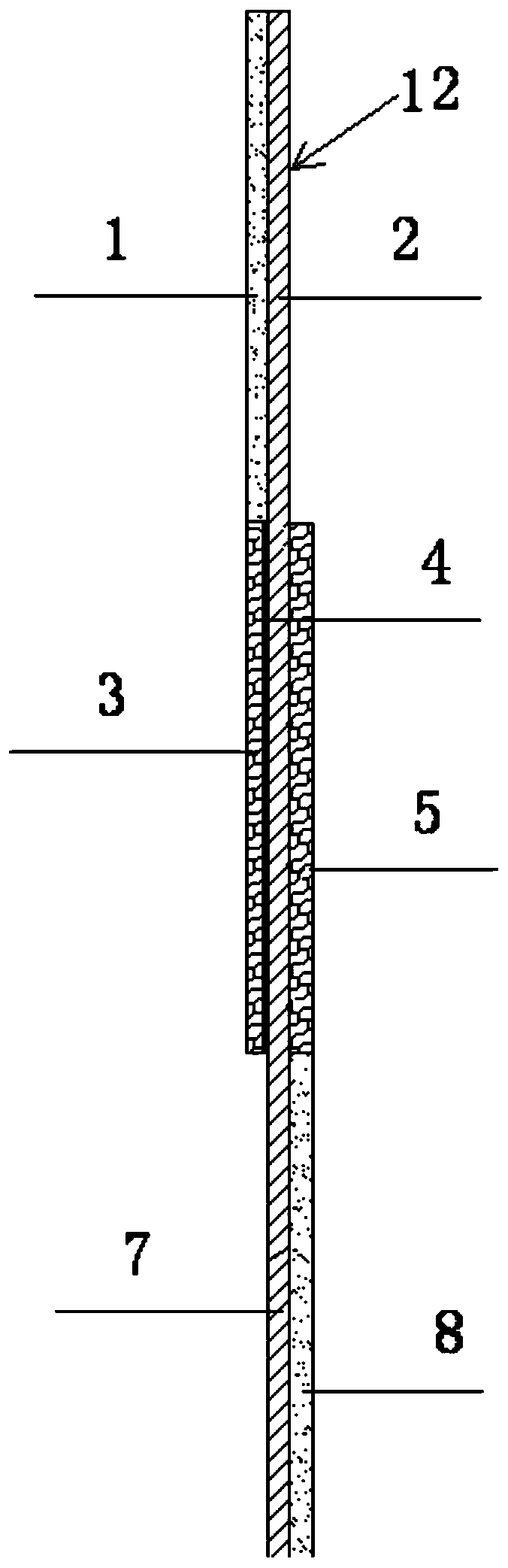

A static and dynamic bond-slip whole process curve test device and test method

ActiveCN104819933BEasy to installAvoid damageUsing mechanical meansMaterial analysisControl signalBond slip

The invention relates to the technical field of the experimental study and in particular relates to a device and a method for testing bonding-slipping of a reinforced bar material and concrete in a reinforced bar pulling-out process. A static and dynamic bonding-slipping whole-process curve testing apparatus comprises a hydraulic servo testing machine, a test-piece drawing frame, an LVDT fixing protective clamp and a spherical hinge, wherein the hydraulic servo testing machine is connected with the test-piece drawing frame by the spherical hinge, the test-piece drawing frame is used for fixing a test piece, and the LVDT fixing protective clamp is arranged at the free end of the reinforced bar of the test piece. The static and dynamic bonding-slipping whole-process curve testing apparatus is simple, can be utilized repeatedly, and can be operated conveniently; the whole loading scheme comprises two stages, in the first stage, an LVDT is used as a control signal and can be used for eliminating influences of all link intervals and self-deformation of the testing apparatus; in the second stage, the displacement is used as a control signal and can be used for avoiding the influence of the rigidity change in a reinforced bar pulling-out process, the stable slippage rate can be acquired in the whole loading process, and the influences of different slippage rate on the bonding-slipping constitutive relation can be researched.

Owner:HOHAI UNIV

A strain gauge for measuring bond-slip between steel and concrete and its pasting method

ActiveCN107421664BNo damage to actual strengthReduce manufacturing costForce measurementClassical mechanicsEngineering

The present invention provides a strain gauge for measuring steel and concrete bonding slipping and a paste method thereof. The strain gauge comprises a base layer, the base layer is divided into an upper portion, a middle portion and a lower portion, the upper portion is taken as a concrete base layer, a concrete cover layer is pasted at the front side surface of the concrete base layer, and the concrete base layer and the concrete cover layer commonly form a concrete paste section; the middle portion forms a non-pasting section which is formed by a sensitive grid pasted at the front side surface of the middle portion of the base layer, a protection slipping upper layer pasted at the front side surface of the sensitive grid and a protection slipping lower layer pasted at the back side surface of the middle portion, and the sensitive grid is provided with a leading-out wire configured to connect with an external measurement device; and the lower portion is taken as a steel base layer, a steel cover layer is pasted at the back side surface of the steel base layer, and the steel base layer and the steel cover layer commonly form a steel pasting section. The strain gauge and the test method thereof employ steel with no need for grooving processing so as to save a lot of manufacturing cost, and the stain pasting method is simple and easy to operate and does not damage the real intensity of steel.

Owner:TIANJIN CHENGJIAN UNIV

A pull-out test device suitable for testing the bond-slip hysteretic performance of reinforced bars

ActiveCN106018270BConsistent stress stateWill not affect test resultsUsing mechanical meansMaterial strength using repeated/pulsating forcesHysteresisRelative displacement

The invention belongs to the field of civil and structural engineering, and relates to a pull-out test device for bond-slip hysteretic behavior testing of a stiffening rib. The pull-out test device comprises a counter-force frame, a fastening steel plate, an upper clamping device and a pull-out test piece, wherein the counter-force frame is formed through fixed connection of a top plate, side plates and a bottom plate through bolts, and the counter-force frame is fixedly connected with a tester base through a connecting part; the fastening steel plate and the pull-out test piece are pressed through a bolt; the upper portion of a deformed steel bar shaft in the upper clamping device is in spiral connection with a load sensor of a tester, the lower portion of the deformed steel bar shaft is in spiral connection with the inner side of the upper portion of a steel sleeve and rotates in the thread direction to enable the steel sleeve to rise and fall, and the lower portion of the steel sleeve is connected with the end of the stiffening rib. The pull-out test device is simple in structure. During cycling load application, static balancing is maintained between the test piece and the counter-force frame, and relative displacement is avoided; the stiffening rib and concrete have the same stress state.

Owner:DALIAN UNIV OF TECH

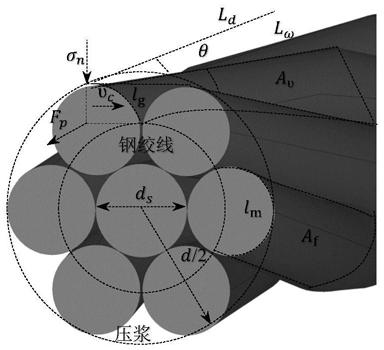

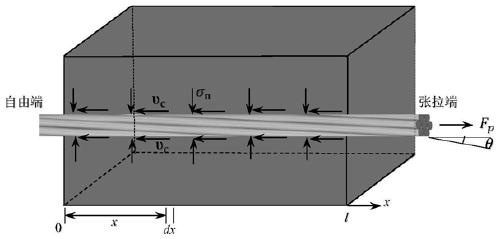

A Finite Element Simulation Method of Bonding Behavior Between Prestressed Beam and Concrete

The invention discloses a finite element modeling method of binding performance between prestress beam and concrete, and presents a prestress beam binding slippage equivalent modeling method. The finite element modeling method includes steps of firstly, presenting a confirming principle of an overall slippage face and an effective working face of the prestress beam, building up an interface micro-unit stress balance relationship of the prestress beam, and presenting the calculating method of the prestress beam extreme binding force; secondly, providing an equivalent principle of the prestressbeam extreme binding force, and accordingly deducing the calculating formula of the equivalent maximum binding stress of single prestress rib; updating the BPE binding slippage model and making clearthe property of a spring unit of the molding binding slippage; realizing the finite element modeling of the equivalent binding slippage of single prestress rib. On this basis, the finite element modeling method of prestress beam binding slippage is realized according to the principle of acquiring prestress beam binding force by overlapping the equivalent binding force of single prestress rib and using the average slippage of single prestress rib as the prestress beam slippage. Finally, the precision of the method is verified by combining with the existing testing result.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com