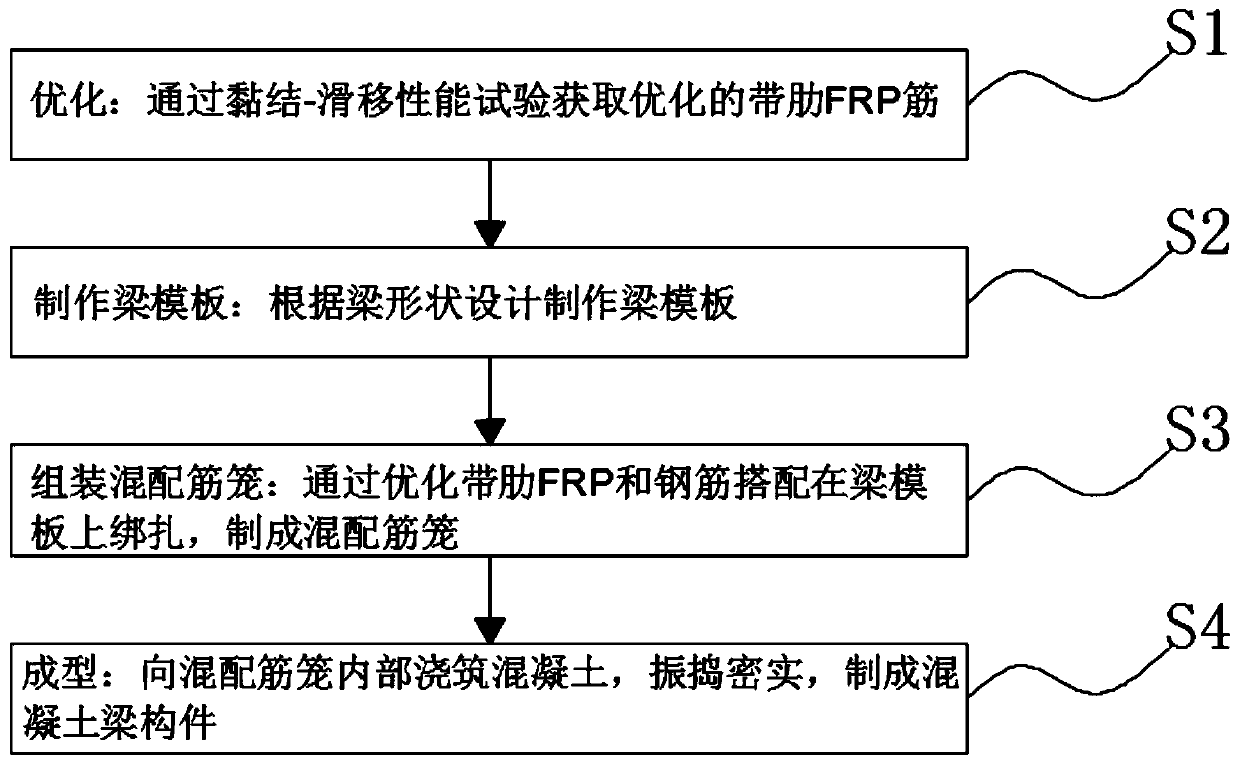

Method for realizing crack resistance of concrete beam member by optimizing ribbed FRP bars

A technology of concrete beams and ribs, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of small number of cracks, poor ductility, large crack width, etc., and achieve flexible construction methods, safe and convenient use, and scientific structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

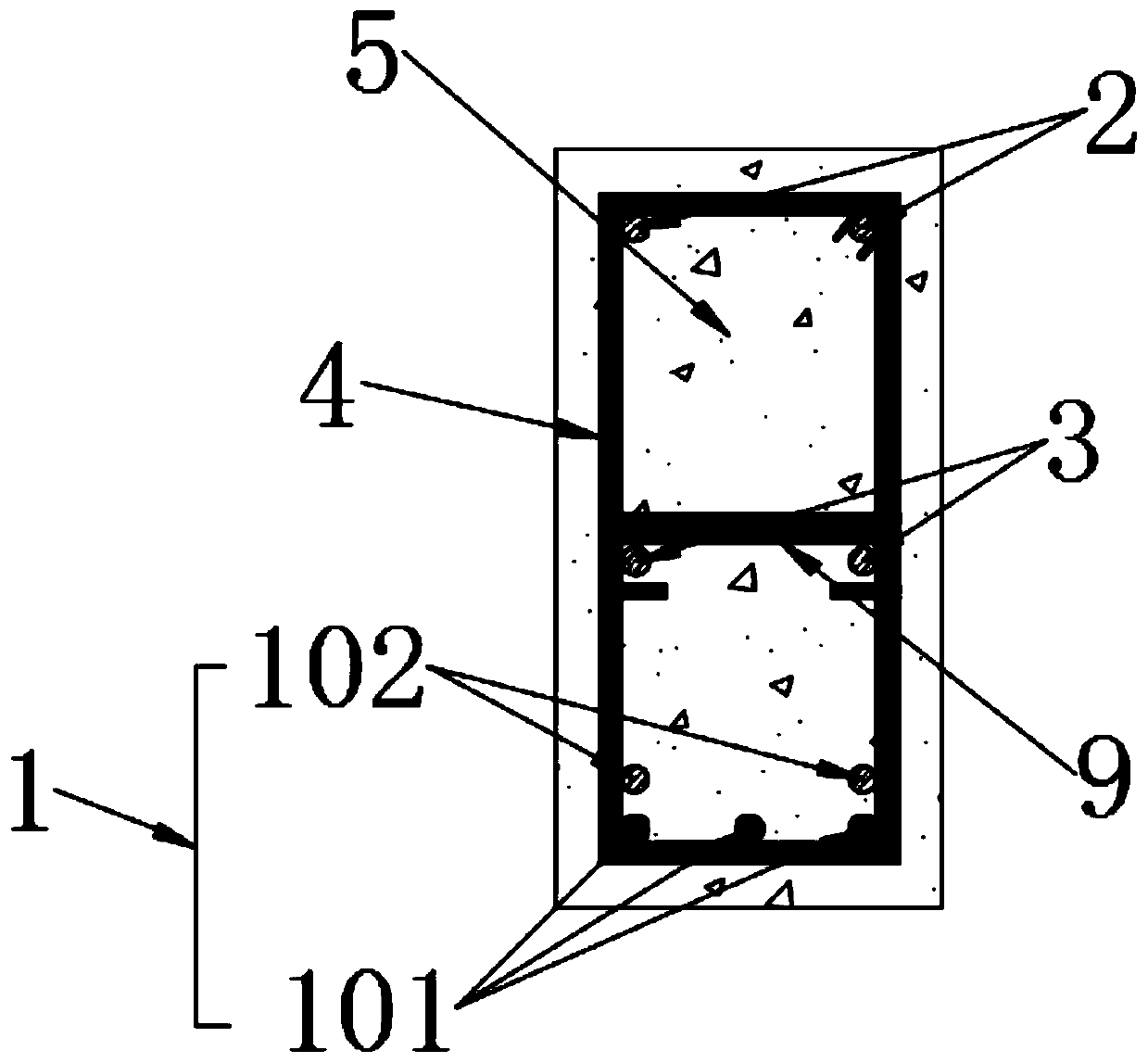

[0038] Example 1, such as figure 2 As shown, the cross-section of the mixed reinforcement cage in step S3 is a rectangular cross-section, including the lower longitudinal reinforcement 101 near the bottom of the beam, the stirrup 4 using optimized ribbed FRP reinforcement, the lower longitudinal reinforcement 102, the upper longitudinal reinforcement 2, and the waist near the bottom of the beam. Both the rib 3 and the middle tie bar 9 can be ordinary steel bars, the lower longitudinal bar 1 and the upper longitudinal bar 2 are bound on the inside of the stirrup 4, and the waist bar 3 is fixed on the inner middle of the stirrup 4 after being tied by the middle tie bar 9. After the mixed reinforcement cage is bound, put it into the pre-fabricated formwork, pour concrete 5, vibrate and compact it, and then maintain it. Among them, if the height of the beam section is less than 450mm, it is not necessary to set the waist reinforcement and the central tension reinforcement.

Embodiment 2

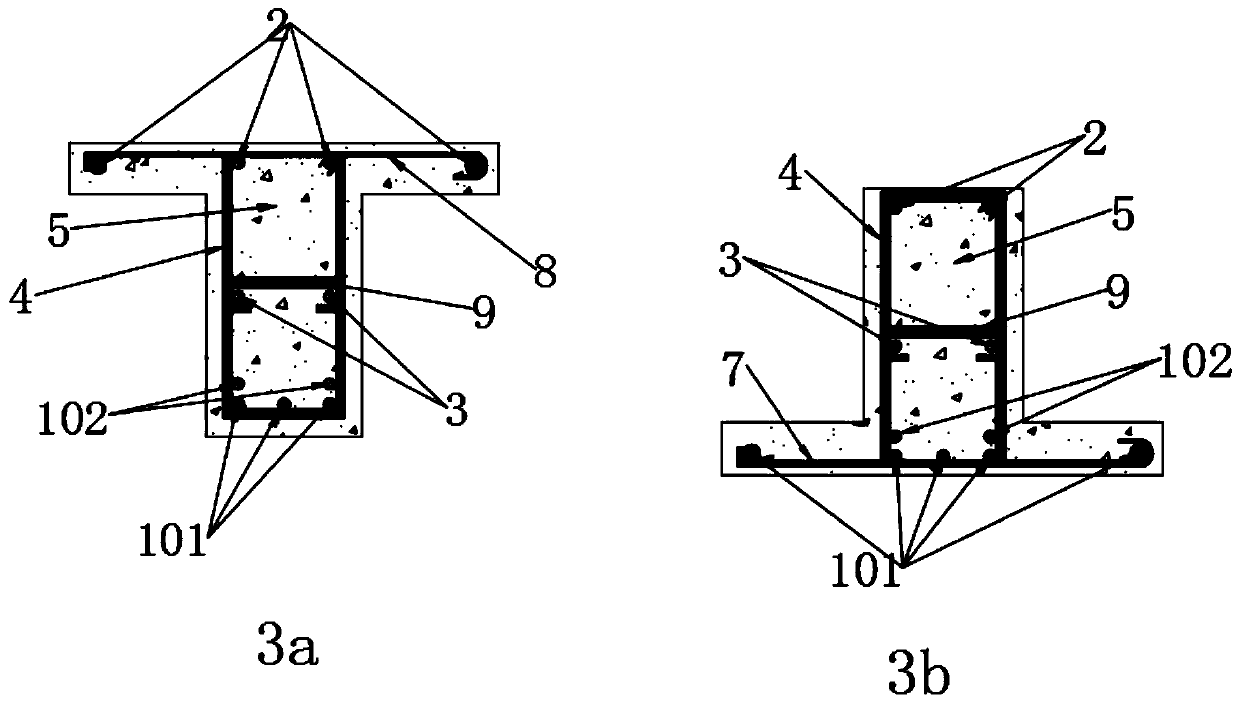

[0039] Example 2, such as image 3 As shown, the cross-section of the mixed reinforcement cage in step S3 is a T-shaped cross-section or an inverted T-shaped cross-section, and the reinforcement configuration of the web part of the two T-shaped cross-sections is consistent with the rectangular cross-section of Embodiment 1. The difference is that, as image 3 As shown in a, when binding the T-shaped cross-section mixed reinforcement cage, the reinforcement on the inner side of the upper longitudinal reinforcement 2 is first bound in the stirrup 4, and then the upper reinforcement 8 is used to tie the reinforcement on both sides of the upper longitudinal reinforcement 2 together. Binding with the inner steel bar of the upper longitudinal bar 2 and the stirrup bar 4, such as image 3 As shown in b, when binding the inverted T-shaped cross-section mixed reinforcement cage, the reinforcement inside the lower longitudinal reinforcement 1 is first bound in the stirrup 4, and then th...

Embodiment 3

[0040] Example 3, such as Figure 4As shown, the section of the mixed reinforcement cage in step S3 is an I-shaped cross section, and the configuration of the reinforcing bars of the I-shaped section web part is consistent with the rectangular section of Example 1. The difference is that when the I-shaped cross-section mixed reinforcement cage is bound, the I The steel bars on both sides of the lower longitudinal bar 1 of the I-shaped section are tied together and then bound with the inner steel bar of the lower longitudinal bar 1 and the stirrup 4, and the inner steel bar of the upper longitudinal bar 2 of the I-shaped section is bound in the stirrup 4 first, and then the upper tension bar is used The tendon 8 binds the steel bars on both sides of the upper longitudinal bar 2 together and then binds the inner steel bar of the upper longitudinal bar 2 and the stirrup 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com