Pull-out test device for bond-slip hysteretic behavior testing of stiffening rib

A technique for pulling out tests and reinforcing ribs, which is applied in the direction of measuring devices, using mechanical devices, and using repeated force/pulsation force to test the strength of materials, etc., which can solve the inaccurate bond-slip hysteresis relationship and bond failure form influence and other issues, to achieve the effect of maintaining a consistent stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

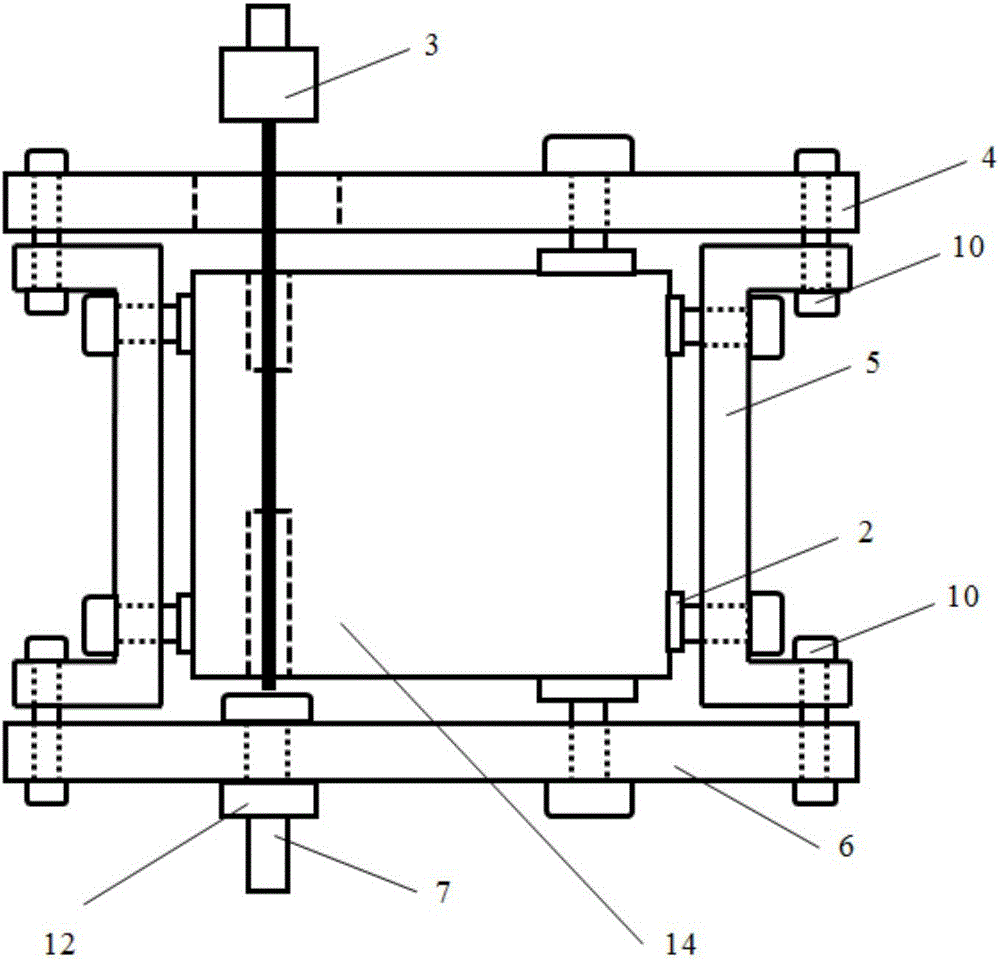

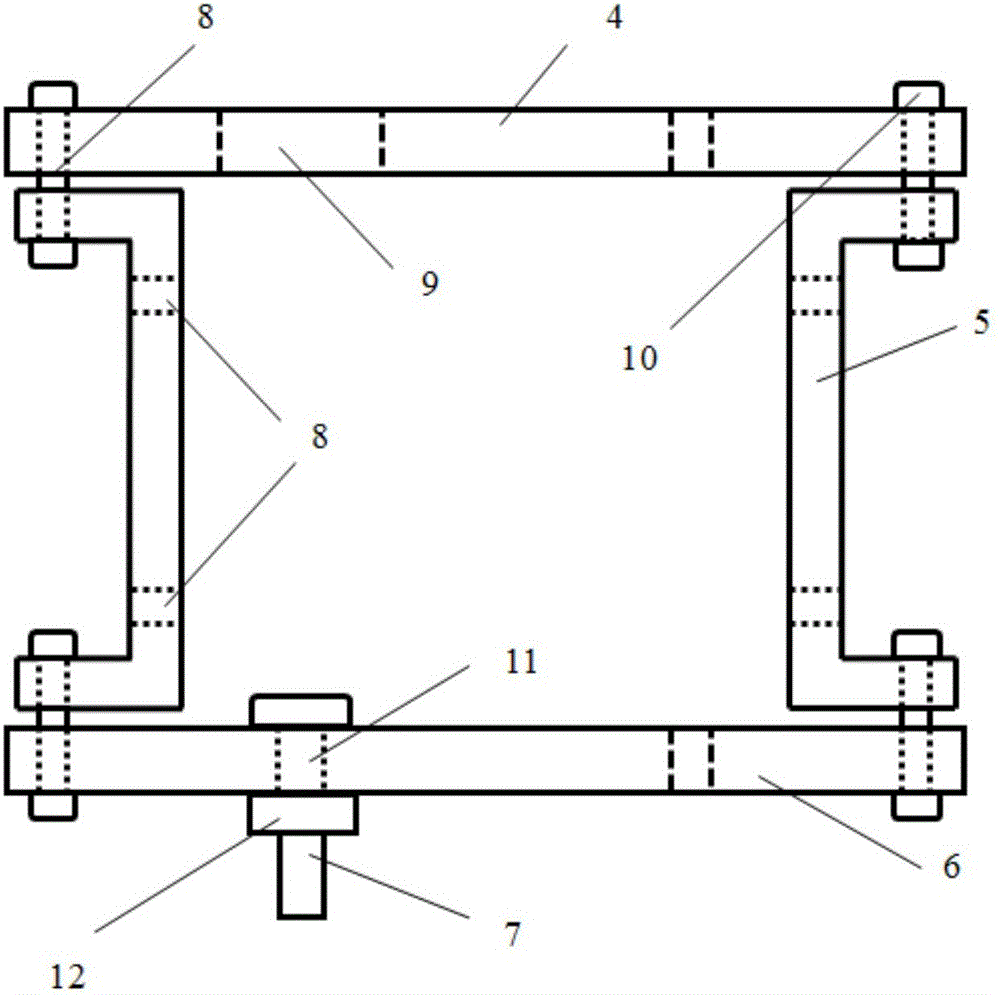

[0022] A pull-out test device suitable for testing the bond-slip hysteretic performance of reinforced bars, including a reaction frame 1, a fastening steel plate 2, an upper clamping device 3, and a pull-out test piece 14 (Fig. 8(a) and Fig. 8 (b) is a side view and a top view of the pull test piece 14), the overall structure schematic diagram of the present invention is as figure 1 shown.

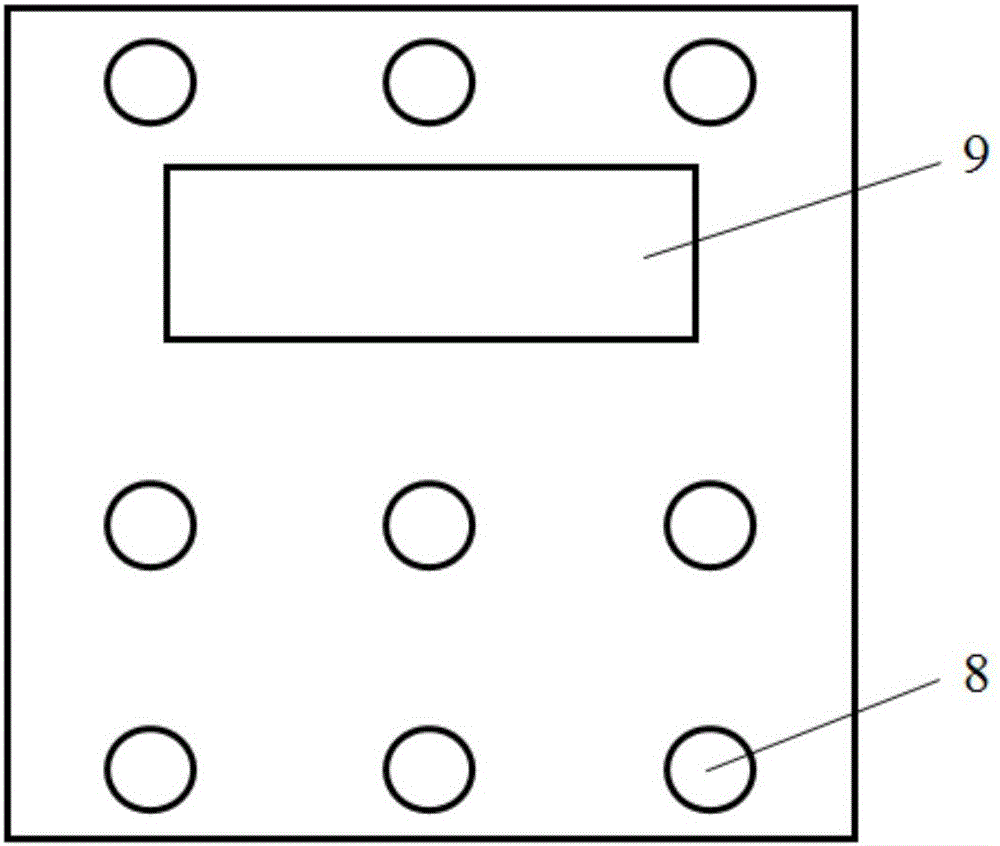

[0023] The reaction force frame 1 includes a frame top plate 4 , two frame side plates 5 and a frame bottom plate 6 . Three rows of threaded holes 8 and rectangular slots 9 are distributed on the frame top plate 4 . Three rows of threaded holes 8 and circular slots 11 are distributed on the frame bottom plate 6. The rectangular slots 9 and the circular slots 11 are located on the same center line. The frame side plate 5 is a cuboid with grooves and threaded holes 8 . The connecting piece 7 passes through the circular slot 11 of the frame bottom plate 4 and is screwed and fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com