Test method for accurately simulating bond-slip property of male pin in tensile area

A bond-slip, test method technology, applied in the testing of machine/structural components, the use of a stable shear force to test the strength of materials, measuring devices, etc., can solve problems such as the inaccurate simulation of bond-slip properties, To achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

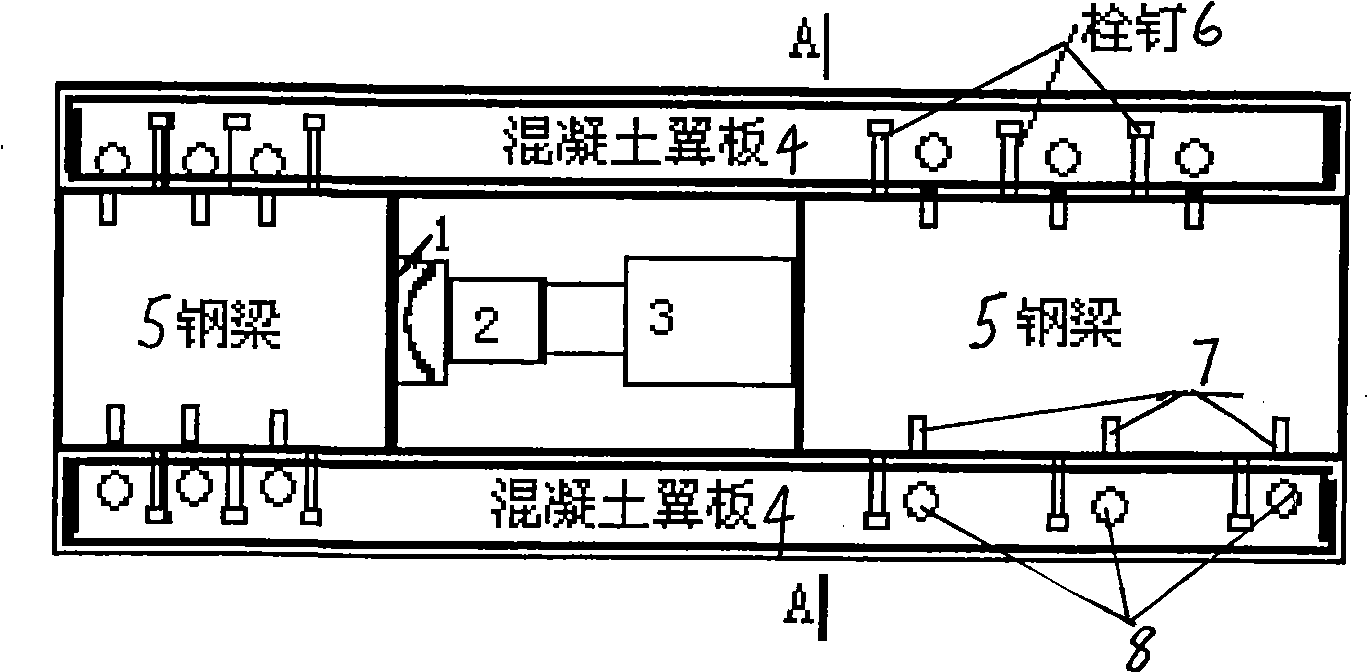

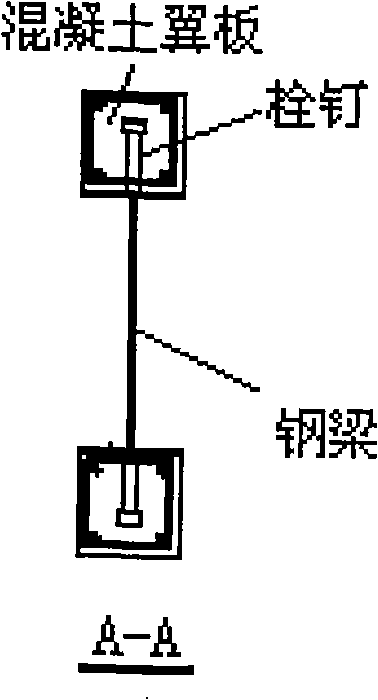

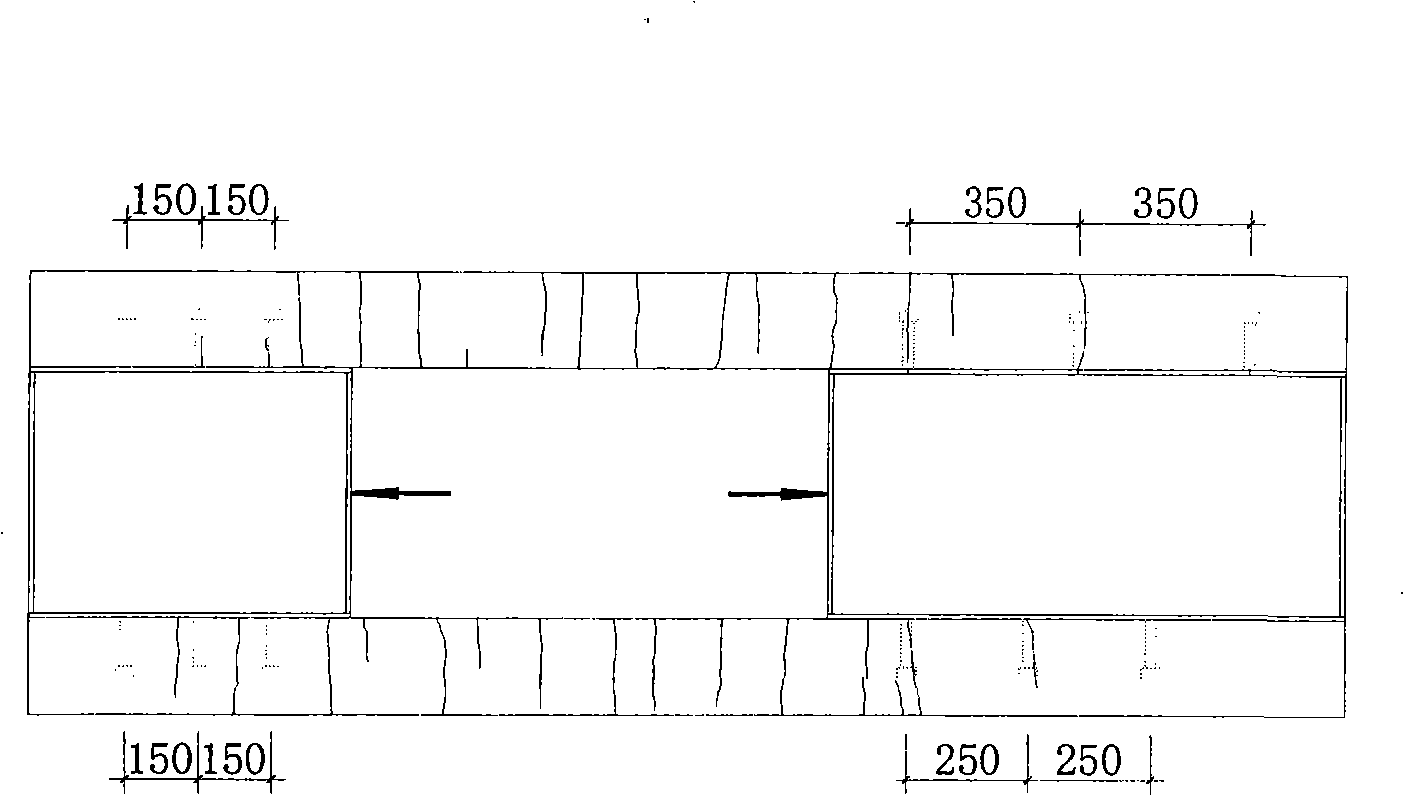

[0028] According to the current "Code for Design of Steel Structures" and Eurocodes, two sets of push-out tests are used to combine, and the steel beams and concrete wings are placed horizontally, such as figure 1 with figure 2 Shown: the establishment of a self-balanced test system built by combining two tensile specimens:

[0029] The first step is to combine the two push-out test pieces specified in the specification, and place the two steel beams 5 welded with studs 6 and the concrete wing plate template horizontally; in this embodiment, the upper and lower sides of each steel beam The three studs are evenly distributed. In order to facilitate the installation of the displacement sensor, a sensor baffle 8 is provided corresponding to each stud along the shear plane for installing the displacement sensor 7;

[0030] The second step is to pour the concrete. At this time, pay attention to the verticality of the embedded baffle plate and the wing plate; make the stud 6 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com