Bond-slip model between steel bars and nano-SiO2 and PVA fiber reinforced geopolymer mortar

A geopolymer, bond-slip technology, applied in the fields of instrumentation, computer material science, cement production, etc., can solve the problems of low deformation resistance, inability to guarantee building safety, insufficient durability, etc., and improve the ultimate bond strength. , Suppress original cracks, enhance the effect of remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention provides a steel bar and nano SiO 2 Bond slip model between PVA fiber reinforced geopolymer mortar:

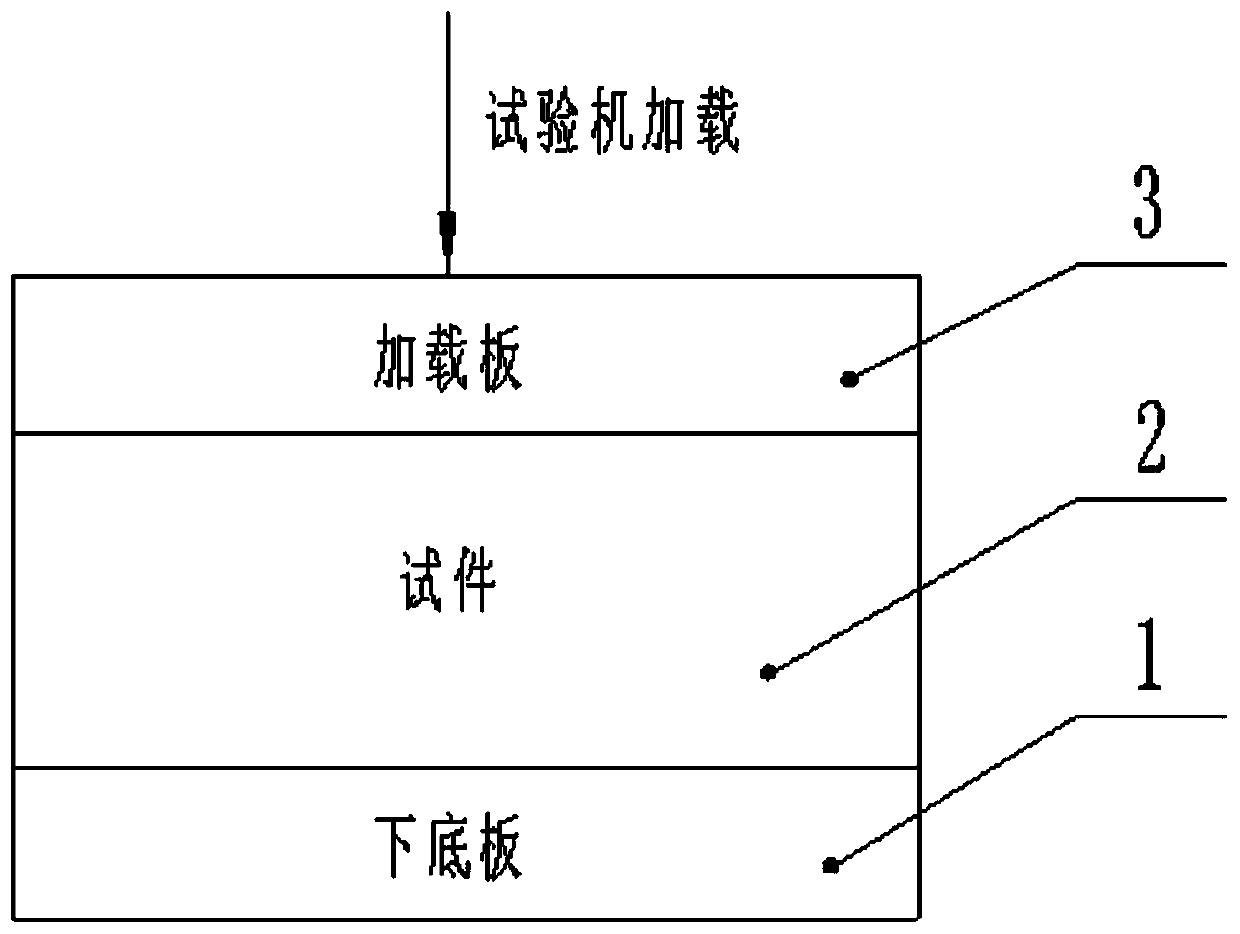

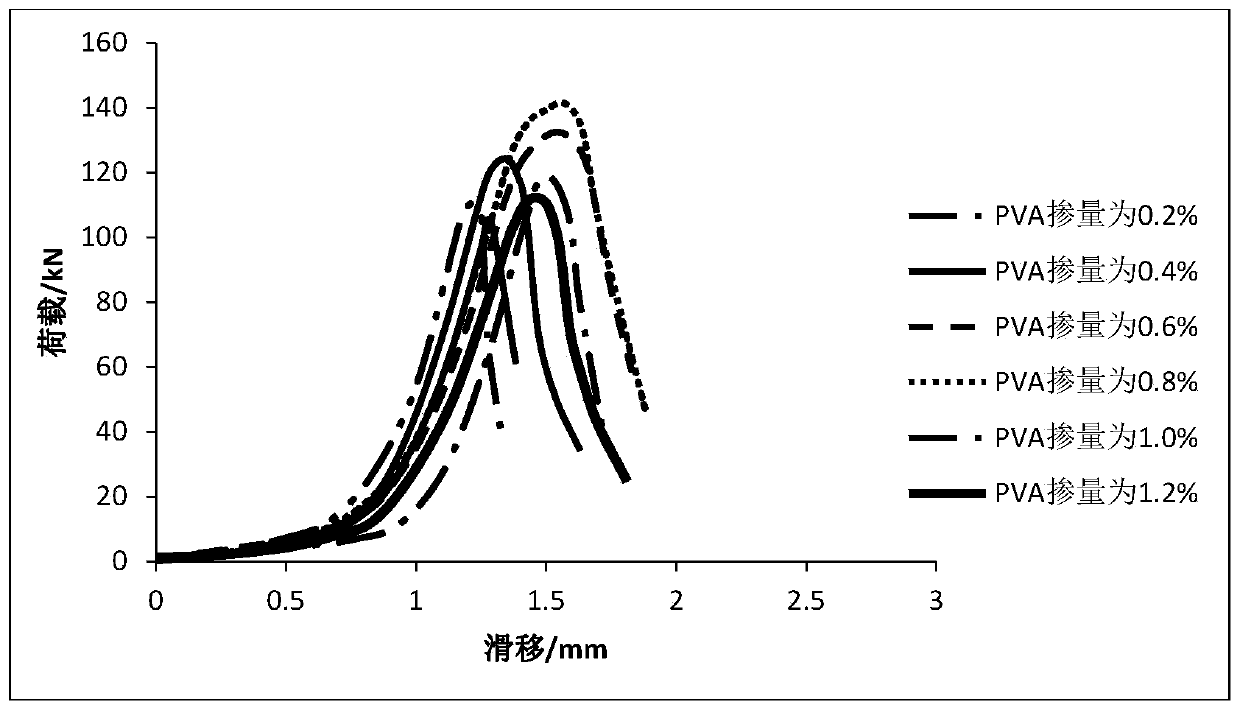

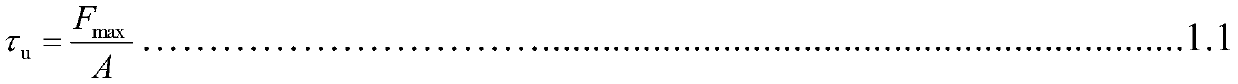

[0028] Step S1: Put several identical SiO 2 Wipe test piece 2 of PVA fiber with different content and different content, measure the size, and calculate the shear area of test piece 2;

[0029] Step S2: Place the test piece 2 in the middle position of the lower base plate 1, make the lower end of the shear test piece 2 contact the lower base plate 1, and the upper end contact the loading plate 3, so as to form a shear to the test piece 2. Align the center of the electro-hydraulic three-axis servo tester with the center of the lower plate 1 of the electro-hydraulic three-axis servo tester, start the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com