Method of FRP reinforced concrete bond slip test

A technology of bond-slip and concrete specimens, which is applied in the field of testing, can solve problems such as unreliable data and cracks, and achieve the effect of low cost and simple test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

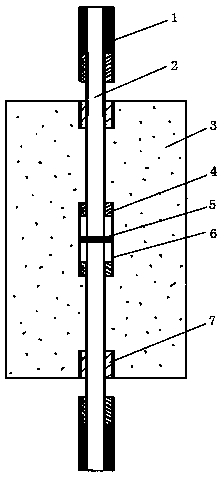

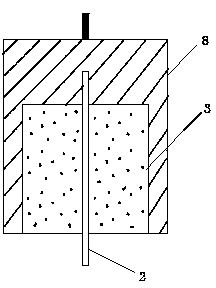

[0030] Such as figure 1 Shown, the method for a kind of FRP reinforced concrete bond-slip test of the present invention may further comprise the steps:

[0031] Step 1. Determine the test piece: make two FRP bars with the same diameter, length and surface form;

[0032] Step 2, making the connection structure of the FRP-reinforced concrete specimen: the specimen assembly is placed in the middle of the poured concrete 3, and the specimen assembly is inserted into the two ends of the casing 6 by two FRP tendons 2; and two FRP The other ends of the ribs 2 protrude from the casing 6, and the middle part of the casing 6 is provided with an adhesive layer 5; the two ends of the casing 6 are respectively provided with three wedge-shaped key blocks 4 in the inner key groove of the casing 6 along the direction of the FRP tendons. The two FRP tendons 2 protrude from both ends of the concrete 3 respectively; and the matching positions of the protruding ends of the two FRP tendons 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com