A method for adding a spring unit to a concrete filled steel tube finite element model

A technology of steel tube concrete and spring elements, applied in special data processing applications, instruments, geometric CAD, etc., can solve problems such as complex operations and low efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

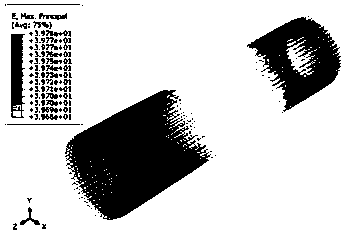

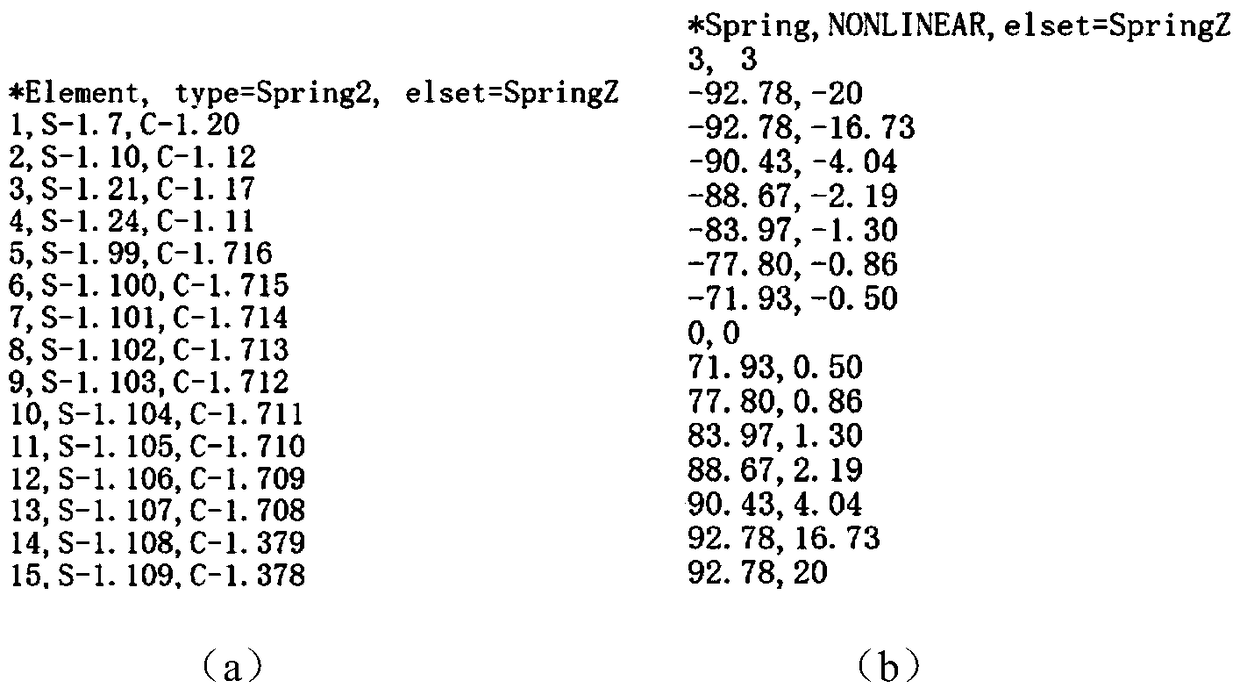

[0044] The research train of thought of the present invention is as follows: first utilize ABAQUS finite element software to set up the finite element model that does not consider the bond-slip characteristic of steel pipe and concrete interface and generate the inp format file of this model; Secondly, the inp format file can be compiled by Python language A general program for a series of processing, automatically adding the spring unit to the inp format file according to ABAQUS's format and position requirements; finally submit the modified inp format file to the Job.

[0045] This embodiment follows the technical scheme of the present invention, and takes the test specimen RCA in the document "Study on the Bonding Performance of Steel Tubes and Regenerated Concrete" as an example to perform finite element analysis, specifically including the following steps:

[0046] (1) Establish the finite element model of the steel pipe and recycled concrete. At this time, the interaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com