A measuring device and measuring method for dusty gas flow velocity

A technology of gas flow rate and measuring device, which is applied in the direction of measuring fluid velocity by using pressure difference, etc., which can solve the problems of increasing the complexity of operation, unrepresentative measurement position, and clogging of measuring devices, etc., and achieves easy construction and sealing cover, and reduces Influence and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

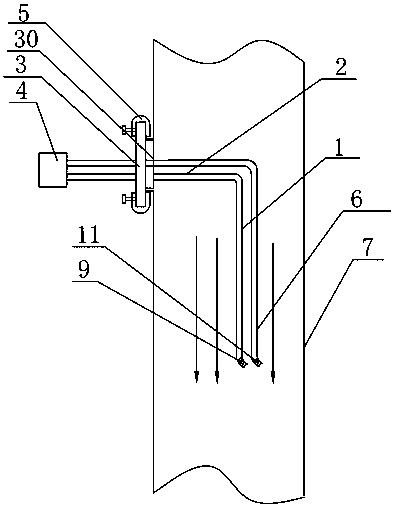

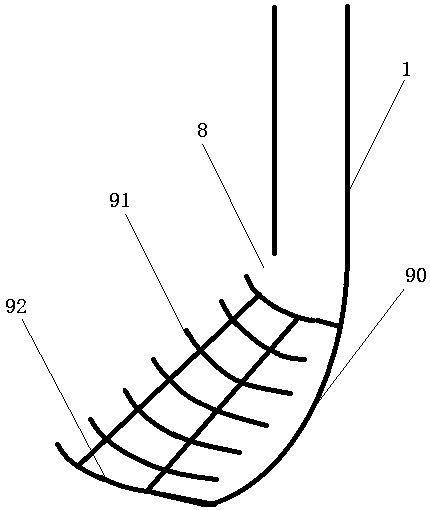

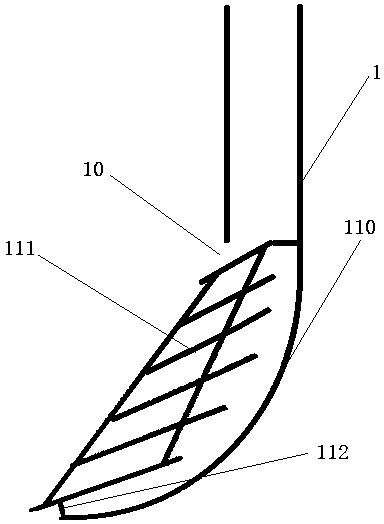

[0022] Such as Figure 1~3 As shown, the embodiment of the present invention provides a measuring device for the flow rate of dust-laden gas, which includes more than one positive pressure measuring tube 1 and a negative pressure measuring tube extending into the measured pipeline and parallel to the air flow in the measured pipeline 6. The bottom ends of the positive pressure sensing tube 1 and the negative pressure sensing tube 6 are provided with a positive pressure sensing port 8 and a negative pressure sensing port 10 respectively, and a positive pressure sensing port 8 is provided at the positive pressure sensing port 8. A diversion mechanism 9; a negative pressure diversion mechanism 11 is provided at the negative pressure take-off port 10; the positive pressure take-off pipe 1 and the negative pressure take-off pipe 6 stretch out to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com