Vertical support method for B type fuel tank at container ship step

A technology of container ship and support method, which is applied in the direction of ship components, deck loading, ship construction, etc., can solve the problems of inability to support effectively, achieve the effect of avoiding creep deformation, avoiding shear force, and ensuring effective heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

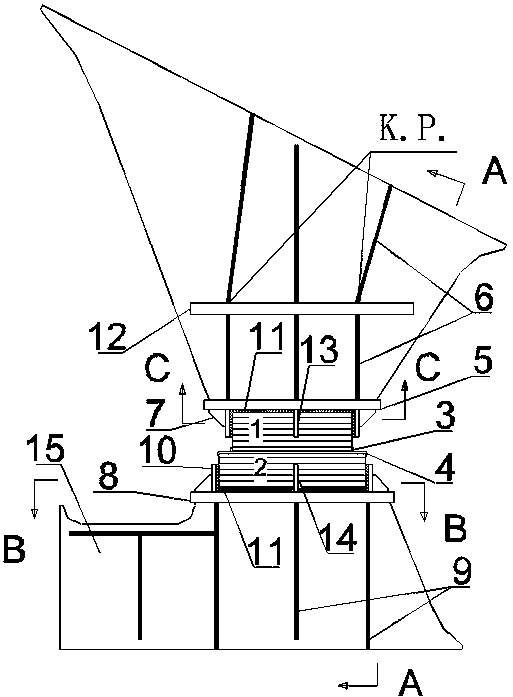

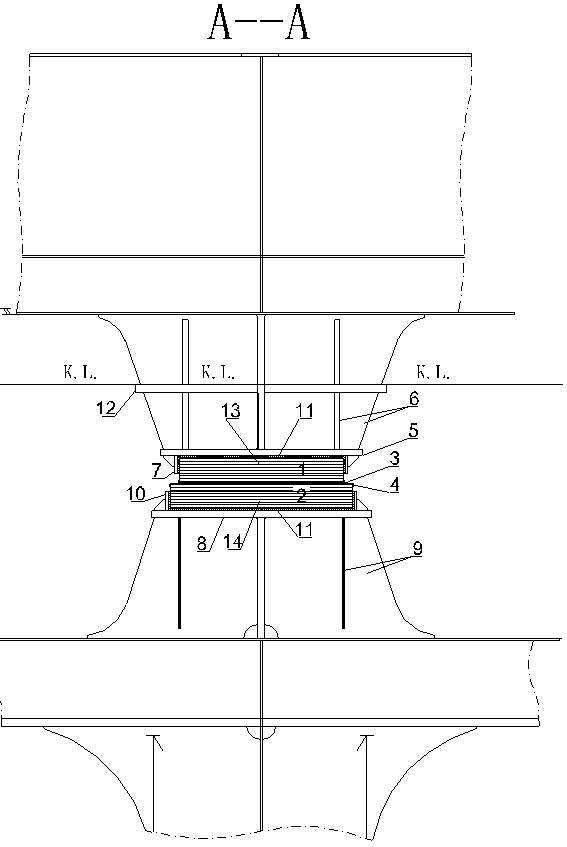

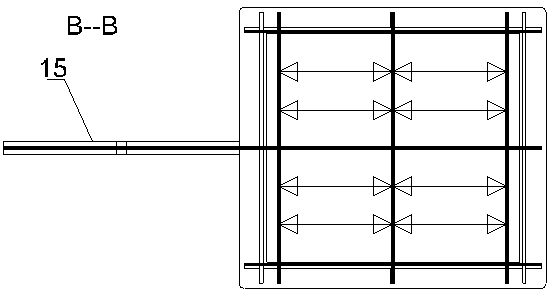

[0028] Below we will further elaborate on the vertical support device of the present invention for the B-type fuel tank at the step of the container ship in combination with the accompanying drawings and specific embodiments, in order to understand its structural composition and application mode more clearly , but it cannot be used to limit the protection scope of the present invention.

[0029] The invention relates to a vertical support method for a B-type fuel tank at the steps of a container ship. In the method, a special vertical support device is used, and the upper part of the vertical support device is supported on the side wall of the B-type fuel tank. The position of the inclined plane, the lower part is set at the step in the container, the structure of the vertical support device includes fuel tank support, step base, laminated wood and stainless steel plate, the top of the fuel tank support passes through The bottom plate of the B-type fuel tank is welded, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com