Knitting tool block and method for creating same

A loop-forming tool and bar technology are used in textiles, papermaking, knitting, warp knitting and other directions to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

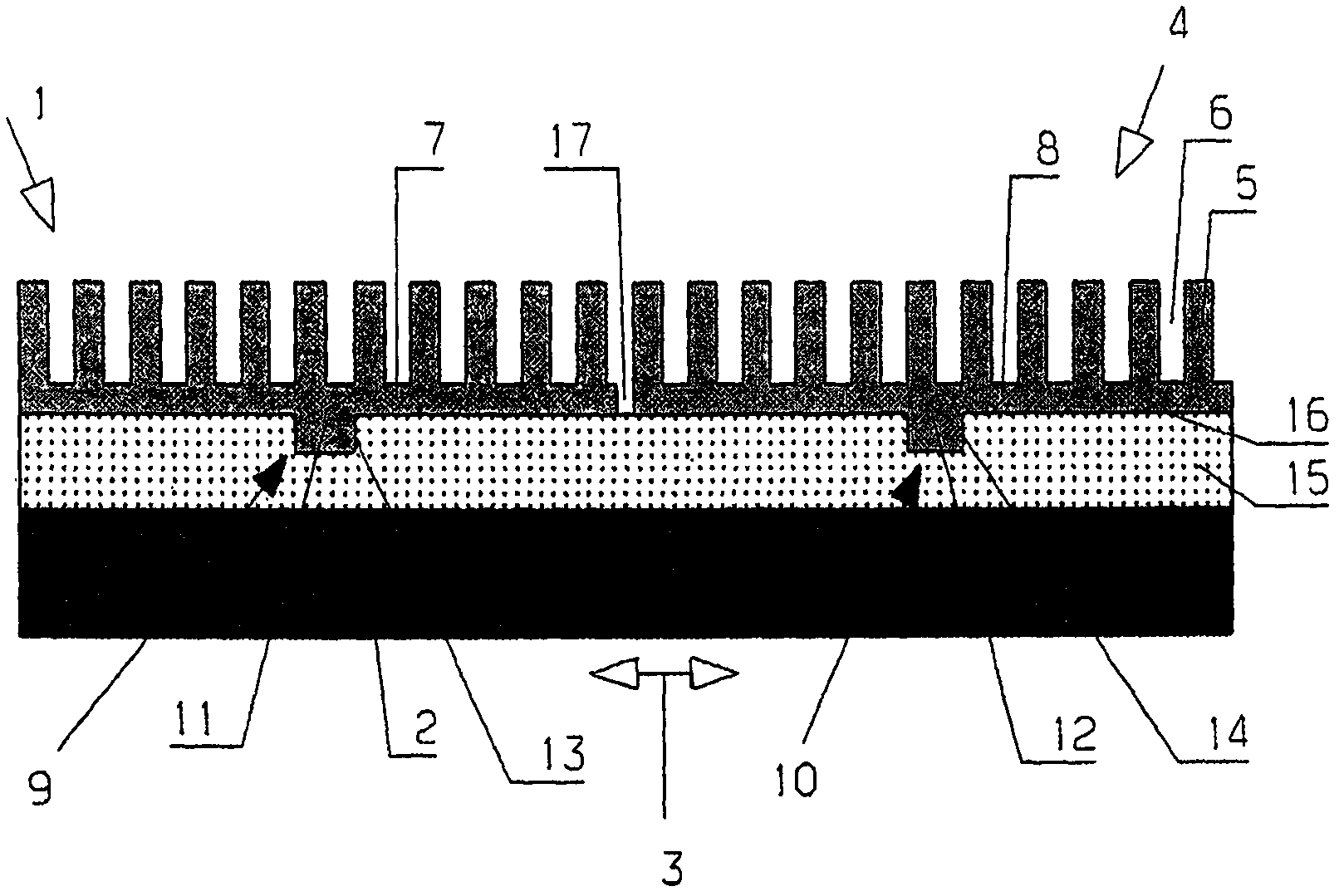

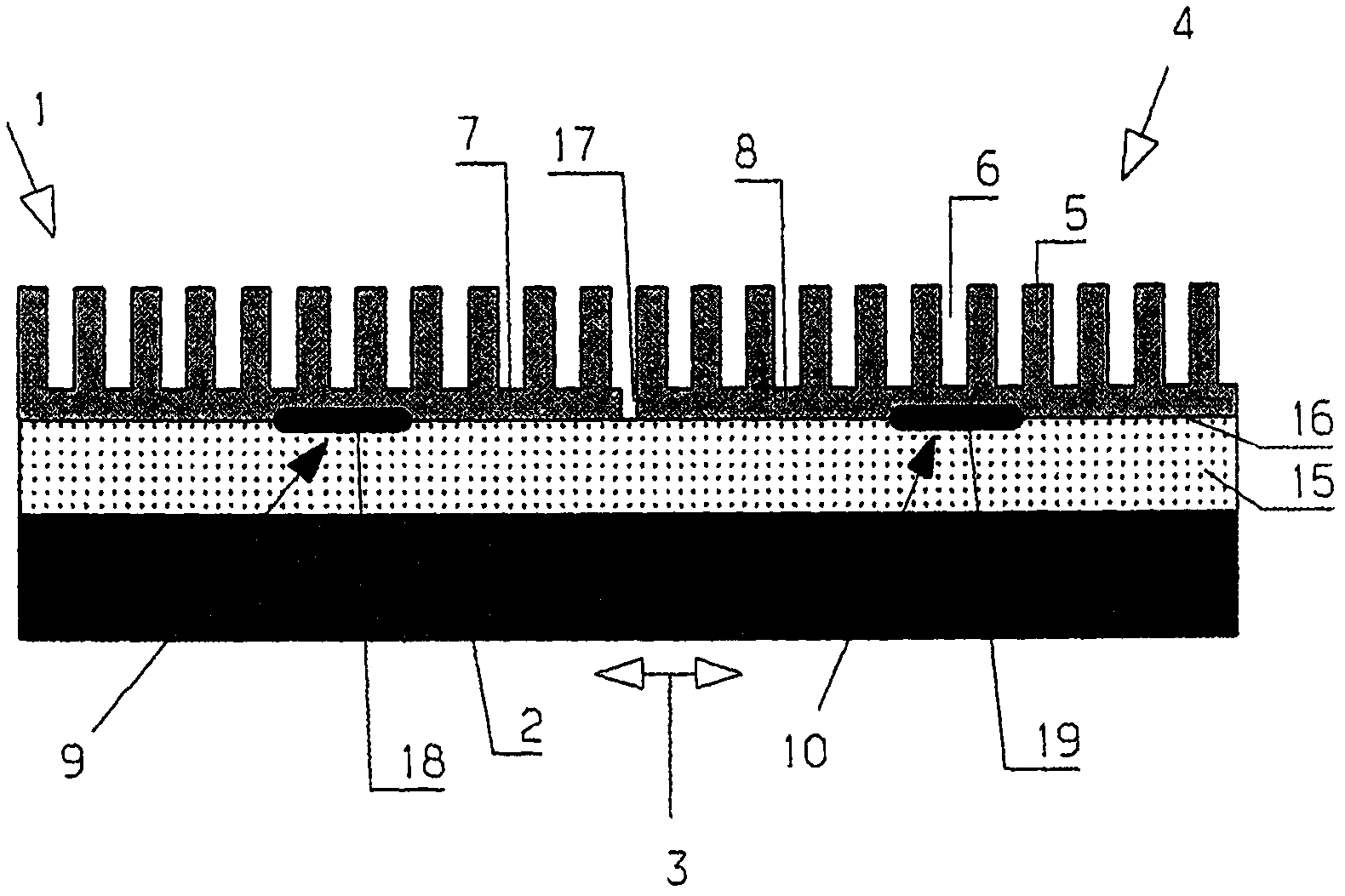

[0032] figure 1 Shown is a loop forming tool bar 1 with a body 2, which is formed from carbon fiber reinforced plastic. The body 2 has a longitudinal direction, which is indicated by the double arrow 3 . The body 2 may well have a length of several meters in the longitudinal direction. Accordingly, only a section of the looper bar is shown. The drawings are not to scale.

[0033] Such looping tool bars are used to similarly move groups of looping tools during the weaving process. Knitting tools may involve knitting needles, guide needles, loop sinkers and the like.

[0034] For receiving the looping tool, a looping tool holder 4 is provided which has a plurality of webs 5 and grooves 6 next to each other in the longitudinal direction 3 . The groove 6 serves to accommodate a loop forming tool, not shown in detail. The width of the groove 6 corresponds in the longitudinal direction to the thickness of the loop forming tool. In order to be able to insert the looping tool i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com