Corrosion-proof vibration-proof wire

An anti-vibration and wire technology, which is applied in the direction of conductors, insulated conductors, insulated cables, etc., can solve the problems of low transmission capacity of wires, inability to erect with large spans, and short service life of steel cores, so as to reduce the investment and weight of erection Lightweight and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

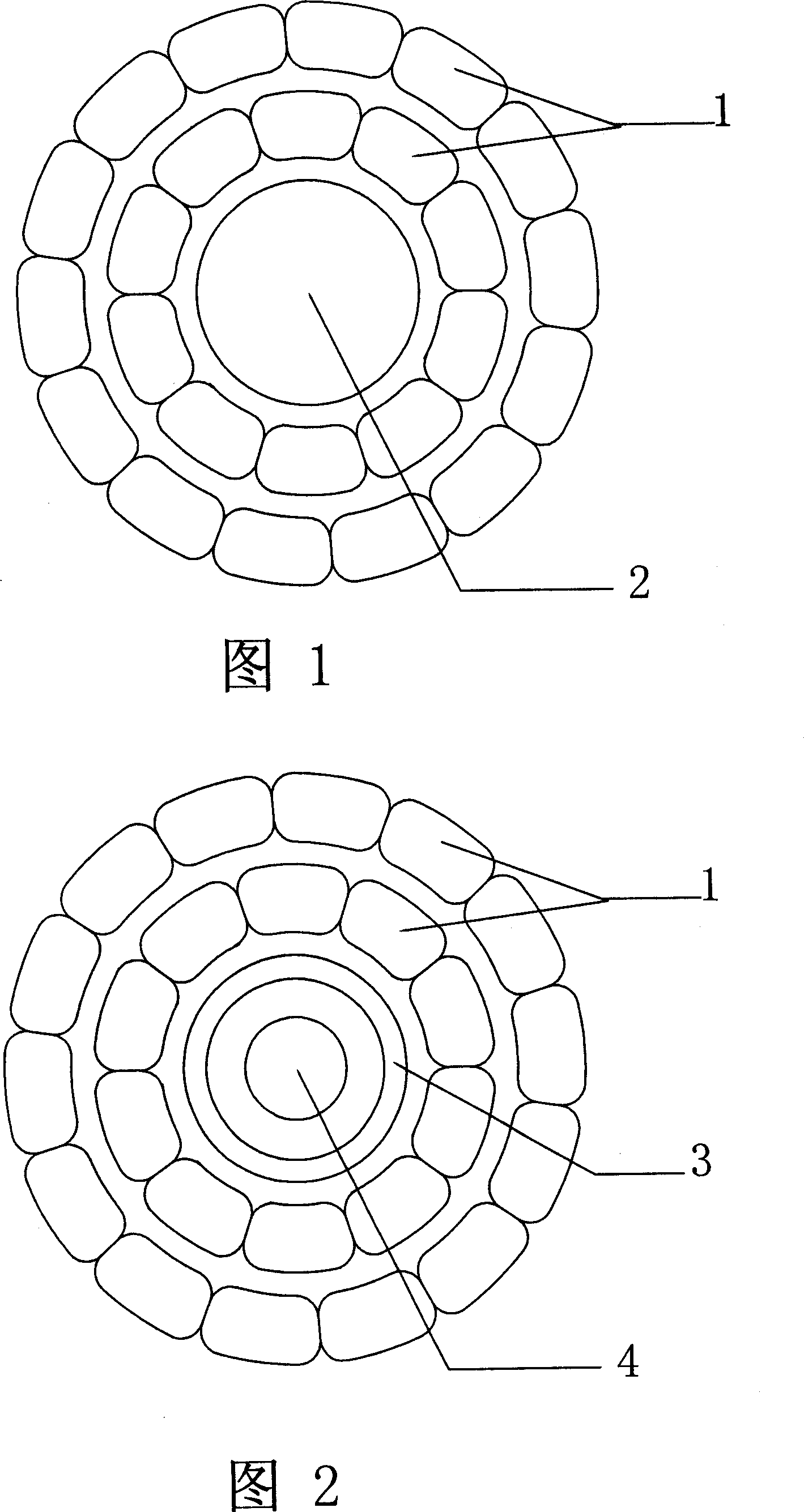

[0019] Embodiment 1: Referring to Fig. 1, the corrosion-resistant and anti-vibration wire of the present invention is made of a fiber resin rod 2 as an inner core, and a trapezoidal aluminum conductor 1 is stranded outside, and there is a 1 mm gap between the innermost conductor and the 1 reinforcing core. The fiber resin rod is mixed with 60vt% carbon fiber and 35vt% glass fiber, and is cured and shaped with 5vt% epoxy resin. The tensile strength of the obtained wire reaches 2500Mpa, and the modulus of elasticity is 113Gpa.

Embodiment 2

[0020] Embodiment 2: Referring to Fig. 2, as in embodiment 1, the reinforced inner core is composed of fiber resin tube 3 and central fiber resin rod 4 (there is a gap between the two), and there is 5mm between the innermost electric conductor and the fiber resin tube. gap. Wherein the fiber resin rod 4 is 60vt% basalt fiber and 35% glass fiber, cured and shaped with 5vt% epoxy resin, and the fiber resin tube 3 is 60vt% carbon fiber and 35vt% glass fiber, cured and shaped with 5vt% epoxy resin. The obtained wire has a tensile strength of 3050Mpa and an elastic modulus of 110Gpa.

Embodiment 3

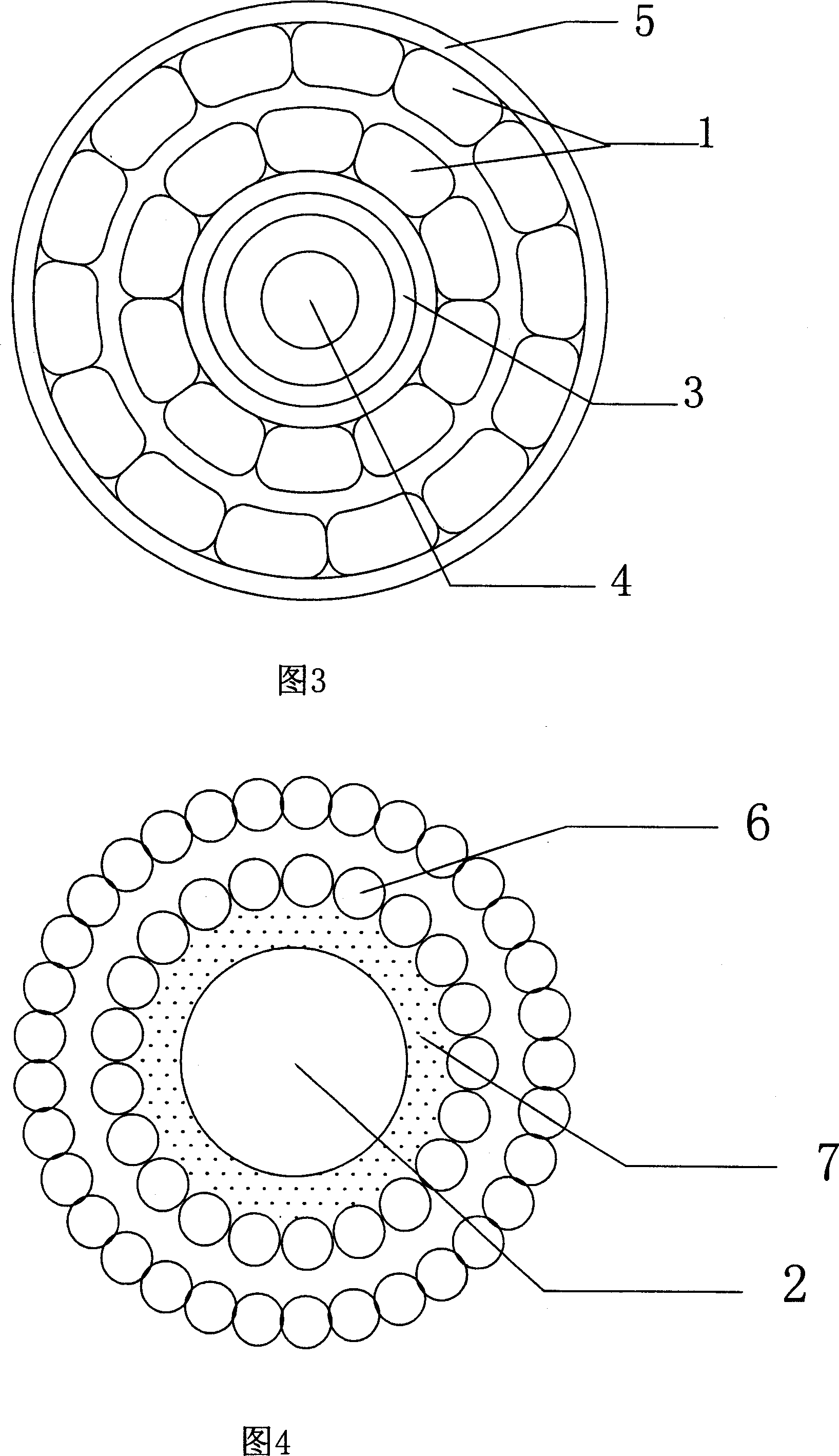

[0021] Embodiment 3: Referring to FIG. 3, as in Embodiment 2, a polyurethane heat dissipation layer 5 is sprayed on the outermost layer of the wire, and there is a gap of 3mm between the innermost conductor and the fiber resin tube. Among them, the fiber resin rod 4 is cured and shaped by 95vt% carbon fiber and 5vt% epoxy resin, and the fiber resin tube 3 is cured and shaped by 95vt% basalt fiber and 5vt% epoxy resin. The obtained wire has a tensile strength of 5800Mpa and an elastic modulus of 98Gpa. 1mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com